How Material Jetting Reaches High-Resolution Patterns Without Stair-Stepping Artifacts?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Evolution and Objectives

Material jetting technology has evolved significantly since its inception in the late 1980s, transforming from basic droplet deposition systems to sophisticated additive manufacturing platforms capable of multi-material and multi-color printing. The technology originated from developments in inkjet printing technology, where pioneers adapted the precise droplet control mechanisms for depositing build materials rather than inks. By the early 2000s, commercial material jetting systems emerged, primarily focused on producing wax models for investment casting applications.

The evolution accelerated in the mid-2000s with the introduction of photopolymer-based material jetting, which expanded the application scope beyond prototyping to functional parts production. This period marked a critical transition as resolution capabilities improved from hundreds of microns to tens of microns, enabling more detailed and accurate part production. The development of support materials that could be easily removed post-processing further enhanced the technology's capabilities for complex geometries.

A significant technological milestone occurred around 2010-2015 with the integration of multi-nozzle print heads and advanced droplet placement algorithms. These innovations directly addressed the stair-stepping artifacts—undesirable visible layer lines that compromise surface quality and dimensional accuracy. The implementation of variable droplet size technology and grayscale printing techniques allowed for smoother transitions between layers, substantially reducing these artifacts.

Recent advancements have focused on high-resolution pattern achievement through synchronized multi-axis motion systems and dynamic droplet control. Modern material jetting systems employ sophisticated feedback mechanisms that adjust droplet trajectory and volume in real-time, compensating for environmental factors and material behavior variations. This adaptive approach has been crucial in overcoming the resolution limitations inherent in layer-by-layer fabrication processes.

The current technological objective centers on achieving sub-micron resolution while maintaining build speed and material versatility. Researchers are exploring nanoscale material formulations and advanced curing mechanisms that can solidify material precisely at the deposition point. There is also significant interest in developing hybrid approaches that combine material jetting with other fabrication techniques to leverage the strengths of multiple processes.

Looking forward, the industry aims to eliminate stair-stepping artifacts entirely through continuous surface formation rather than discrete layering. This paradigm shift requires fundamental innovations in material science, motion control systems, and computational modeling of fluid dynamics. The ultimate goal is to create a seamless transition between digital design and physical realization, where the resolution limitations of the manufacturing process become imperceptible in the final product.

The evolution accelerated in the mid-2000s with the introduction of photopolymer-based material jetting, which expanded the application scope beyond prototyping to functional parts production. This period marked a critical transition as resolution capabilities improved from hundreds of microns to tens of microns, enabling more detailed and accurate part production. The development of support materials that could be easily removed post-processing further enhanced the technology's capabilities for complex geometries.

A significant technological milestone occurred around 2010-2015 with the integration of multi-nozzle print heads and advanced droplet placement algorithms. These innovations directly addressed the stair-stepping artifacts—undesirable visible layer lines that compromise surface quality and dimensional accuracy. The implementation of variable droplet size technology and grayscale printing techniques allowed for smoother transitions between layers, substantially reducing these artifacts.

Recent advancements have focused on high-resolution pattern achievement through synchronized multi-axis motion systems and dynamic droplet control. Modern material jetting systems employ sophisticated feedback mechanisms that adjust droplet trajectory and volume in real-time, compensating for environmental factors and material behavior variations. This adaptive approach has been crucial in overcoming the resolution limitations inherent in layer-by-layer fabrication processes.

The current technological objective centers on achieving sub-micron resolution while maintaining build speed and material versatility. Researchers are exploring nanoscale material formulations and advanced curing mechanisms that can solidify material precisely at the deposition point. There is also significant interest in developing hybrid approaches that combine material jetting with other fabrication techniques to leverage the strengths of multiple processes.

Looking forward, the industry aims to eliminate stair-stepping artifacts entirely through continuous surface formation rather than discrete layering. This paradigm shift requires fundamental innovations in material science, motion control systems, and computational modeling of fluid dynamics. The ultimate goal is to create a seamless transition between digital design and physical realization, where the resolution limitations of the manufacturing process become imperceptible in the final product.

Market Demand for High-Resolution Additive Manufacturing

The additive manufacturing market is experiencing a significant shift towards high-resolution applications, with material jetting technology positioned as a key enabler for this transition. Current market analysis indicates that industries including medical devices, aerospace components, microfluidics, and consumer electronics are driving substantial demand for high-precision 3D printing capabilities that eliminate visible layer lines and stair-stepping artifacts.

