Material Jetting Repair And Rework Considerations: Cleaning, Re-Cure And Integrity

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting (MJ) technology has evolved significantly since its inception in the late 1990s as a promising additive manufacturing method. Initially developed as an extension of traditional inkjet printing technology, Material Jetting has transformed into a sophisticated manufacturing process capable of producing high-precision multi-material parts with exceptional surface finish. The technology operates by selectively depositing droplets of build material onto a build platform, where they are subsequently cured or solidified, typically using ultraviolet (UV) light.

The evolution of Material Jetting has been marked by several key advancements, including improvements in printhead technology, material formulation, and process control systems. Early systems were limited to simple polymeric materials, but contemporary MJ platforms can process a diverse range of materials including photopolymers, waxes, and even certain ceramic-loaded resins, enabling applications across various industries from consumer products to medical devices.

A critical aspect of Material Jetting technology that has received increasing attention is the repair and rework considerations. As the technology matures and finds applications in high-value, high-reliability sectors such as aerospace, automotive, and medical industries, the need for effective repair methodologies becomes paramount. The ability to salvage parts with minor defects rather than discarding them entirely represents significant economic and sustainability advantages.

The primary technical objectives in the field of Material Jetting repair and rework are threefold. First, developing efficient cleaning protocols to remove uncured or partially cured materials without damaging the underlying structure. Second, establishing reliable re-cure methodologies that ensure proper bonding between original and repair materials while maintaining dimensional accuracy. Third, implementing comprehensive integrity verification techniques to validate that repaired components meet or exceed the performance specifications of pristine parts.

Current research trends are focused on understanding the fundamental material interactions during the repair process, particularly the adhesion mechanisms between cured and newly deposited materials. Additionally, there is significant interest in developing specialized materials specifically formulated for repair applications, which offer enhanced compatibility with existing structures and improved mechanical properties at interface regions.

The trajectory of Material Jetting technology is moving toward more automated and integrated repair systems, potentially incorporating real-time monitoring and adaptive control mechanisms to optimize the repair process based on defect characteristics. The ultimate goal is to establish standardized repair protocols that can be reliably implemented across different material systems and application domains, thereby enhancing the overall value proposition of Material Jetting as a manufacturing technology.

The evolution of Material Jetting has been marked by several key advancements, including improvements in printhead technology, material formulation, and process control systems. Early systems were limited to simple polymeric materials, but contemporary MJ platforms can process a diverse range of materials including photopolymers, waxes, and even certain ceramic-loaded resins, enabling applications across various industries from consumer products to medical devices.

A critical aspect of Material Jetting technology that has received increasing attention is the repair and rework considerations. As the technology matures and finds applications in high-value, high-reliability sectors such as aerospace, automotive, and medical industries, the need for effective repair methodologies becomes paramount. The ability to salvage parts with minor defects rather than discarding them entirely represents significant economic and sustainability advantages.

The primary technical objectives in the field of Material Jetting repair and rework are threefold. First, developing efficient cleaning protocols to remove uncured or partially cured materials without damaging the underlying structure. Second, establishing reliable re-cure methodologies that ensure proper bonding between original and repair materials while maintaining dimensional accuracy. Third, implementing comprehensive integrity verification techniques to validate that repaired components meet or exceed the performance specifications of pristine parts.

Current research trends are focused on understanding the fundamental material interactions during the repair process, particularly the adhesion mechanisms between cured and newly deposited materials. Additionally, there is significant interest in developing specialized materials specifically formulated for repair applications, which offer enhanced compatibility with existing structures and improved mechanical properties at interface regions.

The trajectory of Material Jetting technology is moving toward more automated and integrated repair systems, potentially incorporating real-time monitoring and adaptive control mechanisms to optimize the repair process based on defect characteristics. The ultimate goal is to establish standardized repair protocols that can be reliably implemented across different material systems and application domains, thereby enhancing the overall value proposition of Material Jetting as a manufacturing technology.

