Material Jetting Predictive Quality: Physics-Informed Models And Data Analytics

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting (MJ) has emerged as a transformative additive manufacturing technology since its inception in the early 1990s. Initially developed as a method for precise deposition of photopolymer materials, this technology has evolved significantly over the past three decades. Material Jetting operates on principles similar to inkjet printing, where droplets of build material are selectively deposited layer by layer to create three-dimensional objects with high precision and surface finish.

The evolution of Material Jetting technology has been marked by several significant milestones. Early systems were limited to single material capabilities and relatively simple geometries. However, advancements in printhead technology, material science, and computational modeling have expanded the capabilities to include multi-material printing, enhanced resolution down to micron levels, and compatibility with a wider range of materials including rigid photopolymers, elastomers, and even certain metals and ceramics in specialized applications.

Current technological trends in Material Jetting focus on improving process reliability, expanding material compatibility, and enhancing production efficiency. The integration of in-situ monitoring systems has begun to address quality control challenges, while developments in UV curing mechanisms have improved material properties and reduced processing times. Despite these advances, the technology still faces challenges related to material property consistency, dimensional accuracy prediction, and long-term stability of printed parts.

The primary objective of Physics-Informed Models and Data Analytics in Material Jetting is to develop predictive frameworks that can accurately forecast print quality outcomes based on process parameters and material properties. This involves creating computational models that incorporate fundamental physical principles governing droplet formation, deposition, spreading, and curing processes. These models aim to predict defects, dimensional accuracy, and mechanical properties before physical production begins.

Additionally, the integration of machine learning algorithms with physics-based models represents a hybrid approach that leverages both theoretical understanding and empirical data. This combination promises more robust predictive capabilities that can adapt to new materials and process conditions without extensive experimental validation. The ultimate goal is to establish a digital twin framework for Material Jetting processes that enables real-time quality prediction and process optimization.

The successful development of these predictive models would significantly reduce the trial-and-error approach currently prevalent in Material Jetting applications, leading to material and time savings, improved part quality, and expanded adoption of the technology across various industrial sectors including aerospace, medical devices, and consumer products.

The evolution of Material Jetting technology has been marked by several significant milestones. Early systems were limited to single material capabilities and relatively simple geometries. However, advancements in printhead technology, material science, and computational modeling have expanded the capabilities to include multi-material printing, enhanced resolution down to micron levels, and compatibility with a wider range of materials including rigid photopolymers, elastomers, and even certain metals and ceramics in specialized applications.

Current technological trends in Material Jetting focus on improving process reliability, expanding material compatibility, and enhancing production efficiency. The integration of in-situ monitoring systems has begun to address quality control challenges, while developments in UV curing mechanisms have improved material properties and reduced processing times. Despite these advances, the technology still faces challenges related to material property consistency, dimensional accuracy prediction, and long-term stability of printed parts.

The primary objective of Physics-Informed Models and Data Analytics in Material Jetting is to develop predictive frameworks that can accurately forecast print quality outcomes based on process parameters and material properties. This involves creating computational models that incorporate fundamental physical principles governing droplet formation, deposition, spreading, and curing processes. These models aim to predict defects, dimensional accuracy, and mechanical properties before physical production begins.

Additionally, the integration of machine learning algorithms with physics-based models represents a hybrid approach that leverages both theoretical understanding and empirical data. This combination promises more robust predictive capabilities that can adapt to new materials and process conditions without extensive experimental validation. The ultimate goal is to establish a digital twin framework for Material Jetting processes that enables real-time quality prediction and process optimization.

The successful development of these predictive models would significantly reduce the trial-and-error approach currently prevalent in Material Jetting applications, leading to material and time savings, improved part quality, and expanded adoption of the technology across various industrial sectors including aerospace, medical devices, and consumer products.

Market Analysis for Predictive Quality Solutions

The predictive quality solutions market for material jetting technologies is experiencing significant growth, driven by increasing adoption of additive manufacturing across industries. Current market valuations indicate that the global predictive maintenance market, which encompasses predictive quality solutions, reached approximately $4.5 billion in 2022 and is projected to grow at a CAGR of 31% through 2028.

