Material Jetting Drop Formation Dynamics: Satellite Suppression And Line Uniformity

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

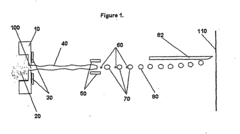

Material jetting technology has evolved significantly since its inception in the 1950s, originating from continuous inkjet printing systems. The fundamental principle involves the precise deposition of liquid material droplets onto a substrate, which then solidify through various mechanisms including cooling, evaporation, or chemical reactions. Over the past two decades, this technology has transitioned from primarily graphic arts applications to becoming a cornerstone of advanced manufacturing processes, particularly in additive manufacturing and printed electronics.

The evolution of material jetting has been characterized by continuous improvements in droplet formation control, material compatibility expansion, and resolution enhancement. Early systems struggled with consistent droplet generation and placement accuracy, while contemporary systems can achieve micron-level precision. This progression has been driven by advancements in piezoelectric actuators, microfluidic channel designs, and sophisticated waveform control algorithms.

Current research in material jetting focuses intensively on drop formation dynamics, with particular emphasis on satellite suppression and line uniformity. Satellite droplets—secondary smaller droplets that form during the jetting process—represent a significant challenge to print quality and resolution. These unwanted formations can lead to material waste, dimensional inaccuracies, and surface finish degradation in manufactured components.

Line uniformity presents another critical challenge, as inconsistent material deposition creates functional and aesthetic defects in printed structures. The physics governing these phenomena involve complex interactions between fluid properties (viscosity, surface tension), jetting parameters (pressure, temperature, waveform shape), and environmental conditions. Understanding and controlling these interactions remains a primary objective for advancing material jetting capabilities.

The technical objectives for material jetting development include achieving predictable and repeatable droplet formation without satellites across a wider range of material viscosities and surface tensions. Researchers aim to develop comprehensive models that can accurately predict droplet behavior based on material properties and jetting parameters, enabling real-time adjustments to maintain optimal print quality.

Additionally, there is significant focus on expanding the range of jettable materials to include higher viscosity fluids, particle-loaded suspensions, and multi-component reactive systems. This expansion would dramatically increase the application potential of material jetting in fields ranging from biomedical devices to advanced electronics manufacturing.

The ultimate goal is to establish material jetting as a reliable, high-precision manufacturing technology capable of consistent performance across diverse material systems and complex geometries, while maintaining the speed advantages inherent to this non-contact deposition method.

The evolution of material jetting has been characterized by continuous improvements in droplet formation control, material compatibility expansion, and resolution enhancement. Early systems struggled with consistent droplet generation and placement accuracy, while contemporary systems can achieve micron-level precision. This progression has been driven by advancements in piezoelectric actuators, microfluidic channel designs, and sophisticated waveform control algorithms.

Current research in material jetting focuses intensively on drop formation dynamics, with particular emphasis on satellite suppression and line uniformity. Satellite droplets—secondary smaller droplets that form during the jetting process—represent a significant challenge to print quality and resolution. These unwanted formations can lead to material waste, dimensional inaccuracies, and surface finish degradation in manufactured components.

Line uniformity presents another critical challenge, as inconsistent material deposition creates functional and aesthetic defects in printed structures. The physics governing these phenomena involve complex interactions between fluid properties (viscosity, surface tension), jetting parameters (pressure, temperature, waveform shape), and environmental conditions. Understanding and controlling these interactions remains a primary objective for advancing material jetting capabilities.

The technical objectives for material jetting development include achieving predictable and repeatable droplet formation without satellites across a wider range of material viscosities and surface tensions. Researchers aim to develop comprehensive models that can accurately predict droplet behavior based on material properties and jetting parameters, enabling real-time adjustments to maintain optimal print quality.

Additionally, there is significant focus on expanding the range of jettable materials to include higher viscosity fluids, particle-loaded suspensions, and multi-component reactive systems. This expansion would dramatically increase the application potential of material jetting in fields ranging from biomedical devices to advanced electronics manufacturing.

The ultimate goal is to establish material jetting as a reliable, high-precision manufacturing technology capable of consistent performance across diverse material systems and complex geometries, while maintaining the speed advantages inherent to this non-contact deposition method.

