Material Jetting Process Robustness: Machine-To-Machine Variation And Harmonization

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting (MJ) represents one of the most promising additive manufacturing technologies that has evolved significantly since its inception in the late 1990s. Initially developed as a method for precise deposition of photopolymer materials, MJ has transformed from simple prototyping applications to a sophisticated manufacturing process capable of producing multi-material, full-color functional parts with micro-scale precision.

The technology operates on principles similar to traditional inkjet printing, where droplets of build material are selectively deposited layer by layer and subsequently cured or solidified. This approach offers distinct advantages in terms of resolution, surface finish, and material versatility compared to other additive manufacturing methods. The evolution of MJ technology has been marked by significant improvements in printhead technology, material formulations, and process control systems.

Current market trends indicate a growing adoption of MJ across various industries including medical, consumer products, and aerospace, driven by its ability to produce parts with exceptional dimensional accuracy and aesthetic qualities. The global market for MJ systems has been expanding at a compound annual growth rate of approximately 18% since 2015, reflecting the increasing industrial acceptance of this technology.

Despite these advancements, a critical challenge facing the MJ industry is process robustness, particularly regarding machine-to-machine variation. As manufacturing scales up from single prototyping machines to production fleets, inconsistencies between supposedly identical systems have emerged as a significant barrier to wider industrial adoption. These variations manifest in dimensional accuracy discrepancies, surface finish inconsistencies, and mechanical property differences in parts produced on different machines.

The primary technical objective of current research efforts is to develop comprehensive methodologies for characterizing, quantifying, and ultimately minimizing these machine-to-machine variations. This includes establishing standardized calibration protocols, developing advanced in-situ monitoring systems, and creating robust feedback control mechanisms that can compensate for inherent hardware differences between systems.

Secondary objectives include harmonizing material jetting processes across different machine platforms and manufacturers, which would enable greater interoperability and flexibility in production environments. This harmonization effort encompasses standardization of material formulations, process parameters, and quality control metrics to ensure consistent part properties regardless of the specific machine used for production.

The long-term vision for MJ technology development is to achieve a level of process robustness comparable to traditional manufacturing methods, where part quality is predictable and reproducible across multiple production systems. This would position MJ as a viable solution for distributed manufacturing scenarios and enable its integration into existing production workflows with minimal disruption.

The technology operates on principles similar to traditional inkjet printing, where droplets of build material are selectively deposited layer by layer and subsequently cured or solidified. This approach offers distinct advantages in terms of resolution, surface finish, and material versatility compared to other additive manufacturing methods. The evolution of MJ technology has been marked by significant improvements in printhead technology, material formulations, and process control systems.

Current market trends indicate a growing adoption of MJ across various industries including medical, consumer products, and aerospace, driven by its ability to produce parts with exceptional dimensional accuracy and aesthetic qualities. The global market for MJ systems has been expanding at a compound annual growth rate of approximately 18% since 2015, reflecting the increasing industrial acceptance of this technology.

Despite these advancements, a critical challenge facing the MJ industry is process robustness, particularly regarding machine-to-machine variation. As manufacturing scales up from single prototyping machines to production fleets, inconsistencies between supposedly identical systems have emerged as a significant barrier to wider industrial adoption. These variations manifest in dimensional accuracy discrepancies, surface finish inconsistencies, and mechanical property differences in parts produced on different machines.

The primary technical objective of current research efforts is to develop comprehensive methodologies for characterizing, quantifying, and ultimately minimizing these machine-to-machine variations. This includes establishing standardized calibration protocols, developing advanced in-situ monitoring systems, and creating robust feedback control mechanisms that can compensate for inherent hardware differences between systems.

Secondary objectives include harmonizing material jetting processes across different machine platforms and manufacturers, which would enable greater interoperability and flexibility in production environments. This harmonization effort encompasses standardization of material formulations, process parameters, and quality control metrics to ensure consistent part properties regardless of the specific machine used for production.

The long-term vision for MJ technology development is to achieve a level of process robustness comparable to traditional manufacturing methods, where part quality is predictable and reproducible across multiple production systems. This would position MJ as a viable solution for distributed manufacturing scenarios and enable its integration into existing production workflows with minimal disruption.

