Material Jetting High-Resolution Patterns: Pixelation, Anti-Aliasing And Edge Quality

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting technology has evolved significantly since its inception in the late 1990s as a promising additive manufacturing technique. Initially developed as a derivative of inkjet printing technology, Material Jetting has transformed from simple prototype visualization to a sophisticated manufacturing process capable of multi-material, full-color production with micro-scale precision. The technology fundamentally operates by selectively depositing droplets of build materials onto a substrate, which are then solidified through various curing mechanisms, predominantly UV light polymerization.

The evolution trajectory shows a clear trend toward higher resolution capabilities, with early systems offering 300-600 DPI resolution, while contemporary advanced systems can achieve up to 1600 DPI. This progression has been driven by innovations in printhead technology, material science advancements, and sophisticated control algorithms that optimize droplet formation and placement.

Despite these advancements, achieving high-resolution patterns remains challenging due to three interconnected issues: pixelation, anti-aliasing limitations, and edge quality control. Pixelation occurs when the discrete nature of material deposition becomes visible in the final part, particularly at curved or angled geometries. This phenomenon is exacerbated at lower resolutions and becomes particularly problematic for applications requiring smooth surfaces or precise feature definition.

Anti-aliasing techniques, borrowed from digital imaging, have been implemented to mitigate pixelation effects by creating transitional zones between features. However, current implementations in Material Jetting are limited by the physical constraints of droplet size, placement accuracy, and material interaction dynamics. These limitations directly impact edge quality, which encompasses sharpness, consistency, and dimensional accuracy of printed features.

The primary technical objective in this domain is to develop advanced Material Jetting systems capable of producing parts with significantly improved resolution while maintaining production speed and material compatibility. Specifically, the goals include: achieving sub-10 micron feature resolution consistently across various geometries; implementing sophisticated anti-aliasing algorithms that account for material behavior during deposition and curing; and developing edge enhancement techniques that can produce sharp, well-defined boundaries without sacrificing dimensional accuracy.

Secondary objectives include reducing the computational complexity of high-resolution processing to maintain reasonable build preparation times, and developing standardized metrics for quantifying and comparing edge quality and effective resolution across different Material Jetting platforms and materials. These advancements would position Material Jetting as the premier technology for applications requiring both high precision and material versatility.

The evolution trajectory shows a clear trend toward higher resolution capabilities, with early systems offering 300-600 DPI resolution, while contemporary advanced systems can achieve up to 1600 DPI. This progression has been driven by innovations in printhead technology, material science advancements, and sophisticated control algorithms that optimize droplet formation and placement.

Despite these advancements, achieving high-resolution patterns remains challenging due to three interconnected issues: pixelation, anti-aliasing limitations, and edge quality control. Pixelation occurs when the discrete nature of material deposition becomes visible in the final part, particularly at curved or angled geometries. This phenomenon is exacerbated at lower resolutions and becomes particularly problematic for applications requiring smooth surfaces or precise feature definition.

Anti-aliasing techniques, borrowed from digital imaging, have been implemented to mitigate pixelation effects by creating transitional zones between features. However, current implementations in Material Jetting are limited by the physical constraints of droplet size, placement accuracy, and material interaction dynamics. These limitations directly impact edge quality, which encompasses sharpness, consistency, and dimensional accuracy of printed features.

The primary technical objective in this domain is to develop advanced Material Jetting systems capable of producing parts with significantly improved resolution while maintaining production speed and material compatibility. Specifically, the goals include: achieving sub-10 micron feature resolution consistently across various geometries; implementing sophisticated anti-aliasing algorithms that account for material behavior during deposition and curing; and developing edge enhancement techniques that can produce sharp, well-defined boundaries without sacrificing dimensional accuracy.

Secondary objectives include reducing the computational complexity of high-resolution processing to maintain reasonable build preparation times, and developing standardized metrics for quantifying and comparing edge quality and effective resolution across different Material Jetting platforms and materials. These advancements would position Material Jetting as the premier technology for applications requiring both high precision and material versatility.

Market Demand for High-Resolution Material Jetting

The material jetting market is experiencing significant growth driven by increasing demand for high-resolution applications across multiple industries. According to recent market analyses, the global material jetting market is projected to grow at a compound annual growth rate of 19.1% through 2028, with high-resolution applications representing the fastest-growing segment.

