How Material Jetting Suppresses Satellite Formation Through Waveform And Fluid Control?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material jetting technology has evolved significantly over the past three decades, originating from conventional inkjet printing technologies in the 1980s. This additive manufacturing process has transformed from simple document printing to sophisticated 3D fabrication methods capable of producing complex multi-material structures with high precision. The fundamental principle involves the selective deposition of liquid material droplets that subsequently solidify through various mechanisms including cooling, evaporation, or chemical reactions.

The evolution of material jetting has been marked by several key milestones, including the development of piezoelectric and thermal inkjet technologies, continuous inkjet systems, and more recently, electrohydrodynamic jetting. Each advancement has progressively improved resolution, material compatibility, and process control, enabling applications across diverse industries from biomedical to electronics manufacturing.

A persistent challenge in material jetting processes has been satellite droplet formation—unintended smaller droplets that accompany the main droplet during ejection. These satellites significantly compromise print quality, dimensional accuracy, and material waste efficiency. The formation of these satellite droplets represents a complex fluid dynamics problem influenced by multiple parameters including surface tension, viscosity, and jetting waveform characteristics.

Current technological trends are moving toward greater precision in droplet formation control through advanced waveform engineering and fluid property manipulation. Research indicates that carefully designed bipolar and tripolar waveforms can substantially reduce satellite formation by controlling the necking behavior of the fluid column during droplet ejection. Additionally, tailoring fluid properties through additives and temperature control provides another avenue for satellite suppression.

The primary objective of current material jetting research is to develop comprehensive strategies that combine optimized waveform designs with precise fluid property control to eliminate satellite formation while maintaining high throughput and compatibility with a wide range of materials. This includes establishing predictive models that can anticipate satellite formation based on fluid properties and jetting parameters, enabling real-time adjustments during manufacturing processes.

Secondary objectives include expanding the range of jettable materials, particularly high-viscosity fluids and non-Newtonian materials that traditionally present significant challenges for clean droplet formation. The ultimate goal is to achieve satellite-free jetting across diverse material systems, enabling higher resolution, improved surface quality, and enhanced functional performance of jetted structures in applications ranging from printed electronics to bioprinting.

The evolution of material jetting has been marked by several key milestones, including the development of piezoelectric and thermal inkjet technologies, continuous inkjet systems, and more recently, electrohydrodynamic jetting. Each advancement has progressively improved resolution, material compatibility, and process control, enabling applications across diverse industries from biomedical to electronics manufacturing.

A persistent challenge in material jetting processes has been satellite droplet formation—unintended smaller droplets that accompany the main droplet during ejection. These satellites significantly compromise print quality, dimensional accuracy, and material waste efficiency. The formation of these satellite droplets represents a complex fluid dynamics problem influenced by multiple parameters including surface tension, viscosity, and jetting waveform characteristics.

Current technological trends are moving toward greater precision in droplet formation control through advanced waveform engineering and fluid property manipulation. Research indicates that carefully designed bipolar and tripolar waveforms can substantially reduce satellite formation by controlling the necking behavior of the fluid column during droplet ejection. Additionally, tailoring fluid properties through additives and temperature control provides another avenue for satellite suppression.

The primary objective of current material jetting research is to develop comprehensive strategies that combine optimized waveform designs with precise fluid property control to eliminate satellite formation while maintaining high throughput and compatibility with a wide range of materials. This includes establishing predictive models that can anticipate satellite formation based on fluid properties and jetting parameters, enabling real-time adjustments during manufacturing processes.

Secondary objectives include expanding the range of jettable materials, particularly high-viscosity fluids and non-Newtonian materials that traditionally present significant challenges for clean droplet formation. The ultimate goal is to achieve satellite-free jetting across diverse material systems, enabling higher resolution, improved surface quality, and enhanced functional performance of jetted structures in applications ranging from printed electronics to bioprinting.

Market Applications and Demand Analysis

Material jetting technology with advanced satellite suppression capabilities is experiencing robust market demand across multiple high-value industries. The global additive manufacturing market, where material jetting is a key technology, is projected to reach $51 billion by 2030, with material jetting segments showing particularly strong growth rates of 15-20% annually due to precision improvements.