Material jetting specifically represents a high-value segment within this market due to its precision requirements and application in high-value industries such as aerospace, medical devices, and electronics. The demand for physics-informed models and data analytics solutions in this sector is particularly strong, as manufacturers seek to minimize waste, reduce production costs, and ensure consistent quality.

Key market drivers include the increasing complexity of manufactured parts, rising material costs, and stringent quality requirements in regulated industries. Organizations are increasingly recognizing that traditional quality control methods—which rely on post-production inspection—are insufficient for complex material jetting processes where defects can be difficult to detect and costly to correct.

The market segmentation reveals distinct customer profiles: large manufacturers with in-house capabilities seeking specialized solutions to integrate with existing systems; mid-sized manufacturers looking for comprehensive turnkey solutions; and service bureaus requiring flexible systems that can adapt to diverse client requirements. Each segment presents unique opportunities and challenges for solution providers.

Regional analysis shows North America leading the market adoption with approximately 38% market share, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is demonstrating the fastest growth rate as manufacturing hubs in China, Japan, and South Korea invest heavily in advanced manufacturing technologies.

Industry-specific demand varies significantly, with aerospace and defense showing the highest willingness to invest in premium predictive quality solutions due to critical performance requirements and regulatory compliance needs. Healthcare and automotive sectors follow closely, while consumer electronics manufacturers are increasingly adopting these solutions to maintain competitive advantages in product quality.

The return on investment for implementing predictive quality solutions in material jetting operations typically ranges from 15-25% within the first year of deployment, primarily through reduced material waste, decreased quality inspection costs, and minimized production downtime. This compelling economic case is accelerating market penetration despite the relatively high initial implementation costs.

Material jetting specifically represents a high-value segment within this market due to its precision requirements and application in high-value industries such as aerospace, medical devices, and electronics. The demand for physics-informed models and data analytics solutions in this sector is particularly strong, as manufacturers seek to minimize waste, reduce production costs, and ensure consistent quality.

Key market drivers include the increasing complexity of manufactured parts, rising material costs, and stringent quality requirements in regulated industries. Organizations are increasingly recognizing that traditional quality control methods—which rely on post-production inspection—are insufficient for complex material jetting processes where defects can be difficult to detect and costly to correct.

The market segmentation reveals distinct customer profiles: large manufacturers with in-house capabilities seeking specialized solutions to integrate with existing systems; mid-sized manufacturers looking for comprehensive turnkey solutions; and service bureaus requiring flexible systems that can adapt to diverse client requirements. Each segment presents unique opportunities and challenges for solution providers.

Regional analysis shows North America leading the market adoption with approximately 38% market share, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is demonstrating the fastest growth rate as manufacturing hubs in China, Japan, and South Korea invest heavily in advanced manufacturing technologies.

Industry-specific demand varies significantly, with aerospace and defense showing the highest willingness to invest in premium predictive quality solutions due to critical performance requirements and regulatory compliance needs. Healthcare and automotive sectors follow closely, while consumer electronics manufacturers are increasingly adopting these solutions to maintain competitive advantages in product quality.

The return on investment for implementing predictive quality solutions in material jetting operations typically ranges from 15-25% within the first year of deployment, primarily through reduced material waste, decreased quality inspection costs, and minimized production downtime. This compelling economic case is accelerating market penetration despite the relatively high initial implementation costs.

Current Challenges in Material Jetting Quality Control

Material jetting technology faces significant quality control challenges that impede its wider industrial adoption. The inherent complexity of the material jetting process creates substantial variability in printed parts, with inconsistencies occurring both within single production runs and between different batches. These variations manifest as dimensional inaccuracies, surface defects, internal voids, and mechanical property inconsistencies that compromise the functional integrity of manufactured components.

Real-time monitoring capabilities remain severely limited, with most quality assessment occurring post-production through destructive testing methods. This approach is both time-consuming and wasteful, preventing manufacturers from implementing effective in-process adjustments. The lack of standardized quality metrics specific to material jetting further complicates quality control efforts, as different industries and applications require varying performance parameters that are difficult to universally define and measure.