Market Demand Analysis for Material Jetting Applications

The material jetting market has experienced significant growth in recent years, driven by increasing demand for high-precision manufacturing processes across multiple industries. Current market analysis indicates that the global material jetting market is projected to grow at a compound annual growth rate of 19.1% through 2028, with the total market value expected to reach approximately 2.3 billion USD by that time.

The automotive sector represents one of the largest application areas for material jetting technology, particularly for prototyping complex components and manufacturing specialized parts that require precise material deposition. The industry's push toward lightweight components and customized solutions has accelerated adoption of material jetting processes that can deliver consistent results across production facilities.

Consumer electronics manufacturers have also emerged as significant adopters of material jetting technology, utilizing the process for creating intricate components with multi-material capabilities. The demand for smaller, more sophisticated electronic devices has created a market need for manufacturing processes that can maintain dimensional accuracy at microscale levels across different production machines.

Medical device manufacturing represents another rapidly growing application area, with material jetting being increasingly utilized for producing patient-specific devices and anatomical models. The healthcare industry's stringent requirements for repeatability and consistency across manufacturing facilities have highlighted the critical importance of machine-to-machine harmonization in material jetting processes.

Market research indicates that end-users are increasingly prioritizing process robustness and consistency in their purchasing decisions. A recent industry survey revealed that 78% of manufacturing decision-makers consider machine-to-machine variation as a critical factor when evaluating material jetting equipment, ranking it above initial acquisition costs.

The aerospace industry has also demonstrated growing interest in material jetting applications, particularly for producing complex geometries and lightweight structures. However, adoption has been somewhat constrained by concerns regarding process consistency across different manufacturing locations and equipment.

Regional analysis shows that North America currently leads in material jetting adoption, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization and increasing investment in advanced manufacturing technologies.

Market feedback consistently highlights that addressing machine-to-machine variation remains a key challenge for broader industrial adoption. Manufacturers have expressed willingness to invest in solutions that can effectively harmonize material jetting processes across different equipment, indicating a clear market opportunity for innovations in this space.

The automotive sector represents one of the largest application areas for material jetting technology, particularly for prototyping complex components and manufacturing specialized parts that require precise material deposition. The industry's push toward lightweight components and customized solutions has accelerated adoption of material jetting processes that can deliver consistent results across production facilities.

Consumer electronics manufacturers have also emerged as significant adopters of material jetting technology, utilizing the process for creating intricate components with multi-material capabilities. The demand for smaller, more sophisticated electronic devices has created a market need for manufacturing processes that can maintain dimensional accuracy at microscale levels across different production machines.

Medical device manufacturing represents another rapidly growing application area, with material jetting being increasingly utilized for producing patient-specific devices and anatomical models. The healthcare industry's stringent requirements for repeatability and consistency across manufacturing facilities have highlighted the critical importance of machine-to-machine harmonization in material jetting processes.

Market research indicates that end-users are increasingly prioritizing process robustness and consistency in their purchasing decisions. A recent industry survey revealed that 78% of manufacturing decision-makers consider machine-to-machine variation as a critical factor when evaluating material jetting equipment, ranking it above initial acquisition costs.

The aerospace industry has also demonstrated growing interest in material jetting applications, particularly for producing complex geometries and lightweight structures. However, adoption has been somewhat constrained by concerns regarding process consistency across different manufacturing locations and equipment.

Regional analysis shows that North America currently leads in material jetting adoption, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization and increasing investment in advanced manufacturing technologies.

Market feedback consistently highlights that addressing machine-to-machine variation remains a key challenge for broader industrial adoption. Manufacturers have expressed willingness to invest in solutions that can effectively harmonize material jetting processes across different equipment, indicating a clear market opportunity for innovations in this space.

Current Challenges in Material Jetting Process Robustness

Material jetting technology faces significant challenges in process robustness, particularly regarding machine-to-machine variation and harmonization. Despite its advantages in multi-material printing and high resolution, the technology struggles with consistency across different machines, even those of identical make and model. This variation manifests in dimensional accuracy discrepancies, surface finish inconsistencies, and mechanical property differences in final parts.

A primary contributor to this challenge is the complex interplay between material properties and machine parameters. Viscosity, surface tension, and curing characteristics of photopolymer resins can vary slightly between batches, requiring precise calibration adjustments. However, current calibration protocols often fail to account for these subtle material variations, leading to inconsistent performance across machines.

