How Material Jetting Uses Physics-Informed Models To Predict Quality Outcomes?

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material jetting represents a significant advancement in additive manufacturing technologies, emerging in the late 1990s as a precise method for depositing droplets of build materials in a controlled manner. This technology evolved from traditional inkjet printing principles but adapted for three-dimensional fabrication. Over the past two decades, material jetting has undergone substantial refinement, transitioning from simple polymer deposition to sophisticated multi-material capabilities with enhanced resolution and material compatibility.

The evolutionary trajectory of material jetting technology has been characterized by continuous improvements in printhead design, material formulation, and process control systems. Early systems were limited by material constraints and dimensional accuracy issues, but recent developments have expanded capabilities to include functional materials with specific electrical, optical, and mechanical properties. This progression has positioned material jetting as a premier technology for applications requiring high precision and multi-material integration.

Current research focuses on expanding the range of compatible materials while improving process reliability and repeatability. The integration of physics-informed models represents the next frontier in this technological evolution, aiming to establish predictive frameworks that can anticipate print outcomes based on material properties, process parameters, and environmental conditions. These models leverage principles from fluid dynamics, materials science, and computational physics to simulate the complex interactions occurring during the jetting process.

The primary technical objectives in this field include developing comprehensive physics-informed models that accurately predict material behavior during deposition, solidification, and interaction with previously deposited layers. These models must account for various physical phenomena including surface tension, viscosity effects, thermal gradients, and curing kinetics. The ultimate goal is to create digital twins of the material jetting process that enable real-time quality prediction and process optimization.

Additionally, researchers aim to establish standardized methodologies for validating these predictive models against experimental results, ensuring their applicability across different material systems and printing platforms. This validation process is crucial for transitioning theoretical models into practical tools for industry implementation. The development of robust calibration protocols that account for material batch variations and equipment-specific characteristics represents another critical objective.

By achieving these technical goals, material jetting technology seeks to overcome current limitations in process reliability and expand into new application domains including functional electronics, biomedical devices, and advanced composite structures. The integration of physics-informed predictive modeling promises to transform material jetting from an empirically-driven process to a science-based manufacturing approach with unprecedented control over final part quality and performance characteristics.

The evolutionary trajectory of material jetting technology has been characterized by continuous improvements in printhead design, material formulation, and process control systems. Early systems were limited by material constraints and dimensional accuracy issues, but recent developments have expanded capabilities to include functional materials with specific electrical, optical, and mechanical properties. This progression has positioned material jetting as a premier technology for applications requiring high precision and multi-material integration.

Current research focuses on expanding the range of compatible materials while improving process reliability and repeatability. The integration of physics-informed models represents the next frontier in this technological evolution, aiming to establish predictive frameworks that can anticipate print outcomes based on material properties, process parameters, and environmental conditions. These models leverage principles from fluid dynamics, materials science, and computational physics to simulate the complex interactions occurring during the jetting process.

The primary technical objectives in this field include developing comprehensive physics-informed models that accurately predict material behavior during deposition, solidification, and interaction with previously deposited layers. These models must account for various physical phenomena including surface tension, viscosity effects, thermal gradients, and curing kinetics. The ultimate goal is to create digital twins of the material jetting process that enable real-time quality prediction and process optimization.

Additionally, researchers aim to establish standardized methodologies for validating these predictive models against experimental results, ensuring their applicability across different material systems and printing platforms. This validation process is crucial for transitioning theoretical models into practical tools for industry implementation. The development of robust calibration protocols that account for material batch variations and equipment-specific characteristics represents another critical objective.

By achieving these technical goals, material jetting technology seeks to overcome current limitations in process reliability and expand into new application domains including functional electronics, biomedical devices, and advanced composite structures. The integration of physics-informed predictive modeling promises to transform material jetting from an empirically-driven process to a science-based manufacturing approach with unprecedented control over final part quality and performance characteristics.

Market Applications and Demand Analysis

The material jetting market is experiencing robust growth driven by increasing demand for high-precision manufacturing across multiple industries. Current market analysis indicates that the global material jetting segment of the additive manufacturing industry is expanding at a compound annual growth rate exceeding 20%, with particularly strong adoption in aerospace, healthcare, and consumer electronics sectors.