Market Analysis for Material Jetting Repair Solutions

The material jetting repair and rework solutions market has experienced significant growth in recent years, driven by increasing adoption of additive manufacturing technologies across various industries. The global market for material jetting repair solutions was valued at approximately $1.2 billion in 2022 and is projected to grow at a compound annual growth rate of 18% through 2028.

The electronics manufacturing sector represents the largest market segment, accounting for nearly 40% of the total market share. This dominance is attributed to the critical need for high-precision repairs in printed circuit boards, semiconductor packaging, and microelectronic components. The aerospace industry follows as the second-largest consumer of material jetting repair solutions, particularly for high-value components where traditional repair methods prove inadequate or cost-prohibitive.

Demand patterns show regional variations, with North America and Europe currently leading market consumption due to their established manufacturing bases and higher technology adoption rates. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, primarily driven by rapid industrialization in China, Japan, and South Korea, along with increasing investment in advanced manufacturing technologies.

Customer requirements are evolving toward more sophisticated repair solutions that offer higher precision, material compatibility, and process integration capabilities. End-users increasingly demand systems that can seamlessly integrate with existing production lines and quality control processes, creating opportunities for comprehensive repair ecosystem solutions rather than standalone technologies.

The market is witnessing a shift toward environmentally sustainable repair solutions, with growing demand for systems that minimize material waste and utilize eco-friendly cleaning agents. This trend is particularly pronounced in European markets where regulatory pressures regarding manufacturing waste and chemical usage continue to intensify.

Price sensitivity varies significantly across market segments. While high-tech industries like aerospace and medical devices prioritize performance and reliability over cost, consumer electronics and automotive sectors demonstrate greater price sensitivity, creating distinct market approaches for solution providers.

Future market growth is expected to be driven by three key factors: increasing complexity of manufactured components requiring more sophisticated repair capabilities, growing adoption of Industry 4.0 principles necessitating integrated repair solutions, and expanding applications of additive manufacturing across new industry verticals creating novel repair challenges and opportunities.

The electronics manufacturing sector represents the largest market segment, accounting for nearly 40% of the total market share. This dominance is attributed to the critical need for high-precision repairs in printed circuit boards, semiconductor packaging, and microelectronic components. The aerospace industry follows as the second-largest consumer of material jetting repair solutions, particularly for high-value components where traditional repair methods prove inadequate or cost-prohibitive.

Demand patterns show regional variations, with North America and Europe currently leading market consumption due to their established manufacturing bases and higher technology adoption rates. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, primarily driven by rapid industrialization in China, Japan, and South Korea, along with increasing investment in advanced manufacturing technologies.

Customer requirements are evolving toward more sophisticated repair solutions that offer higher precision, material compatibility, and process integration capabilities. End-users increasingly demand systems that can seamlessly integrate with existing production lines and quality control processes, creating opportunities for comprehensive repair ecosystem solutions rather than standalone technologies.

The market is witnessing a shift toward environmentally sustainable repair solutions, with growing demand for systems that minimize material waste and utilize eco-friendly cleaning agents. This trend is particularly pronounced in European markets where regulatory pressures regarding manufacturing waste and chemical usage continue to intensify.

Price sensitivity varies significantly across market segments. While high-tech industries like aerospace and medical devices prioritize performance and reliability over cost, consumer electronics and automotive sectors demonstrate greater price sensitivity, creating distinct market approaches for solution providers.

Future market growth is expected to be driven by three key factors: increasing complexity of manufactured components requiring more sophisticated repair capabilities, growing adoption of Industry 4.0 principles necessitating integrated repair solutions, and expanding applications of additive manufacturing across new industry verticals creating novel repair challenges and opportunities.