Market Analysis for Material Jetting Applications

The material jetting market has experienced significant growth in recent years, driven by increasing demand for high-precision manufacturing processes across multiple industries. The global material jetting market was valued at approximately $2.3 billion in 2022 and is projected to reach $4.7 billion by 2028, representing a compound annual growth rate of 12.7%. This growth trajectory is primarily fueled by advancements in drop formation dynamics, particularly in satellite suppression and line uniformity technologies.

The electronics manufacturing sector currently dominates the material jetting application landscape, accounting for nearly 35% of the total market share. The demand for miniaturized electronic components with increasingly complex geometries has necessitated printing technologies capable of delivering microscale precision and consistency. Material jetting's ability to produce uniform lines with minimal satellite droplets makes it particularly valuable for printed circuit board manufacturing and semiconductor packaging applications.

Healthcare and biomedical applications represent the fastest-growing segment, with an estimated growth rate of 18.3% annually. The ability to precisely control droplet formation and placement has enabled significant advancements in bioprinting, drug delivery systems, and medical device manufacturing. Particularly, the development of satellite-free jetting techniques has opened new possibilities for printing biocompatible materials with cellular structures.

Aerospace and automotive industries have also embraced material jetting technology for prototyping and production of specialized components. These sectors value the technology's ability to maintain consistent line uniformity across large surface areas, which is critical for aerodynamic performance and structural integrity. Market penetration in these industries has increased by approximately 15% annually since 2020.

Consumer goods manufacturing represents another significant market segment, particularly for customized products and packaging solutions. The demand for high-resolution graphics and textures has driven innovation in multi-material jetting systems with enhanced drop formation control.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 16.2% annually, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

Key market challenges include the high cost of implementation, material limitations, and technical complexities in achieving consistent drop formation across different viscosities and surface tensions. These challenges have created market opportunities for companies specializing in satellite suppression technologies and line uniformity enhancement solutions, with several startups securing significant venture capital funding in this niche.

The electronics manufacturing sector currently dominates the material jetting application landscape, accounting for nearly 35% of the total market share. The demand for miniaturized electronic components with increasingly complex geometries has necessitated printing technologies capable of delivering microscale precision and consistency. Material jetting's ability to produce uniform lines with minimal satellite droplets makes it particularly valuable for printed circuit board manufacturing and semiconductor packaging applications.

Healthcare and biomedical applications represent the fastest-growing segment, with an estimated growth rate of 18.3% annually. The ability to precisely control droplet formation and placement has enabled significant advancements in bioprinting, drug delivery systems, and medical device manufacturing. Particularly, the development of satellite-free jetting techniques has opened new possibilities for printing biocompatible materials with cellular structures.

Aerospace and automotive industries have also embraced material jetting technology for prototyping and production of specialized components. These sectors value the technology's ability to maintain consistent line uniformity across large surface areas, which is critical for aerodynamic performance and structural integrity. Market penetration in these industries has increased by approximately 15% annually since 2020.

Consumer goods manufacturing represents another significant market segment, particularly for customized products and packaging solutions. The demand for high-resolution graphics and textures has driven innovation in multi-material jetting systems with enhanced drop formation control.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 16.2% annually, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

Key market challenges include the high cost of implementation, material limitations, and technical complexities in achieving consistent drop formation across different viscosities and surface tensions. These challenges have created market opportunities for companies specializing in satellite suppression technologies and line uniformity enhancement solutions, with several startups securing significant venture capital funding in this niche.

Current Challenges in Drop Formation Dynamics

Material jetting technology faces several critical challenges in drop formation dynamics that significantly impact manufacturing precision and product quality. The primary issue revolves around satellite droplet formation, which occurs when the main droplet ejects smaller secondary droplets during the jetting process. These satellite droplets lead to reduced print resolution, material waste, and surface defects in the final product. Despite extensive research, complete elimination of satellite formation remains elusive, particularly at higher production speeds.

Line uniformity presents another substantial challenge, as maintaining consistent droplet placement and size across printing lines directly affects product quality. Environmental factors such as temperature fluctuations, humidity variations, and air currents can disrupt the trajectory of droplets, leading to positioning errors and inconsistent material deposition. These environmental sensitivities become increasingly problematic as manufacturing scales up and operates in less controlled environments.

