Material Jetting 3D Printed Optics: Form Accuracy, Scatter And Coating Compatibility

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Optics Background and Objectives

Material Jetting (MJ) technology has emerged as a promising additive manufacturing method for optical applications, representing a significant evolution in the field of 3D printed optics. Since its inception in the early 2000s, MJ has progressed from basic prototyping capabilities to a sophisticated manufacturing technique capable of producing functional optical components. The technology leverages photopolymer deposition through inkjet printheads, offering unprecedented precision in creating transparent and optically functional parts.

The evolution of Material Jetting for optical applications has been marked by several key developments. Initially limited by material constraints and surface quality issues, recent advancements in photopolymer formulations have dramatically improved optical clarity, refractive index control, and long-term stability. These improvements have expanded the potential applications from simple display prototypes to functional optical elements including lenses, waveguides, and light pipes.

Current technical objectives in the field focus on three critical aspects: form accuracy, scatter reduction, and coating compatibility. Form accuracy represents the ability to produce optical surfaces with precise geometries at micro and nanoscales, essential for maintaining optical performance. Scatter reduction addresses the challenge of minimizing internal light scattering caused by material inhomogeneities and layer interfaces. Coating compatibility explores the integration of MJ-printed optics with traditional optical coatings for enhanced functionality.

The trajectory of Material Jetting technology indicates a convergence with traditional optical manufacturing techniques, potentially offering a hybrid approach that combines the geometric freedom of additive manufacturing with the optical performance of conventional methods. This convergence aims to address the growing demand for customized optical solutions in industries ranging from consumer electronics to medical devices and automotive applications.

The ultimate goal of current research efforts is to establish Material Jetting as a viable manufacturing method for production-grade optical components, capable of meeting stringent industry specifications for transmission efficiency, wavefront quality, and dimensional stability. This requires overcoming persistent challenges related to material properties, process control, and post-processing techniques.

As the technology continues to mature, researchers and industry stakeholders are increasingly focused on developing standardized characterization methods and quality control processes specific to additively manufactured optics. These efforts aim to bridge the gap between traditional optical manufacturing standards and the unique capabilities and constraints of Material Jetting technology, facilitating broader adoption across various high-value optical applications.

The evolution of Material Jetting for optical applications has been marked by several key developments. Initially limited by material constraints and surface quality issues, recent advancements in photopolymer formulations have dramatically improved optical clarity, refractive index control, and long-term stability. These improvements have expanded the potential applications from simple display prototypes to functional optical elements including lenses, waveguides, and light pipes.

Current technical objectives in the field focus on three critical aspects: form accuracy, scatter reduction, and coating compatibility. Form accuracy represents the ability to produce optical surfaces with precise geometries at micro and nanoscales, essential for maintaining optical performance. Scatter reduction addresses the challenge of minimizing internal light scattering caused by material inhomogeneities and layer interfaces. Coating compatibility explores the integration of MJ-printed optics with traditional optical coatings for enhanced functionality.

The trajectory of Material Jetting technology indicates a convergence with traditional optical manufacturing techniques, potentially offering a hybrid approach that combines the geometric freedom of additive manufacturing with the optical performance of conventional methods. This convergence aims to address the growing demand for customized optical solutions in industries ranging from consumer electronics to medical devices and automotive applications.

The ultimate goal of current research efforts is to establish Material Jetting as a viable manufacturing method for production-grade optical components, capable of meeting stringent industry specifications for transmission efficiency, wavefront quality, and dimensional stability. This requires overcoming persistent challenges related to material properties, process control, and post-processing techniques.

As the technology continues to mature, researchers and industry stakeholders are increasingly focused on developing standardized characterization methods and quality control processes specific to additively manufactured optics. These efforts aim to bridge the gap between traditional optical manufacturing standards and the unique capabilities and constraints of Material Jetting technology, facilitating broader adoption across various high-value optical applications.

Market Analysis for 3D Printed Optical Components

The global market for 3D printed optical components is experiencing significant growth, driven by advancements in material jetting technologies that enable the production of high-precision optical elements. Current market valuations place the 3D printed optics sector at approximately $320 million in 2023, with projections indicating a compound annual growth rate of 24.7% through 2028, potentially reaching $960 million by the end of the forecast period.