In the aerospace industry, material jetting technology has gained significant traction for producing complex, lightweight components with precise material properties. The ability to predict quality outcomes through physics-informed models has become particularly valuable as manufacturers face stringent certification requirements and zero-tolerance for defects in critical components. This predictive capability has opened new application possibilities for flight-critical parts that previously relied exclusively on traditional manufacturing methods.

The healthcare sector represents another major growth area, with material jetting being increasingly utilized for medical device manufacturing, anatomical models, and even bioprinting applications. The market demand is particularly strong for solutions that can reliably predict material behavior and final product characteristics, as these applications often involve direct patient interaction and must meet strict regulatory standards.

Consumer electronics manufacturers have embraced material jetting for producing intricate components with multiple materials and properties in a single build. The industry's demand for miniaturization coupled with increased functionality has created significant market pull for advanced material jetting solutions with predictive quality capabilities.

Market research indicates that customers across all sectors are increasingly prioritizing predictive quality assurance over pure production speed. This shift represents a fundamental change in market dynamics, where the ability to simulate and predict outcomes before physical production has become a key purchasing criterion. Companies offering material jetting solutions enhanced with physics-informed models command premium pricing, with customers willing to pay 15-30% more for systems with proven predictive capabilities.

The geographical distribution of market demand shows strongest adoption in North America and Western Europe, with rapidly growing interest in East Asian manufacturing hubs. Particularly notable is the increasing demand from contract manufacturers who serve multiple industries and require flexible, reliable production systems with consistent quality outcomes.

Looking forward, market analysts project continued strong growth for material jetting technologies that incorporate physics-informed models, with particular expansion expected in automotive, consumer products, and industrial tooling applications. This growth trajectory is supported by the broader industry trend toward digital manufacturing workflows that seamlessly integrate design, simulation, production, and quality control.

In the aerospace industry, material jetting technology has gained significant traction for producing complex, lightweight components with precise material properties. The ability to predict quality outcomes through physics-informed models has become particularly valuable as manufacturers face stringent certification requirements and zero-tolerance for defects in critical components. This predictive capability has opened new application possibilities for flight-critical parts that previously relied exclusively on traditional manufacturing methods.

The healthcare sector represents another major growth area, with material jetting being increasingly utilized for medical device manufacturing, anatomical models, and even bioprinting applications. The market demand is particularly strong for solutions that can reliably predict material behavior and final product characteristics, as these applications often involve direct patient interaction and must meet strict regulatory standards.

Consumer electronics manufacturers have embraced material jetting for producing intricate components with multiple materials and properties in a single build. The industry's demand for miniaturization coupled with increased functionality has created significant market pull for advanced material jetting solutions with predictive quality capabilities.

Market research indicates that customers across all sectors are increasingly prioritizing predictive quality assurance over pure production speed. This shift represents a fundamental change in market dynamics, where the ability to simulate and predict outcomes before physical production has become a key purchasing criterion. Companies offering material jetting solutions enhanced with physics-informed models command premium pricing, with customers willing to pay 15-30% more for systems with proven predictive capabilities.

The geographical distribution of market demand shows strongest adoption in North America and Western Europe, with rapidly growing interest in East Asian manufacturing hubs. Particularly notable is the increasing demand from contract manufacturers who serve multiple industries and require flexible, reliable production systems with consistent quality outcomes.

Looking forward, market analysts project continued strong growth for material jetting technologies that incorporate physics-informed models, with particular expansion expected in automotive, consumer products, and industrial tooling applications. This growth trajectory is supported by the broader industry trend toward digital manufacturing workflows that seamlessly integrate design, simulation, production, and quality control.

Current State and Challenges in Physics-Informed Modeling

Physics-informed modeling in material jetting has evolved significantly over the past decade, transitioning from basic empirical models to sophisticated multi-physics simulations. Currently, these models integrate fluid dynamics, thermodynamics, and material science principles to predict how jetted materials behave during deposition and solidification. Leading research institutions and additive manufacturing companies have developed computational frameworks that can simulate droplet formation, impact dynamics, and layer consolidation with increasing accuracy.