Material viscosity management represents a significant technical hurdle, as viscosity must be precisely controlled to ensure proper droplet formation. Too high viscosity prevents proper droplet ejection, while too low viscosity leads to excessive satellite formation. The relationship between material properties and jetting parameters remains complex, with many materials requiring specific customization of printing parameters that cannot be easily transferred between different material systems.

Nozzle design limitations further complicate drop formation dynamics. Current nozzle technologies struggle to maintain consistent performance over extended production runs due to material buildup, clogging, and wear. The trade-off between nozzle diameter (affecting resolution) and production speed creates a technical bottleneck that limits industrial adoption of high-precision material jetting processes.

Multi-material jetting introduces additional complexities, as different materials exhibit varying rheological properties that affect droplet formation. Achieving uniform drop characteristics across different materials simultaneously is particularly challenging, yet essential for advanced applications requiring functional gradients or complex material combinations.

Real-time monitoring and feedback systems for drop formation remain underdeveloped, limiting the ability to detect and correct formation issues during production. Current visual inspection systems lack the speed and resolution to capture the microsecond-level dynamics of droplet formation, resulting in quality control challenges that increase rejection rates and production costs.

Cross-disciplinary integration of fluid dynamics modeling with practical manufacturing constraints represents perhaps the most fundamental challenge. Theoretical models often fail to account for real-world manufacturing variables, creating a gap between simulation predictions and actual production outcomes that hampers systematic improvement of drop formation technologies.

Line uniformity presents another substantial challenge, as maintaining consistent droplet placement and size across printing lines directly affects product quality. Environmental factors such as temperature fluctuations, humidity variations, and air currents can disrupt the trajectory of droplets, leading to positioning errors and inconsistent material deposition. These environmental sensitivities become increasingly problematic as manufacturing scales up and operates in less controlled environments.

Material viscosity management represents a significant technical hurdle, as viscosity must be precisely controlled to ensure proper droplet formation. Too high viscosity prevents proper droplet ejection, while too low viscosity leads to excessive satellite formation. The relationship between material properties and jetting parameters remains complex, with many materials requiring specific customization of printing parameters that cannot be easily transferred between different material systems.

Nozzle design limitations further complicate drop formation dynamics. Current nozzle technologies struggle to maintain consistent performance over extended production runs due to material buildup, clogging, and wear. The trade-off between nozzle diameter (affecting resolution) and production speed creates a technical bottleneck that limits industrial adoption of high-precision material jetting processes.

Multi-material jetting introduces additional complexities, as different materials exhibit varying rheological properties that affect droplet formation. Achieving uniform drop characteristics across different materials simultaneously is particularly challenging, yet essential for advanced applications requiring functional gradients or complex material combinations.

Real-time monitoring and feedback systems for drop formation remain underdeveloped, limiting the ability to detect and correct formation issues during production. Current visual inspection systems lack the speed and resolution to capture the microsecond-level dynamics of droplet formation, resulting in quality control challenges that increase rejection rates and production costs.

Cross-disciplinary integration of fluid dynamics modeling with practical manufacturing constraints represents perhaps the most fundamental challenge. Theoretical models often fail to account for real-world manufacturing variables, creating a gap between simulation predictions and actual production outcomes that hampers systematic improvement of drop formation technologies.

Current Solutions for Satellite Droplet Suppression

01 Waveform and pulse modulation techniques for satellite suppression

Various waveform and pulse modulation techniques can be employed to suppress satellite droplets in material jetting processes. By carefully controlling the voltage waveform applied to piezoelectric actuators, the formation of unwanted satellite droplets can be minimized. Advanced algorithms adjust pulse timing, amplitude, and shape to optimize droplet formation and breakoff, resulting in cleaner ejection and improved line uniformity. These techniques often involve multi-stage pulses with specific rise and fall times tailored to the fluid properties.- Waveform optimization for satellite suppression: Optimizing the driving waveform for material jetting printheads can significantly reduce satellite droplet formation. By carefully controlling the voltage profile, pulse timing, and frequency parameters, the primary droplet can be ejected cleanly while minimizing or eliminating smaller satellite droplets. Advanced waveform designs may include multi-pulse sequences with precisely timed expansion and contraction phases to ensure clean droplet break-off and improved line uniformity.