Material jetting technology for optical applications represents a particularly promising segment within the broader additive manufacturing market. This technology addresses critical needs across multiple industries, with the most substantial demand coming from consumer electronics, automotive, aerospace, and medical device sectors. These industries collectively account for over 75% of the current market adoption.

The consumer electronics industry leads adoption, utilizing 3D printed optics for smartphone camera lenses, AR/VR displays, and sensor components. This sector values the ability to rapidly prototype and customize optical designs while maintaining precise form accuracy. The automotive industry follows closely, implementing these components in advanced driver-assistance systems (ADAS), heads-up displays, and lighting systems, where coating compatibility is essential for durability and performance.

Market analysis reveals significant regional variations in adoption patterns. North America currently holds the largest market share at 42%, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is demonstrating the fastest growth rate, primarily due to expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing investments in optical technologies.

A key market driver is the growing demand for customized optical solutions with complex geometries that traditional manufacturing methods struggle to produce efficiently. Material jetting's ability to create optically clear components with controlled scatter properties addresses this need directly, offering design freedom previously unattainable.

Market challenges include the relatively high cost of specialized optical printing materials, which currently range from $300-$800 per kilogram, significantly higher than conventional optical manufacturing materials. Additionally, concerns regarding long-term durability and coating compatibility have slowed adoption in certain high-reliability applications.

Industry surveys indicate that manufacturers value form accuracy as the most critical parameter (cited by 68% of respondents), followed by optical clarity (54%) and coating compatibility (47%). This aligns with the technical focus areas identified in recent material jetting research for optical applications.

The market is currently experiencing a transition from primarily prototyping applications toward end-use production components, with this shift expected to accelerate as material properties and processing techniques continue to improve. Analysts predict that by 2026, production parts will represent over 60% of the 3D printed optics market, compared to approximately 35% today.

Material jetting technology for optical applications represents a particularly promising segment within the broader additive manufacturing market. This technology addresses critical needs across multiple industries, with the most substantial demand coming from consumer electronics, automotive, aerospace, and medical device sectors. These industries collectively account for over 75% of the current market adoption.

The consumer electronics industry leads adoption, utilizing 3D printed optics for smartphone camera lenses, AR/VR displays, and sensor components. This sector values the ability to rapidly prototype and customize optical designs while maintaining precise form accuracy. The automotive industry follows closely, implementing these components in advanced driver-assistance systems (ADAS), heads-up displays, and lighting systems, where coating compatibility is essential for durability and performance.

Market analysis reveals significant regional variations in adoption patterns. North America currently holds the largest market share at 42%, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is demonstrating the fastest growth rate, primarily due to expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing investments in optical technologies.

A key market driver is the growing demand for customized optical solutions with complex geometries that traditional manufacturing methods struggle to produce efficiently. Material jetting's ability to create optically clear components with controlled scatter properties addresses this need directly, offering design freedom previously unattainable.

Market challenges include the relatively high cost of specialized optical printing materials, which currently range from $300-$800 per kilogram, significantly higher than conventional optical manufacturing materials. Additionally, concerns regarding long-term durability and coating compatibility have slowed adoption in certain high-reliability applications.

Industry surveys indicate that manufacturers value form accuracy as the most critical parameter (cited by 68% of respondents), followed by optical clarity (54%) and coating compatibility (47%). This aligns with the technical focus areas identified in recent material jetting research for optical applications.

The market is currently experiencing a transition from primarily prototyping applications toward end-use production components, with this shift expected to accelerate as material properties and processing techniques continue to improve. Analysts predict that by 2026, production parts will represent over 60% of the 3D printed optics market, compared to approximately 35% today.

Technical Challenges in Material Jetting Optics

Material jetting technology for 3D printed optics faces several significant technical challenges that currently limit its widespread adoption in optical applications. The primary challenge lies in achieving the necessary form accuracy for optical components. Unlike conventional manufacturing methods, material jetting must contend with issues such as shrinkage during curing, which can lead to dimensional inaccuracies and surface deformations. These deviations, even at the microscale, can significantly impact optical performance.

