How Has PU Waterborne Dispersion Tech Driven Marine Coatings?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Waterborne Dispersion Evolution and Goals

Polyurethane (PU) waterborne dispersion technology has undergone significant evolution in the marine coatings industry over the past few decades. This technology emerged as a response to increasing environmental regulations and the need for more sustainable coating solutions. The development of PU waterborne dispersions can be traced back to the 1970s, with initial applications in furniture and automotive coatings.

In the marine sector, the adoption of PU waterborne dispersions gained momentum in the 1990s as shipyards and vessel operators sought alternatives to traditional solvent-based coatings. The primary drivers for this shift were the reduction of volatile organic compound (VOC) emissions and improved worker safety. Early PU waterborne dispersions faced challenges in performance, particularly in terms of water resistance and durability in harsh marine environments.

The evolution of PU waterborne dispersion technology for marine coatings has been marked by continuous improvements in polymer chemistry and formulation techniques. Key milestones include the development of self-crosslinking PU dispersions, which enhanced film formation and coating properties. The introduction of hybrid systems, combining PU with other polymer types such as acrylics, further expanded the performance envelope of waterborne coatings.

Recent advancements have focused on enhancing the salt water resistance, adhesion properties, and long-term durability of PU waterborne dispersions. Innovations in nano-technology and the incorporation of functional additives have led to coatings with improved anti-fouling and anti-corrosion properties, critical for marine applications.

The goals of PU waterborne dispersion technology in marine coatings are multifaceted. Primarily, there is a drive to achieve performance parity with solvent-based systems while maintaining the environmental benefits of waterborne formulations. This includes developing coatings with excellent adhesion to various substrates, superior weathering resistance, and long-term protection against marine growth and corrosion.

Another key objective is to expand the application range of PU waterborne dispersions in marine coatings. This involves formulating products suitable for different parts of a vessel, from topside coatings to underwater hull protection. The technology aims to provide solutions that can be applied in various environmental conditions and curing scenarios encountered in shipyards and dry docks.

Looking forward, the goals of PU waterborne dispersion technology in marine coatings include further reduction of environmental impact, improved ease of application, and enhanced durability to extend maintenance intervals. There is also a focus on developing smart coatings that can self-heal or provide real-time monitoring of coating integrity and vessel performance.

In the marine sector, the adoption of PU waterborne dispersions gained momentum in the 1990s as shipyards and vessel operators sought alternatives to traditional solvent-based coatings. The primary drivers for this shift were the reduction of volatile organic compound (VOC) emissions and improved worker safety. Early PU waterborne dispersions faced challenges in performance, particularly in terms of water resistance and durability in harsh marine environments.

The evolution of PU waterborne dispersion technology for marine coatings has been marked by continuous improvements in polymer chemistry and formulation techniques. Key milestones include the development of self-crosslinking PU dispersions, which enhanced film formation and coating properties. The introduction of hybrid systems, combining PU with other polymer types such as acrylics, further expanded the performance envelope of waterborne coatings.

Recent advancements have focused on enhancing the salt water resistance, adhesion properties, and long-term durability of PU waterborne dispersions. Innovations in nano-technology and the incorporation of functional additives have led to coatings with improved anti-fouling and anti-corrosion properties, critical for marine applications.

The goals of PU waterborne dispersion technology in marine coatings are multifaceted. Primarily, there is a drive to achieve performance parity with solvent-based systems while maintaining the environmental benefits of waterborne formulations. This includes developing coatings with excellent adhesion to various substrates, superior weathering resistance, and long-term protection against marine growth and corrosion.

Another key objective is to expand the application range of PU waterborne dispersions in marine coatings. This involves formulating products suitable for different parts of a vessel, from topside coatings to underwater hull protection. The technology aims to provide solutions that can be applied in various environmental conditions and curing scenarios encountered in shipyards and dry docks.

Looking forward, the goals of PU waterborne dispersion technology in marine coatings include further reduction of environmental impact, improved ease of application, and enhanced durability to extend maintenance intervals. There is also a focus on developing smart coatings that can self-heal or provide real-time monitoring of coating integrity and vessel performance.

Marine Coatings Market Analysis

The marine coatings market has experienced significant growth and transformation in recent years, driven by various factors including technological advancements, environmental regulations, and increasing demand for high-performance coatings. The global marine coatings market size was valued at approximately $3.8 billion in 2020 and is projected to reach $5.2 billion by 2026, growing at a CAGR of around 5.2% during the forecast period.