- Fluid property modification for improved jetting: Adjusting the rheological properties of jetting materials can significantly improve droplet formation and reduce satellites. By controlling viscosity, surface tension, and viscoelastic properties through additives or temperature management, the fluid behavior during droplet formation can be optimized. Materials engineered with specific polymer concentrations or surfactants can maintain the desired jetting characteristics while promoting clean droplet break-off, resulting in more uniform printed lines with minimal satellite formation.

- Nozzle design and surface treatment: The geometry and surface properties of the nozzle significantly impact droplet formation and satellite suppression. Optimized nozzle designs with specific taper angles, exit diameters, and surface treatments can control the fluid flow dynamics during ejection. Hydrophobic or hydrophilic coatings applied to nozzle surfaces can prevent wetting issues that lead to directional errors and satellite formation. Advanced manufacturing techniques enable precise nozzle geometries that promote clean droplet break-off and consistent line formation.

- Real-time monitoring and feedback systems: Implementing vision systems and sensors for real-time droplet formation monitoring allows for immediate adjustments to printing parameters. These systems can detect satellite formation or line uniformity issues during the printing process and automatically adjust jetting parameters to compensate. Machine learning algorithms can analyze droplet formation patterns and optimize printing parameters dynamically, ensuring consistent quality throughout the printing process even as conditions change.

- Environmental control and substrate interaction management: Controlling the printing environment and managing substrate interactions are crucial for satellite suppression and line uniformity. Temperature and humidity control systems can maintain optimal conditions for droplet formation and landing. Substrate pre-treatments or heating elements can be employed to control the spreading and absorption behavior of droplets upon impact. By managing the wetting characteristics of the substrate and controlling evaporation rates, printed lines maintain uniform width and consistent edge definition without satellite artifacts.

02 Fluid composition optimization for improved jetting performance

The composition of jetting materials can be modified to improve satellite suppression and line uniformity. By adjusting viscosity, surface tension, and particle size distribution, the fluid's jetting behavior can be optimized. Additives such as surfactants and polymers can be incorporated to control droplet formation and spreading characteristics. Some formulations include rheology modifiers that help maintain consistent flow properties during jetting, reducing the likelihood of satellite formation and ensuring more uniform printed lines.Expand Specific Solutions03 Nozzle design and printhead architecture for satellite control

Specialized nozzle designs and printhead architectures can significantly reduce satellite droplet formation. Features such as optimized nozzle geometry, surface treatments for controlled wettability, and integrated filters help achieve clean droplet ejection. Some designs incorporate flow restrictors or pressure-balancing chambers to stabilize the fluid meniscus. Advanced printhead architectures may include multiple nozzle arrays with coordinated firing sequences to compensate for potential irregularities and ensure uniform line deposition.Expand Specific Solutions04 Real-time monitoring and feedback control systems

Implementing real-time monitoring and feedback control systems can dynamically adjust jetting parameters to suppress satellites and maintain line uniformity. These systems use optical sensors, cameras, or other detection methods to observe droplet formation and printed line quality. When deviations are detected, the system automatically adjusts parameters such as firing voltage, temperature, or pressure to correct issues before they affect print quality. Machine learning algorithms can be employed to continuously optimize the printing process based on observed outcomes.Expand Specific Solutions05 Environmental and substrate conditioning techniques

Controlling environmental conditions and substrate properties can significantly improve jetting performance and line uniformity. Techniques include maintaining precise temperature and humidity levels in the printing environment, substrate pre-treatment to optimize surface energy, and controlled drying or curing processes. Some systems employ localized heating or cooling elements to adjust fluid viscosity at the nozzle. Electrostatic field manipulation can also be used to guide droplets more precisely to their intended positions, reducing satellite formation and improving line definition.Expand Specific Solutions

Leading Companies in Material Jetting Industry

Material Jetting Drop Formation Dynamics is currently in a growth phase, with the market expanding due to increasing applications in additive manufacturing and precision printing. The global market is projected to reach significant scale as industries adopt this technology for high-precision manufacturing. Technologically, the field is advancing rapidly but still maturing, with key players demonstrating varying levels of expertise. Seiko Epson, Canon, and FUJIFILM lead in satellite droplet suppression technologies, while Ricoh and Xerox focus on line uniformity improvements. Industrial players like ASML and Boeing are exploring specialized applications, with research institutions such as Industrial Technology Research Institute and universities contributing fundamental research to overcome current technical limitations in drop formation control.

