How does ignition timing optimization affect L92 engines?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Ignition Timing Background

The L92 engine, a member of the GM Gen IV small-block V8 family, has been a cornerstone of high-performance automotive engineering since its introduction in the mid-2000s. Ignition timing optimization plays a crucial role in maximizing the engine's efficiency, power output, and overall performance. Understanding the background of ignition timing in L92 engines is essential for comprehending its impact and potential for improvement.

Ignition timing refers to the precise moment when the spark plug fires in relation to the piston's position in the cylinder. In L92 engines, this timing is controlled by the engine's electronic control unit (ECU), which uses various sensors to determine the optimal ignition point. The goal is to ignite the air-fuel mixture at the most advantageous moment to achieve maximum combustion efficiency and power.

Historically, ignition timing in earlier engine designs was fixed or mechanically adjusted. However, the L92 engine benefits from advanced electronic control systems that allow for dynamic timing adjustments based on real-time operating conditions. This adaptability is crucial for maintaining optimal performance across various driving scenarios and environmental conditions.

The L92 engine's ignition system is designed to work in harmony with its other advanced features, such as variable valve timing and direct fuel injection. These technologies collectively contribute to the engine's ability to deliver high power output while maintaining fuel efficiency and meeting stringent emissions standards.

One of the key challenges in L92 engine ignition timing optimization is balancing performance with reliability and longevity. Aggressive timing can increase power output but may also lead to increased stress on engine components and potential detonation issues. Engineers must carefully calibrate the ignition timing to find the sweet spot that maximizes performance without compromising engine durability.

The evolution of ignition timing technology in L92 engines has been driven by advancements in sensor technology, computational power, and engine management software. Modern L92 engines can adjust timing on a cylinder-by-cylinder basis, compensating for variations in combustion characteristics across different cylinders. This level of precision was not possible in earlier engine designs and represents a significant leap forward in engine control technology.

Understanding the background of L92 engine ignition timing provides a foundation for exploring optimization strategies. It highlights the complex interplay between various engine systems and the critical role that precise timing plays in achieving peak performance. As technology continues to advance, further refinements in ignition timing control are expected to unlock even greater potential from the L92 engine platform.

Ignition timing refers to the precise moment when the spark plug fires in relation to the piston's position in the cylinder. In L92 engines, this timing is controlled by the engine's electronic control unit (ECU), which uses various sensors to determine the optimal ignition point. The goal is to ignite the air-fuel mixture at the most advantageous moment to achieve maximum combustion efficiency and power.

Historically, ignition timing in earlier engine designs was fixed or mechanically adjusted. However, the L92 engine benefits from advanced electronic control systems that allow for dynamic timing adjustments based on real-time operating conditions. This adaptability is crucial for maintaining optimal performance across various driving scenarios and environmental conditions.

The L92 engine's ignition system is designed to work in harmony with its other advanced features, such as variable valve timing and direct fuel injection. These technologies collectively contribute to the engine's ability to deliver high power output while maintaining fuel efficiency and meeting stringent emissions standards.

One of the key challenges in L92 engine ignition timing optimization is balancing performance with reliability and longevity. Aggressive timing can increase power output but may also lead to increased stress on engine components and potential detonation issues. Engineers must carefully calibrate the ignition timing to find the sweet spot that maximizes performance without compromising engine durability.

The evolution of ignition timing technology in L92 engines has been driven by advancements in sensor technology, computational power, and engine management software. Modern L92 engines can adjust timing on a cylinder-by-cylinder basis, compensating for variations in combustion characteristics across different cylinders. This level of precision was not possible in earlier engine designs and represents a significant leap forward in engine control technology.

Understanding the background of L92 engine ignition timing provides a foundation for exploring optimization strategies. It highlights the complex interplay between various engine systems and the critical role that precise timing plays in achieving peak performance. As technology continues to advance, further refinements in ignition timing control are expected to unlock even greater potential from the L92 engine platform.

Market Demand for L92 Engine Performance

The market demand for L92 engine performance has been steadily growing, driven by the increasing focus on fuel efficiency and environmental regulations. As automotive manufacturers strive to meet stricter emission standards while maintaining or improving vehicle performance, the optimization of engine components, including ignition timing, has become crucial.

L92 engines, known for their high-performance capabilities, have found applications in various vehicle models, particularly in the luxury and sports car segments. The demand for these engines is closely tied to the overall market trends in the automotive industry, which has seen a shift towards more powerful yet efficient powertrains.