The global high-resolution additive manufacturing segment is growing at approximately twice the rate of the overall 3D printing market, reflecting the increasing importance of surface quality and dimensional accuracy in end-use applications. This acceleration is particularly evident in sectors where microscale features and smooth surfaces directly impact product functionality and performance.

Medical device manufacturing represents one of the largest demand segments, with requirements for patient-specific implants, intricate surgical instruments, and anatomical models that accurately represent fine biological structures. The ability to produce these items without post-processing to remove stair-stepping artifacts translates directly to reduced production time and enhanced clinical outcomes.

In the electronics industry, the miniaturization trend continues to push manufacturing capabilities toward ever-smaller feature sizes. Material jetting systems capable of producing high-resolution patterns without artifacts are becoming essential for printing conductive traces, embedded electronics, and complex multi-material assemblies. Market research indicates that electronics manufacturers are willing to pay premium prices for systems that can deliver sub-10 micron resolution without compromising surface quality.

Aerospace and defense applications constitute another significant market driver, with requirements for lightweight components featuring complex internal geometries that must meet stringent performance specifications. The elimination of stair-stepping artifacts directly impacts aerodynamic performance, structural integrity, and weight optimization—all critical factors in next-generation aircraft and spacecraft design.

The jewelry and luxury goods sector has emerged as an unexpected growth area for high-resolution material jetting. Designers are increasingly leveraging artifact-free printing to create intricate patterns and textures previously achievable only through traditional craftsmanship, while maintaining the advantages of digital design iteration and customization.

Market forecasts suggest that the demand for high-resolution, artifact-free additive manufacturing will continue to expand as industries discover new applications that benefit from these capabilities. This growth is further accelerated by the increasing adoption of digital manufacturing workflows that integrate design optimization, simulation, and production—processes that require faithful reproduction of complex geometries without the limitations imposed by layer-based artifacts.

The global high-resolution additive manufacturing segment is growing at approximately twice the rate of the overall 3D printing market, reflecting the increasing importance of surface quality and dimensional accuracy in end-use applications. This acceleration is particularly evident in sectors where microscale features and smooth surfaces directly impact product functionality and performance.

Medical device manufacturing represents one of the largest demand segments, with requirements for patient-specific implants, intricate surgical instruments, and anatomical models that accurately represent fine biological structures. The ability to produce these items without post-processing to remove stair-stepping artifacts translates directly to reduced production time and enhanced clinical outcomes.

In the electronics industry, the miniaturization trend continues to push manufacturing capabilities toward ever-smaller feature sizes. Material jetting systems capable of producing high-resolution patterns without artifacts are becoming essential for printing conductive traces, embedded electronics, and complex multi-material assemblies. Market research indicates that electronics manufacturers are willing to pay premium prices for systems that can deliver sub-10 micron resolution without compromising surface quality.

Aerospace and defense applications constitute another significant market driver, with requirements for lightweight components featuring complex internal geometries that must meet stringent performance specifications. The elimination of stair-stepping artifacts directly impacts aerodynamic performance, structural integrity, and weight optimization—all critical factors in next-generation aircraft and spacecraft design.

The jewelry and luxury goods sector has emerged as an unexpected growth area for high-resolution material jetting. Designers are increasingly leveraging artifact-free printing to create intricate patterns and textures previously achievable only through traditional craftsmanship, while maintaining the advantages of digital design iteration and customization.

Market forecasts suggest that the demand for high-resolution, artifact-free additive manufacturing will continue to expand as industries discover new applications that benefit from these capabilities. This growth is further accelerated by the increasing adoption of digital manufacturing workflows that integrate design optimization, simulation, and production—processes that require faithful reproduction of complex geometries without the limitations imposed by layer-based artifacts.

Technical Barriers in Material Jetting Resolution

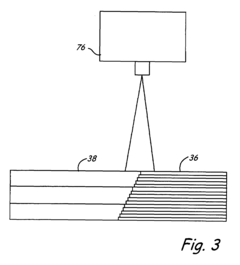

Material jetting technology faces several significant technical barriers in achieving high-resolution patterns without stair-stepping artifacts. The layer-by-layer deposition process inherently creates a stepped approximation of curved or angled surfaces, resulting in the characteristic "stair-stepping" effect that compromises surface quality and dimensional accuracy.