Manufacturing sectors, particularly electronics and semiconductor industries, are driving substantial demand for high-resolution material jetting technologies. These industries require increasingly precise deposition capabilities for creating microelectronic components, circuit boards, and semiconductor packaging. The miniaturization trend in electronics continues to push resolution requirements below 10 microns, creating strong market pull for advanced material jetting solutions.

The medical and bioprinting sectors represent another significant market driver. High-resolution material jetting enables the production of precise medical devices, customized implants, and tissue engineering constructs. The market for bioprinting alone is expected to reach $4.2 billion by 2028, with material jetting technologies capturing a substantial share due to their superior resolution capabilities.

Consumer product manufacturers are increasingly adopting high-resolution material jetting for prototyping and production applications. The ability to create detailed textures, smooth surfaces, and precise color gradients has made material jetting particularly valuable for consumer electronics, luxury goods, and customized products. Market research indicates that 68% of consumer product companies plan to increase their investment in high-resolution additive manufacturing technologies over the next three years.

Edge quality and surface finish have emerged as critical differentiators in the material jetting market. End-users consistently rank edge definition and surface smoothness among their top three selection criteria when evaluating material jetting systems. This has intensified competition among equipment manufacturers to develop advanced anti-aliasing and edge enhancement technologies.

The automotive and aerospace industries are rapidly expanding their use of material jetting for both prototyping and end-use parts production. These sectors value the ability to create complex geometries with high-resolution details and excellent surface finish. The demand for lightweight components with intricate internal structures has further accelerated adoption of advanced material jetting technologies in these industries.

Geographically, North America and Europe currently represent the largest markets for high-resolution material jetting, accounting for approximately 65% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and significant investments in advanced manufacturing technologies across China, Japan, South Korea, and Singapore.

Manufacturing sectors, particularly electronics and semiconductor industries, are driving substantial demand for high-resolution material jetting technologies. These industries require increasingly precise deposition capabilities for creating microelectronic components, circuit boards, and semiconductor packaging. The miniaturization trend in electronics continues to push resolution requirements below 10 microns, creating strong market pull for advanced material jetting solutions.

The medical and bioprinting sectors represent another significant market driver. High-resolution material jetting enables the production of precise medical devices, customized implants, and tissue engineering constructs. The market for bioprinting alone is expected to reach $4.2 billion by 2028, with material jetting technologies capturing a substantial share due to their superior resolution capabilities.

Consumer product manufacturers are increasingly adopting high-resolution material jetting for prototyping and production applications. The ability to create detailed textures, smooth surfaces, and precise color gradients has made material jetting particularly valuable for consumer electronics, luxury goods, and customized products. Market research indicates that 68% of consumer product companies plan to increase their investment in high-resolution additive manufacturing technologies over the next three years.

Edge quality and surface finish have emerged as critical differentiators in the material jetting market. End-users consistently rank edge definition and surface smoothness among their top three selection criteria when evaluating material jetting systems. This has intensified competition among equipment manufacturers to develop advanced anti-aliasing and edge enhancement technologies.

The automotive and aerospace industries are rapidly expanding their use of material jetting for both prototyping and end-use parts production. These sectors value the ability to create complex geometries with high-resolution details and excellent surface finish. The demand for lightweight components with intricate internal structures has further accelerated adoption of advanced material jetting technologies in these industries.

Geographically, North America and Europe currently represent the largest markets for high-resolution material jetting, accounting for approximately 65% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and significant investments in advanced manufacturing technologies across China, Japan, South Korea, and Singapore.

Technical Challenges in Pattern Resolution and Edge Quality

Material jetting technology faces significant challenges in achieving high-resolution patterns, particularly concerning pixelation, anti-aliasing, and edge quality. The fundamental limitation stems from the physical properties of jetted materials and the mechanical constraints of print heads. Current systems typically operate with droplet sizes ranging from 10-50 microns, which inherently limits the achievable resolution and introduces pixelation effects at pattern edges.

Edge definition remains a critical challenge as material droplets tend to spread upon impact with the substrate, creating what is known as the "coffee ring effect." This phenomenon occurs when the solvent in the jetted material evaporates faster at the edges than in the center, causing solute particles to accumulate at the periphery. The result is uneven material distribution that compromises edge sharpness and dimensional accuracy.