In recent years, there has been a notable increase in consumer interest in vehicles that offer both performance and fuel economy. This trend has led to a growing demand for technologies that can enhance engine efficiency without compromising power output. Ignition timing optimization plays a significant role in achieving this balance, making it a key area of focus for manufacturers and aftermarket tuners alike.

The aftermarket performance parts industry has also contributed to the demand for L92 engine performance enhancements. Enthusiasts and performance-oriented consumers are constantly seeking ways to improve their vehicles' power, torque, and overall drivability. This has created a substantial market for ignition timing optimization solutions, including advanced engine management systems and programmable ECUs.

Furthermore, the racing and motorsports sectors have shown continued interest in L92 engines and related performance technologies. The competitive nature of these industries drives constant innovation and improvement in engine performance, with ignition timing optimization being a critical factor in extracting maximum power and efficiency.

From a geographical perspective, the demand for L92 engine performance enhancements is particularly strong in North America, where these engines are commonly found in popular vehicle models. However, there is also growing interest in other regions, such as Europe and Asia, as performance car culture continues to expand globally.

The market potential for L92 engine performance optimization is further amplified by the broader trend towards vehicle electrification. As the automotive industry transitions towards hybrid and electric powertrains, there is an increased focus on maximizing the efficiency of internal combustion engines in hybrid systems. This creates opportunities for advanced ignition timing technologies that can contribute to overall powertrain optimization in hybrid vehicles.

L92 engines, known for their high-performance capabilities, have found applications in various vehicle models, particularly in the luxury and sports car segments. The demand for these engines is closely tied to the overall market trends in the automotive industry, which has seen a shift towards more powerful yet efficient powertrains.

In recent years, there has been a notable increase in consumer interest in vehicles that offer both performance and fuel economy. This trend has led to a growing demand for technologies that can enhance engine efficiency without compromising power output. Ignition timing optimization plays a significant role in achieving this balance, making it a key area of focus for manufacturers and aftermarket tuners alike.

The aftermarket performance parts industry has also contributed to the demand for L92 engine performance enhancements. Enthusiasts and performance-oriented consumers are constantly seeking ways to improve their vehicles' power, torque, and overall drivability. This has created a substantial market for ignition timing optimization solutions, including advanced engine management systems and programmable ECUs.

Furthermore, the racing and motorsports sectors have shown continued interest in L92 engines and related performance technologies. The competitive nature of these industries drives constant innovation and improvement in engine performance, with ignition timing optimization being a critical factor in extracting maximum power and efficiency.

From a geographical perspective, the demand for L92 engine performance enhancements is particularly strong in North America, where these engines are commonly found in popular vehicle models. However, there is also growing interest in other regions, such as Europe and Asia, as performance car culture continues to expand globally.

The market potential for L92 engine performance optimization is further amplified by the broader trend towards vehicle electrification. As the automotive industry transitions towards hybrid and electric powertrains, there is an increased focus on maximizing the efficiency of internal combustion engines in hybrid systems. This creates opportunities for advanced ignition timing technologies that can contribute to overall powertrain optimization in hybrid vehicles.

Current Ignition Timing Challenges

The L92 engine, a high-performance V8 powerplant developed by General Motors, faces several challenges in optimizing its ignition timing. One of the primary issues is the need for precise control over the ignition timing across a wide range of operating conditions. As engine speeds and loads vary, maintaining optimal timing becomes increasingly complex, requiring sophisticated engine management systems.

A significant challenge lies in balancing performance with fuel efficiency and emissions compliance. Advanced ignition timing can improve power output and fuel economy, but it also increases the risk of engine knock and higher nitrogen oxide (NOx) emissions. Conversely, retarding the timing can reduce emissions but at the cost of power and efficiency. This delicate balance is particularly crucial for the L92 engine, which is often used in high-performance applications where both power and efficiency are paramount.

The L92's high compression ratio, typically around 10.5:1, further complicates ignition timing optimization. Higher compression ratios increase the engine's thermal efficiency but also make it more susceptible to pre-ignition and knock. This necessitates a more conservative approach to ignition timing, potentially limiting the engine's performance potential.

Another challenge is the variability in fuel quality and octane ratings. The L92 engine, designed for premium fuel, may encounter issues when lower octane fuels are used, requiring the engine management system to adapt the ignition timing accordingly. This adaptability is crucial for maintaining performance and preventing engine damage across different fuel qualities.