Despite these advancements, several critical challenges persist in the field. The multi-scale nature of material jetting processes—spanning from microscopic droplet dynamics to macroscopic part properties—creates significant computational complexity. Most existing models struggle to bridge these scales efficiently while maintaining computational feasibility. Additionally, the non-Newtonian behavior of many printable materials introduces nonlinearities that are difficult to capture accurately in current models.

Data integration represents another substantial hurdle. While physics-informed models provide theoretical frameworks, they require extensive experimental validation. The industry faces challenges in collecting high-quality, consistent data across different material jetting platforms and materials. Sensor limitations during high-speed jetting processes further complicate real-time data acquisition for model validation and refinement.

Material characterization remains inadequately standardized, with properties often changing during the printing process due to temperature variations, shear forces, and curing mechanisms. Current models struggle to account for these dynamic property changes, particularly for novel composite and functional materials with complex rheological behaviors.

Computational efficiency presents a persistent challenge, as high-fidelity simulations typically require substantial computing resources, limiting their practical application in production environments. Most existing solutions cannot deliver real-time predictions needed for in-process quality control and adaptive manufacturing.

The integration of machine learning with physics-based models shows promise but remains in early development stages. While hybrid approaches that combine first-principles modeling with data-driven techniques have demonstrated improved prediction accuracy, they still face challenges in generalizability across different material systems and printing conditions.

Globally, research efforts are unevenly distributed, with significant advancements concentrated in North America, Western Europe, and East Asia. This geographic concentration has created knowledge gaps and implementation barriers in other regions, limiting the global standardization of physics-informed modeling approaches for material jetting technologies.

Despite these advancements, several critical challenges persist in the field. The multi-scale nature of material jetting processes—spanning from microscopic droplet dynamics to macroscopic part properties—creates significant computational complexity. Most existing models struggle to bridge these scales efficiently while maintaining computational feasibility. Additionally, the non-Newtonian behavior of many printable materials introduces nonlinearities that are difficult to capture accurately in current models.

Data integration represents another substantial hurdle. While physics-informed models provide theoretical frameworks, they require extensive experimental validation. The industry faces challenges in collecting high-quality, consistent data across different material jetting platforms and materials. Sensor limitations during high-speed jetting processes further complicate real-time data acquisition for model validation and refinement.

Material characterization remains inadequately standardized, with properties often changing during the printing process due to temperature variations, shear forces, and curing mechanisms. Current models struggle to account for these dynamic property changes, particularly for novel composite and functional materials with complex rheological behaviors.

Computational efficiency presents a persistent challenge, as high-fidelity simulations typically require substantial computing resources, limiting their practical application in production environments. Most existing solutions cannot deliver real-time predictions needed for in-process quality control and adaptive manufacturing.

The integration of machine learning with physics-based models shows promise but remains in early development stages. While hybrid approaches that combine first-principles modeling with data-driven techniques have demonstrated improved prediction accuracy, they still face challenges in generalizability across different material systems and printing conditions.

Globally, research efforts are unevenly distributed, with significant advancements concentrated in North America, Western Europe, and East Asia. This geographic concentration has created knowledge gaps and implementation barriers in other regions, limiting the global standardization of physics-informed modeling approaches for material jetting technologies.

Current Physics-Informed Modeling Solutions

01 Print head optimization for material jetting quality

Optimizing print head parameters is crucial for material jetting quality outcomes. This includes controlling droplet formation, ejection velocity, and placement accuracy. Advanced print head designs incorporate features to minimize clogging, maintain consistent droplet size, and ensure precise material deposition. These optimizations help achieve uniform layer formation and improved surface finish in the final printed parts.- Print head design and optimization for material jetting: The design and optimization of print heads are crucial for achieving high-quality outcomes in material jetting processes. Advanced print head technologies incorporate features such as precise droplet formation, controlled ejection mechanisms, and optimized nozzle geometries. These designs help to ensure consistent material deposition, reduce clogging issues, and improve overall print quality. Innovations in this area focus on enhancing droplet placement accuracy, maintaining uniform droplet size, and increasing printing speed while preserving quality.