The primary resolution limitation stems from droplet size constraints. Current printhead technologies typically produce droplets in the 20-80 micron range, which fundamentally limits the achievable resolution. While smaller droplets would enable finer features, they present challenges in consistent generation, precise placement, and material compatibility.

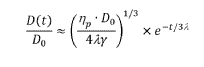

Droplet spreading behavior upon impact represents another critical barrier. When a droplet contacts the substrate or previous layers, it spreads according to complex fluid dynamics influenced by surface tension, viscosity, and substrate properties. This spreading can cause feature blurring and dimensional inaccuracy, particularly problematic for high-resolution applications requiring precise edge definition.

Material viscosity management presents a delicate balance. Materials must be fluid enough for jetting but viscous enough to maintain shape after deposition. This balance becomes increasingly difficult to achieve as resolution requirements increase, as lower viscosity materials enable smoother surfaces but risk excessive spreading.

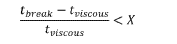

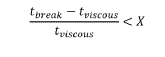

Surface tension effects significantly impact high-resolution printing. The Plateau-Rayleigh instability can cause jetted filaments to break into droplets, while surface tension forces can reshape deposited material, potentially eliminating fine features. These effects become more pronounced at smaller scales, directly affecting achievable resolution.

Thermal management represents another substantial challenge. Temperature fluctuations during printing affect material viscosity, surface tension, and curing behavior. Even minor thermal variations can cause inconsistent droplet formation and placement, leading to resolution degradation and surface irregularities.

Printhead-substrate distance control is crucial for high-resolution printing. Variations in this distance affect droplet placement accuracy and impact dynamics. Maintaining precise, consistent standoff distance becomes increasingly challenging with larger build areas and complex geometries.

Curing kinetics also significantly impact resolution. Rapid, controlled solidification is essential to prevent droplet spreading, but must be balanced against potential issues like shrinkage, warping, and internal stress. The curing process must be precisely synchronized with deposition to maintain feature fidelity.

These technical barriers collectively limit the achievable resolution in material jetting processes, requiring innovative approaches in hardware design, material formulation, and process control to overcome the inherent limitations of the technology.

The primary resolution limitation stems from droplet size constraints. Current printhead technologies typically produce droplets in the 20-80 micron range, which fundamentally limits the achievable resolution. While smaller droplets would enable finer features, they present challenges in consistent generation, precise placement, and material compatibility.

Droplet spreading behavior upon impact represents another critical barrier. When a droplet contacts the substrate or previous layers, it spreads according to complex fluid dynamics influenced by surface tension, viscosity, and substrate properties. This spreading can cause feature blurring and dimensional inaccuracy, particularly problematic for high-resolution applications requiring precise edge definition.

Material viscosity management presents a delicate balance. Materials must be fluid enough for jetting but viscous enough to maintain shape after deposition. This balance becomes increasingly difficult to achieve as resolution requirements increase, as lower viscosity materials enable smoother surfaces but risk excessive spreading.

Surface tension effects significantly impact high-resolution printing. The Plateau-Rayleigh instability can cause jetted filaments to break into droplets, while surface tension forces can reshape deposited material, potentially eliminating fine features. These effects become more pronounced at smaller scales, directly affecting achievable resolution.

Thermal management represents another substantial challenge. Temperature fluctuations during printing affect material viscosity, surface tension, and curing behavior. Even minor thermal variations can cause inconsistent droplet formation and placement, leading to resolution degradation and surface irregularities.

Printhead-substrate distance control is crucial for high-resolution printing. Variations in this distance affect droplet placement accuracy and impact dynamics. Maintaining precise, consistent standoff distance becomes increasingly challenging with larger build areas and complex geometries.

Curing kinetics also significantly impact resolution. Rapid, controlled solidification is essential to prevent droplet spreading, but must be balanced against potential issues like shrinkage, warping, and internal stress. The curing process must be precisely synchronized with deposition to maintain feature fidelity.

These technical barriers collectively limit the achievable resolution in material jetting processes, requiring innovative approaches in hardware design, material formulation, and process control to overcome the inherent limitations of the technology.