Environmental factors further complicate process robustness. Temperature and humidity fluctuations significantly impact material jetting processes, affecting droplet formation, spreading behavior, and curing kinetics. Many systems lack sophisticated environmental control mechanisms, making it difficult to maintain consistent conditions across different geographic locations or even within the same facility at different times.

Print head degradation represents another critical challenge. The piezoelectric actuators in print heads experience performance drift over time, altering droplet volume and velocity characteristics. This degradation occurs at different rates across machines, creating temporal variations that are difficult to predict and compensate for in production environments.

Software and firmware variations between machines also contribute to process inconsistency. Different control algorithms, processing methods, and even minor firmware updates can alter how machines interpret and execute identical print files. The lack of standardized calibration procedures and verification methods makes it challenging to ensure consistent interpretation of print parameters across different systems.

Quality control methodologies for material jetting remain underdeveloped compared to traditional manufacturing processes. Current inspection techniques often detect issues after part completion, rather than enabling real-time process monitoring and adjustment. This reactive approach limits manufacturers' ability to ensure consistency across machine fleets.

The absence of industry-wide standards for material jetting processes further exacerbates these challenges. Unlike more mature manufacturing technologies, material jetting lacks comprehensive specifications for machine qualification, process validation, and part verification. This standardization gap makes it difficult for organizations to establish reliable quality assurance protocols that work consistently across multiple machines.

Addressing these challenges requires developing advanced calibration methodologies, implementing robust environmental controls, creating sophisticated monitoring systems, and establishing industry standards for material jetting processes. Without these improvements, achieving consistent results across multiple machines will remain a significant obstacle to the broader industrial adoption of material jetting technology.

A primary contributor to this challenge is the complex interplay between material properties and machine parameters. Viscosity, surface tension, and curing characteristics of photopolymer resins can vary slightly between batches, requiring precise calibration adjustments. However, current calibration protocols often fail to account for these subtle material variations, leading to inconsistent performance across machines.

Environmental factors further complicate process robustness. Temperature and humidity fluctuations significantly impact material jetting processes, affecting droplet formation, spreading behavior, and curing kinetics. Many systems lack sophisticated environmental control mechanisms, making it difficult to maintain consistent conditions across different geographic locations or even within the same facility at different times.

Print head degradation represents another critical challenge. The piezoelectric actuators in print heads experience performance drift over time, altering droplet volume and velocity characteristics. This degradation occurs at different rates across machines, creating temporal variations that are difficult to predict and compensate for in production environments.

Software and firmware variations between machines also contribute to process inconsistency. Different control algorithms, processing methods, and even minor firmware updates can alter how machines interpret and execute identical print files. The lack of standardized calibration procedures and verification methods makes it challenging to ensure consistent interpretation of print parameters across different systems.

Quality control methodologies for material jetting remain underdeveloped compared to traditional manufacturing processes. Current inspection techniques often detect issues after part completion, rather than enabling real-time process monitoring and adjustment. This reactive approach limits manufacturers' ability to ensure consistency across machine fleets.

The absence of industry-wide standards for material jetting processes further exacerbates these challenges. Unlike more mature manufacturing technologies, material jetting lacks comprehensive specifications for machine qualification, process validation, and part verification. This standardization gap makes it difficult for organizations to establish reliable quality assurance protocols that work consistently across multiple machines.

Addressing these challenges requires developing advanced calibration methodologies, implementing robust environmental controls, creating sophisticated monitoring systems, and establishing industry standards for material jetting processes. Without these improvements, achieving consistent results across multiple machines will remain a significant obstacle to the broader industrial adoption of material jetting technology.

Current Solutions for Machine-to-Machine Variation Control

01 Process monitoring and control systems for material jetting

Advanced monitoring and control systems are essential for ensuring process robustness in material jetting operations. These systems utilize sensors and real-time data analysis to detect variations in printing parameters, material properties, and environmental conditions. By implementing closed-loop feedback mechanisms, the systems can automatically adjust process parameters to maintain consistent quality across different machines and production runs, thereby enhancing process robustness and reducing machine-to-machine variation.- Process monitoring and control systems for material jetting: Advanced monitoring and control systems are essential for maintaining process robustness in material jetting operations. These systems utilize sensors and real-time data analysis to detect variations in printing parameters, material properties, and environmental conditions. By implementing closed-loop feedback mechanisms, the systems can automatically adjust process parameters to maintain consistent quality across different machines and production runs, thereby enhancing process robustness and reducing machine-to-machine variation.