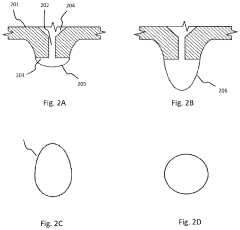

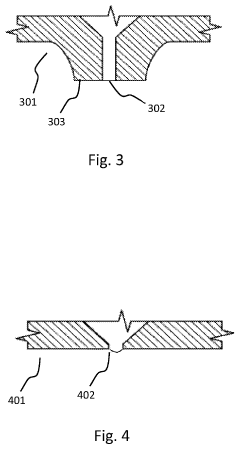

Material-specific challenges present another significant obstacle. The rheological properties of printable materials can change during processing due to temperature fluctuations, aging effects, and environmental conditions. These changes affect droplet formation, spreading behavior, and curing characteristics, ultimately impacting final part quality. Additionally, multi-material printing introduces complex interface issues that are difficult to predict and control, particularly when materials with different physical and chemical properties are combined.

Process parameter optimization remains largely empirical, with limited theoretical frameworks to guide parameter selection. The vast parameter space—including nozzle temperature, platform temperature, droplet spacing, printing speed, and curing conditions—creates a combinatorial challenge that makes systematic optimization prohibitively resource-intensive. Current approaches often rely on trial-and-error methodologies that are inefficient and fail to capture the complex interactions between parameters.

Environmental factors introduce further variability, with ambient temperature, humidity, and air quality all affecting print outcomes. These factors are difficult to control consistently in production environments, creating additional quality control challenges. The lack of robust closed-loop control systems means that even when deviations are detected, automated corrective actions remain limited.

Data integration presents a final major challenge. While various sensing technologies can capture different aspects of the printing process, integrating this heterogeneous data into cohesive quality models remains difficult. The absence of standardized data formats and processing pipelines hampers efforts to develop comprehensive quality prediction frameworks that could anticipate defects before they occur and suggest preventive measures.

Real-time monitoring capabilities remain severely limited, with most quality assessment occurring post-production through destructive testing methods. This approach is both time-consuming and wasteful, preventing manufacturers from implementing effective in-process adjustments. The lack of standardized quality metrics specific to material jetting further complicates quality control efforts, as different industries and applications require varying performance parameters that are difficult to universally define and measure.

Material-specific challenges present another significant obstacle. The rheological properties of printable materials can change during processing due to temperature fluctuations, aging effects, and environmental conditions. These changes affect droplet formation, spreading behavior, and curing characteristics, ultimately impacting final part quality. Additionally, multi-material printing introduces complex interface issues that are difficult to predict and control, particularly when materials with different physical and chemical properties are combined.

Process parameter optimization remains largely empirical, with limited theoretical frameworks to guide parameter selection. The vast parameter space—including nozzle temperature, platform temperature, droplet spacing, printing speed, and curing conditions—creates a combinatorial challenge that makes systematic optimization prohibitively resource-intensive. Current approaches often rely on trial-and-error methodologies that are inefficient and fail to capture the complex interactions between parameters.

Environmental factors introduce further variability, with ambient temperature, humidity, and air quality all affecting print outcomes. These factors are difficult to control consistently in production environments, creating additional quality control challenges. The lack of robust closed-loop control systems means that even when deviations are detected, automated corrective actions remain limited.

Data integration presents a final major challenge. While various sensing technologies can capture different aspects of the printing process, integrating this heterogeneous data into cohesive quality models remains difficult. The absence of standardized data formats and processing pipelines hampers efforts to develop comprehensive quality prediction frameworks that could anticipate defects before they occur and suggest preventive measures.