Surface tension interactions between adjacent droplets further complicate high-resolution patterning. When droplets are positioned too closely together, they may coalesce before solidification, distorting intended geometries. Conversely, insufficient droplet overlap creates gaps and inconsistencies in the printed pattern. This delicate balance between droplet spacing and overlap directly impacts edge quality and feature definition.

Anti-aliasing techniques, while common in digital imaging, present unique challenges in material jetting. Traditional digital anti-aliasing algorithms must be adapted to account for the physical behavior of jetted materials. The translation from digital design to physical output is complicated by material-specific properties such as viscosity, surface tension, and curing characteristics, which can vary significantly between formulations and environmental conditions.

Temperature gradients during printing introduce additional complexity, as they affect material flow properties and solidification rates. Even minor fluctuations in ambient or substrate temperature can lead to inconsistent droplet formation and placement, resulting in irregular edges and compromised pattern fidelity. This is particularly problematic for multi-material printing where different materials may have varying thermal responses.

Resolution limitations are further exacerbated by nozzle clogging and material buildup during extended printing operations. Particulates in the jetted material or partially cured residue can obstruct nozzles, leading to droplet trajectory deviations or complete nozzle failure. These issues manifest as missing pixels or misaligned droplets that significantly degrade pattern quality and edge definition.

The digital-to-physical conversion process introduces computational challenges as well. Slicing algorithms must accurately translate vector-based designs into discrete droplet placement instructions while preserving intended geometries. Current algorithms struggle to maintain feature fidelity when pattern dimensions approach the resolution limits of the printing system, resulting in compromised edge quality and loss of fine details.

Edge definition remains a critical challenge as material droplets tend to spread upon impact with the substrate, creating what is known as the "coffee ring effect." This phenomenon occurs when the solvent in the jetted material evaporates faster at the edges than in the center, causing solute particles to accumulate at the periphery. The result is uneven material distribution that compromises edge sharpness and dimensional accuracy.

Surface tension interactions between adjacent droplets further complicate high-resolution patterning. When droplets are positioned too closely together, they may coalesce before solidification, distorting intended geometries. Conversely, insufficient droplet overlap creates gaps and inconsistencies in the printed pattern. This delicate balance between droplet spacing and overlap directly impacts edge quality and feature definition.

Anti-aliasing techniques, while common in digital imaging, present unique challenges in material jetting. Traditional digital anti-aliasing algorithms must be adapted to account for the physical behavior of jetted materials. The translation from digital design to physical output is complicated by material-specific properties such as viscosity, surface tension, and curing characteristics, which can vary significantly between formulations and environmental conditions.

Temperature gradients during printing introduce additional complexity, as they affect material flow properties and solidification rates. Even minor fluctuations in ambient or substrate temperature can lead to inconsistent droplet formation and placement, resulting in irregular edges and compromised pattern fidelity. This is particularly problematic for multi-material printing where different materials may have varying thermal responses.

Resolution limitations are further exacerbated by nozzle clogging and material buildup during extended printing operations. Particulates in the jetted material or partially cured residue can obstruct nozzles, leading to droplet trajectory deviations or complete nozzle failure. These issues manifest as missing pixels or misaligned droplets that significantly degrade pattern quality and edge definition.

The digital-to-physical conversion process introduces computational challenges as well. Slicing algorithms must accurately translate vector-based designs into discrete droplet placement instructions while preserving intended geometries. Current algorithms struggle to maintain feature fidelity when pattern dimensions approach the resolution limits of the printing system, resulting in compromised edge quality and loss of fine details.

Current Anti-Aliasing and Edge Enhancement Solutions

01 Anti-aliasing techniques for improved edge quality

Anti-aliasing techniques are employed to reduce the jagged appearance of edges in material jetting processes. These methods involve blending pixel colors at boundaries to create smoother transitions between different areas. Advanced algorithms can detect edges and apply appropriate levels of anti-aliasing to improve visual quality while maintaining detail. These techniques are particularly important in high-resolution printing applications where edge quality directly impacts the perceived quality of the final product.- Anti-aliasing techniques for improved edge quality: Anti-aliasing techniques are employed to reduce the jagged appearance of edges in material jetting processes. These methods involve blending pixel colors at boundaries to create smoother transitions between different areas. Advanced algorithms can analyze edge patterns and apply appropriate levels of anti-aliasing to maintain detail while reducing pixelation artifacts. These techniques significantly improve the visual quality of printed objects by minimizing the stair-stepping effect that occurs at diagonal or curved edges.