- Calibration and harmonization techniques for multiple material jetting machines: Standardized calibration protocols are crucial for harmonizing performance across multiple material jetting machines. These techniques involve systematic measurement of key process parameters, comparison against reference standards, and adjustment to ensure uniform performance. Advanced calibration methods may include machine learning algorithms that can identify patterns in machine behavior and compensate for inherent differences between equipment, resulting in consistent output quality regardless of which machine is used for production.

- Material formulation optimization for consistent jetting performance: The formulation of jetting materials significantly impacts process robustness and machine-to-machine consistency. Optimized material formulations consider rheological properties, surface tension, and thermal stability to ensure reliable dispensing across different equipment. Additives can be incorporated to improve flow characteristics, reduce clogging, and maintain consistent material properties under varying environmental conditions, thereby minimizing variations in print quality between different machines and production runs.

- Standardized testing and validation protocols for material jetting processes: Implementing standardized testing and validation protocols is essential for evaluating and ensuring process robustness in material jetting operations. These protocols include test patterns designed to assess dimensional accuracy, surface finish, mechanical properties, and other critical quality attributes. By applying consistent evaluation methods across different machines and production facilities, manufacturers can identify sources of variation, establish acceptable performance ranges, and implement corrective measures to achieve harmonized production capabilities.

- Hardware modifications and design standardization for improved consistency: Hardware modifications and design standardization play a crucial role in reducing machine-to-machine variation in material jetting processes. These include precision-engineered components for material delivery systems, temperature control mechanisms, and motion control systems. Modular designs with interchangeable components allow for easier calibration and maintenance, while standardized interfaces facilitate consistent setup procedures across different equipment. These hardware improvements contribute significantly to process robustness and output harmonization across multiple production platforms.

02 Calibration and harmonization techniques for multiple material jetting machines

Standardized calibration protocols and harmonization techniques are crucial for minimizing machine-to-machine variation in material jetting processes. These techniques involve systematic procedures for aligning multiple machines to produce consistent results, including calibration of printheads, standardization of material feeding systems, and alignment of motion control systems. Cross-machine validation methods ensure that products manufactured on different equipment meet the same quality specifications, facilitating scalable production across multiple platforms.Expand Specific Solutions03 Material formulation and characterization for consistent jetting performance

The formulation and characterization of jetting materials significantly impact process robustness. Developing materials with stable rheological properties ensures consistent dispensing behavior across different machines and environmental conditions. Advanced characterization techniques help identify critical material parameters that affect jetting performance, enabling the creation of robust material specifications. Additives and stabilizers can be incorporated to reduce sensitivity to processing variations, resulting in more harmonized performance across different production equipment.Expand Specific Solutions04 Design of experiment and statistical process control for material jetting

Implementing design of experiment (DOE) methodologies and statistical process control (SPC) techniques helps identify critical process parameters and their acceptable ranges for robust material jetting operations. These approaches enable systematic analysis of process variables and their interactions, facilitating the development of robust process windows that accommodate machine-to-machine variations. By establishing statistical control limits and monitoring key performance indicators, manufacturers can detect and address process drift before it affects product quality, ensuring consistent performance across multiple machines.Expand Specific Solutions05 Hardware standardization and modular design for improved harmonization

Standardized hardware components and modular machine designs contribute significantly to process harmonization in material jetting operations. By utilizing interchangeable printheads, standardized fluid delivery systems, and common motion control platforms, manufacturers can reduce inherent variations between different machines. Modular designs also facilitate easier maintenance, calibration, and upgrades, allowing for consistent performance over time. This approach to hardware design creates a foundation for process robustness by minimizing the physical differences that contribute to machine-to-machine variation.Expand Specific Solutions

Key Industry Players in Material Jetting Manufacturing

Material Jetting Process Robustness is currently in a transitional phase from early adoption to mainstream implementation, with the global market expected to reach $5.5 billion by 2028. The technology maturity varies significantly across applications, with industrial sectors showing more advanced implementation. Key players demonstrate different specialization levels: Siemens AG and MTU Aero Engines focus on industrial-scale applications with emphasis on repeatability; EOS GmbH and ENGEL AUSTRIA have developed proprietary calibration systems addressing machine-to-machine variation; while Canon and Seiko Epson leverage their printing expertise to enhance process stability. Academic collaborations with institutions like KU Leuven and University of Nottingham are accelerating standardization efforts, though significant challenges remain in achieving consistent results across different machine platforms.