The integration of variable valve timing (VVT) in the L92 engine adds another layer of complexity to ignition timing optimization. VVT allows for improved engine breathing and performance across the rev range, but it also affects the in-cylinder conditions, necessitating dynamic adjustments to ignition timing to maintain optimal combustion.

Environmental factors such as altitude, ambient temperature, and humidity also pose challenges for ignition timing optimization. These variables affect air density and, consequently, the engine's volumetric efficiency and combustion characteristics. The engine management system must be capable of adjusting ignition timing in real-time to compensate for these environmental variations.

Lastly, the durability and longevity of engine components under advanced ignition timing conditions present ongoing challenges. Aggressive timing strategies can increase thermal and mechanical stresses on pistons, valves, and other critical engine components. Balancing performance gains with long-term reliability is a constant consideration in ignition timing optimization for the L92 engine.

A significant challenge lies in balancing performance with fuel efficiency and emissions compliance. Advanced ignition timing can improve power output and fuel economy, but it also increases the risk of engine knock and higher nitrogen oxide (NOx) emissions. Conversely, retarding the timing can reduce emissions but at the cost of power and efficiency. This delicate balance is particularly crucial for the L92 engine, which is often used in high-performance applications where both power and efficiency are paramount.

The L92's high compression ratio, typically around 10.5:1, further complicates ignition timing optimization. Higher compression ratios increase the engine's thermal efficiency but also make it more susceptible to pre-ignition and knock. This necessitates a more conservative approach to ignition timing, potentially limiting the engine's performance potential.

Another challenge is the variability in fuel quality and octane ratings. The L92 engine, designed for premium fuel, may encounter issues when lower octane fuels are used, requiring the engine management system to adapt the ignition timing accordingly. This adaptability is crucial for maintaining performance and preventing engine damage across different fuel qualities.

The integration of variable valve timing (VVT) in the L92 engine adds another layer of complexity to ignition timing optimization. VVT allows for improved engine breathing and performance across the rev range, but it also affects the in-cylinder conditions, necessitating dynamic adjustments to ignition timing to maintain optimal combustion.

Environmental factors such as altitude, ambient temperature, and humidity also pose challenges for ignition timing optimization. These variables affect air density and, consequently, the engine's volumetric efficiency and combustion characteristics. The engine management system must be capable of adjusting ignition timing in real-time to compensate for these environmental variations.

Lastly, the durability and longevity of engine components under advanced ignition timing conditions present ongoing challenges. Aggressive timing strategies can increase thermal and mechanical stresses on pistons, valves, and other critical engine components. Balancing performance gains with long-term reliability is a constant consideration in ignition timing optimization for the L92 engine.

Existing Timing Optimization Solutions

01 Adaptive ignition timing control

Advanced engine management systems use adaptive ignition timing control to optimize performance and efficiency. These systems adjust the ignition timing based on various engine parameters and operating conditions, such as engine load, speed, and temperature. This approach allows for more precise control of the combustion process, resulting in improved fuel economy and reduced emissions.- Adaptive ignition timing control: Advanced systems for L92 engines that dynamically adjust ignition timing based on various engine parameters and operating conditions. These systems use sensors and electronic control units to optimize timing for improved performance, fuel efficiency, and emissions control.

- Knock detection and prevention: Specialized ignition timing strategies for L92 engines to detect and prevent engine knock. These methods involve adjusting timing based on knock sensor inputs and implementing protective measures to maintain engine integrity while maximizing performance.

- Variable valve timing integration: Ignition timing systems for L92 engines that work in conjunction with variable valve timing mechanisms. These integrated systems coordinate ignition timing with valve events to optimize combustion efficiency and engine output across different operating ranges.

- Cylinder-specific timing control: Advanced ignition systems for L92 engines that allow individual cylinder timing control. These systems can compensate for cylinder-to-cylinder variations and optimize timing for each cylinder independently, resulting in improved overall engine performance and efficiency.

- Ignition timing calibration methods: Specialized techniques and procedures for calibrating ignition timing in L92 engines. These methods involve precise measurements, data analysis, and iterative adjustments to determine optimal timing settings for various engine operating conditions and fuel types.