Current Challenges in Material Jetting Repair Processes

Material jetting technology faces several significant challenges in repair and rework processes that limit its widespread industrial adoption. The primary obstacle remains the difficulty in achieving proper adhesion between the original printed part and repair material. This interface often becomes a weak point in the structure, compromising the mechanical integrity of the repaired component. Surface preparation techniques currently employed often fail to create optimal bonding conditions, resulting in delamination under stress or environmental exposure.

Contamination management presents another major hurdle in material jetting repair processes. Even microscopic contaminants can significantly impact the quality of repairs, creating voids, weak spots, or preventing proper curing. Current cleaning protocols struggle to completely remove residual uncured resin, support material residues, and environmental contaminants without damaging the original part structure.

The re-curing process introduces its own set of challenges. Achieving uniform curing at the repair interface is particularly problematic, as the energy distribution during secondary curing often differs from the initial fabrication conditions. This discrepancy leads to inconsistent material properties across the repaired region, including variations in hardness, flexibility, and dimensional stability. Additionally, thermal management during re-curing can cause warping or internal stresses that manifest as defects over time.

Material compatibility issues further complicate repair procedures. As materials age, their chemical properties change, making perfect matching between original and repair materials increasingly difficult. This mismatch frequently results in differential aging, where the repair area deteriorates at a different rate than the surrounding material, ultimately leading to premature failure.

Quality assurance and validation of repairs remain inadequately addressed. Non-destructive testing methods specifically calibrated for evaluating material jetting repairs are still in early development stages. The industry lacks standardized protocols for verifying repair integrity, particularly for internal structures that cannot be visually inspected.

Automation of repair processes represents another significant gap. Current repair workflows are largely manual, requiring skilled technicians and resulting in high variability between repairs. The precision required for material jetting repairs makes automation challenging, as systems must adapt to unique damage patterns and part geometries while maintaining tight tolerances.

Environmental factors also impact repair efficacy. Humidity, temperature, and ambient particulates can all interfere with the repair process, yet controlled environment solutions specifically designed for on-site repairs remain limited. This environmental sensitivity restricts where and when effective repairs can be performed, limiting the technology's flexibility in field applications.

Contamination management presents another major hurdle in material jetting repair processes. Even microscopic contaminants can significantly impact the quality of repairs, creating voids, weak spots, or preventing proper curing. Current cleaning protocols struggle to completely remove residual uncured resin, support material residues, and environmental contaminants without damaging the original part structure.

The re-curing process introduces its own set of challenges. Achieving uniform curing at the repair interface is particularly problematic, as the energy distribution during secondary curing often differs from the initial fabrication conditions. This discrepancy leads to inconsistent material properties across the repaired region, including variations in hardness, flexibility, and dimensional stability. Additionally, thermal management during re-curing can cause warping or internal stresses that manifest as defects over time.

Material compatibility issues further complicate repair procedures. As materials age, their chemical properties change, making perfect matching between original and repair materials increasingly difficult. This mismatch frequently results in differential aging, where the repair area deteriorates at a different rate than the surrounding material, ultimately leading to premature failure.

Quality assurance and validation of repairs remain inadequately addressed. Non-destructive testing methods specifically calibrated for evaluating material jetting repairs are still in early development stages. The industry lacks standardized protocols for verifying repair integrity, particularly for internal structures that cannot be visually inspected.

Automation of repair processes represents another significant gap. Current repair workflows are largely manual, requiring skilled technicians and resulting in high variability between repairs. The precision required for material jetting repairs makes automation challenging, as systems must adapt to unique damage patterns and part geometries while maintaining tight tolerances.

Environmental factors also impact repair efficacy. Humidity, temperature, and ambient particulates can all interfere with the repair process, yet controlled environment solutions specifically designed for on-site repairs remain limited. This environmental sensitivity restricts where and when effective repairs can be performed, limiting the technology's flexibility in field applications.