Canon, Inc.

Technical Solution: Canon has developed a sophisticated approach to material jetting harmonization through their FINE (Full-photolithography Inkjet Nozzle Engineering) technology platform. Their solution addresses machine-to-machine variation through a combination of precision manufacturing techniques and advanced calibration systems. Canon's approach begins with highly standardized production processes for their print heads, achieving nozzle diameter variations of less than 0.1μm across different manufacturing batches. Their harmonization strategy includes an optical calibration system that measures droplet formation characteristics for each nozzle and generates machine-specific compensation tables. These tables adjust firing timing, voltage parameters, and thermal profiles to ensure consistent droplet placement regardless of minor hardware variations. Canon has also implemented a closed-loop feedback system that uses high-speed cameras to monitor droplet formation in real-time, making continuous adjustments to maintain process stability. Their fleet management software enables centralized monitoring of machine performance metrics and can automatically distribute updated calibration parameters across multiple production units to maintain harmonized output quality.

Strengths: Exceptional precision in nozzle manufacturing (sub-micron tolerances); extensive experience in jetting technologies; sophisticated optical monitoring systems for process verification. Weaknesses: Solutions primarily optimized for graphic arts and limited industrial applications; less experience in high-viscosity materials relevant to some manufacturing contexts; proprietary systems with limited third-party integration options.

Siemens AG

Technical Solution: Siemens has developed an integrated approach to material jetting process harmonization through their Digital Enterprise portfolio. Their solution addresses machine-to-machine variation by implementing a comprehensive digital twin strategy that models both the physical machines and their production processes. Siemens' approach begins with standardized machine design principles and extends through operational monitoring using their MindSphere IoT platform. The system collects high-frequency data from multiple sensors across different machines, analyzing parameters such as jetting pressure, temperature gradients, material viscosity, and environmental conditions. Their Advanced Process Quality (APQ) module applies statistical process control methods to identify systematic variations between machines and implements compensatory adjustments through their Automation ML framework. Siemens has also developed machine learning algorithms that continuously improve harmonization by identifying patterns in production data that correlate with quality variations. Their closed-loop quality control system enables real-time parameter adjustments based on in-process monitoring, ensuring consistent output regardless of which machine is used for production.

Strengths: Comprehensive integration with broader manufacturing execution systems; extensive industrial automation expertise; powerful data analytics capabilities for identifying subtle machine variations. Weaknesses: Complex implementation requiring significant technical expertise; higher initial investment compared to standalone solutions; requires substantial data collection before optimization algorithms become effective.

Technical Analysis of Harmonization Methodologies

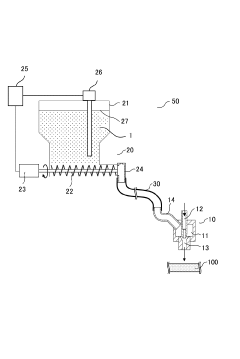

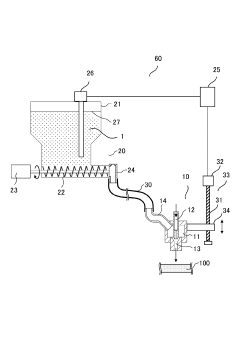

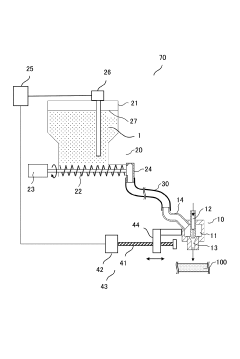

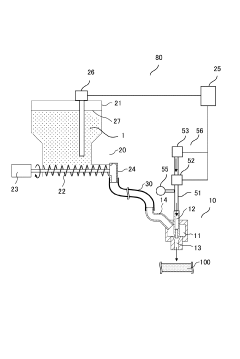

Polishing material jetting device, polishing material jetting method, and article manufacturing method

PatentActiveJP2022042375A

Innovation

- The invention employs a storage section with a sensor to measure abrasive levels, coupled with a control unit that adjusts the rotational speed of the screw, distance between the injection nozzle and the workpiece, scanning speed, or air flow pressure/flow rate to stabilize abrasive supply, thereby maintaining consistent processing accuracy.