The electronics manufacturing sector represents the largest application area, with circuit board printing and semiconductor packaging demanding increasingly precise droplet placement without satellite formation. The elimination of satellites through waveform and fluid control has enabled the production of finer circuit traces below 20 microns, addressing the miniaturization requirements of next-generation electronic devices. This precision capability has expanded the addressable market for material jetting by approximately 30% in the electronics sector alone.

Medical device manufacturing constitutes another significant market segment, particularly for the production of microfluidic devices, lab-on-chip solutions, and drug delivery systems. The healthcare 3D printing market is growing at 18% annually, with material jetting applications benefiting from satellite suppression technologies that ensure biocompatibility and precise dosing capabilities. Pharmaceutical companies are increasingly adopting these systems for personalized medicine applications, creating a new market segment estimated at $2.5 billion by 2025.

Aerospace and automotive industries are rapidly expanding their utilization of material jetting for prototyping and production of functional components. The demand is driven by the ability to create multi-material parts with complex internal geometries that maintain structural integrity without the defects caused by satellite droplets. The aerospace sector alone has increased material jetting adoption by 25% year-over-year, primarily for lightweight component manufacturing.

Consumer product manufacturing represents an emerging market opportunity, with companies leveraging satellite-free material jetting for customized products with superior surface finishes. The market for custom consumer goods produced via advanced 3D printing technologies is growing at 22% annually, with material jetting capturing an increasing share due to its superior aesthetic qualities.

The geographical distribution of demand shows North America leading with 40% market share, followed by Europe at 30% and Asia-Pacific at 25%, with the latter showing the fastest growth rate. Industry surveys indicate that 78% of manufacturing companies plan to increase investment in precision additive manufacturing technologies over the next three years, with satellite suppression capabilities frequently cited as a critical decision factor for material jetting adoption.

The electronics manufacturing sector represents the largest application area, with circuit board printing and semiconductor packaging demanding increasingly precise droplet placement without satellite formation. The elimination of satellites through waveform and fluid control has enabled the production of finer circuit traces below 20 microns, addressing the miniaturization requirements of next-generation electronic devices. This precision capability has expanded the addressable market for material jetting by approximately 30% in the electronics sector alone.

Medical device manufacturing constitutes another significant market segment, particularly for the production of microfluidic devices, lab-on-chip solutions, and drug delivery systems. The healthcare 3D printing market is growing at 18% annually, with material jetting applications benefiting from satellite suppression technologies that ensure biocompatibility and precise dosing capabilities. Pharmaceutical companies are increasingly adopting these systems for personalized medicine applications, creating a new market segment estimated at $2.5 billion by 2025.

Aerospace and automotive industries are rapidly expanding their utilization of material jetting for prototyping and production of functional components. The demand is driven by the ability to create multi-material parts with complex internal geometries that maintain structural integrity without the defects caused by satellite droplets. The aerospace sector alone has increased material jetting adoption by 25% year-over-year, primarily for lightweight component manufacturing.

Consumer product manufacturing represents an emerging market opportunity, with companies leveraging satellite-free material jetting for customized products with superior surface finishes. The market for custom consumer goods produced via advanced 3D printing technologies is growing at 22% annually, with material jetting capturing an increasing share due to its superior aesthetic qualities.

The geographical distribution of demand shows North America leading with 40% market share, followed by Europe at 30% and Asia-Pacific at 25%, with the latter showing the fastest growth rate. Industry surveys indicate that 78% of manufacturing companies plan to increase investment in precision additive manufacturing technologies over the next three years, with satellite suppression capabilities frequently cited as a critical decision factor for material jetting adoption.

Current Challenges in Satellite Droplet Formation

Satellite droplet formation represents one of the most significant challenges in material jetting technologies, affecting print quality, resolution, and material waste. These unintended secondary droplets form during the ejection process when the liquid thread connecting the main droplet to the nozzle breaks up irregularly. Current industrial applications struggle with satellite formation across various viscosity ranges, particularly in high-precision manufacturing sectors such as printed electronics, bioprinting, and advanced materials deposition.

The primary physical mechanisms driving satellite formation include surface tension effects, viscoelastic properties of printing fluids, and complex fluid-nozzle interactions. Recent experimental studies have demonstrated that satellite formation becomes particularly problematic when the Weber number (ratio of inertial forces to surface tension) falls within specific critical ranges, creating unstable breakup regimes that are difficult to control consistently across production runs.