Seiko Epson Corp.

Technical Solution: Epson has developed Multi-Layer Actuator (MLA) technology for precise drop formation control in material jetting. Their PrecisionCore printhead technology utilizes piezoelectric elements that can be precisely controlled to adjust drop size, velocity, and trajectory. The system employs advanced waveform modulation techniques that actively suppress satellite droplets by creating a negative pressure pulse immediately following the main ejection pulse. This creates a controlled retraction effect that prevents secondary droplet formation. For line uniformity, Epson implements real-time feedback systems with high-speed cameras that monitor droplet formation and adjust firing parameters dynamically. Their Variable-Sized Droplet Technology (VSDT) allows for multiple drop sizes from a single nozzle, enhancing resolution while maintaining uniform line formation across different materials with varying viscosities and surface tensions.

Strengths: Superior satellite droplet suppression through advanced waveform control; exceptional line uniformity through real-time monitoring and adjustment; versatility across different material viscosities. Weaknesses: Higher implementation costs compared to simpler systems; requires sophisticated electronic control systems; more complex calibration procedures for new materials.

Canon, Inc.

Technical Solution: Canon has pioneered FINE (Full-photolithography Inkjet Nozzle Engineering) technology specifically addressing satellite droplet formation in material jetting applications. Their approach utilizes precisely engineered nozzle geometry with microscopic tolerances achieved through photolithographic manufacturing processes. This enables controlled droplet formation with minimal satellite generation. Canon's system incorporates multi-pulse jetting techniques where a primary pulse is followed by carefully timed secondary pulses that manipulate the fluid column to prevent satellite formation. For line uniformity, Canon employs Dynamic Droplet Modulation (DDM) that adjusts firing frequency and droplet volume based on printing speed and substrate characteristics. Their proprietary algorithms analyze the substrate in real-time and adjust jetting parameters to maintain consistent line width and density regardless of printing direction or speed variations. Canon has also developed specialized surfactant formulations that modify fluid surface tension during flight to optimize droplet landing characteristics.

Strengths: Exceptional nozzle precision through photolithographic manufacturing; sophisticated multi-pulse jetting for satellite control; advanced substrate-adaptive algorithms for line consistency. Weaknesses: Higher manufacturing costs for precision nozzles; system complexity requires specialized maintenance; somewhat limited material compatibility compared to competitors.

Key Patents in Line Uniformity Control

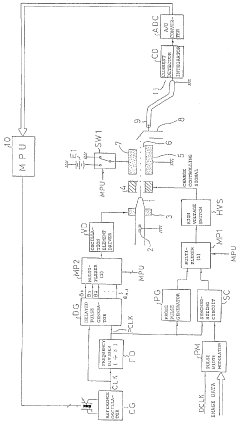

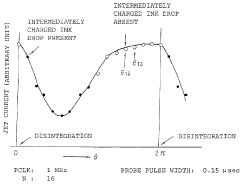

Method and apparatus for determining optimum ink drop formation-frequency in an ink jet printer

PatentInactiveUS5940101A

Innovation

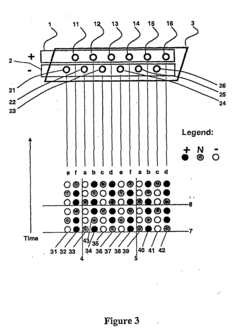

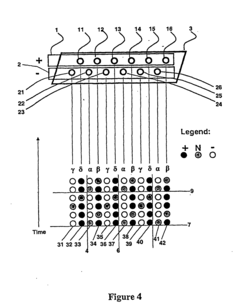

- A continuous jet type ink jet recording apparatus with automatic optimization of excitation frequency, utilizing jet formation, charging, deflection, and detection mechanisms to determine the optimal frequency by analyzing jet current waveforms and shifting phases, eliminating the need for manual testing and ensuring accurate and efficient operation.