Surface quality represents another major hurdle. Material jetted components often exhibit "stair-stepping" effects between layers, creating micro-roughness that causes light scattering. This phenomenon is particularly problematic for optical applications where smooth surfaces are essential for proper light transmission and reflection. Current post-processing techniques to address surface roughness are often labor-intensive and may compromise dimensional accuracy.

Material limitations further constrain the technology's optical applications. Most commercially available photopolymers for material jetting lack the optical clarity, refractive index range, and long-term stability required for high-performance optics. These materials often suffer from yellowing over time due to UV exposure, significantly degrading optical performance. Additionally, the limited range of available refractive indices restricts the design possibilities for complex optical systems.

The multi-material capabilities of material jetting, while promising for creating gradient index optics, introduce challenges related to material interface quality. Sharp transitions between different materials can create internal scattering sites, reducing optical efficiency. Controlling these interfaces at the microscale remains technically challenging.

Coating compatibility presents another significant obstacle. Many optical components require specialized coatings for anti-reflection, hardness, or other functional properties. However, the surface chemistry of jetted photopolymers often differs from traditional optical materials, leading to poor adhesion or coating performance. Developing compatible coating processes or surface treatment methods is essential for advancing this technology.

Process repeatability and quality control also remain challenging. Variations in material properties between batches, environmental factors during printing, and inconsistencies in post-processing can all lead to unpredictable optical performance. Establishing robust quality control methods and standards specifically for optically functional printed parts is necessary for industrial adoption.

Finally, the technology faces challenges in scaling production while maintaining optical quality. While material jetting offers advantages for prototyping and small-batch production, ensuring consistent optical performance across larger production runs requires significant process optimization and quality control infrastructure.

Surface quality represents another major hurdle. Material jetted components often exhibit "stair-stepping" effects between layers, creating micro-roughness that causes light scattering. This phenomenon is particularly problematic for optical applications where smooth surfaces are essential for proper light transmission and reflection. Current post-processing techniques to address surface roughness are often labor-intensive and may compromise dimensional accuracy.

Material limitations further constrain the technology's optical applications. Most commercially available photopolymers for material jetting lack the optical clarity, refractive index range, and long-term stability required for high-performance optics. These materials often suffer from yellowing over time due to UV exposure, significantly degrading optical performance. Additionally, the limited range of available refractive indices restricts the design possibilities for complex optical systems.

The multi-material capabilities of material jetting, while promising for creating gradient index optics, introduce challenges related to material interface quality. Sharp transitions between different materials can create internal scattering sites, reducing optical efficiency. Controlling these interfaces at the microscale remains technically challenging.

Coating compatibility presents another significant obstacle. Many optical components require specialized coatings for anti-reflection, hardness, or other functional properties. However, the surface chemistry of jetted photopolymers often differs from traditional optical materials, leading to poor adhesion or coating performance. Developing compatible coating processes or surface treatment methods is essential for advancing this technology.

Process repeatability and quality control also remain challenging. Variations in material properties between batches, environmental factors during printing, and inconsistencies in post-processing can all lead to unpredictable optical performance. Establishing robust quality control methods and standards specifically for optically functional printed parts is necessary for industrial adoption.

Finally, the technology faces challenges in scaling production while maintaining optical quality. While material jetting offers advantages for prototyping and small-batch production, ensuring consistent optical performance across larger production runs requires significant process optimization and quality control infrastructure.

Current Form Accuracy and Scatter Reduction Solutions

01 Form accuracy optimization in material jetting for optical components

Material jetting 3D printing technology can be optimized to achieve high form accuracy for optical components. This involves precise control of printing parameters, material deposition, and post-processing techniques to minimize geometric deviations. Advanced calibration methods and compensation algorithms can be employed to correct for systematic errors in the printing process, resulting in optical components with improved dimensional accuracy and surface quality.- Form accuracy optimization in material jetting for optical components: Material jetting 3D printing technologies can be optimized to achieve high form accuracy for optical components. This involves precise control of printing parameters, material deposition strategies, and post-processing techniques to minimize geometric deviations. Advanced calibration methods and compensation algorithms can be employed to correct for systematic errors, resulting in optical components with improved dimensional accuracy and surface quality necessary for functional optical applications.