Existing Cleaning and Re-Cure Methodologies

01 Cleaning methods for material jetting systems

Various cleaning methods are employed to maintain and repair material jetting systems. These include solvent-based cleaning processes to remove residual materials, ultrasonic cleaning techniques for precision components, and automated cleaning systems that can be integrated into the production workflow. Effective cleaning is essential for ensuring consistent material flow and preventing clogging in nozzles and delivery systems, which directly impacts print quality and system longevity.- Cleaning methods for material jetting systems: Various cleaning methods are employed to maintain and repair material jetting systems. These include solvent-based cleaning processes to remove residual materials, ultrasonic cleaning techniques for precision components, and automated cleaning systems that can be integrated into the production line. Proper cleaning is essential to prevent clogging of nozzles and ensure consistent material deposition quality in subsequent operations.

- Re-curing techniques for material jetting repairs: Re-curing techniques are critical for repairing defects in material jetted parts. These include localized UV curing for photopolymer materials, thermal post-processing methods to enhance mechanical properties, and controlled environment curing to ensure proper cross-linking of polymers. These techniques help restore structural integrity to repaired areas and ensure consistent material properties throughout the part.

- Integrity verification systems for repaired components: After repair and rework of material jetted parts, various methods are employed to verify structural and functional integrity. These include non-destructive testing techniques such as optical scanning, ultrasonic inspection, and mechanical property testing. Advanced systems may incorporate machine vision and AI-based defect detection to ensure repaired areas meet quality standards and maintain the original design specifications.

- Automated repair and rework systems: Automated systems have been developed to streamline the repair and rework process for material jetted components. These systems integrate cleaning, repair material application, and re-curing in a single workflow. They often feature precision positioning systems, multiple material delivery mechanisms, and in-process monitoring to ensure repair quality. Such automation reduces human error and increases consistency in the repair process.

- Material formulations for repair applications: Specialized material formulations have been developed specifically for repair applications in material jetting processes. These include materials with enhanced adhesion to partially cured substrates, formulations with matching mechanical and optical properties to the original materials, and multi-component systems that can be activated on demand. These specialized repair materials ensure seamless integration with the original part and maintain consistent performance after repair.

02 Re-curing techniques for material jetting repairs

Re-curing processes are critical for repairing defects in jetted materials. These techniques include localized UV exposure for photopolymer resins, thermal post-processing for thermoplastic materials, and hybrid curing approaches that combine multiple energy sources. Advanced re-curing methods can restore mechanical properties and surface integrity of repaired areas, ensuring that reworked components meet original specifications and performance requirements.Expand Specific Solutions03 Integrity testing and quality control for repaired components

After repair and rework of material jetted components, various integrity testing methods are employed to verify quality. These include non-destructive testing techniques such as optical inspection, CT scanning, and mechanical property verification. Automated systems can detect defects, measure dimensional accuracy, and assess the structural integrity of repaired areas. Quality control protocols ensure that repaired components meet design specifications and performance requirements before returning to service.Expand Specific Solutions04 Specialized tools and equipment for material jetting rework

Purpose-built tools and equipment facilitate precise repair and rework of material jetted components. These include micro-dispensing systems for localized material application, specialized fixtures for component alignment during repair, and custom probes for accessing difficult geometries. Advanced repair stations may incorporate multiple functionalities such as cleaning, material removal, reapplication, and curing capabilities within a single workstation to streamline the rework process.Expand Specific Solutions05 Material formulations for repair applications

Specialized material formulations are developed specifically for repair applications in material jetting processes. These include repair resins with enhanced adhesion properties, materials with matched viscosity and surface tension for seamless integration with existing structures, and formulations with improved curing characteristics for repair scenarios. Some repair materials incorporate indicators or markers to distinguish repaired areas during quality control, while maintaining compatibility with the original material's mechanical and optical properties.Expand Specific Solutions

Key Industry Players in Material Jetting Repair

Material Jetting technology for repair and rework is currently in a growth phase, with the market expanding as industries recognize its potential for precision maintenance. The global market is estimated to reach $1.5 billion by 2025, driven by increasing adoption in electronics, aerospace, and medical sectors. Technologically, the field is advancing rapidly but still maturing, with companies at different development stages. Industry leaders like Seiko Epson and Canon Finetech Nisca have established robust cleaning and re-cure protocols, while Thales DIS France and Panasonic Holdings are advancing integrity verification methods. Emerging players such as Heraeus Quarzglas and Ferrotec are developing specialized material formulations to enhance repair durability and compatibility with existing components.