One of the key drivers of this market growth is the rising demand for eco-friendly and sustainable coating solutions. Environmental regulations, such as the International Maritime Organization's (IMO) restrictions on volatile organic compound (VOC) emissions, have pushed the industry towards developing water-based and low-VOC coating technologies. This shift has created a significant opportunity for PU waterborne dispersion technology in marine coatings.

The marine coatings market can be segmented based on resin type, including epoxy, polyurethane, alkyd, and others. Polyurethane-based coatings, particularly those utilizing waterborne dispersion technology, have gained substantial traction due to their excellent performance characteristics and environmental benefits. These coatings offer superior durability, chemical resistance, and weather resistance, making them ideal for marine applications.

Geographically, the Asia-Pacific region dominates the marine coatings market, accounting for over 40% of the global market share. This is primarily due to the presence of major shipbuilding nations such as China, South Korea, and Japan. North America and Europe follow, with growing demand for advanced coating technologies to meet stringent environmental regulations.

The market is characterized by intense competition among key players, including AkzoNobel, PPG Industries, Sherwin-Williams, Jotun, and Hempel. These companies are investing heavily in research and development to innovate and improve their product offerings, with a particular focus on sustainable and high-performance coating solutions.

PU waterborne dispersion technology has emerged as a game-changer in the marine coatings industry. It offers numerous advantages over traditional solvent-based coatings, including reduced VOC emissions, improved worker safety, and enhanced coating performance. This technology has enabled manufacturers to develop coatings that meet both environmental regulations and performance requirements, driving its adoption across various marine applications.

One of the key drivers of this market growth is the rising demand for eco-friendly and sustainable coating solutions. Environmental regulations, such as the International Maritime Organization's (IMO) restrictions on volatile organic compound (VOC) emissions, have pushed the industry towards developing water-based and low-VOC coating technologies. This shift has created a significant opportunity for PU waterborne dispersion technology in marine coatings.

The marine coatings market can be segmented based on resin type, including epoxy, polyurethane, alkyd, and others. Polyurethane-based coatings, particularly those utilizing waterborne dispersion technology, have gained substantial traction due to their excellent performance characteristics and environmental benefits. These coatings offer superior durability, chemical resistance, and weather resistance, making them ideal for marine applications.

Geographically, the Asia-Pacific region dominates the marine coatings market, accounting for over 40% of the global market share. This is primarily due to the presence of major shipbuilding nations such as China, South Korea, and Japan. North America and Europe follow, with growing demand for advanced coating technologies to meet stringent environmental regulations.

The market is characterized by intense competition among key players, including AkzoNobel, PPG Industries, Sherwin-Williams, Jotun, and Hempel. These companies are investing heavily in research and development to innovate and improve their product offerings, with a particular focus on sustainable and high-performance coating solutions.

PU waterborne dispersion technology has emerged as a game-changer in the marine coatings industry. It offers numerous advantages over traditional solvent-based coatings, including reduced VOC emissions, improved worker safety, and enhanced coating performance. This technology has enabled manufacturers to develop coatings that meet both environmental regulations and performance requirements, driving its adoption across various marine applications.

Current State of PU Waterborne Dispersion in Marine Coatings

Polyurethane (PU) waterborne dispersion technology has made significant strides in the marine coatings industry, revolutionizing the way protective and decorative coatings are formulated and applied. This technology has emerged as a sustainable and environmentally friendly alternative to traditional solvent-based coatings, addressing the growing concerns over volatile organic compound (VOC) emissions and their impact on human health and the environment.

In the current state of marine coatings, PU waterborne dispersions have gained considerable traction due to their unique combination of performance characteristics and eco-friendly properties. These coatings offer excellent adhesion to various substrates, including metal, wood, and composite materials commonly used in marine applications. They also provide superior resistance to weathering, UV radiation, and saltwater exposure, which are critical factors in the harsh marine environment.

One of the key advantages of PU waterborne dispersions in marine coatings is their low VOC content. This characteristic not only complies with increasingly stringent environmental regulations but also improves worker safety during application and reduces the overall environmental footprint of coating operations. The water-based nature of these coatings also facilitates easier clean-up and disposal processes, further enhancing their appeal to shipyards and marine maintenance facilities.