- Edge detection and enhancement algorithms: Edge detection algorithms identify boundaries between different regions in digital models before material jetting. These algorithms analyze pixel intensity gradients to locate edges precisely. Once detected, enhancement techniques can be applied to improve edge definition and quality. This approach allows for targeted processing of edge areas while preserving interior details, resulting in printed objects with sharper, more defined boundaries and improved overall appearance.

- Resolution optimization for material jetting: Resolution optimization involves adjusting the density and placement of jetted material droplets to achieve the best possible edge quality. This includes techniques for dynamic resolution adjustment based on feature complexity, where more droplets are used in areas with fine details or critical edges. Adaptive resolution systems can analyze model geometry to determine optimal jetting parameters for different regions, balancing quality requirements with processing efficiency.

- Pixel interpolation and sub-pixel rendering: Pixel interpolation techniques calculate intermediate values between existing pixels to increase effective resolution without changing hardware capabilities. Sub-pixel rendering further enhances this by manipulating individual color components at a sub-pixel level. These approaches allow material jetting systems to achieve smoother gradients and more precise edge placement than would be possible with standard pixel-based processing. The result is printed objects with significantly reduced visible pixelation and improved surface quality.

- Multi-pass jetting and error diffusion: Multi-pass jetting techniques involve depositing material in multiple layers or passes to average out irregularities and improve edge definition. This is often combined with error diffusion algorithms that distribute quantization errors across neighboring pixels to reduce visible artifacts. By spreading unavoidable errors across larger areas rather than concentrating them at edges, these methods significantly reduce the perception of pixelation. This approach is particularly effective for creating smooth transitions and gradients in material jetting applications.

02 Pixel-based edge enhancement methods

Various pixel-based methods are used to enhance edge quality in material jetting applications. These include adaptive pixel mapping, edge detection algorithms, and pixel interpolation techniques that specifically target boundary regions. By analyzing the pixel data around edges and applying specialized processing, these methods can significantly reduce pixelation artifacts while preserving the intended design features. Some approaches dynamically adjust pixel density at edges to achieve optimal visual results.Expand Specific Solutions03 Resolution optimization for material jetting

Resolution optimization techniques focus on maximizing the effective resolution of material jetting processes to minimize visible pixelation. These approaches include dynamic resolution adjustment based on feature complexity, multi-resolution rendering systems, and adaptive scaling algorithms. By allocating higher resolution to areas with fine details or critical edges, these methods efficiently use processing resources while maintaining high quality output. Some techniques also incorporate hardware-specific optimizations to leverage the capabilities of particular printing systems.Expand Specific Solutions04 Material distribution control for edge definition

Controlling the precise distribution of jetted materials at edge boundaries can significantly improve edge quality and reduce pixelation effects. These techniques include gradient-based material deposition, variable droplet sizing, and controlled material spreading methods. By carefully managing how materials interact at boundaries, these approaches can create smoother transitions and more defined edges. Some methods also incorporate feedback systems that analyze previous layers to optimize subsequent material deposition patterns.Expand Specific Solutions05 Image processing algorithms for pixelation reduction

Specialized image processing algorithms are applied to reduce pixelation artifacts in material jetting processes. These include pre-processing techniques such as edge-aware filtering, adaptive sharpening, and contour enhancement. Post-processing methods may involve digital smoothing, artifact removal, and pattern recognition to identify and correct pixelation issues. These algorithms often work in conjunction with material-specific parameters to optimize the final output quality based on the physical properties of the jetted materials.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Material Jetting High-Resolution Patterning technology is currently in a growth phase, with the market expanding due to increasing demand for precision manufacturing across electronics, medical, and aerospace sectors. The global market size is estimated at $2.5-3 billion, with projected annual growth of 15-20%. Technologically, this field shows varying maturity levels among key players. Xerox, Adobe, and 3D Systems lead with advanced anti-aliasing algorithms and edge quality optimization, while companies like Samsung Electronics, Sony, and NVIDIA are making significant strides in pixelation reduction and resolution enhancement. Applied Materials and Intel are focusing on semiconductor applications, developing specialized material jetting solutions for high-precision circuit patterning. Emerging players like Kateeva and Mojo Vision are introducing innovative approaches to overcome traditional resolution limitations.