- Scatter reduction techniques for 3D printed optics: Various approaches can be implemented to reduce light scatter in material jetted optical components. These include optimizing material formulations with enhanced transparency, implementing specialized surface finishing techniques, and controlling the internal structure of printed parts. By minimizing material inhomogeneities, reducing surface roughness, and eliminating internal voids or defects, the optical clarity and performance of 3D printed optical components can be significantly improved, making them suitable for precision optical applications.

- Coating compatibility for enhanced optical performance: Material jetted optical components can be enhanced through the application of specialized optical coatings. The compatibility between the printed substrate and various coating materials is critical for achieving desired optical properties. Surface preparation methods, adhesion promotion techniques, and customized coating formulations can be developed specifically for 3D printed optical substrates. These coatings can provide anti-reflection properties, increase durability, improve light transmission, or add specific filtering capabilities to the printed optical components.

- Material formulations for improved optical properties: Advanced material formulations specifically designed for optical applications in material jetting processes can significantly improve the performance of 3D printed optics. These formulations may incorporate specialized monomers, additives, and nanoparticles to enhance transparency, refractive index control, and mechanical stability. By carefully engineering the photopolymer chemistry and curing mechanisms, materials can be developed that exhibit minimal shrinkage, high clarity, and consistent optical properties throughout the printed component.

- Post-processing methods for optical quality enhancement: Various post-processing techniques can be applied to material jetted optical components to enhance their optical quality. These methods include thermal treatments to reduce internal stresses, chemical polishing to improve surface smoothness, and specialized curing processes to optimize material properties. Advanced polishing techniques, such as magnetorheological finishing or computer-controlled optical surfacing, can be adapted for 3D printed optics to achieve surface qualities comparable to conventionally manufactured optical components.

02 Scatter reduction techniques for 3D printed optics

Various techniques can be implemented to reduce light scatter in material jetted optical components. These include optimizing material formulations to enhance transparency, implementing specialized post-processing methods to decrease surface roughness, and developing multi-material printing approaches that minimize internal interfaces. By controlling the microstructure and surface characteristics of the printed optics, scatter effects can be significantly reduced, leading to improved optical performance and clarity.Expand Specific Solutions03 Coating compatibility for material jetted optical components

Ensuring compatibility between 3D printed optical substrates and functional coatings is essential for high-performance optical systems. This involves developing surface preparation techniques specific to material jetted components, selecting coating materials that adhere well to the printed substrates, and optimizing coating processes to accommodate the unique characteristics of 3D printed surfaces. Proper coating compatibility enhances durability, optical performance, and enables additional functionalities such as anti-reflection or scratch resistance.Expand Specific Solutions04 Multi-material jetting for advanced optical properties

Multi-material jetting enables the fabrication of optical components with spatially varying properties and complex internal structures. By precisely depositing different materials with complementary optical characteristics, gradient refractive index profiles, embedded optical elements, and integrated functionalities can be achieved. This approach allows for the creation of novel optical designs that would be difficult or impossible to manufacture using conventional methods, while maintaining high form accuracy and minimizing scatter.Expand Specific Solutions05 Post-processing methods for enhanced optical performance

Post-processing techniques play a crucial role in improving the optical performance of material jetted components. These methods include thermal treatments to reduce internal stress and enhance transparency, polishing procedures to decrease surface roughness, and specialized curing processes to optimize material properties. Advanced post-processing approaches can significantly improve form accuracy, reduce scatter, and enhance coating compatibility, resulting in 3D printed optical components with performance characteristics approaching those of conventionally manufactured optics.Expand Specific Solutions

Leading Companies in 3D Printed Optics Industry

Material Jetting 3D Printed Optics is currently in an early growth phase, with the market expanding as the technology matures from experimental to commercial applications. The global market for 3D printed optics is projected to reach significant scale as industries recognize its potential for customized optical components with reduced production time. Technologically, companies are at varying stages of development: established players like Xerox, HP, and Nikon are leveraging their imaging expertise to advance material jetting for optical applications, while specialized firms like Luxexcel have developed proprietary processes specifically for optical-grade printing. Desktop Metal, EOS GmbH, and Velo3D are enhancing precision capabilities, while research institutions such as Peking University and Korea Electronics Technology Institute are exploring fundamental material science challenges related to form accuracy, scatter reduction, and coating compatibility that remain critical barriers to widespread adoption.