Current Anti-Stair-Stepping Methodologies

01 Advanced droplet control techniques

Material jetting systems can achieve high-resolution patterns without stair-stepping artifacts by implementing precise droplet control techniques. These include optimizing droplet size, adjusting droplet placement accuracy, and controlling the timing of droplet ejection. By carefully managing these parameters, the system can create smooth transitions between layers and reduce the visibility of layer boundaries that typically cause stair-stepping effects.- Advanced droplet control techniques: Material jetting systems can achieve high-resolution patterns without stair-stepping artifacts by implementing advanced droplet control techniques. These include precise control of droplet size, velocity, and placement, as well as optimizing the timing and sequence of droplet deposition. By carefully controlling these parameters, the system can create smooth transitions between layers and reduce the visibility of layer boundaries that typically cause stair-stepping artifacts.

- Multi-resolution printing strategies: Implementing multi-resolution printing strategies allows material jetting systems to adapt the resolution based on the geometric complexity of different regions of the printed object. By using higher resolution in areas with fine details or curved surfaces and lower resolution in less complex regions, the system can minimize stair-stepping artifacts while maintaining efficiency. This approach often involves variable droplet sizes and dynamic adjustment of printing parameters during the fabrication process.

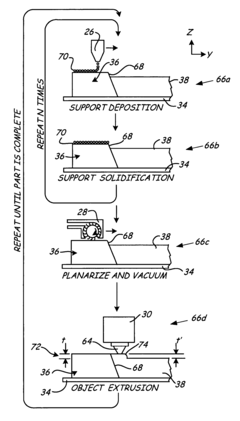

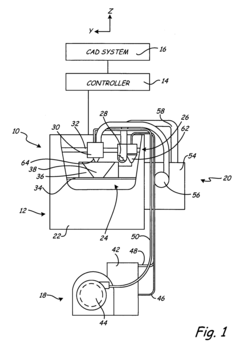

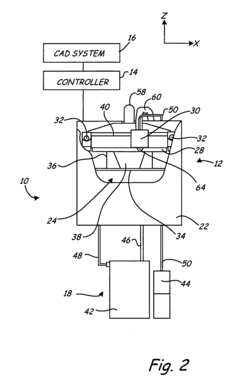

- Surface smoothing algorithms: Specialized software algorithms can be employed to analyze the digital model before printing and modify the printing path to reduce stair-stepping artifacts. These algorithms identify areas prone to visible layer lines and adjust the material deposition strategy accordingly. Some approaches include adaptive slicing, where layer thickness varies based on surface geometry, and contour-based printing paths that follow the natural curvature of the object rather than rigid horizontal layers.

- Post-processing techniques integrated with printing: Some material jetting systems incorporate in-situ post-processing techniques to smooth surfaces during or immediately after deposition. These may include localized heating, UV curing with controlled intensity, or chemical treatments that can be applied selectively to areas where stair-stepping artifacts would be most visible. By integrating these processes directly into the printing workflow, high-resolution patterns can be achieved without requiring separate finishing steps.

- Material formulation for artifact reduction: Specialized material formulations can significantly reduce the appearance of stair-stepping artifacts in material jetting processes. These formulations may include self-leveling properties that allow deposited material to flow slightly before curing, filling in gaps between adjacent droplets. Other approaches include materials with controlled surface tension, viscosity modifiers, and additives that promote smooth interfaces between layers while maintaining dimensional accuracy and structural integrity of the printed object.

02 Multi-resolution printing strategies

Implementing multi-resolution printing strategies allows material jetting systems to adapt the resolution based on the geometric complexity of different regions. By using higher resolution in areas with fine details or curved surfaces and lower resolution in less complex regions, the system can minimize stair-stepping artifacts while maintaining efficiency. This approach often involves variable droplet sizes and dynamic adjustment of printing parameters during the fabrication process.Expand Specific Solutions03 Surface smoothing algorithms

Advanced software algorithms can significantly reduce stair-stepping artifacts in material jetting processes. These algorithms analyze the 3D model before printing and modify the toolpath to optimize surface smoothness. Techniques include adaptive slicing, where layer thickness varies according to surface geometry, and contour-based printing strategies that prioritize the quality of external surfaces. The algorithms can also predict and compensate for material shrinkage or expansion during curing.Expand Specific Solutions04 Post-processing techniques