Xerox Holdings Corp.

Technical Solution: Xerox has developed advanced Material Jetting technology that addresses pixelation and edge quality challenges through their Multi-Pass Jetting (MPJ) system. This proprietary approach utilizes variable droplet sizes (ranging from 6-30 picoliters) and precise droplet placement algorithms to achieve sub-pixel accuracy. Their system employs stochastic screening techniques that dynamically adjust dot patterns based on image content, significantly reducing visible pixelation artifacts. For anti-aliasing, Xerox implements a multi-level grayscale rendering process that creates smooth transitions at edges by intelligently blending multiple smaller droplets rather than single large ones. Their High Definition Image Processing (HDIP) technology pre-processes pattern data to optimize edge definition, applying content-aware sharpening algorithms that enhance perceived resolution without introducing artifacts.

Strengths: Superior edge definition through proprietary variable droplet technology; excellent integration with digital workflow systems; advanced anti-aliasing algorithms that maintain detail integrity. Weaknesses: Higher implementation costs compared to standard systems; requires specialized materials optimized for their specific jetting parameters; system complexity demands higher technical expertise for maintenance.

Seiko Epson Corp.

Technical Solution: Epson's Material Jetting technology employs their PrecisionCore MicroTFP printhead architecture to address high-resolution pattern challenges. Their system achieves exceptional edge quality through ultra-precise 1.5 picoliter droplet control and placement accuracy of ±2.5 microns. For anti-aliasing, Epson utilizes a proprietary Variable-Sized Droplet Technology (VSDT) that dynamically adjusts droplet size based on pattern requirements, creating smoother gradients and transitions. Their Multi-Layer Halftoning algorithm analyzes pattern data across multiple processing layers to optimize dot placement for reduced pixelation. Epson's Look-Ahead Processing technology anticipates pattern transitions and adjusts jetting parameters in real-time to enhance edge definition. The system incorporates advanced waveform control that modifies piezoelectric actuation patterns based on material viscosity and pattern density requirements.

Strengths: Industry-leading droplet placement precision; exceptional material compatibility range; sophisticated real-time processing capabilities for dynamic pattern optimization. Weaknesses: Higher initial investment compared to conventional systems; complex calibration requirements for optimal performance; more sensitive to environmental variations affecting material viscosity.

Key Patents and Research in Pixelation Reduction

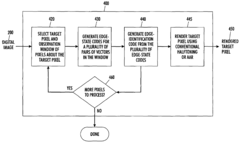

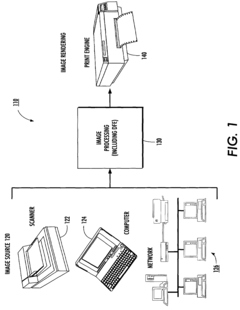

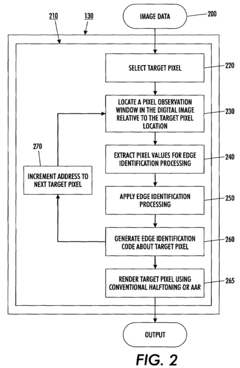

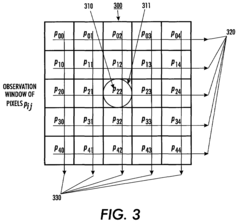

Anti-aliased tagging using look-up table edge pixel identification

PatentInactiveUS7518618B2

Innovation

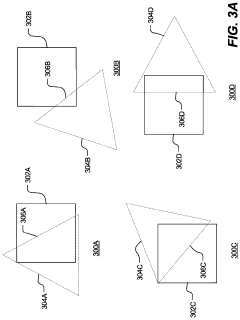

- An image processing method using a look-up table-based approach to identify and render anti-aliased pixels by generating edge-state codes for neighboring pixel vectors within a pixel observation window, allowing for the selection of either anti-aliased rendering or conventional halftoning based on edge identification codes.