02 Cylinder-specific ignition timing

Some L92 engine ignition systems employ cylinder-specific timing control. This method allows for individual adjustment of ignition timing for each cylinder, compensating for variations in combustion characteristics. By optimizing the ignition timing for each cylinder separately, overall engine performance and efficiency can be enhanced.Expand Specific Solutions03 Knock detection and ignition timing adjustment

L92 engines often incorporate knock detection systems to prevent engine damage and optimize performance. These systems monitor for engine knock and automatically adjust the ignition timing to eliminate or reduce knock occurrences. This adaptive approach ensures optimal ignition timing while protecting the engine from potentially damaging detonation.Expand Specific Solutions04 Variable cam timing and ignition synchronization

Advanced L92 engines may feature variable cam timing systems that work in conjunction with the ignition timing control. These systems adjust the camshaft timing to optimize valve events, which in turn affects the ideal ignition timing. The engine management system coordinates the cam timing and ignition timing to achieve the best possible performance, fuel efficiency, and emissions control across various operating conditions.Expand Specific Solutions05 Ignition timing maps and lookup tables

L92 engine control units often use pre-programmed ignition timing maps or lookup tables to determine the base ignition timing. These maps contain optimal timing values for various combinations of engine speed and load. The base timing is then further adjusted based on other factors such as coolant temperature, intake air temperature, and altitude. This approach allows for quick and efficient ignition timing control while still providing flexibility for fine-tuning.Expand Specific Solutions

Key L92 Engine Manufacturers

The ignition timing optimization for L92 engines represents a mature technology within the automotive industry, with significant market penetration and ongoing refinement. The competitive landscape is characterized by established players like Toyota, Ford, Honda, and GM, who have invested heavily in engine management systems. The market size for this technology is substantial, given its widespread application across various vehicle models. While the core principles are well-established, there's continuous innovation in areas such as precision control and integration with other engine systems. Companies like Bosch and DENSO are at the forefront of developing advanced ignition timing solutions, leveraging their expertise in automotive electronics to enhance engine performance and efficiency.

Ford Global Technologies LLC

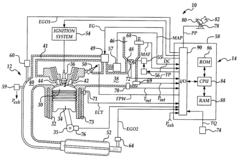

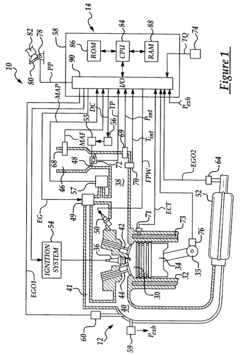

Technical Solution: Ford has implemented a comprehensive ignition timing optimization strategy for their engines, including those similar to the L92. Their approach utilizes adaptive spark timing control, which adjusts ignition timing based on real-time engine operating conditions and fuel quality. Ford's system employs advanced algorithms that consider factors such as air-fuel ratio, intake air temperature, and exhaust gas recirculation (EGR) rates to determine optimal ignition timing[4]. The company has also integrated cylinder pressure sensing technology in some models, allowing for even more precise control of ignition timing on a per-cylinder basis[5]. This level of control helps to maximize engine performance while minimizing emissions and fuel consumption across a wide range of operating conditions.

Strengths: Highly adaptive system, improved engine efficiency, and reduced emissions. Weaknesses: Higher initial cost due to advanced sensors and control systems.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced ignition timing optimization techniques for their L92 engines, which are part of their Gen IV small-block V8 family. Their approach involves using sophisticated engine control modules (ECMs) that continuously adjust ignition timing based on multiple factors such as engine load, RPM, and knock sensor feedback. This real-time optimization allows for maximum power output while maintaining fuel efficiency and engine longevity. GM's system incorporates a dual knock sensor design, enabling more precise detection of engine knock across a wider range of operating conditions[1][3]. Additionally, GM has implemented variable valve timing (VVT) technology in conjunction with ignition timing optimization, allowing for even greater control over the combustion process[2].

Strengths: Improved power output, better fuel efficiency, and enhanced engine protection. Weaknesses: Increased system complexity and potential for higher maintenance costs.

Core Ignition Timing Innovations

System and method for controlling ignition timing in an engine

PatentInactiveUS20040079332A1

Innovation

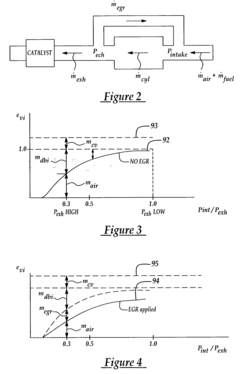

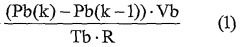

- A system and method that determines the change in combustion temperature rise based on engine operating parameters such as EGR rate, air-fuel ratio, and exhaust gas pressure, allowing for simultaneous adjustment of ignition timing to optimize engine performance across varying altitudes.