Material-specific challenges further complicate satellite suppression efforts. High-viscosity materials tend to form elongated filaments that break into multiple satellites, while low-viscosity fluids may generate numerous tiny satellites due to capillary instabilities. Additionally, non-Newtonian fluids exhibit time-dependent rheological behaviors that make waveform optimization exceptionally difficult, as the same driving signal may produce different ejection behaviors depending on the fluid's shear history.

Current industrial approaches to mitigate satellite formation include empirical waveform tuning, which lacks theoretical foundations and requires extensive trial-and-error testing for each new material. Temperature control systems attempt to stabilize fluid properties but introduce thermal gradients that can create inconsistent ejection behaviors across the printhead. Nozzle geometry modifications show promise but face manufacturing limitations in achieving optimal designs at commercial scales.

The measurement and detection of satellite droplets present another significant challenge. High-speed imaging systems currently used for characterization operate at frame rates insufficient to capture the complete dynamics of satellite formation, which occurs on microsecond timescales. This limitation creates blind spots in understanding the precise mechanisms of satellite suppression when implementing control strategies.

Computational fluid dynamics (CFD) models have advanced significantly but still struggle to accurately predict satellite formation across diverse material properties. The multi-physics nature of the problem—involving surface tension, viscoelasticity, and thermal effects—creates computational challenges that limit the predictive power of current simulation approaches, especially for complex industrial fluids with proprietary formulations.

The primary physical mechanisms driving satellite formation include surface tension effects, viscoelastic properties of printing fluids, and complex fluid-nozzle interactions. Recent experimental studies have demonstrated that satellite formation becomes particularly problematic when the Weber number (ratio of inertial forces to surface tension) falls within specific critical ranges, creating unstable breakup regimes that are difficult to control consistently across production runs.

Material-specific challenges further complicate satellite suppression efforts. High-viscosity materials tend to form elongated filaments that break into multiple satellites, while low-viscosity fluids may generate numerous tiny satellites due to capillary instabilities. Additionally, non-Newtonian fluids exhibit time-dependent rheological behaviors that make waveform optimization exceptionally difficult, as the same driving signal may produce different ejection behaviors depending on the fluid's shear history.

Current industrial approaches to mitigate satellite formation include empirical waveform tuning, which lacks theoretical foundations and requires extensive trial-and-error testing for each new material. Temperature control systems attempt to stabilize fluid properties but introduce thermal gradients that can create inconsistent ejection behaviors across the printhead. Nozzle geometry modifications show promise but face manufacturing limitations in achieving optimal designs at commercial scales.

The measurement and detection of satellite droplets present another significant challenge. High-speed imaging systems currently used for characterization operate at frame rates insufficient to capture the complete dynamics of satellite formation, which occurs on microsecond timescales. This limitation creates blind spots in understanding the precise mechanisms of satellite suppression when implementing control strategies.

Computational fluid dynamics (CFD) models have advanced significantly but still struggle to accurately predict satellite formation across diverse material properties. The multi-physics nature of the problem—involving surface tension, viscoelasticity, and thermal effects—creates computational challenges that limit the predictive power of current simulation approaches, especially for complex industrial fluids with proprietary formulations.

Current Waveform and Fluid Parameter Solutions

01 Ink composition modification for satellite suppression

Modifying the ink composition can effectively suppress satellite formation during material jetting processes. By adjusting viscosity, surface tension, and incorporating specific additives, the ink can maintain better droplet integrity. Formulations with optimized rheological properties help prevent the formation of smaller satellite droplets that typically trail behind the main droplet. These modifications can include adding polymeric thickeners, surfactants, or other rheology modifiers that control droplet break-off dynamics.- Waveform and pulse control techniques: Controlling the waveform and pulse characteristics during material jetting can significantly reduce satellite formation. By optimizing parameters such as pulse duration, amplitude, and frequency, the formation of unwanted droplets can be minimized. Advanced waveform designs that incorporate pre-pulses, main pulses, and echo-dampening phases help maintain droplet integrity and prevent satellite formation during the jetting process.