Anti-aliasing by encoding primitive edge representations

PatentInactiveUS20230196627A1

Innovation

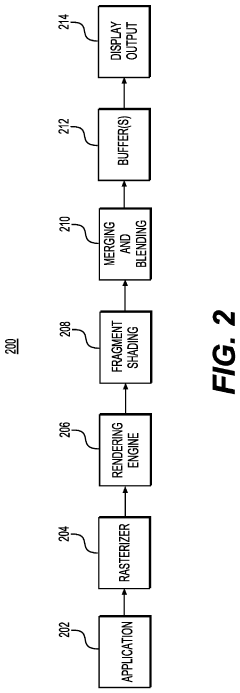

- The technique involves encoding primitive edge representations by generating fragments that cover pixels, including orientation and pixel coverage information, to determine alpha values and merge or blend colors, thereby reducing processing and memory resources while performing anti-aliasing.

Materials Science Impact on Pattern Quality

The material properties used in material jetting processes significantly influence the quality of printed patterns, particularly in terms of pixelation, anti-aliasing, and edge definition. The rheological characteristics of jetted materials—including viscosity, surface tension, and viscoelasticity—directly affect droplet formation, spreading behavior, and coalescence mechanisms that determine final pattern resolution.

Viscosity plays a crucial role in determining how materials flow through nozzles and spread upon deposition. Materials with optimized viscosity profiles enable more precise droplet formation and controlled spreading, which is essential for achieving sharp edges and minimizing pixelation effects. Research indicates that materials with shear-thinning properties often perform better in high-resolution applications, as they can flow easily during jetting but quickly stabilize after deposition.

Surface tension characteristics of jetted materials govern the wetting behavior and interaction with substrate surfaces. Higher surface tension materials tend to maintain more defined droplet shapes, potentially reducing bleeding between adjacent pixels but sometimes creating challenges for smooth transitions in anti-aliased regions. Conversely, materials with lower surface tension values may facilitate better blending for anti-aliasing but risk excessive spreading that compromises edge definition.

The drying and curing kinetics of materials also substantially impact pattern quality. Rapid-curing materials can "freeze" droplets in place before excessive spreading occurs, preserving intended geometries and edge sharpness. However, if curing occurs too quickly, it may prevent proper droplet coalescence needed for smooth anti-aliased transitions. Materials science innovations in UV-curable resins and hybrid formulations have enabled more precise control over these competing requirements.

Particle size and distribution in pigmented materials directly affect the minimum feature size achievable. Nano-pigmented formulations have demonstrated superior performance in high-resolution applications by minimizing light scattering and enabling more precise color transitions at edges. Recent advances in material science have produced specialized formulations with optimized particle stabilization mechanisms that prevent agglomeration during the jetting process.

The substrate-material interaction represents another critical factor influencing pattern quality. Materials designed with specific functional groups can promote controlled adhesion to various substrates, enabling more predictable spreading behaviors and sharper pattern edges. Surface energy matching between materials and substrates has emerged as a key design parameter for achieving optimal pattern resolution and edge quality in advanced manufacturing applications.

Viscosity plays a crucial role in determining how materials flow through nozzles and spread upon deposition. Materials with optimized viscosity profiles enable more precise droplet formation and controlled spreading, which is essential for achieving sharp edges and minimizing pixelation effects. Research indicates that materials with shear-thinning properties often perform better in high-resolution applications, as they can flow easily during jetting but quickly stabilize after deposition.

Surface tension characteristics of jetted materials govern the wetting behavior and interaction with substrate surfaces. Higher surface tension materials tend to maintain more defined droplet shapes, potentially reducing bleeding between adjacent pixels but sometimes creating challenges for smooth transitions in anti-aliased regions. Conversely, materials with lower surface tension values may facilitate better blending for anti-aliasing but risk excessive spreading that compromises edge definition.

The drying and curing kinetics of materials also substantially impact pattern quality. Rapid-curing materials can "freeze" droplets in place before excessive spreading occurs, preserving intended geometries and edge sharpness. However, if curing occurs too quickly, it may prevent proper droplet coalescence needed for smooth anti-aliased transitions. Materials science innovations in UV-curable resins and hybrid formulations have enabled more precise control over these competing requirements.

Particle size and distribution in pigmented materials directly affect the minimum feature size achievable. Nano-pigmented formulations have demonstrated superior performance in high-resolution applications by minimizing light scattering and enabling more precise color transitions at edges. Recent advances in material science have produced specialized formulations with optimized particle stabilization mechanisms that prevent agglomeration during the jetting process.