Physics-Informed Models for Quality Prediction

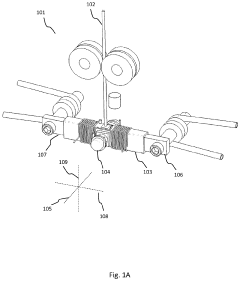

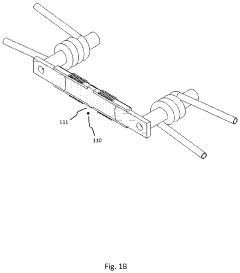

01 Predictive quality control systems for material jetting

Advanced systems that monitor and predict quality issues in material jetting processes. These systems utilize sensors, cameras, and data analytics to detect potential defects before they occur. By analyzing parameters such as temperature, pressure, and material flow in real-time, these systems can make adjustments to maintain optimal print quality and reduce waste. The predictive algorithms can identify patterns that lead to defects and automatically implement corrective actions.- Predictive quality control systems for material jetting: Advanced systems that monitor and predict quality issues in material jetting processes. These systems utilize sensors, cameras, and data analytics to detect anomalies in real-time, allowing for immediate adjustments to printing parameters. By continuously monitoring factors such as droplet formation, material flow, and deposition accuracy, these predictive systems can significantly reduce defects and improve overall print quality.

- Machine learning algorithms for quality prediction: Implementation of machine learning and artificial intelligence algorithms to predict and optimize material jetting quality. These algorithms analyze historical printing data, identify patterns, and make predictions about potential quality issues before they occur. By learning from past printing jobs, these systems can recommend optimal printing parameters, predict maintenance needs, and continuously improve print quality through adaptive learning processes.

- Real-time monitoring and adjustment technologies: Technologies that enable real-time monitoring and automatic adjustment of material jetting processes. These systems incorporate various sensors to track critical parameters such as temperature, pressure, viscosity, and droplet formation. When deviations from optimal conditions are detected, the system automatically adjusts printing parameters to maintain quality. This closed-loop approach ensures consistent print quality even when environmental conditions or material properties fluctuate.

- Material property analysis for quality prediction: Methods for analyzing and predicting how material properties affect jetting quality. These approaches involve characterizing materials before printing to determine optimal processing parameters. By understanding how viscosity, surface tension, particle size, and other properties influence droplet formation and adhesion, manufacturers can predict print quality outcomes and adjust formulations accordingly. This enables the development of materials specifically optimized for high-quality material jetting applications.

- Digital twin technology for quality simulation: Implementation of digital twin technology to create virtual models of material jetting processes for quality prediction. These digital replicas simulate the entire printing process, allowing manufacturers to predict outcomes before physical production begins. By testing different parameters and scenarios virtually, potential quality issues can be identified and resolved proactively. Digital twins also enable continuous improvement by comparing simulated predictions with actual results and refining the models accordingly.

02 Machine learning algorithms for quality prediction

Implementation of machine learning and artificial intelligence algorithms to predict and improve material jetting quality. These algorithms analyze historical printing data to identify correlations between process parameters and final product quality. By learning from past printing jobs, the system can predict potential issues in future prints and suggest optimal parameters. Deep learning models can be trained to recognize visual patterns in printed parts that indicate quality issues, enabling proactive quality management.Expand Specific Solutions03 Real-time monitoring and feedback systems

Systems that provide continuous monitoring and feedback during the material jetting process. These systems incorporate various sensors to track critical parameters such as droplet formation, curing conditions, and layer adhesion. When deviations from optimal conditions are detected, the system can automatically adjust printing parameters or alert operators. This real-time approach allows for immediate correction of issues before they affect the entire print job, significantly improving overall quality consistency.Expand Specific Solutions04 Digital twin technology for process simulation

Implementation of digital twin technology to create virtual replicas of material jetting processes for simulation and optimization. These digital models accurately represent the physical printing system and can predict how changes in parameters will affect print quality. By running simulations before actual printing, manufacturers can identify optimal settings and potential issues. The digital twin continuously updates based on real-world data, improving its predictive accuracy over time and enabling virtual testing of new materials or designs.Expand Specific Solutions05 Material formulation optimization for quality enhancement

Methods for optimizing material formulations to enhance printability and final product quality in material jetting processes. These approaches involve analyzing how different material compositions affect viscosity, surface tension, and curing properties. Additives can be incorporated to improve flow characteristics, reduce clogging, and enhance layer adhesion. Predictive models help determine the optimal formulation for specific applications, considering factors such as environmental conditions and desired mechanical properties of the final product.Expand Specific Solutions