Various post-processing methods can be applied to material jetted parts to eliminate stair-stepping artifacts. These include chemical treatments that selectively dissolve or smooth the surface, thermal processing to reflow the material, and mechanical finishing techniques. Some advanced systems incorporate these post-processing steps directly into the manufacturing workflow, allowing for automated surface enhancement without manual intervention.Expand Specific Solutions05 Material formulation optimization

The composition of jetting materials can be specifically formulated to minimize stair-stepping artifacts. By developing materials with optimized viscosity, surface tension, and curing characteristics, manufacturers can achieve better flow between layers before solidification. Some advanced formulations include self-leveling properties that naturally smooth out layer transitions, while others incorporate nanoparticles or specialized polymers that enhance resolution and surface quality during the printing process.Expand Specific Solutions

Leading Material Jetting Equipment Manufacturers

Material jetting technology is currently in a growth phase, with the market expanding due to increasing demand for high-resolution 3D printing without stair-stepping artifacts. The global market size for material jetting is projected to grow significantly as industries adopt this technology for its precision capabilities. Technologically, material jetting has reached moderate maturity, with companies like Stratasys and Optomec leading innovation in high-resolution patterning techniques. Stratasys has developed advanced multi-material jetting systems, while companies such as Ricoh, Seiko Epson, and Xerox leverage their expertise in traditional printing to enhance material jetting precision. Emerging players like Zhuhai Sailner Technology are introducing proprietary technologies like WJP white ink filling, further advancing the field's capabilities for artifact-free, high-resolution printing.

Seiko Epson Corp.

Technical Solution: Seiko Epson has adapted its precision inkjet printing expertise to material jetting applications, developing Micro Piezo technology that achieves high-resolution patterns without stair-stepping artifacts. Their approach utilizes piezoelectric print heads with variable droplet size technology (1-25 picoliters) that can precisely control the volume and placement of each material droplet with accuracy down to 1.5 microns. The system employs multi-pass printing algorithms that strategically overlap droplets to create smooth transitions between layers. Epson's proprietary waveform control technology manipulates the electrical signals sent to the piezoelectric elements, allowing for precise control over droplet formation, velocity, and landing position. To further minimize artifacts, they've developed specialized substrate heating systems that control material viscosity and spreading behavior upon deposition. Their latest systems incorporate real-time optical monitoring that detects and compensates for any irregularities during the printing process[2][5]. Epson has also developed specialized UV-curable resins with optimized surface tension and curing characteristics specifically designed to minimize layer boundaries.

Strengths: Exceptional droplet placement precision derived from decades of inkjet printing expertise; variable droplet technology allows for gradient transitions between features; high-frequency jetting capabilities enable faster production while maintaining quality. Weaknesses: More limited material compatibility compared to some competitors; systems typically designed for smaller build volumes focused on high-precision applications rather than larger industrial parts.

Xerox Holdings Corp.

Technical Solution: Xerox has leveraged its extensive expertise in document printing to develop advanced material jetting technologies that minimize stair-stepping artifacts. Their approach centers on Direct-to-Object printing technology that utilizes high-precision print heads capable of jetting materials with droplet volumes as small as 1 picoliter. The system achieves smooth surfaces through multi-level grayscale printing capabilities that vary the density of material deposition across each layer, effectively creating sub-layer resolution. Xerox's proprietary image processing algorithms analyze 3D models to identify areas prone to stair-stepping and automatically adjust printing parameters to compensate. Their technology incorporates acoustic wave monitoring that detects and corrects droplet formation irregularities in real-time, ensuring consistent material deposition. To further enhance surface quality, Xerox has developed specialized post-processing techniques including controlled thermal reflow that allows deposited materials to slightly redistribute after initial placement, naturally smoothing layer transitions[4][6]. The company has also pioneered multi-material jetting with precisely controlled interface boundaries, enabling gradient material transitions that inherently mask layer lines.

Strengths: Superior image processing capabilities derived from document printing heritage; acoustic monitoring ensures exceptional consistency in droplet formation; advanced thermal management systems provide precise control over material flow behavior. Weaknesses: Relatively new entrant to 3D material jetting market compared to established players; more limited range of compatible materials compared to some competitors; systems primarily optimized for smaller, high-detail objects rather than larger industrial applications.