Ignition timing controlling device and method

PatentWO2005047692A1

Innovation

- An ignition timing control system that calculates the optimum ignition timing by adding a fluctuation component to the set ignition timing, using a mean effective pressure calculator and an MBT calculator to estimate the ignition timing characteristic curve, and a controller to converge the ignition timing to the optimum, thereby maximizing in-cylinder pressure and preventing combustion efficiency decreases.

Emissions Regulations Impact

Emissions regulations have significantly influenced the development and optimization of ignition timing in L92 engines. As environmental concerns continue to grow, governments worldwide have implemented increasingly stringent emissions standards, forcing engine manufacturers to adapt their technologies. The impact of these regulations on L92 engine ignition timing optimization is multifaceted and far-reaching.

One of the primary effects of emissions regulations on ignition timing optimization is the need to reduce nitrogen oxide (NOx) emissions. NOx formation is highly dependent on combustion temperature, which is directly affected by ignition timing. Advanced ignition timing typically leads to higher peak cylinder pressures and temperatures, resulting in increased NOx production. To comply with stricter NOx limits, engine designers have had to retard ignition timing in L92 engines, particularly at high loads and speeds.

However, retarding ignition timing can lead to decreased engine efficiency and increased fuel consumption. This presents a challenge for engineers working on L92 engines, as they must balance emissions compliance with performance and fuel economy targets. To address this issue, more sophisticated ignition timing control strategies have been developed, incorporating real-time adjustments based on engine operating conditions and emissions sensor feedback.

The focus on reducing carbon dioxide (CO2) emissions has also influenced ignition timing optimization in L92 engines. As CO2 emissions are directly related to fuel consumption, there is a strong incentive to improve engine efficiency. This has led to the development of more precise ignition timing control systems that can optimize combustion across a wider range of operating conditions, helping to minimize fuel consumption while still meeting emissions standards.

Particulate matter (PM) emissions regulations have further complicated ignition timing optimization. While L92 engines, being gasoline-powered, generally produce less PM than diesel engines, the introduction of gasoline direct injection (GDI) technology has increased PM emissions in some cases. Ignition timing plays a crucial role in controlling PM formation, with later ignition potentially leading to increased PM due to incomplete combustion. This has necessitated a delicate balance in timing optimization to manage both NOx and PM emissions simultaneously.

The implementation of on-board diagnostics (OBD) requirements as part of emissions regulations has also impacted ignition timing strategies. OBD systems must monitor the performance of emissions-related components, including those affecting ignition timing. This has led to the integration of more advanced sensors and control algorithms in L92 engines to ensure that ignition timing remains optimized throughout the engine's lifecycle, even as components wear or performance degrades.

One of the primary effects of emissions regulations on ignition timing optimization is the need to reduce nitrogen oxide (NOx) emissions. NOx formation is highly dependent on combustion temperature, which is directly affected by ignition timing. Advanced ignition timing typically leads to higher peak cylinder pressures and temperatures, resulting in increased NOx production. To comply with stricter NOx limits, engine designers have had to retard ignition timing in L92 engines, particularly at high loads and speeds.

However, retarding ignition timing can lead to decreased engine efficiency and increased fuel consumption. This presents a challenge for engineers working on L92 engines, as they must balance emissions compliance with performance and fuel economy targets. To address this issue, more sophisticated ignition timing control strategies have been developed, incorporating real-time adjustments based on engine operating conditions and emissions sensor feedback.

The focus on reducing carbon dioxide (CO2) emissions has also influenced ignition timing optimization in L92 engines. As CO2 emissions are directly related to fuel consumption, there is a strong incentive to improve engine efficiency. This has led to the development of more precise ignition timing control systems that can optimize combustion across a wider range of operating conditions, helping to minimize fuel consumption while still meeting emissions standards.

Particulate matter (PM) emissions regulations have further complicated ignition timing optimization. While L92 engines, being gasoline-powered, generally produce less PM than diesel engines, the introduction of gasoline direct injection (GDI) technology has increased PM emissions in some cases. Ignition timing plays a crucial role in controlling PM formation, with later ignition potentially leading to increased PM due to incomplete combustion. This has necessitated a delicate balance in timing optimization to manage both NOx and PM emissions simultaneously.