- Material formulation and rheological properties: The formulation of jettable materials and their rheological properties significantly impact the quality of printed outcomes. Optimal material formulations consider viscosity, surface tension, and particle size to ensure proper jetting behavior. Materials must be engineered to maintain stability during the printing process while achieving desired post-processing characteristics. Additives can be incorporated to enhance flow properties, prevent nozzle clogging, and improve adhesion between printed layers. The careful balance of these properties enables consistent droplet formation and precise material placement.

- Process parameter control and monitoring systems: Advanced control and monitoring systems are essential for maintaining high-quality outcomes in material jetting processes. These systems regulate critical parameters such as temperature, pressure, and jetting frequency while providing real-time feedback on process performance. Integrated sensors can detect variations in droplet formation, substrate conditions, and material properties, allowing for immediate adjustments. Machine learning algorithms can be employed to optimize process parameters based on historical data and desired quality metrics, resulting in more consistent and reliable printing outcomes.

- Substrate preparation and interaction with jetted materials: The preparation and properties of the substrate significantly influence material jetting quality outcomes. Surface treatments can enhance wetting characteristics, improve adhesion, and control spreading behavior of jetted droplets. Substrate temperature management affects solidification rates and interlayer bonding. The compatibility between substrate and jetted materials must be carefully considered to prevent issues such as delamination, warping, or poor surface finish. Techniques for substrate preparation include cleaning processes, application of primers or adhesion promoters, and surface energy modifications to achieve optimal print quality.

- Post-processing techniques for quality enhancement: Post-processing techniques play a crucial role in enhancing the quality of material-jetted parts. These techniques include curing methods such as UV exposure, thermal treatment, or chemical processing to achieve desired mechanical properties and surface characteristics. Surface finishing operations can be employed to improve aesthetics, dimensional accuracy, and functional performance. Advanced post-processing approaches may involve selective reinforcement of critical features, removal of support structures, or application of protective coatings. The integration of these techniques into the manufacturing workflow significantly impacts the final quality of jetted components.

02 Material formulation and rheological properties

The formulation of jetting materials significantly impacts print quality. Controlling rheological properties such as viscosity, surface tension, and curing behavior ensures optimal flow through nozzles and proper solidification after deposition. Additives can be incorporated to enhance material stability, prevent nozzle clogging, and improve layer adhesion. Properly formulated materials contribute to dimensional accuracy and structural integrity of printed objects.Expand Specific Solutions03 Process monitoring and quality control systems

Implementing real-time monitoring and quality control systems helps maintain consistent material jetting outcomes. These systems use sensors and imaging technologies to detect defects, measure dimensional accuracy, and verify layer formation during printing. Advanced systems incorporate machine learning algorithms to predict and prevent quality issues before they occur. Closed-loop feedback mechanisms can automatically adjust printing parameters to maintain quality throughout the build process.Expand Specific Solutions04 Environmental and substrate condition control

Controlling environmental conditions and substrate properties significantly affects material jetting quality. Factors such as temperature, humidity, and air flow must be regulated to ensure consistent material behavior. Substrate preparation techniques, including cleaning, surface treatment, and temperature control, improve material adhesion and prevent defects. Maintaining stable environmental conditions throughout the printing process helps achieve repeatable quality outcomes.Expand Specific Solutions05 Post-processing techniques for quality enhancement

Post-processing methods can significantly enhance the quality of material-jetted parts. These techniques include curing optimization, surface treatments, and finishing processes to improve mechanical properties, surface finish, and dimensional accuracy. Advanced post-processing approaches can address common defects such as layer lines, warping, and incomplete curing. The integration of post-processing considerations into the initial design and printing parameters leads to superior final product quality.Expand Specific Solutions