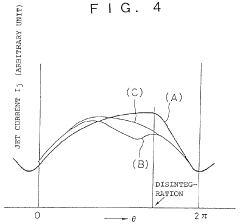

Anharmonic stimulation of inkjet drop formation

PatentInactiveEP1720709B1

Innovation

- The use of a composite cyclical perturbing signal with frequencies not harmonically related, but related by small integers, controls satellite drop formation by producing a repeating pattern of drops with different satellite behaviors, allowing for optimal droplet selection and alignment with guard drop schemes to minimize electrostatic crosstalk and enhance printing accuracy.

Material Properties Impact on Jetting Performance

Material properties play a crucial role in determining the performance and outcomes of material jetting processes. The rheological characteristics of jetted materials directly influence drop formation dynamics, satellite droplet behavior, and ultimately line uniformity in printed structures. Viscosity emerges as one of the most significant properties affecting jetting performance, with optimal ranges typically between 10-40 mPa·s. Materials with viscosities outside this range often exhibit either excessive satellite formation (low viscosity) or insufficient droplet detachment (high viscosity).

Surface tension represents another critical parameter, typically ranging from 20-50 mN/m for effective jetting. This property governs the droplet shape during flight and upon impact with the substrate. Materials with higher surface tension tend to maintain spherical droplet shapes longer during flight, which can be advantageous for precision but may impede spreading behavior upon impact. Conversely, lower surface tension materials spread more readily but may generate unwanted satellites.

The viscoelastic properties of jetting materials significantly impact filament breakup dynamics. Materials with higher elasticity exhibit longer filament lifetimes before breakup, often resulting in satellite formation. Recent research has demonstrated that carefully engineered viscoelastic properties can actually suppress satellite formation through controlled filament retraction mechanisms.

Density affects droplet momentum and impact dynamics, while thermal properties determine how quickly materials solidify after deposition. For temperature-sensitive applications, materials with precisely controlled glass transition or melting temperatures are essential to achieve desired line uniformity and layer adhesion characteristics.

Particle loading in composite jetting materials introduces additional complexity, as particles can disrupt normal fluid dynamics. Research indicates that particle size should generally remain below 1/50 of the nozzle diameter to prevent clogging and ensure consistent jetting. Furthermore, particle distribution homogeneity directly correlates with print quality consistency.

Advanced material formulations now incorporate additives specifically designed to modify rheological behavior for satellite suppression. These include polymeric modifiers that increase extensional viscosity without significantly affecting shear viscosity, thereby improving filament breakup characteristics while maintaining good jetting performance. Such tailored material properties represent a promising approach to achieving the high-precision deposition required for next-generation printed electronics and biomedical applications.

Surface tension represents another critical parameter, typically ranging from 20-50 mN/m for effective jetting. This property governs the droplet shape during flight and upon impact with the substrate. Materials with higher surface tension tend to maintain spherical droplet shapes longer during flight, which can be advantageous for precision but may impede spreading behavior upon impact. Conversely, lower surface tension materials spread more readily but may generate unwanted satellites.

The viscoelastic properties of jetting materials significantly impact filament breakup dynamics. Materials with higher elasticity exhibit longer filament lifetimes before breakup, often resulting in satellite formation. Recent research has demonstrated that carefully engineered viscoelastic properties can actually suppress satellite formation through controlled filament retraction mechanisms.

Density affects droplet momentum and impact dynamics, while thermal properties determine how quickly materials solidify after deposition. For temperature-sensitive applications, materials with precisely controlled glass transition or melting temperatures are essential to achieve desired line uniformity and layer adhesion characteristics.

Particle loading in composite jetting materials introduces additional complexity, as particles can disrupt normal fluid dynamics. Research indicates that particle size should generally remain below 1/50 of the nozzle diameter to prevent clogging and ensure consistent jetting. Furthermore, particle distribution homogeneity directly correlates with print quality consistency.

Advanced material formulations now incorporate additives specifically designed to modify rheological behavior for satellite suppression. These include polymeric modifiers that increase extensional viscosity without significantly affecting shear viscosity, thereby improving filament breakup characteristics while maintaining good jetting performance. Such tailored material properties represent a promising approach to achieving the high-precision deposition required for next-generation printed electronics and biomedical applications.