HP Development Co. LP

Technical Solution: HP has developed Multi Jet Fusion (MJF) technology that, while primarily focused on non-optical applications, has been adapted for certain optical prototyping applications. Their approach uses a proprietary HP Agent and detailed energy control to achieve precise dimensional accuracy. For optical applications, HP has developed specialized post-processing techniques to improve surface finish quality, reducing scatter through a combination of chemical and thermal treatments. Their research has focused on achieving form accuracy within ±50 microns for optical components, with particular attention to maintaining consistent wall thickness and preventing warpage during cooling. HP's coating compatibility research has yielded promising results with certain anti-reflective coatings, though adhesion remains challenging on some printed surfaces. Their material development has focused on increasing transparency and reducing internal scatter through improved fusion control during the printing process[3][4].

Strengths: Established industrial-scale production capabilities; excellent dimensional accuracy; strong R&D resources for material development. Weaknesses: Technology primarily optimized for non-optical applications; surface finish requires significant post-processing; limited optical transparency compared to specialized optical printing technologies.

Olympus Corp.

Technical Solution: Olympus has developed a precision material jetting technology specifically for creating custom optical components for their imaging systems. Their approach utilizes multi-material jetting capabilities to create gradient index optics with spatially varying optical properties. The technology achieves form accuracy through a combination of high-resolution printing (with droplet sizes below 15 picoliters) and specialized toolpath algorithms that compensate for material shrinkage during curing. Olympus has focused on minimizing scatter through careful control of the interface between printed layers, utilizing proprietary UV curing protocols that promote molecular bonding across layers. Their coating compatibility research has yielded specialized surface preparation techniques that enable standard optical coatings to adhere effectively to their printed optics. The company has also developed in-line metrology systems that verify optical performance during the printing process, allowing for real-time adjustments to maintain tight tolerances. Their technology achieves surface roughness values of approximately 8nm RMS without polishing[9][10].

Strengths: Integration with established optical design expertise; multi-material capabilities enabling gradient index optics; excellent surface quality. Weaknesses: Technology primarily developed for internal use rather than as a commercial printing solution; limited material options compared to specialized optical printing companies; higher costs associated with precision requirements.

Key Innovations in Coating Compatibility for Printed Optics

Material jetting

PatentWO2025133018A1

Innovation

- A computer-implemented method that processes input models to identify vulnerable regions prone to deformation by surface tension-induced flow, and modifies material jetting parameters such as ink volume, curing time, and UV intensity to mitigate these deformations.

3D printer and 3D model printing method based on material jetting type

PatentActiveKR1020210015145A

Innovation

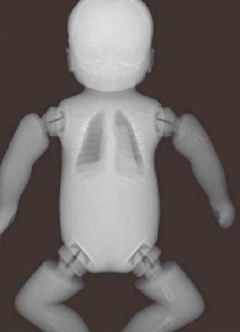

- A 3D printer and printing method that mixes metal nanoparticles with liquid materials to achieve differential radiation attenuation rates, adjusting the mixing ratio to match the attenuation characteristics of various human tissues, using a material injection method with a cartridge, actuator, ejection head, UV curing, and control device to form 3D models.

Manufacturing Process Optimization for Optical Quality

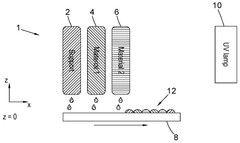

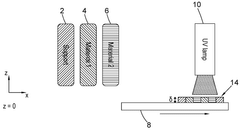

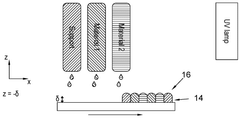

Achieving optimal optical quality in Material Jetting 3D printed optics requires systematic optimization of manufacturing processes. The layer-by-layer deposition characteristic of Material Jetting technology presents unique challenges for optical applications, where surface finish, dimensional accuracy, and material homogeneity are critical parameters.