- Fluid composition modification: Modifying the rheological properties of jetting materials is an effective approach to suppress satellite formation. By adjusting viscosity, surface tension, and incorporating additives such as surfactants or polymers, the fluid behavior during jetting can be controlled. These modifications help maintain droplet cohesion and prevent the formation of satellite droplets during the breakoff process, resulting in more precise material deposition.

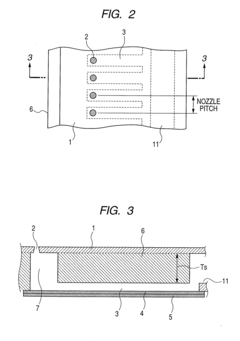

- Nozzle design optimization: The geometry and surface properties of jetting nozzles significantly impact satellite formation. Optimized nozzle designs featuring specific orifice shapes, hydrophobic or hydrophilic coatings, and carefully engineered internal flow paths can reduce satellite droplets. Advanced nozzle configurations help control the fluid meniscus behavior and breakoff dynamics, leading to cleaner droplet formation and ejection.

- Environmental and operational condition control: Controlling the environmental and operational conditions during material jetting processes helps suppress satellite formation. Factors such as temperature regulation, humidity control, gas flow management, and substrate positioning can significantly impact droplet formation dynamics. Maintaining optimal environmental conditions ensures consistent jetting behavior and reduces the likelihood of satellite droplet generation.

- Real-time monitoring and feedback systems: Implementing real-time monitoring and feedback control systems enables dynamic adjustment of jetting parameters to suppress satellite formation. These systems use high-speed imaging, droplet trajectory analysis, and advanced algorithms to detect potential satellite formation and automatically adjust printing parameters. This adaptive approach allows for continuous optimization of the jetting process, resulting in higher precision and reduced satellite droplets.

02 Waveform and voltage control techniques

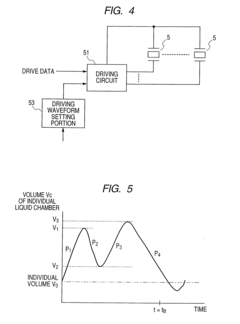

Precise control of the electrical waveform and voltage parameters applied to piezoelectric actuators can significantly reduce satellite formation. By optimizing the pulse shape, duration, and amplitude, the ejection dynamics can be fine-tuned to ensure clean droplet formation. Advanced waveform designs featuring specific rise and fall times, dwell periods, and multi-pulse sequences help control the meniscus behavior and prevent satellite droplets from forming during the jetting process.Expand Specific Solutions03 Nozzle design optimization

The geometric design of the nozzle plays a crucial role in preventing satellite formation during material jetting. Features such as nozzle diameter, shape, surface treatment, and exit geometry can be optimized to improve droplet formation. Specially designed nozzles with hydrophobic coatings or tapered profiles help control the fluid flow dynamics and break-off characteristics, resulting in more uniform droplets without satellites. Some designs incorporate flow restrictors or special channel geometries to stabilize the jetting process.Expand Specific Solutions04 Temperature management systems

Implementing precise temperature control systems throughout the material jetting process can effectively reduce satellite formation. By maintaining optimal temperature conditions for the printing material, its viscosity and surface tension remain consistent, leading to more predictable droplet formation. Temperature management includes both heating and cooling elements strategically placed at the printhead, reservoir, and substrate to ensure thermal uniformity and prevent variations that could lead to satellite droplets.Expand Specific Solutions05 Real-time monitoring and feedback control

Advanced systems incorporating real-time monitoring and feedback control mechanisms can detect and correct conditions that lead to satellite formation. Using high-speed cameras, optical sensors, or other detection methods, these systems analyze droplet formation in real-time and make immediate adjustments to printing parameters. Machine learning algorithms can be employed to predict and prevent satellite formation by continuously optimizing jetting parameters based on observed droplet behavior and environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Material jetting technology's competitive landscape is evolving rapidly in a growth phase market, with global projections reaching $400-500 million by 2025. The technology has matured significantly through innovations in waveform control and fluid dynamics to suppress satellite droplet formation. Leading players include Seiko Epson, Canon, and Brother Industries, who have developed advanced piezoelectric actuation systems, while Fujifilm and Ricoh focus on specialized industrial applications. Research institutions like Fraunhofer-Gesellschaft and ITRI are advancing fundamental understanding of fluid-structure interactions. Companies such as Kateeva are pioneering applications in emerging fields like OLED manufacturing, while traditional printing giants like Xerox are adapting material jetting for next-generation manufacturing processes.