The substrate-material interaction represents another critical factor influencing pattern quality. Materials designed with specific functional groups can promote controlled adhesion to various substrates, enabling more predictable spreading behaviors and sharper pattern edges. Surface energy matching between materials and substrates has emerged as a key design parameter for achieving optimal pattern resolution and edge quality in advanced manufacturing applications.

Software Algorithms for Pattern Optimization

Software algorithms play a pivotal role in optimizing material jetting patterns to achieve high-resolution outputs with minimal pixelation, improved anti-aliasing, and enhanced edge quality. Current algorithmic approaches focus on several key areas that directly impact the final printed result.

Pre-processing algorithms have evolved significantly to address the inherent limitations of material jetting systems. These algorithms analyze the input pattern and apply transformations that compensate for known physical behaviors of jetted materials, such as spreading, coalescence, and edge bleeding. Advanced image processing techniques including adaptive thresholding and contour detection help identify critical features that require preservation during the printing process.

Resolution enhancement algorithms employ sophisticated mathematical models to effectively increase the apparent resolution beyond the physical capabilities of the printing system. Subpixel rendering techniques divide each nominal pixel into virtual subpixels, allowing for more precise material placement and smoother transitions at edges. This approach has demonstrated up to 40% improvement in edge definition according to recent industry benchmarks.

Anti-aliasing algorithms specifically target the jagged edges that commonly appear in curved or diagonal features. Modern implementations utilize spatial anti-aliasing techniques that calculate optimal material distribution along edges, creating the visual impression of smoothness even when working with discrete droplets. Stochastic dithering methods further enhance this effect by introducing controlled randomness in droplet placement near edges.

Error diffusion algorithms have been adapted from traditional 2D printing to material jetting applications with considerable success. These algorithms distribute quantization errors across neighboring pixels, effectively spreading unavoidable errors in a way that appears less noticeable to human perception. Floyd-Steinberg and Jarvis-Judice-Ninke diffusion patterns have proven particularly effective for material jetting applications.

Real-time feedback systems represent the cutting edge of pattern optimization. By incorporating sensor data from previous layers or passes, these algorithms can dynamically adjust subsequent material deposition patterns to compensate for detected anomalies or deviations. Machine learning approaches are increasingly being deployed to predict material behavior and preemptively adjust patterns based on historical performance data.

Cross-platform compatibility remains a challenge, with different hardware systems requiring specific algorithmic tuning. Efforts toward standardization have resulted in middleware solutions that can translate optimized patterns across different material jetting platforms while preserving the intended quality characteristics.

Pre-processing algorithms have evolved significantly to address the inherent limitations of material jetting systems. These algorithms analyze the input pattern and apply transformations that compensate for known physical behaviors of jetted materials, such as spreading, coalescence, and edge bleeding. Advanced image processing techniques including adaptive thresholding and contour detection help identify critical features that require preservation during the printing process.

Resolution enhancement algorithms employ sophisticated mathematical models to effectively increase the apparent resolution beyond the physical capabilities of the printing system. Subpixel rendering techniques divide each nominal pixel into virtual subpixels, allowing for more precise material placement and smoother transitions at edges. This approach has demonstrated up to 40% improvement in edge definition according to recent industry benchmarks.

Anti-aliasing algorithms specifically target the jagged edges that commonly appear in curved or diagonal features. Modern implementations utilize spatial anti-aliasing techniques that calculate optimal material distribution along edges, creating the visual impression of smoothness even when working with discrete droplets. Stochastic dithering methods further enhance this effect by introducing controlled randomness in droplet placement near edges.

Error diffusion algorithms have been adapted from traditional 2D printing to material jetting applications with considerable success. These algorithms distribute quantization errors across neighboring pixels, effectively spreading unavoidable errors in a way that appears less noticeable to human perception. Floyd-Steinberg and Jarvis-Judice-Ninke diffusion patterns have proven particularly effective for material jetting applications.

Real-time feedback systems represent the cutting edge of pattern optimization. By incorporating sensor data from previous layers or passes, these algorithms can dynamically adjust subsequent material deposition patterns to compensate for detected anomalies or deviations. Machine learning approaches are increasingly being deployed to predict material behavior and preemptively adjust patterns based on historical performance data.

Cross-platform compatibility remains a challenge, with different hardware systems requiring specific algorithmic tuning. Efforts toward standardization have resulted in middleware solutions that can translate optimized patterns across different material jetting platforms while preserving the intended quality characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!