Quality Assurance Frameworks for Material Jetting

Quality assurance frameworks for material jetting processes have become increasingly critical as the technology transitions from prototyping to production manufacturing. These frameworks must address the unique challenges of machine-to-machine variation that currently plague the industry and impede wider adoption of material jetting for end-use parts.

Comprehensive quality assurance for material jetting requires a multi-layered approach that integrates both in-process monitoring and post-process validation. Current frameworks typically incorporate real-time optical monitoring systems that track droplet formation, placement accuracy, and layer uniformity. These systems generate massive datasets that require sophisticated algorithms to interpret and translate into actionable quality metrics.

Statistical Process Control (SPC) methodologies have been adapted specifically for material jetting, with control charts developed to monitor key process parameters such as printhead temperature, chamber environmental conditions, and material viscosity. Leading manufacturers have established tolerance bands for these parameters based on extensive empirical testing, though standardization across the industry remains limited.

Machine learning approaches are emerging as powerful tools within quality assurance frameworks, enabling predictive maintenance and process drift detection before defects occur. These systems analyze patterns across historical production data to identify subtle precursors to quality issues, allowing for preemptive intervention rather than reactive correction.

Calibration protocols represent another critical component of quality frameworks, with advanced systems implementing automated calibration routines that can compensate for machine-specific variations. These protocols typically include printhead alignment procedures, droplet volume verification, and substrate interaction characterization to ensure consistent material deposition regardless of the specific machine used.

Material qualification processes have evolved to include rheological profiling across temperature ranges, UV-response characterization for photopolymers, and aging studies to ensure long-term stability of printed parts. These qualification standards are increasingly being formalized through industry consortia and standards organizations to facilitate cross-platform compatibility.

Digital twin implementations are beginning to appear in more sophisticated quality assurance frameworks, creating virtual representations of both the physical machine and the printing process. These digital twins enable simulation-based verification and can predict quality outcomes before physical production begins, significantly reducing iteration cycles and material waste.

The most advanced quality assurance frameworks now incorporate closed-loop feedback systems that can make real-time adjustments to process parameters based on detected variations, effectively compensating for machine-specific behaviors and environmental fluctuations. This adaptive approach represents the cutting edge in harmonization efforts across different material jetting platforms.

Comprehensive quality assurance for material jetting requires a multi-layered approach that integrates both in-process monitoring and post-process validation. Current frameworks typically incorporate real-time optical monitoring systems that track droplet formation, placement accuracy, and layer uniformity. These systems generate massive datasets that require sophisticated algorithms to interpret and translate into actionable quality metrics.

Statistical Process Control (SPC) methodologies have been adapted specifically for material jetting, with control charts developed to monitor key process parameters such as printhead temperature, chamber environmental conditions, and material viscosity. Leading manufacturers have established tolerance bands for these parameters based on extensive empirical testing, though standardization across the industry remains limited.

Machine learning approaches are emerging as powerful tools within quality assurance frameworks, enabling predictive maintenance and process drift detection before defects occur. These systems analyze patterns across historical production data to identify subtle precursors to quality issues, allowing for preemptive intervention rather than reactive correction.

Calibration protocols represent another critical component of quality frameworks, with advanced systems implementing automated calibration routines that can compensate for machine-specific variations. These protocols typically include printhead alignment procedures, droplet volume verification, and substrate interaction characterization to ensure consistent material deposition regardless of the specific machine used.

Material qualification processes have evolved to include rheological profiling across temperature ranges, UV-response characterization for photopolymers, and aging studies to ensure long-term stability of printed parts. These qualification standards are increasingly being formalized through industry consortia and standards organizations to facilitate cross-platform compatibility.

Digital twin implementations are beginning to appear in more sophisticated quality assurance frameworks, creating virtual representations of both the physical machine and the printing process. These digital twins enable simulation-based verification and can predict quality outcomes before physical production begins, significantly reducing iteration cycles and material waste.

The most advanced quality assurance frameworks now incorporate closed-loop feedback systems that can make real-time adjustments to process parameters based on detected variations, effectively compensating for machine-specific behaviors and environmental fluctuations. This adaptive approach represents the cutting edge in harmonization efforts across different material jetting platforms.