Breakthrough Patents in High-Resolution Material Jetting

High-resolution rapid manufacturing

PatentInactiveUS7502023B2

Innovation

- A system employing dual deposition heads, where one head forms a support structure with high resolution and the other deposits modeling material at a lower resolution within the support structure, allowing the object to conform to its shape and improve surface finish, combined with a controlled build chamber environment to enhance material properties.

Compositions and methods for high-temperature jetting of viscous thermosets to create solid articles via additive fabrication

PatentWO2019117723A1

Innovation

- The method involves ejecting droplets of highly viscous thermoset materials at elevated temperatures using a jetting system configured to operate at viscosities up to 60 cP, with a nozzle temperature ranging from 30°C to 180°C, and using a CaBER extensional rheology method to ensure suitable rheological characteristics, allowing for the formation of three-dimensional objects with enhanced mechanical properties.

Material Science Developments for Enhanced Resolution

Recent advancements in material science have significantly contributed to overcoming resolution limitations in material jetting processes. The development of novel photopolymer resins with optimized rheological properties has been crucial for achieving high-resolution patterns without stair-stepping artifacts. These next-generation materials exhibit carefully controlled viscosity profiles that allow for precise deposition while maintaining shape fidelity during the curing process.

Nanoparticle-enhanced composite materials represent another breakthrough, incorporating sub-micron particles that modify surface tension and improve edge definition. These engineered composites demonstrate superior resistance to the "coffee ring effect" - a common cause of edge irregularities in printed structures. The strategic integration of silica nanoparticles at concentrations between 0.5-2% has shown particular promise in maintaining homogeneous material distribution during solidification.

Thermo-responsive polymers have emerged as an innovative solution for high-resolution material jetting. These materials undergo rapid phase transitions at specific temperature thresholds, enabling precise control over solidification timing. This property allows for smoother transitions between layers and significantly reduces the visibility of step artifacts. Recent formulations incorporating poly(N-isopropylacrylamide) derivatives have demonstrated transition temperatures optimized for common material jetting processes.

Surface-active additives have been developed to modify the interfacial properties of jetted materials. These additives control droplet spreading behavior upon deposition, preventing excessive material flow that would otherwise compromise feature definition. Advanced fluorosurfactants at concentrations as low as 0.1% have proven effective in maintaining sharp boundaries between adjacent features without interfering with subsequent curing processes.

Multi-functional monomers and oligomers with tailored molecular weights provide enhanced control over curing kinetics and mechanical properties. These materials enable rapid solidification upon exposure to UV light or thermal energy, minimizing the time available for gravity-induced deformation that contributes to stair-stepping. The incorporation of dendritic polymers with multiple reactive sites has shown particular promise in achieving both rapid curing and excellent mechanical integrity.

Cross-linking density modifiers represent another significant advancement, allowing for precise control over the final material properties. These additives enable the creation of gradient structures with varying degrees of rigidity, facilitating smoother transitions between layers. Recent research has demonstrated that controlled heterogeneity in cross-linking density can effectively mask layer boundaries that would otherwise manifest as visible artifacts.

Nanoparticle-enhanced composite materials represent another breakthrough, incorporating sub-micron particles that modify surface tension and improve edge definition. These engineered composites demonstrate superior resistance to the "coffee ring effect" - a common cause of edge irregularities in printed structures. The strategic integration of silica nanoparticles at concentrations between 0.5-2% has shown particular promise in maintaining homogeneous material distribution during solidification.

Thermo-responsive polymers have emerged as an innovative solution for high-resolution material jetting. These materials undergo rapid phase transitions at specific temperature thresholds, enabling precise control over solidification timing. This property allows for smoother transitions between layers and significantly reduces the visibility of step artifacts. Recent formulations incorporating poly(N-isopropylacrylamide) derivatives have demonstrated transition temperatures optimized for common material jetting processes.

Surface-active additives have been developed to modify the interfacial properties of jetted materials. These additives control droplet spreading behavior upon deposition, preventing excessive material flow that would otherwise compromise feature definition. Advanced fluorosurfactants at concentrations as low as 0.1% have proven effective in maintaining sharp boundaries between adjacent features without interfering with subsequent curing processes.