Seiko Epson Corp.

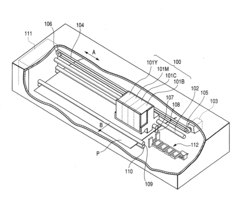

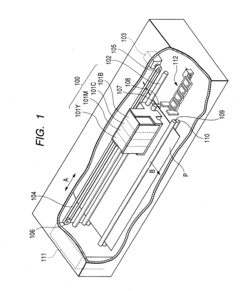

Technical Solution: Epson's material jetting technology employs a proprietary multi-pulse waveform control system called PrecisionCore that precisely manages droplet formation. Their approach utilizes piezoelectric actuators that generate carefully timed pressure waves within the fluid chamber. By applying a complex sequence of voltage pulses with specific amplitudes and timing (expansion-hold-contraction pattern), they create controlled pressure oscillations that effectively suppress satellite droplets. The system dynamically adjusts waveform parameters based on real-time feedback from droplet formation sensors, allowing adaptation to changing fluid properties during operation. Additionally, Epson incorporates fluid channel geometries specifically designed to dampen unwanted pressure reflections that could lead to satellite formation. Their fluid formulations include carefully balanced surfactants and polymeric additives that optimize surface tension and viscoelasticity to maintain clean droplet separation.

Strengths: Superior precision with droplet sizes as small as 1.5 picoliters and placement accuracy of ±2.5μm. Highly adaptable to various fluid viscosities through dynamic waveform adjustment. Weaknesses: System complexity requires sophisticated electronics and precise manufacturing tolerances, increasing production costs. Limited compatibility with certain high-viscosity materials without specialized formulation adjustments.

Canon, Inc.

Technical Solution: Canon's approach to satellite droplet suppression in material jetting combines advanced FINE (Full-photolithography Inkjet Nozzle Engineering) technology with sophisticated fluid dynamics control. Their system utilizes a dual-pulse waveform strategy where an initial pulse creates a controlled meniscus deformation, followed by a precisely timed second pulse that ejects the main droplet with minimal satellite formation. Canon has developed proprietary algorithms that analyze fluid properties in real-time and automatically adjust waveform parameters to maintain optimal droplet formation across varying environmental conditions. Their nozzle architecture incorporates specialized anti-wetting coatings and geometric features that prevent fluid accumulation around the orifice, which is a common cause of satellite droplets. Additionally, Canon's fluid formulations include carefully selected polymer additives that enhance viscoelastic properties, creating a clean filament break-off without secondary droplets.

Strengths: Exceptional consistency in droplet formation with reported satellite reduction of over 95% compared to conventional systems. Highly scalable technology that maintains performance across large printhead arrays. Weaknesses: Higher sensitivity to temperature variations requiring more sophisticated environmental controls. More complex fluid formulation requirements that may limit material compatibility without extensive reformulation.

Key Patents in Satellite Suppression Technology

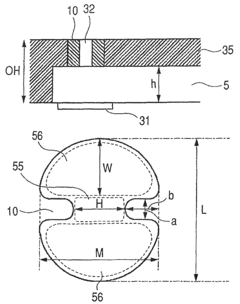

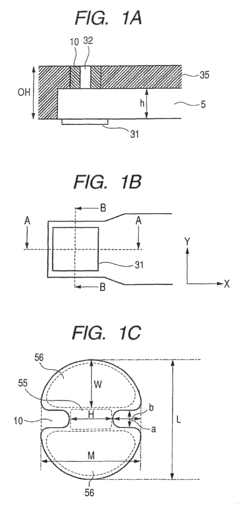

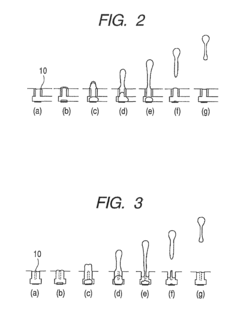

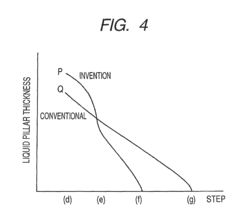

Liquid discharging method and liquid discharging apparatus

PatentInactiveUS20080291236A1

Innovation

- A liquid discharging method and apparatus that gradually thickens the liquid column toward the discharge port after the main droplet separation, followed by sucking the liquid back into the port to prevent further separation and satellite formation, utilizing a driving voltage waveform that includes holding regions to maintain a consistent voltage and control the volume variation of the liquid chamber.