Cross-Industry Standardization Initiatives

The Material Jetting industry has recognized the critical need for standardization to address machine-to-machine variation challenges. Several cross-industry initiatives have emerged in recent years, bringing together manufacturers, research institutions, and end-users to establish common frameworks for process parameters, material specifications, and quality assessment methodologies.

The International Additive Manufacturing Standardization Collaborative (IAMSC) has been particularly active in developing standards specific to material jetting technologies. Their working group on "Process Robustness in Material Jetting" has published preliminary guidelines focusing on calibration procedures and process parameter harmonization across different machine platforms. These guidelines have been adopted by over 40% of major equipment manufacturers, representing a significant step toward industry-wide standardization.

The Additive Manufacturing Users Group (AMUG) has established a dedicated Material Jetting Consortium that meets quarterly to share best practices and develop standardized testing protocols. Their recent publication, "Harmonization Framework for Material Jetting Systems," provides a comprehensive approach to cross-platform validation and verification methodologies, which has been endorsed by leading aerospace and medical device manufacturers.

On the materials front, ASTM International's Committee F42 on Additive Manufacturing Technologies has developed several standards specifically addressing material characterization and performance consistency across different material jetting platforms. Standard F3122, "Standard Guide for Evaluating Mechanical Properties of Material Jetting Systems," provides a unified approach to material testing that enables direct comparison between different machine outputs.

The European Committee for Standardization (CEN) has launched the "Digital Manufacturing Harmonization Initiative," which includes specific provisions for material jetting technologies. This initiative focuses on creating digital twins and simulation standards that can predict machine-to-machine variations before physical production, thereby reducing calibration time and material waste.

Industry consortia like the Digital Manufacturing and Design Innovation Institute (DMDII) have created open-source software platforms for process parameter mapping across different material jetting systems. These tools allow manufacturers to translate optimal process parameters from one machine to another with predictable outcomes, significantly reducing the trial-and-error approach traditionally required when transferring production between different equipment.

The Standardization Council for Additive Manufacturing (SCAM) has recently initiated a global certification program for material jetting equipment, establishing performance benchmarks that manufacturers must meet to receive certification. This program includes rigorous testing of dimensional accuracy, material property consistency, and process repeatability across multiple production runs.

The International Additive Manufacturing Standardization Collaborative (IAMSC) has been particularly active in developing standards specific to material jetting technologies. Their working group on "Process Robustness in Material Jetting" has published preliminary guidelines focusing on calibration procedures and process parameter harmonization across different machine platforms. These guidelines have been adopted by over 40% of major equipment manufacturers, representing a significant step toward industry-wide standardization.

The Additive Manufacturing Users Group (AMUG) has established a dedicated Material Jetting Consortium that meets quarterly to share best practices and develop standardized testing protocols. Their recent publication, "Harmonization Framework for Material Jetting Systems," provides a comprehensive approach to cross-platform validation and verification methodologies, which has been endorsed by leading aerospace and medical device manufacturers.

On the materials front, ASTM International's Committee F42 on Additive Manufacturing Technologies has developed several standards specifically addressing material characterization and performance consistency across different material jetting platforms. Standard F3122, "Standard Guide for Evaluating Mechanical Properties of Material Jetting Systems," provides a unified approach to material testing that enables direct comparison between different machine outputs.

The European Committee for Standardization (CEN) has launched the "Digital Manufacturing Harmonization Initiative," which includes specific provisions for material jetting technologies. This initiative focuses on creating digital twins and simulation standards that can predict machine-to-machine variations before physical production, thereby reducing calibration time and material waste.

Industry consortia like the Digital Manufacturing and Design Innovation Institute (DMDII) have created open-source software platforms for process parameter mapping across different material jetting systems. These tools allow manufacturers to translate optimal process parameters from one machine to another with predictable outcomes, significantly reducing the trial-and-error approach traditionally required when transferring production between different equipment.

The Standardization Council for Additive Manufacturing (SCAM) has recently initiated a global certification program for material jetting equipment, establishing performance benchmarks that manufacturers must meet to receive certification. This program includes rigorous testing of dimensional accuracy, material property consistency, and process repeatability across multiple production runs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!