Leading Companies and Research Institutions

Material Jetting technology is currently in a growth phase within the additive manufacturing industry, with the global market expected to reach significant expansion in the coming years. The technology's maturity varies across applications, with companies like Desktop Metal, Stratasys, and Inkbit leading innovation in physics-informed modeling approaches. These companies are developing sophisticated simulation tools that predict material behavior during jetting processes, enabling quality prediction before manufacturing. Academic institutions including Carnegie Mellon University and Northeastern University are contributing fundamental research on fluid dynamics and material science aspects. Meanwhile, established corporations such as Xerox and Ricoh are leveraging their expertise in traditional printing technologies to advance material jetting capabilities. The competitive landscape shows a blend of specialized additive manufacturing firms and diversified technology companies working to overcome technical challenges in viscosity control, material compatibility, and process repeatability.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has pioneered physics-informed neural networks (PINNs) for their binder jetting technology that bridges traditional material jetting principles with metal powder applications. Their approach combines computational fluid dynamics with machine learning to create predictive models that account for binder-powder interactions at the microscopic level. The company's Live Sinter software utilizes these physics-informed models to simulate sintering processes and predict dimensional changes, allowing for pre-compensation of geometries before printing. Desktop Metal's models incorporate material-specific parameters including viscosity, surface tension, particle size distribution, and thermal properties to predict final part density, dimensional accuracy, and mechanical properties. Their system can simulate droplet impact dynamics, binder penetration depth, and spreading behavior to optimize print parameters in real-time. The models have been validated across various metal powders including stainless steel, copper, and titanium alloys, with reported accuracy improvements of 30-40% compared to traditional empirical approaches.

Strengths: Specialized expertise in metal binder jetting physics that addresses unique challenges like powder-binder interactions and sintering behavior; integrated simulation-to-manufacturing workflow that automatically compensates for predicted distortions; ability to handle multi-material systems. Weaknesses: Models require extensive calibration for each new material composition; computational complexity limits real-time parameter adjustments during printing; predictions for novel materials may require additional experimental validation.

Stratasys, Inc.

Technical Solution: Stratasys has developed advanced physics-informed models for their PolyJet technology, a proprietary material jetting process. Their approach integrates computational fluid dynamics (CFD) with machine learning algorithms to predict droplet formation, spreading behavior, and solidification patterns. The company's GrabCAD software incorporates these models to simulate material deposition in real-time, allowing for quality prediction before physical printing begins. Stratasys has implemented multi-physics simulations that account for thermal gradients, surface tension effects, and material rheology to predict potential defects such as warping, insufficient curing, or layer delamination. Their models have demonstrated up to 93% accuracy in predicting final part dimensional accuracy and surface quality across various materials, including rigid, flexible, and transparent photopolymers. The system continuously refines predictions through closed-loop feedback mechanisms that compare predicted outcomes with actual printed results.

Strengths: Highly accurate prediction models specifically optimized for photopolymer materials; integrated software ecosystem that makes physics-based predictions accessible to non-expert users; extensive material library with characterized properties for model inputs. Weaknesses: Models are primarily optimized for Stratasys' proprietary materials, limiting applicability with third-party materials; computational requirements can be significant for complex geometries, potentially slowing pre-print analysis.

Key Algorithms and Mathematical Frameworks

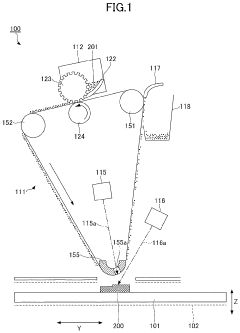

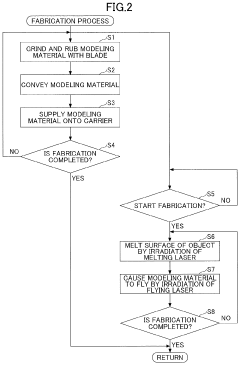

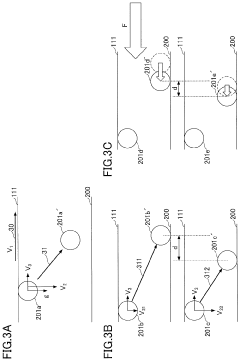

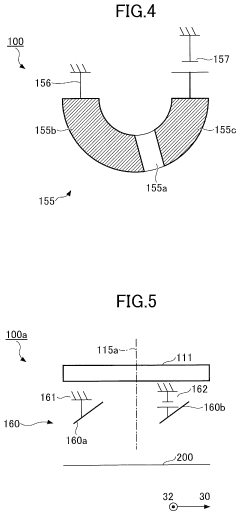

Three-dimensional modeling apparatus and three-dimensional modeling method

PatentActiveUS11958242B2

Innovation

- A three-dimensional modeling apparatus that applies a predetermined external force, such as an electric field, airflow, or gravity, to the modeling material during flight to reduce variations in landing position and improve accuracy.