The implementation of on-board diagnostics (OBD) requirements as part of emissions regulations has also impacted ignition timing strategies. OBD systems must monitor the performance of emissions-related components, including those affecting ignition timing. This has led to the integration of more advanced sensors and control algorithms in L92 engines to ensure that ignition timing remains optimized throughout the engine's lifecycle, even as components wear or performance degrades.

Fuel Efficiency Considerations

Ignition timing optimization plays a crucial role in enhancing the fuel efficiency of L92 engines. By precisely controlling the moment of spark ignition relative to the piston's position, engineers can maximize the engine's power output while minimizing fuel consumption. This optimization process involves a delicate balance between various factors, including engine load, speed, and operating conditions.

One of the primary ways ignition timing optimization affects fuel efficiency is through improved combustion efficiency. When the spark is initiated at the optimal moment, it allows for more complete burning of the air-fuel mixture within the combustion chamber. This results in a greater extraction of energy from each fuel molecule, effectively reducing the overall fuel consumption required to produce a given amount of power.

Furthermore, optimized ignition timing can help mitigate the occurrence of engine knock, a phenomenon that can lead to decreased efficiency and potential engine damage. By adjusting the timing to prevent pre-ignition or detonation, the engine can operate more smoothly and efficiently across a wider range of operating conditions.

Advanced ignition timing systems in L92 engines often incorporate variable timing mechanisms, allowing for real-time adjustments based on sensor inputs. This dynamic approach ensures that the engine maintains optimal fuel efficiency under varying loads and speeds. For instance, at higher engine speeds, the ignition timing may be advanced to compensate for the reduced time available for combustion, maintaining efficiency even as RPMs increase.

The impact of ignition timing on fuel efficiency is also closely tied to the engine's compression ratio. L92 engines, known for their high compression ratios, benefit significantly from precise timing control. By optimizing the ignition timing, engineers can take full advantage of the increased cylinder pressure, extracting maximum energy from the combustion process without risking knock or pre-ignition.

Moreover, ignition timing optimization contributes to improved thermal efficiency. Proper timing ensures that the peak cylinder pressure occurs at the most advantageous point in the piston's travel, maximizing the conversion of thermal energy into mechanical work. This optimization not only enhances fuel efficiency but also contributes to reduced emissions, as more complete combustion results in fewer unburned hydrocarbons being released into the exhaust stream.

In conclusion, the optimization of ignition timing in L92 engines is a critical factor in achieving superior fuel efficiency. Through precise control and advanced timing mechanisms, these engines can operate at peak efficiency across a wide range of conditions, ultimately leading to reduced fuel consumption and improved overall performance.

One of the primary ways ignition timing optimization affects fuel efficiency is through improved combustion efficiency. When the spark is initiated at the optimal moment, it allows for more complete burning of the air-fuel mixture within the combustion chamber. This results in a greater extraction of energy from each fuel molecule, effectively reducing the overall fuel consumption required to produce a given amount of power.

Furthermore, optimized ignition timing can help mitigate the occurrence of engine knock, a phenomenon that can lead to decreased efficiency and potential engine damage. By adjusting the timing to prevent pre-ignition or detonation, the engine can operate more smoothly and efficiently across a wider range of operating conditions.

Advanced ignition timing systems in L92 engines often incorporate variable timing mechanisms, allowing for real-time adjustments based on sensor inputs. This dynamic approach ensures that the engine maintains optimal fuel efficiency under varying loads and speeds. For instance, at higher engine speeds, the ignition timing may be advanced to compensate for the reduced time available for combustion, maintaining efficiency even as RPMs increase.

The impact of ignition timing on fuel efficiency is also closely tied to the engine's compression ratio. L92 engines, known for their high compression ratios, benefit significantly from precise timing control. By optimizing the ignition timing, engineers can take full advantage of the increased cylinder pressure, extracting maximum energy from the combustion process without risking knock or pre-ignition.

Moreover, ignition timing optimization contributes to improved thermal efficiency. Proper timing ensures that the peak cylinder pressure occurs at the most advantageous point in the piston's travel, maximizing the conversion of thermal energy into mechanical work. This optimization not only enhances fuel efficiency but also contributes to reduced emissions, as more complete combustion results in fewer unburned hydrocarbons being released into the exhaust stream.

In conclusion, the optimization of ignition timing in L92 engines is a critical factor in achieving superior fuel efficiency. Through precise control and advanced timing mechanisms, these engines can operate at peak efficiency across a wide range of conditions, ultimately leading to reduced fuel consumption and improved overall performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!