Liquid discharge method, liquid discharge head and liquid discharge apparatus

PatentActiveUS8025362B2

Innovation

- The liquid discharge head incorporates a discharge port design with convex projections that create distinct fluid resistance areas, allowing for earlier separation of the liquid droplet by holding the liquid surface in a high fluid resistance area and pulling it back into the discharge port through lower resistance areas, thereby shortening the droplet tail and reducing satellite formation.

Environmental Impact of Material Jetting Processes

Material jetting processes, while offering significant advantages in precision manufacturing, carry notable environmental implications that warrant careful consideration. The environmental footprint begins with raw material production, where the specialized polymers, resins, and metal nanoparticles used in material jetting require energy-intensive extraction and processing methods. These materials often contain volatile organic compounds (VOCs) and potentially hazardous substances that can impact both environmental and human health.

During operation, material jetting systems consume substantial electrical energy, particularly in maintaining precise temperature controls and powering sophisticated droplet formation mechanisms. The waveform control systems that effectively suppress satellite formation require continuous power input, contributing to the overall energy consumption profile of these manufacturing processes.

Waste generation represents another significant environmental concern. Despite the precision of material jetting technologies, material wastage occurs through purging operations, failed prints, and support structure removal. The satellite suppression techniques, while improving efficiency, do not eliminate waste entirely. Additionally, cleaning solvents used in maintenance procedures often contain environmentally persistent chemicals that require specialized disposal protocols.

The environmental impact extends to end-of-life considerations for printed products. Many materials used in advanced material jetting applications have limited recyclability due to their specialized formulations and composite nature. Products containing multiple materials with different melting points and chemical properties present particular challenges for conventional recycling streams.

Water usage in material jetting processes, particularly in cooling systems and post-processing operations, represents another environmental consideration. The fluid control mechanisms that help prevent satellite formation may require regular maintenance involving water-intensive cleaning procedures.

Recent technological advancements have begun addressing these environmental concerns. Bio-based and biodegradable materials are emerging as alternatives to petroleum-derived polymers. Energy-efficient waveform generation systems reduce power consumption while maintaining droplet precision. Closed-loop material recovery systems are being developed to capture and reuse materials that would otherwise become waste.

Regulatory frameworks worldwide are increasingly focusing on the environmental aspects of additive manufacturing technologies, including material jetting. Manufacturers are responding with improved life-cycle assessments and sustainability metrics for their processes and materials. The industry trend points toward more environmentally responsible approaches that balance technical performance requirements with ecological considerations.

During operation, material jetting systems consume substantial electrical energy, particularly in maintaining precise temperature controls and powering sophisticated droplet formation mechanisms. The waveform control systems that effectively suppress satellite formation require continuous power input, contributing to the overall energy consumption profile of these manufacturing processes.

Waste generation represents another significant environmental concern. Despite the precision of material jetting technologies, material wastage occurs through purging operations, failed prints, and support structure removal. The satellite suppression techniques, while improving efficiency, do not eliminate waste entirely. Additionally, cleaning solvents used in maintenance procedures often contain environmentally persistent chemicals that require specialized disposal protocols.

The environmental impact extends to end-of-life considerations for printed products. Many materials used in advanced material jetting applications have limited recyclability due to their specialized formulations and composite nature. Products containing multiple materials with different melting points and chemical properties present particular challenges for conventional recycling streams.

Water usage in material jetting processes, particularly in cooling systems and post-processing operations, represents another environmental consideration. The fluid control mechanisms that help prevent satellite formation may require regular maintenance involving water-intensive cleaning procedures.