Leading Companies in Material Jetting Technology

Material Jetting Predictive Quality technology is currently in a growth phase, with increasing market adoption across manufacturing sectors. The market is expanding rapidly, driven by demand for high-precision additive manufacturing solutions, with projections suggesting a compound annual growth rate of 15-20% over the next five years. Technologically, the field is maturing through integration of physics-informed models with advanced data analytics. Leading players include Desktop Metal and Xerox Holdings developing commercial applications, while academic institutions like MIT and Nanyang Technological University focus on fundamental research. Companies such as DataRobot and Bosch are contributing AI-driven quality control solutions, while traditional manufacturers like JFE Steel and Hyundai are exploring industrial implementations. The convergence of material science expertise from institutions like Korea Research Institute of Chemical Technology with data analytics capabilities is accelerating technology maturation.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered a multiscale modeling framework for material jetting that bridges molecular dynamics simulations with continuum mechanics. Their approach incorporates Lattice Boltzmann methods coupled with deep learning architectures to predict fluid-structure interactions during the jetting process[3]. MIT researchers have developed a novel tensor-based representation of material properties that captures anisotropic behavior during solidification, enabling more accurate prediction of final part mechanical properties. Their computational platform integrates in-situ monitoring data with theoretical models through a Bayesian inference framework, allowing for uncertainty quantification in quality predictions[4]. The system has demonstrated the ability to predict porosity formation with an accuracy of 92% across various material systems, including photopolymers and metal-loaded suspensions. MIT's framework also incorporates thermal history effects on microstructure evolution, providing a comprehensive approach to quality prediction that spans from droplet ejection to final part performance.

Strengths: Exceptional theoretical foundation combining first-principles physics with advanced statistical methods provides unparalleled insight into fundamental mechanisms affecting print quality. Their approach offers superior generalizability across different material systems. Weaknesses: The computational complexity of their models limits practical implementation in industrial settings without significant simplification, and the approach requires extensive experimental validation data for each new application.

Xerox Holdings Corp.

Technical Solution: Xerox has leveraged its decades of expertise in jetting technologies to develop a comprehensive quality prediction system for advanced manufacturing applications. Their approach combines high-fidelity computational fluid dynamics simulations with empirical models derived from their extensive experience in inkjet printing[9]. Xerox's platform incorporates a digital twin methodology that simulates the entire material jetting process, from droplet formation through impact and solidification. Their system features a proprietary droplet visualization technology capable of capturing images at over 100,000 frames per second, enabling precise validation of simulation results against actual jetting behavior. Xerox has implemented a hierarchical machine learning architecture that operates at multiple time scales, from microsecond-level droplet ejection dynamics to minute-level build quality trends[10]. Their quality prediction system has demonstrated the ability to detect and classify 14 distinct defect types with 93% accuracy, enabling automated quality control and process parameter optimization. The company has also developed specialized algorithms for multi-material jetting that predict interface quality and adhesion characteristics.

Strengths: Unparalleled experience in jetting technologies provides deep domain knowledge that enhances model accuracy and practical applicability. Their integrated approach spans from fundamental droplet dynamics to final part quality assessment. Weaknesses: Their solutions are often optimized for Xerox hardware systems, potentially limiting compatibility with third-party equipment, and the proprietary nature of their algorithms restricts open scientific collaboration.

Key Innovations in Data Analytics for Material Jetting

Material jetting

PatentWO2025133018A1

Innovation

- A computer-implemented method that processes input models to identify vulnerable regions prone to deformation by surface tension-induced flow, and modifies material jetting parameters such as ink volume, curing time, and UV intensity to mitigate these deformations.

The jetting performance of molten metal alloys by controlling the concentration of key alloying elements

PatentInactiveUS20220258240A1

Innovation

- Controlling the concentration of alloying elements such as strontium, magnesium, and zinc in the meniscus material to minimize dross formation and ensure proper wetting, thereby stabilizing jet quality and reducing maintenance needs.