Recent advancements in PU waterborne dispersion technology have led to improved coating performance in terms of durability, chemical resistance, and abrasion resistance. These enhancements have expanded the application range of waterborne coatings in the marine sector, allowing them to compete effectively with traditional solvent-based systems in areas where high performance is crucial, such as hull coatings and deck finishes.

The marine industry has also witnessed an increase in the adoption of self-healing and anti-fouling coatings based on PU waterborne dispersions. These innovative formulations incorporate advanced additives and nanotechnology to provide extended protection against corrosion and biofouling, reducing maintenance costs and improving vessel efficiency.

Despite these advancements, challenges remain in the widespread adoption of PU waterborne dispersions in marine coatings. Issues such as longer drying times compared to solvent-based alternatives and sensitivity to application conditions (temperature and humidity) are areas of ongoing research and development. Additionally, the marine industry's conservative nature and stringent performance requirements pose hurdles to the rapid adoption of new coating technologies.

Overall, the current state of PU waterborne dispersion in marine coatings reflects a technology on the cusp of widespread adoption, driven by environmental concerns, regulatory pressures, and continuous improvements in performance and application properties. As research progresses and more success stories emerge, this technology is poised to play an increasingly significant role in the future of marine coatings.

In the current state of marine coatings, PU waterborne dispersions have gained considerable traction due to their unique combination of performance characteristics and eco-friendly properties. These coatings offer excellent adhesion to various substrates, including metal, wood, and composite materials commonly used in marine applications. They also provide superior resistance to weathering, UV radiation, and saltwater exposure, which are critical factors in the harsh marine environment.

One of the key advantages of PU waterborne dispersions in marine coatings is their low VOC content. This characteristic not only complies with increasingly stringent environmental regulations but also improves worker safety during application and reduces the overall environmental footprint of coating operations. The water-based nature of these coatings also facilitates easier clean-up and disposal processes, further enhancing their appeal to shipyards and marine maintenance facilities.

Recent advancements in PU waterborne dispersion technology have led to improved coating performance in terms of durability, chemical resistance, and abrasion resistance. These enhancements have expanded the application range of waterborne coatings in the marine sector, allowing them to compete effectively with traditional solvent-based systems in areas where high performance is crucial, such as hull coatings and deck finishes.

The marine industry has also witnessed an increase in the adoption of self-healing and anti-fouling coatings based on PU waterborne dispersions. These innovative formulations incorporate advanced additives and nanotechnology to provide extended protection against corrosion and biofouling, reducing maintenance costs and improving vessel efficiency.

Despite these advancements, challenges remain in the widespread adoption of PU waterborne dispersions in marine coatings. Issues such as longer drying times compared to solvent-based alternatives and sensitivity to application conditions (temperature and humidity) are areas of ongoing research and development. Additionally, the marine industry's conservative nature and stringent performance requirements pose hurdles to the rapid adoption of new coating technologies.

Overall, the current state of PU waterborne dispersion in marine coatings reflects a technology on the cusp of widespread adoption, driven by environmental concerns, regulatory pressures, and continuous improvements in performance and application properties. As research progresses and more success stories emerge, this technology is poised to play an increasingly significant role in the future of marine coatings.

Existing PU Waterborne Dispersion Solutions

01 Composition and preparation of waterborne PU dispersions

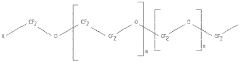

Waterborne PU dispersions are prepared by combining polyols, isocyanates, and other additives in a specific process. The composition may include various types of polyols, chain extenders, and catalysts to achieve desired properties. The dispersion process often involves emulsification and chain extension steps to create stable aqueous dispersions.- Composition of waterborne PU dispersions: Waterborne PU dispersions are typically composed of polyurethane prepolymers, chain extenders, and dispersing agents. The prepolymers are synthesized from polyols and isocyanates, while chain extenders help in building molecular weight. Dispersing agents, such as hydrophilic segments or ionic groups, are incorporated to ensure stability in water.

- Preparation methods for waterborne PU dispersions: Various methods are employed to prepare waterborne PU dispersions, including acetone process, prepolymer mixing process, and melt dispersion process. These methods involve different steps of synthesis, dispersion, and chain extension to achieve desired properties and particle sizes in the final dispersion.