Simulation and Modeling Approaches for Optimization

Simulation and modeling approaches have become indispensable tools for optimizing material jetting processes, particularly in addressing the complex challenges of satellite droplet suppression and line uniformity. Computational fluid dynamics (CFD) simulations offer detailed insights into the fluid behavior during droplet formation, enabling researchers to predict and control satellite formation without extensive physical experimentation.

Volume of Fluid (VOF) methods have emerged as particularly effective for modeling the free surface dynamics in material jetting. These simulations capture the interface between the ejected fluid and surrounding air, providing critical information about surface tension effects and breakup mechanisms that lead to satellite formation. Recent advancements in VOF algorithms have improved computational efficiency while maintaining high accuracy in predicting droplet behavior across various material properties.

Lattice Boltzmann Methods (LBM) represent another powerful approach, especially suitable for modeling multiphase flows with complex rheological properties. LBM simulations have demonstrated exceptional capability in predicting the behavior of non-Newtonian fluids commonly used in advanced manufacturing applications, offering insights into how viscoelastic properties influence satellite formation and subsequent line deposition characteristics.

Machine learning integration with traditional physics-based models has revolutionized optimization approaches. Neural networks trained on simulation data can rapidly predict droplet formation outcomes for new parameter combinations, reducing the computational burden of full-scale simulations. This hybrid approach enables real-time process optimization and adaptive control strategies previously unattainable with conventional modeling techniques.

Multi-scale modeling frameworks have proven particularly valuable, connecting molecular-level interactions to macroscopic printing outcomes. These models bridge the gap between material formulation and final print quality by incorporating molecular dynamics simulations to inform continuum-level models of droplet formation and deposition behavior.

Validation methodologies have evolved to ensure simulation accuracy, with high-speed imaging techniques providing experimental benchmarks against which models can be calibrated. The integration of in-situ monitoring data with simulation feedback loops has enabled adaptive modeling approaches that continuously refine predictions based on real-world observations.

Future directions in simulation approaches include the development of digital twins for material jetting systems, where real-time simulation models run parallel to physical processes, enabling predictive maintenance and process optimization. Additionally, quantum computing applications show promise for handling the extreme computational demands of high-fidelity multiphysics simulations necessary for complete process optimization.

Volume of Fluid (VOF) methods have emerged as particularly effective for modeling the free surface dynamics in material jetting. These simulations capture the interface between the ejected fluid and surrounding air, providing critical information about surface tension effects and breakup mechanisms that lead to satellite formation. Recent advancements in VOF algorithms have improved computational efficiency while maintaining high accuracy in predicting droplet behavior across various material properties.

Lattice Boltzmann Methods (LBM) represent another powerful approach, especially suitable for modeling multiphase flows with complex rheological properties. LBM simulations have demonstrated exceptional capability in predicting the behavior of non-Newtonian fluids commonly used in advanced manufacturing applications, offering insights into how viscoelastic properties influence satellite formation and subsequent line deposition characteristics.

Machine learning integration with traditional physics-based models has revolutionized optimization approaches. Neural networks trained on simulation data can rapidly predict droplet formation outcomes for new parameter combinations, reducing the computational burden of full-scale simulations. This hybrid approach enables real-time process optimization and adaptive control strategies previously unattainable with conventional modeling techniques.

Multi-scale modeling frameworks have proven particularly valuable, connecting molecular-level interactions to macroscopic printing outcomes. These models bridge the gap between material formulation and final print quality by incorporating molecular dynamics simulations to inform continuum-level models of droplet formation and deposition behavior.

Validation methodologies have evolved to ensure simulation accuracy, with high-speed imaging techniques providing experimental benchmarks against which models can be calibrated. The integration of in-situ monitoring data with simulation feedback loops has enabled adaptive modeling approaches that continuously refine predictions based on real-world observations.

Future directions in simulation approaches include the development of digital twins for material jetting systems, where real-time simulation models run parallel to physical processes, enabling predictive maintenance and process optimization. Additionally, quantum computing applications show promise for handling the extreme computational demands of high-fidelity multiphysics simulations necessary for complete process optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!