Real-time Monitoring Systems Integration

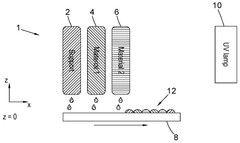

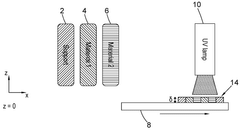

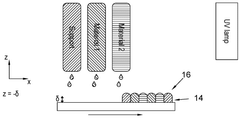

The integration of real-time monitoring systems represents a critical advancement in Material Jetting technology, enabling continuous quality assessment and process optimization. These systems incorporate multiple sensor types strategically positioned throughout the manufacturing workflow to capture vital process parameters and material characteristics during operation. Optical sensors, including high-speed cameras and laser-based measurement devices, track droplet formation, trajectory, and placement accuracy with microsecond precision, while thermal imaging cameras monitor temperature distributions across build platforms.

Pressure sensors installed within material delivery systems provide crucial data on fluid dynamics, detecting fluctuations that might indicate nozzle clogging or material inconsistencies. Viscosity sensors continuously evaluate material properties, ensuring they remain within optimal processing parameters. The implementation of acoustic monitoring devices has emerged as particularly valuable for detecting subtle anomalies in jetting mechanics that other sensor modalities might miss.

Data acquisition systems supporting these monitoring networks operate at sampling rates exceeding 10,000 Hz for critical parameters, transmitting information through robust industrial communication protocols that minimize latency. Edge computing architectures process preliminary data directly at sensor nodes, reducing bandwidth requirements while enabling real-time response capabilities. This distributed intelligence approach allows for immediate process adjustments when deviations are detected.

Modern integration frameworks employ standardized interfaces such as OPC-UA and MQTT to facilitate seamless communication between heterogeneous system components. These frameworks incorporate digital twin technology, creating virtual representations of physical processes that update in real-time and serve as platforms for simulation and predictive analytics. Machine learning algorithms continuously analyze incoming sensor data against physics-informed models, identifying patterns indicative of quality issues before they manifest in finished parts.

The implementation of closed-loop control systems represents the culmination of these monitoring capabilities, automatically adjusting process parameters based on real-time feedback. These systems can modify droplet ejection timing, substrate temperatures, or material flow rates to compensate for detected anomalies, maintaining consistent quality throughout production runs. Advanced implementations incorporate adaptive control algorithms that evolve over time, learning from historical process data to anticipate and prevent quality deviations.

Challenges in system integration include managing the substantial data volumes generated during high-speed manufacturing operations and ensuring sensor reliability in environments containing airborne particulates and electromagnetic interference. Emerging solutions incorporate self-diagnostic capabilities within sensor networks and implement redundant monitoring approaches for critical parameters, enhancing system robustness in production environments.

Pressure sensors installed within material delivery systems provide crucial data on fluid dynamics, detecting fluctuations that might indicate nozzle clogging or material inconsistencies. Viscosity sensors continuously evaluate material properties, ensuring they remain within optimal processing parameters. The implementation of acoustic monitoring devices has emerged as particularly valuable for detecting subtle anomalies in jetting mechanics that other sensor modalities might miss.

Data acquisition systems supporting these monitoring networks operate at sampling rates exceeding 10,000 Hz for critical parameters, transmitting information through robust industrial communication protocols that minimize latency. Edge computing architectures process preliminary data directly at sensor nodes, reducing bandwidth requirements while enabling real-time response capabilities. This distributed intelligence approach allows for immediate process adjustments when deviations are detected.

Modern integration frameworks employ standardized interfaces such as OPC-UA and MQTT to facilitate seamless communication between heterogeneous system components. These frameworks incorporate digital twin technology, creating virtual representations of physical processes that update in real-time and serve as platforms for simulation and predictive analytics. Machine learning algorithms continuously analyze incoming sensor data against physics-informed models, identifying patterns indicative of quality issues before they manifest in finished parts.