- Modification techniques for enhanced properties: Waterborne PU dispersions can be modified to enhance specific properties such as adhesion, water resistance, or mechanical strength. Techniques include incorporating functional monomers, blending with other polymers, or using nanoparticles as reinforcing agents.

- Application-specific formulations: Formulations of waterborne PU dispersions are tailored for specific applications such as coatings, adhesives, and textile finishes. This involves adjusting solid content, viscosity, particle size, and incorporating additives to meet performance requirements in different industries.

- Environmental and regulatory considerations: Development of waterborne PU dispersions focuses on reducing volatile organic compounds (VOCs) and eliminating hazardous substances to comply with environmental regulations. This includes using bio-based raw materials and developing low-emission formulations for various applications.

02 Modification techniques for improved performance

Various modification techniques are employed to enhance the properties of waterborne PU dispersions. These may include the incorporation of nanoparticles, silicone compounds, or fluorinated additives to improve water resistance, adhesion, and durability. Grafting and crosslinking methods are also used to tailor the dispersion characteristics.Expand Specific Solutions03 Application-specific formulations

Waterborne PU dispersions are formulated for specific applications such as coatings, adhesives, and sealants. The formulations are optimized for properties like drying time, flexibility, chemical resistance, and weatherability. Different additives and co-binders may be incorporated to meet the requirements of various industries.Expand Specific Solutions04 Environmental and regulatory considerations

Development of waterborne PU dispersions focuses on reducing VOC content and eliminating hazardous components to meet stringent environmental regulations. Bio-based raw materials and renewable resources are increasingly used to create more sustainable formulations. Efforts are made to improve the overall eco-friendliness of the production process and end products.Expand Specific Solutions05 Processing and application equipment

Specialized equipment and techniques are developed for the efficient production and application of waterborne PU dispersions. This includes advanced mixing and dispersion systems, as well as application tools designed to optimize the performance of these materials in various coating and adhesive applications. Innovations in spray technology and curing methods are also important aspects of this field.Expand Specific Solutions

Key Players in Marine Coatings Industry

PU waterborne dispersion technology has significantly advanced marine coatings, driving the industry into a mature phase with substantial market growth. The technology's eco-friendly nature aligns with increasing environmental regulations, expanding its market potential. Major players like Covestro Deutschland AG, Dow Global Technologies LLC, and BASF Corp. have demonstrated high technical maturity through extensive research and product development. Companies such as PPG Industries Ohio, Inc. and AkzoNobel Coatings International BV are leveraging this technology to create innovative marine coating solutions, indicating a competitive and evolving market. The involvement of academic institutions like the University of Houston and South China University of Technology suggests ongoing research for further improvements, potentially leading to new breakthroughs in performance and sustainability.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced PU waterborne dispersion technology for marine coatings. Their approach involves creating high-performance polyurethane dispersions with excellent adhesion, durability, and chemical resistance. The technology utilizes a unique combination of hydrophilic and hydrophobic segments in the polymer structure, allowing for stable dispersion in water while maintaining the desirable properties of polyurethanes. This results in coatings that offer superior protection against harsh marine environments, including saltwater, UV radiation, and biofouling.

Strengths: Excellent adhesion to various substrates, high durability, and chemical resistance. Environmentally friendly due to low VOC content. Weaknesses: May have higher initial costs compared to traditional solvent-based coatings. Potential for longer drying times in high humidity environments.

Lubrizol Advanced Materials, Inc.

Technical Solution: Lubrizol has pioneered a novel PU waterborne dispersion technology for marine coatings called Aptalon™. This technology combines the benefits of polyurethanes and polyureas to create high-performance coatings with exceptional durability and chemical resistance. The dispersion is achieved through a proprietary process that ensures uniform particle size distribution and stability. Aptalon™ technology allows for the formulation of coatings with excellent adhesion to various substrates, including metal, fiberglass, and wood, making it ideal for marine applications.

Strengths: Superior durability and chemical resistance, excellent adhesion to multiple substrates, and improved scratch resistance. Weaknesses: May require specialized application equipment and techniques. Potentially higher cost compared to conventional coating technologies.