Process parameter optimization begins with print head calibration and material flow control. Precise control of droplet size, spacing, and deposition rate significantly impacts the final optical performance. Research indicates that jetting temperature must be maintained within ±2°C of the optimal value to ensure consistent viscosity and surface tension properties, which directly affect form accuracy and surface smoothness.

Layer thickness configuration represents another critical variable. Studies have demonstrated that thinner layers (15-25μm) generally yield superior optical clarity but extend production time considerably. A balance must be struck between resolution and manufacturing efficiency, with adaptive layer strategies showing promise for optimizing both aspects simultaneously.

Post-processing techniques have emerged as essential components in the manufacturing workflow. UV curing parameters, including intensity, duration, and wavelength distribution, significantly influence the final material properties. Insufficient curing leads to dimensional instability and yellowing over time, while excessive exposure may introduce internal stresses that affect optical performance.

Surface treatment methodologies have evolved to address scatter reduction requirements. Vapor smoothing using controlled solvent exposure has demonstrated up to 85% reduction in surface roughness in recent studies. Alternative approaches include precision polishing with specialized compounds compatible with printed photopolymers and controlled thermal reflow techniques that preserve geometric accuracy while enhancing surface quality.

Coating compatibility presents unique challenges due to the chemical composition of photopolymer resins. Pre-treatment protocols involving plasma activation or chemical primers have shown promising results in enhancing adhesion properties. Anti-reflective coatings specifically formulated for 3D printed substrates are emerging, with modified deposition parameters to accommodate the thermal sensitivity of printed materials.

Environmental control during manufacturing has proven crucial for repeatability. Temperature fluctuations of even 3°C can introduce significant variations in optical performance between production batches. Humidity control is equally important, as moisture absorption during printing can affect material properties and dimensional stability.

Quality control integration throughout the manufacturing process, rather than end-product inspection alone, enables real-time adjustments. In-situ monitoring systems utilizing machine vision and spectroscopic techniques allow for detection and correction of process deviations before they manifest as optical defects in the finished components.

Process parameter optimization begins with print head calibration and material flow control. Precise control of droplet size, spacing, and deposition rate significantly impacts the final optical performance. Research indicates that jetting temperature must be maintained within ±2°C of the optimal value to ensure consistent viscosity and surface tension properties, which directly affect form accuracy and surface smoothness.

Layer thickness configuration represents another critical variable. Studies have demonstrated that thinner layers (15-25μm) generally yield superior optical clarity but extend production time considerably. A balance must be struck between resolution and manufacturing efficiency, with adaptive layer strategies showing promise for optimizing both aspects simultaneously.

Post-processing techniques have emerged as essential components in the manufacturing workflow. UV curing parameters, including intensity, duration, and wavelength distribution, significantly influence the final material properties. Insufficient curing leads to dimensional instability and yellowing over time, while excessive exposure may introduce internal stresses that affect optical performance.

Surface treatment methodologies have evolved to address scatter reduction requirements. Vapor smoothing using controlled solvent exposure has demonstrated up to 85% reduction in surface roughness in recent studies. Alternative approaches include precision polishing with specialized compounds compatible with printed photopolymers and controlled thermal reflow techniques that preserve geometric accuracy while enhancing surface quality.

Coating compatibility presents unique challenges due to the chemical composition of photopolymer resins. Pre-treatment protocols involving plasma activation or chemical primers have shown promising results in enhancing adhesion properties. Anti-reflective coatings specifically formulated for 3D printed substrates are emerging, with modified deposition parameters to accommodate the thermal sensitivity of printed materials.

Environmental control during manufacturing has proven crucial for repeatability. Temperature fluctuations of even 3°C can introduce significant variations in optical performance between production batches. Humidity control is equally important, as moisture absorption during printing can affect material properties and dimensional stability.

Quality control integration throughout the manufacturing process, rather than end-product inspection alone, enables real-time adjustments. In-situ monitoring systems utilizing machine vision and spectroscopic techniques allow for detection and correction of process deviations before they manifest as optical defects in the finished components.