The implementation of closed-loop control systems represents the culmination of these monitoring capabilities, automatically adjusting process parameters based on real-time feedback. These systems can modify droplet ejection timing, substrate temperatures, or material flow rates to compensate for detected anomalies, maintaining consistent quality throughout production runs. Advanced implementations incorporate adaptive control algorithms that evolve over time, learning from historical process data to anticipate and prevent quality deviations.

Challenges in system integration include managing the substantial data volumes generated during high-speed manufacturing operations and ensuring sensor reliability in environments containing airborne particulates and electromagnetic interference. Emerging solutions incorporate self-diagnostic capabilities within sensor networks and implement redundant monitoring approaches for critical parameters, enhancing system robustness in production environments.

Sustainability Impacts of Optimized Material Jetting

The optimization of material jetting processes through physics-informed models and data analytics offers significant sustainability benefits across multiple dimensions. By enhancing predictive quality control, these advanced techniques minimize material waste through precise deposition and reduced error rates. Studies indicate that optimized material jetting can decrease raw material consumption by 15-30% compared to conventional manufacturing methods, directly reducing resource extraction impacts.

Energy efficiency represents another critical sustainability advantage. Predictive models enable process parameter optimization that can lower energy requirements by identifying optimal operating conditions. Real-time monitoring systems integrated with physics-informed models allow for dynamic adjustments that maintain quality while minimizing power consumption, potentially reducing energy usage by 10-25% across production cycles.

The environmental footprint of material jetting is further improved through reduced chemical waste. Advanced predictive analytics enable more precise formulation and application of potentially hazardous materials, minimizing excess usage and associated disposal challenges. This precision contributes to decreased emissions of volatile organic compounds (VOCs) and other harmful substances during manufacturing.

Product lifecycle sustainability benefits significantly from quality optimization. Higher-quality printed components demonstrate improved durability and performance characteristics, extending useful product lifespans and reducing replacement frequency. This longevity effect compounds sustainability benefits beyond the manufacturing phase into the use phase of products.

Supply chain impacts should not be overlooked when assessing sustainability improvements. Localized, on-demand production enabled by reliable material jetting reduces transportation requirements and associated carbon emissions. The ability to produce components closer to points of use, with confidence in quality outcomes, supports distributed manufacturing models that align with circular economy principles.

Quantitative life cycle assessment (LCA) studies comparing optimized material jetting with traditional manufacturing methods demonstrate potential carbon footprint reductions of 30-60% for certain applications, particularly for complex geometries that would otherwise require multiple manufacturing steps or excessive material removal. These environmental benefits position advanced material jetting as a key technology for sustainable manufacturing transformation.

Energy efficiency represents another critical sustainability advantage. Predictive models enable process parameter optimization that can lower energy requirements by identifying optimal operating conditions. Real-time monitoring systems integrated with physics-informed models allow for dynamic adjustments that maintain quality while minimizing power consumption, potentially reducing energy usage by 10-25% across production cycles.

The environmental footprint of material jetting is further improved through reduced chemical waste. Advanced predictive analytics enable more precise formulation and application of potentially hazardous materials, minimizing excess usage and associated disposal challenges. This precision contributes to decreased emissions of volatile organic compounds (VOCs) and other harmful substances during manufacturing.

Product lifecycle sustainability benefits significantly from quality optimization. Higher-quality printed components demonstrate improved durability and performance characteristics, extending useful product lifespans and reducing replacement frequency. This longevity effect compounds sustainability benefits beyond the manufacturing phase into the use phase of products.

Supply chain impacts should not be overlooked when assessing sustainability improvements. Localized, on-demand production enabled by reliable material jetting reduces transportation requirements and associated carbon emissions. The ability to produce components closer to points of use, with confidence in quality outcomes, supports distributed manufacturing models that align with circular economy principles.

Quantitative life cycle assessment (LCA) studies comparing optimized material jetting with traditional manufacturing methods demonstrate potential carbon footprint reductions of 30-60% for certain applications, particularly for complex geometries that would otherwise require multiple manufacturing steps or excessive material removal. These environmental benefits position advanced material jetting as a key technology for sustainable manufacturing transformation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!