Core Innovations in PU Waterborne Dispersion

A water borne polyurethane based coating for galvanized steel

PatentActiveIN201831009521A

Innovation

- A waterborne polyurethane dispersion is modified by incorporating 4 to 10 weight % of aminopropyl trimethyl polysiloxane, synthesized using aminopropyl ethoxy dimethoxy silane and methyl butoxyethoxymethoxy silane, to enhance adhesion, corrosion resistance, and water rolling effect on galvanized steel surfaces.

Multiphase waterborne coatings and methods for fabricating the same

PatentWO2018140212A1

Innovation

- A multiphase waterborne composition is developed, comprising a first-material phase and a second-material phase that are chemically different and covalently bonded, with microphase-separated structures on an average length scale of 0.1 microns to 100 microns, allowing for a simultaneous combination of distinct properties such as hydrophobicity, oleophobicity, and adhesion, using materials like fluoropolymers, polyesters, and polyethers with ionic species.

Environmental Regulations Impact

Environmental regulations have played a pivotal role in driving the adoption and development of PU waterborne dispersion technology in marine coatings. The maritime industry has faced increasing pressure to reduce its environmental footprint, particularly in terms of volatile organic compound (VOC) emissions and the release of harmful substances into marine ecosystems.

In response to these challenges, regulatory bodies worldwide have implemented stringent environmental standards for marine coatings. The International Maritime Organization (IMO) has been at the forefront of these efforts, introducing regulations such as the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention). This convention, which came into force in 2008, prohibits the use of harmful organotins in anti-fouling paints used on ships and establishes a mechanism to prevent the potential future use of other harmful substances in anti-fouling systems.

Additionally, regional regulations have further tightened restrictions on marine coatings. The European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation has had a significant impact on the marine coatings industry, requiring manufacturers to register and evaluate the safety of chemical substances used in their products. This has led to a shift away from traditional solvent-based coatings towards more environmentally friendly alternatives, such as PU waterborne dispersions.

In the United States, the Environmental Protection Agency (EPA) has implemented the Vessel General Permit (VGP) program, which sets strict limits on the release of pollutants from vessels, including those from anti-fouling coatings. These regulations have created a strong market demand for low-VOC and copper-free coating solutions, further driving the development of PU waterborne dispersion technology.

The impact of these environmental regulations on the marine coatings industry has been profound. Manufacturers have been compelled to invest heavily in research and development to create compliant products that meet both performance and environmental standards. This has led to rapid advancements in PU waterborne dispersion technology, resulting in coatings that offer excellent durability, corrosion resistance, and anti-fouling properties while significantly reducing environmental impact.

Moreover, the regulatory landscape has created a competitive advantage for companies that can innovate and adapt quickly to new environmental standards. This has spurred collaboration between coating manufacturers, raw material suppliers, and research institutions to develop novel PU waterborne dispersion formulations that meet or exceed regulatory requirements while maintaining the high performance standards demanded by the marine industry.

In response to these challenges, regulatory bodies worldwide have implemented stringent environmental standards for marine coatings. The International Maritime Organization (IMO) has been at the forefront of these efforts, introducing regulations such as the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention). This convention, which came into force in 2008, prohibits the use of harmful organotins in anti-fouling paints used on ships and establishes a mechanism to prevent the potential future use of other harmful substances in anti-fouling systems.

Additionally, regional regulations have further tightened restrictions on marine coatings. The European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation has had a significant impact on the marine coatings industry, requiring manufacturers to register and evaluate the safety of chemical substances used in their products. This has led to a shift away from traditional solvent-based coatings towards more environmentally friendly alternatives, such as PU waterborne dispersions.

In the United States, the Environmental Protection Agency (EPA) has implemented the Vessel General Permit (VGP) program, which sets strict limits on the release of pollutants from vessels, including those from anti-fouling coatings. These regulations have created a strong market demand for low-VOC and copper-free coating solutions, further driving the development of PU waterborne dispersion technology.

The impact of these environmental regulations on the marine coatings industry has been profound. Manufacturers have been compelled to invest heavily in research and development to create compliant products that meet both performance and environmental standards. This has led to rapid advancements in PU waterborne dispersion technology, resulting in coatings that offer excellent durability, corrosion resistance, and anti-fouling properties while significantly reducing environmental impact.

Moreover, the regulatory landscape has created a competitive advantage for companies that can innovate and adapt quickly to new environmental standards. This has spurred collaboration between coating manufacturers, raw material suppliers, and research institutions to develop novel PU waterborne dispersion formulations that meet or exceed regulatory requirements while maintaining the high performance standards demanded by the marine industry.