Material Development for Enhanced Optical Properties

The development of materials for enhanced optical properties represents a critical frontier in Material Jetting (MJ) 3D printing technology. Current photopolymer resins used in MJ systems exhibit limitations in optical clarity, refractive index control, and surface quality that restrict their application in high-performance optical components. Recent advancements have focused on modifying base polymers with nano-additives to achieve specific optical characteristics while maintaining printability.

Silica nanoparticles have emerged as promising additives for improving transparency and reducing light scatter in printed optics. Research indicates that incorporating functionalized silica nanoparticles at concentrations of 0.5-2% can decrease internal scatter by up to 30% compared to unmodified resins. These particles help maintain homogeneity during the curing process, preventing phase separation that typically leads to optical defects.

Hybrid organic-inorganic materials represent another significant development path. Zirconium and titanium-based monomers incorporated into acrylic matrices have demonstrated the ability to increase refractive indices from typical values of 1.48-1.52 to enhanced values of 1.58-1.65. This advancement enables the printing of optical components with improved light-bending capabilities essential for compact optical systems.

Surface modification techniques have evolved to address the persistent challenge of surface roughness in MJ-printed optics. Post-processing methods including vapor smoothing with controlled solvent exposure have shown promising results in reducing surface roughness from typical Ra values of 100-200nm to below 30nm, approaching the optical quality required for visible light applications. Additionally, specialized coating formulations compatible with photopolymer substrates have been developed to enhance scratch resistance and reduce reflectivity.

Multi-material printing capabilities are being leveraged to create gradient refractive index (GRIN) optics, which were previously difficult to manufacture using conventional methods. By precisely controlling the mixing ratios of high and low refractive index materials during the printing process, researchers have demonstrated functional GRIN lenses with customized optical properties. This approach opens new possibilities for designing complex optical systems with fewer components.

Environmental stability remains a significant challenge, as many photopolymers exhibit yellowing and property degradation under UV exposure. Recent material innovations incorporate UV stabilizers and antioxidants directly into the resin formulation, extending the functional lifetime of printed optics from months to several years under normal operating conditions. These stabilized formulations maintain over 90% of their initial optical transmission properties after accelerated aging tests equivalent to three years of indoor use.

Silica nanoparticles have emerged as promising additives for improving transparency and reducing light scatter in printed optics. Research indicates that incorporating functionalized silica nanoparticles at concentrations of 0.5-2% can decrease internal scatter by up to 30% compared to unmodified resins. These particles help maintain homogeneity during the curing process, preventing phase separation that typically leads to optical defects.

Hybrid organic-inorganic materials represent another significant development path. Zirconium and titanium-based monomers incorporated into acrylic matrices have demonstrated the ability to increase refractive indices from typical values of 1.48-1.52 to enhanced values of 1.58-1.65. This advancement enables the printing of optical components with improved light-bending capabilities essential for compact optical systems.

Surface modification techniques have evolved to address the persistent challenge of surface roughness in MJ-printed optics. Post-processing methods including vapor smoothing with controlled solvent exposure have shown promising results in reducing surface roughness from typical Ra values of 100-200nm to below 30nm, approaching the optical quality required for visible light applications. Additionally, specialized coating formulations compatible with photopolymer substrates have been developed to enhance scratch resistance and reduce reflectivity.

Multi-material printing capabilities are being leveraged to create gradient refractive index (GRIN) optics, which were previously difficult to manufacture using conventional methods. By precisely controlling the mixing ratios of high and low refractive index materials during the printing process, researchers have demonstrated functional GRIN lenses with customized optical properties. This approach opens new possibilities for designing complex optical systems with fewer components.

Environmental stability remains a significant challenge, as many photopolymers exhibit yellowing and property degradation under UV exposure. Recent material innovations incorporate UV stabilizers and antioxidants directly into the resin formulation, extending the functional lifetime of printed optics from months to several years under normal operating conditions. These stabilized formulations maintain over 90% of their initial optical transmission properties after accelerated aging tests equivalent to three years of indoor use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!