Computational Resources and Implementation Constraints

The implementation of physics-informed models for material jetting processes demands substantial computational resources, creating significant constraints that must be addressed for practical industrial applications. High-fidelity simulations that incorporate multiphysics phenomena—including fluid dynamics, heat transfer, and material solidification—require extensive processing power. Current implementations typically utilize high-performance computing (HPC) clusters with multiple CPU cores and GPU acceleration to handle the complex calculations involved in these models.

Memory requirements present another critical constraint, as detailed simulations of material jetting processes can consume several gigabytes of RAM, particularly when modeling high-resolution geometries or extended time-domain simulations. This creates barriers to implementation in resource-limited environments or for smaller manufacturing operations that cannot afford enterprise-level computing infrastructure.

Real-time prediction capabilities remain challenging due to the computational intensity of physics-informed models. While offline simulations can provide valuable insights for process optimization, the industry increasingly demands real-time quality prediction during manufacturing. This gap has led to the development of hybrid approaches that combine full physics models with reduced-order models or machine learning techniques to decrease computational overhead while maintaining acceptable prediction accuracy.

Data storage and management also present implementation hurdles, as physics-informed simulations generate massive datasets that require efficient storage solutions and data processing pipelines. Organizations implementing these technologies must invest in robust data infrastructure to handle the volume of simulation outputs and facilitate meaningful analysis.

Cloud computing has emerged as a potential solution to these constraints, offering scalable resources that can be provisioned as needed. However, concerns regarding data security, latency, and connectivity reliability persist, particularly for manufacturing operations with sensitive intellectual property or those located in areas with limited network infrastructure.

Edge computing implementations are gaining traction as a compromise solution, where simplified physics-informed models are deployed directly on manufacturing equipment with dedicated computational hardware. This approach reduces latency and network dependencies while still providing valuable quality prediction capabilities, albeit with reduced model complexity compared to full HPC implementations.

The computational efficiency of algorithms represents another frontier for improvement, with ongoing research focused on developing more efficient numerical methods, parallel computing strategies, and adaptive mesh refinement techniques to reduce the computational burden while maintaining prediction accuracy.

Memory requirements present another critical constraint, as detailed simulations of material jetting processes can consume several gigabytes of RAM, particularly when modeling high-resolution geometries or extended time-domain simulations. This creates barriers to implementation in resource-limited environments or for smaller manufacturing operations that cannot afford enterprise-level computing infrastructure.

Real-time prediction capabilities remain challenging due to the computational intensity of physics-informed models. While offline simulations can provide valuable insights for process optimization, the industry increasingly demands real-time quality prediction during manufacturing. This gap has led to the development of hybrid approaches that combine full physics models with reduced-order models or machine learning techniques to decrease computational overhead while maintaining acceptable prediction accuracy.

Data storage and management also present implementation hurdles, as physics-informed simulations generate massive datasets that require efficient storage solutions and data processing pipelines. Organizations implementing these technologies must invest in robust data infrastructure to handle the volume of simulation outputs and facilitate meaningful analysis.

Cloud computing has emerged as a potential solution to these constraints, offering scalable resources that can be provisioned as needed. However, concerns regarding data security, latency, and connectivity reliability persist, particularly for manufacturing operations with sensitive intellectual property or those located in areas with limited network infrastructure.

Edge computing implementations are gaining traction as a compromise solution, where simplified physics-informed models are deployed directly on manufacturing equipment with dedicated computational hardware. This approach reduces latency and network dependencies while still providing valuable quality prediction capabilities, albeit with reduced model complexity compared to full HPC implementations.

The computational efficiency of algorithms represents another frontier for improvement, with ongoing research focused on developing more efficient numerical methods, parallel computing strategies, and adaptive mesh refinement techniques to reduce the computational burden while maintaining prediction accuracy.