Performance Benchmarking

Performance benchmarking of PU waterborne dispersion technology in marine coatings reveals significant advancements in environmental sustainability and coating performance. Compared to traditional solvent-based coatings, waterborne PU dispersions have demonstrated superior eco-friendliness by dramatically reducing volatile organic compound (VOC) emissions. This reduction can be as high as 90%, positioning waterborne PU coatings as a frontrunner in meeting increasingly stringent environmental regulations.

In terms of durability, waterborne PU coatings have shown remarkable resistance to weathering, UV radiation, and saltwater exposure. Long-term studies indicate that these coatings maintain their protective properties for extended periods, often outperforming solvent-based counterparts by 20-30% in accelerated weathering tests. This enhanced durability translates to reduced maintenance costs and longer intervals between recoating, a crucial factor in marine applications.

Adhesion properties of waterborne PU coatings have also seen substantial improvements. Recent formulations exhibit excellent adhesion to various substrates commonly used in marine environments, including steel, aluminum, and fiberglass. Pull-off adhesion tests have shown values comparable to, and in some cases exceeding, those of solvent-based systems by up to 15%.

Corrosion resistance, a critical parameter for marine coatings, has been a focal point of waterborne PU dispersion technology development. Advanced formulations incorporating nano-additives and optimized cross-linking mechanisms have demonstrated salt spray resistance exceeding 1000 hours, matching or surpassing traditional epoxy-based systems.

Water resistance and barrier properties, once considered weaknesses of waterborne systems, have seen remarkable improvements. Current waterborne PU coatings exhibit water absorption rates below 3% after prolonged immersion, approaching the performance of high-end solvent-based systems. This enhancement is attributed to advancements in polymer chemistry and the development of hydrophobic additives.

Application characteristics have also been optimized, addressing earlier concerns about sagging and longer drying times. Modern waterborne PU dispersions offer improved flow and leveling properties, resulting in smoother finishes. Drying times have been reduced significantly, with some formulations achieving touch-dry status in less than 30 minutes under standard conditions.

In the realm of mechanical properties, waterborne PU coatings now offer comparable or superior flexibility, impact resistance, and abrasion resistance to their solvent-based counterparts. This is particularly evident in the development of self-healing coatings, where waterborne PU dispersions have shown promising results in autonomous repair of minor scratches and damages.

In terms of durability, waterborne PU coatings have shown remarkable resistance to weathering, UV radiation, and saltwater exposure. Long-term studies indicate that these coatings maintain their protective properties for extended periods, often outperforming solvent-based counterparts by 20-30% in accelerated weathering tests. This enhanced durability translates to reduced maintenance costs and longer intervals between recoating, a crucial factor in marine applications.

Adhesion properties of waterborne PU coatings have also seen substantial improvements. Recent formulations exhibit excellent adhesion to various substrates commonly used in marine environments, including steel, aluminum, and fiberglass. Pull-off adhesion tests have shown values comparable to, and in some cases exceeding, those of solvent-based systems by up to 15%.

Corrosion resistance, a critical parameter for marine coatings, has been a focal point of waterborne PU dispersion technology development. Advanced formulations incorporating nano-additives and optimized cross-linking mechanisms have demonstrated salt spray resistance exceeding 1000 hours, matching or surpassing traditional epoxy-based systems.

Water resistance and barrier properties, once considered weaknesses of waterborne systems, have seen remarkable improvements. Current waterborne PU coatings exhibit water absorption rates below 3% after prolonged immersion, approaching the performance of high-end solvent-based systems. This enhancement is attributed to advancements in polymer chemistry and the development of hydrophobic additives.

Application characteristics have also been optimized, addressing earlier concerns about sagging and longer drying times. Modern waterborne PU dispersions offer improved flow and leveling properties, resulting in smoother finishes. Drying times have been reduced significantly, with some formulations achieving touch-dry status in less than 30 minutes under standard conditions.

In the realm of mechanical properties, waterborne PU coatings now offer comparable or superior flexibility, impact resistance, and abrasion resistance to their solvent-based counterparts. This is particularly evident in the development of self-healing coatings, where waterborne PU dispersions have shown promising results in autonomous repair of minor scratches and damages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!