Recent technological advancements have begun addressing these environmental concerns. Bio-based and biodegradable materials are emerging as alternatives to petroleum-derived polymers. Energy-efficient waveform generation systems reduce power consumption while maintaining droplet precision. Closed-loop material recovery systems are being developed to capture and reuse materials that would otherwise become waste.

Regulatory frameworks worldwide are increasingly focusing on the environmental aspects of additive manufacturing technologies, including material jetting. Manufacturers are responding with improved life-cycle assessments and sustainability metrics for their processes and materials. The industry trend points toward more environmentally responsible approaches that balance technical performance requirements with ecological considerations.

Quality Assurance Methods for Satellite-Free Printing

Quality assurance in material jetting processes requires sophisticated methodologies to ensure satellite-free printing outcomes. Real-time monitoring systems represent the cornerstone of these quality control efforts, employing high-speed cameras and advanced image processing algorithms to detect satellite formation during the printing process. These systems can identify deviations in droplet formation at microsecond timescales, enabling immediate adjustments to printing parameters.

Automated inspection technologies have evolved significantly, incorporating machine learning algorithms that can distinguish between acceptable droplet patterns and those likely to produce satellites. These systems analyze thousands of droplet formations per second, creating statistical models of optimal jetting behavior that serve as reference points for quality control.

Waveform verification protocols constitute another critical component of quality assurance. These protocols systematically evaluate the electrical signals driving the piezoelectric actuators against predetermined optimal waveforms. Any deviation beyond established thresholds triggers automatic adjustment or alerts operators to potential satellite formation risks. Advanced systems implement closed-loop feedback mechanisms that continuously optimize waveforms based on observed droplet formation characteristics.

Fluid property monitoring represents an equally important quality assurance dimension. Inline viscometers and surface tension measurement devices continuously assess fluid properties during printing operations. When properties drift beyond specified parameters, automated systems adjust temperature controls or initiate mixing protocols to maintain optimal fluid characteristics. Some advanced systems incorporate predictive models that anticipate fluid property changes based on environmental conditions and printing duration.

Statistical process control methodologies have been adapted specifically for material jetting applications. These approaches establish control limits for critical parameters such as droplet velocity, volume consistency, and trajectory precision. By tracking these metrics across production runs, manufacturers can identify systematic issues before they manifest as satellite formation problems.

Post-process verification techniques complement real-time monitoring by examining finished products for evidence of satellite-related defects. Advanced optical scanning technologies can detect microscopic imperfections resulting from satellite droplets, while mechanical testing evaluates structural integrity that might be compromised by satellite-induced voids or inclusions. These verification steps provide the final quality assurance checkpoint before products reach end-users.

Automated inspection technologies have evolved significantly, incorporating machine learning algorithms that can distinguish between acceptable droplet patterns and those likely to produce satellites. These systems analyze thousands of droplet formations per second, creating statistical models of optimal jetting behavior that serve as reference points for quality control.

Waveform verification protocols constitute another critical component of quality assurance. These protocols systematically evaluate the electrical signals driving the piezoelectric actuators against predetermined optimal waveforms. Any deviation beyond established thresholds triggers automatic adjustment or alerts operators to potential satellite formation risks. Advanced systems implement closed-loop feedback mechanisms that continuously optimize waveforms based on observed droplet formation characteristics.

Fluid property monitoring represents an equally important quality assurance dimension. Inline viscometers and surface tension measurement devices continuously assess fluid properties during printing operations. When properties drift beyond specified parameters, automated systems adjust temperature controls or initiate mixing protocols to maintain optimal fluid characteristics. Some advanced systems incorporate predictive models that anticipate fluid property changes based on environmental conditions and printing duration.

Statistical process control methodologies have been adapted specifically for material jetting applications. These approaches establish control limits for critical parameters such as droplet velocity, volume consistency, and trajectory precision. By tracking these metrics across production runs, manufacturers can identify systematic issues before they manifest as satellite formation problems.

Post-process verification techniques complement real-time monitoring by examining finished products for evidence of satellite-related defects. Advanced optical scanning technologies can detect microscopic imperfections resulting from satellite droplets, while mechanical testing evaluates structural integrity that might be compromised by satellite-induced voids or inclusions. These verification steps provide the final quality assurance checkpoint before products reach end-users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!