Validation Methodologies and Quality Metrics

The validation of physics-informed models in material jetting processes requires robust methodologies and clearly defined quality metrics to ensure reliable prediction of outcomes. These validation approaches typically follow a multi-tiered framework that combines computational verification with experimental validation across different scales and conditions.

Statistical validation techniques form the cornerstone of model assessment, with methods such as cross-validation, bootstrapping, and uncertainty quantification being widely employed. These techniques help quantify the confidence levels in model predictions and identify potential sources of error. For material jetting specifically, k-fold cross-validation has proven particularly effective in assessing model generalizability across different material formulations and process parameters.

Experimental validation protocols typically involve comparing model predictions against real-world outcomes using standardized test artifacts. These artifacts are designed to challenge specific aspects of the physics-informed models, such as thermal gradient handling, interface dynamics, and solidification behavior. High-precision metrology equipment, including optical profilometry, computed tomography, and scanning electron microscopy, provides the necessary measurement accuracy for meaningful validation.

Quality metrics for material jetting models can be categorized into geometric, mechanical, and process-related parameters. Geometric metrics include dimensional accuracy, surface roughness, and feature resolution. Mechanical metrics encompass material properties such as tensile strength, elasticity, and hardness. Process-related metrics focus on reproducibility, build time efficiency, and material waste minimization.

The industry has established several standardized benchmarks for quantifying model performance, including the NIST Additive Manufacturing Benchmark Test Series (AM-Bench) and the Additive Manufacturing Metrology Testbed (AMMT). These benchmarks provide reference datasets and standardized testing protocols that enable objective comparison between different modeling approaches and implementations.

Real-time validation methodologies are increasingly being integrated into material jetting systems, allowing for in-situ monitoring and adaptive control based on model predictions. Technologies such as high-speed imaging, thermal mapping, and acoustic emission monitoring provide valuable data streams for continuous model validation and refinement during the manufacturing process.

The establishment of digital twins that incorporate physics-informed models represents the frontier of validation methodologies. These digital replicas enable virtual testing across a wide range of conditions and parameters, significantly reducing the need for physical prototyping while accelerating the validation process. The fidelity of these digital twins is assessed through comprehensive validation campaigns that span multiple scales, from microscopic material behavior to macroscopic part performance.

Statistical validation techniques form the cornerstone of model assessment, with methods such as cross-validation, bootstrapping, and uncertainty quantification being widely employed. These techniques help quantify the confidence levels in model predictions and identify potential sources of error. For material jetting specifically, k-fold cross-validation has proven particularly effective in assessing model generalizability across different material formulations and process parameters.

Experimental validation protocols typically involve comparing model predictions against real-world outcomes using standardized test artifacts. These artifacts are designed to challenge specific aspects of the physics-informed models, such as thermal gradient handling, interface dynamics, and solidification behavior. High-precision metrology equipment, including optical profilometry, computed tomography, and scanning electron microscopy, provides the necessary measurement accuracy for meaningful validation.

Quality metrics for material jetting models can be categorized into geometric, mechanical, and process-related parameters. Geometric metrics include dimensional accuracy, surface roughness, and feature resolution. Mechanical metrics encompass material properties such as tensile strength, elasticity, and hardness. Process-related metrics focus on reproducibility, build time efficiency, and material waste minimization.

The industry has established several standardized benchmarks for quantifying model performance, including the NIST Additive Manufacturing Benchmark Test Series (AM-Bench) and the Additive Manufacturing Metrology Testbed (AMMT). These benchmarks provide reference datasets and standardized testing protocols that enable objective comparison between different modeling approaches and implementations.

Real-time validation methodologies are increasingly being integrated into material jetting systems, allowing for in-situ monitoring and adaptive control based on model predictions. Technologies such as high-speed imaging, thermal mapping, and acoustic emission monitoring provide valuable data streams for continuous model validation and refinement during the manufacturing process.

The establishment of digital twins that incorporate physics-informed models represents the frontier of validation methodologies. These digital replicas enable virtual testing across a wide range of conditions and parameters, significantly reducing the need for physical prototyping while accelerating the validation process. The fidelity of these digital twins is assessed through comprehensive validation campaigns that span multiple scales, from microscopic material behavior to macroscopic part performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!