Multi-functional monomers and oligomers with tailored molecular weights provide enhanced control over curing kinetics and mechanical properties. These materials enable rapid solidification upon exposure to UV light or thermal energy, minimizing the time available for gravity-induced deformation that contributes to stair-stepping. The incorporation of dendritic polymers with multiple reactive sites has shown particular promise in achieving both rapid curing and excellent mechanical integrity.

Cross-linking density modifiers represent another significant advancement, allowing for precise control over the final material properties. These additives enable the creation of gradient structures with varying degrees of rigidity, facilitating smoother transitions between layers. Recent research has demonstrated that controlled heterogeneity in cross-linking density can effectively mask layer boundaries that would otherwise manifest as visible artifacts.

Post-Processing Techniques for Surface Refinement

Post-processing techniques represent a critical phase in material jetting workflows, enabling manufacturers to overcome inherent limitations of the printing process and achieve superior surface quality. Chemical smoothing methods utilize solvents that selectively dissolve the outer layer of printed parts, effectively eliminating stair-stepping artifacts by creating a controlled melting effect. This approach is particularly effective for polymeric materials, where appropriate solvent selection can yield mirror-like finishes without compromising dimensional accuracy.

Thermal treatments offer another viable pathway to surface refinement, involving carefully controlled heating processes that allow surface molecules to reflow and reorganize. When precisely managed, these treatments can significantly reduce surface roughness while maintaining geometric integrity. The development of specialized thermal chambers with gradient temperature control has further enhanced this technique's precision and applicability across various material compositions.

Mechanical finishing techniques have evolved substantially beyond traditional sanding and polishing. Advanced methods now include micro-abrasive blasting with precisely calibrated media and robotic polishing systems that adapt to complex geometries. These systems utilize machine learning algorithms to optimize tool paths and pressure distribution, ensuring consistent surface quality across variable topographies without removing excessive material from critical features.

Hybrid approaches combining multiple post-processing techniques have demonstrated superior results in recent industrial applications. Sequential processing—such as initial chemical treatment followed by precision mechanical polishing—creates synergistic effects that neither method could achieve independently. This multi-stage methodology has proven particularly effective for high-precision components in aerospace and medical device manufacturing.

Emerging technologies in post-processing include photonic sintering, where intense, brief light pulses selectively modify surface characteristics without affecting substrate properties. Similarly, plasma treatment systems can alter surface energy and topography at the nanoscale, enhancing both aesthetic qualities and functional performance. These non-contact methods offer significant advantages for delicate or intricate geometries where traditional approaches might cause damage.

The integration of in-line metrology with post-processing equipment represents another significant advancement, enabling real-time quality control and adaptive processing. Optical scanning systems can continuously monitor surface characteristics during refinement operations, automatically adjusting processing parameters to achieve specified surface requirements while minimizing material removal.

Thermal treatments offer another viable pathway to surface refinement, involving carefully controlled heating processes that allow surface molecules to reflow and reorganize. When precisely managed, these treatments can significantly reduce surface roughness while maintaining geometric integrity. The development of specialized thermal chambers with gradient temperature control has further enhanced this technique's precision and applicability across various material compositions.

Mechanical finishing techniques have evolved substantially beyond traditional sanding and polishing. Advanced methods now include micro-abrasive blasting with precisely calibrated media and robotic polishing systems that adapt to complex geometries. These systems utilize machine learning algorithms to optimize tool paths and pressure distribution, ensuring consistent surface quality across variable topographies without removing excessive material from critical features.

Hybrid approaches combining multiple post-processing techniques have demonstrated superior results in recent industrial applications. Sequential processing—such as initial chemical treatment followed by precision mechanical polishing—creates synergistic effects that neither method could achieve independently. This multi-stage methodology has proven particularly effective for high-precision components in aerospace and medical device manufacturing.

Emerging technologies in post-processing include photonic sintering, where intense, brief light pulses selectively modify surface characteristics without affecting substrate properties. Similarly, plasma treatment systems can alter surface energy and topography at the nanoscale, enhancing both aesthetic qualities and functional performance. These non-contact methods offer significant advantages for delicate or intricate geometries where traditional approaches might cause damage.

The integration of in-line metrology with post-processing equipment represents another significant advancement, enabling real-time quality control and adaptive processing. Optical scanning systems can continuously monitor surface characteristics during refinement operations, automatically adjusting processing parameters to achieve specified surface requirements while minimizing material removal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!