Seiko Epson Corp.

Technical Solution: Seiko Epson has developed advanced material jetting repair technologies focusing on precision cleaning and re-curing processes. Their approach utilizes specialized piezoelectric printheads that enable ultra-fine droplet control (as small as 1.5 picoliters) for repair applications. The company's PrecisionCore technology incorporates multi-stage cleaning protocols that remove contaminants without damaging underlying structures, using environmentally-friendly solvents and precision spray techniques. For re-curing, Epson employs variable UV intensity systems that adjust curing parameters based on material characteristics and repair depth, ensuring optimal cross-linking without thermal damage. Their quality control system integrates real-time monitoring with machine vision to verify repair integrity, detecting voids or adhesion issues before they become critical failures. This comprehensive approach enables repairs with up to 95% of original material strength in electronics manufacturing applications.

Strengths: Superior droplet precision control allows for extremely fine repairs in microelectronics; integrated quality verification systems ensure repair integrity. Weaknesses: Higher implementation costs compared to conventional repair methods; requires specialized training for operators to fully utilize the advanced features.

Brother Industries, Ltd.

Technical Solution: Brother Industries has developed material jetting repair technologies primarily focused on office equipment and consumer electronics applications. Their approach emphasizes accessibility and integration with existing manufacturing processes. The cleaning subsystem employs a combination of precision solvent delivery and controlled air flow to remove contaminants while minimizing environmental impact. Brother's jetting technology utilizes modified industrial printheads with enhanced temperature control, allowing for consistent deposition of repair materials across varying ambient conditions. Their re-curing methodology incorporates staged UV exposure with progressive intensity increases to minimize internal stress development during polymerization. For repair integrity verification, Brother employs optical coherence tomography to detect subsurface defects and ensure complete material consolidation. The system is designed for operator accessibility, with semi-automated cleaning and material handling processes that reduce training requirements while maintaining repair quality. Their approach achieves repair strengths of 80-88% compared to original materials, with particular success in repairing complex polymer assemblies where traditional methods would require complete component replacement.

Strengths: User-friendly operation reduces training requirements; well-integrated with existing manufacturing workflows. Weaknesses: Lower precision than specialized systems; limited effectiveness for extremely fine feature repairs.

Critical Patents in Material Jetting Repair Integrity

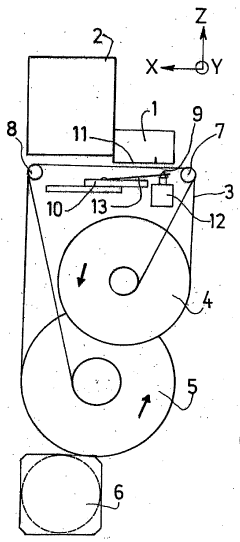

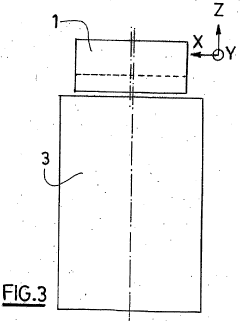

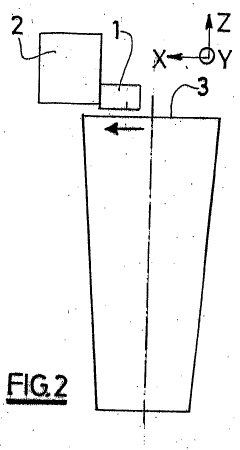

Material jet spray head cleaning

PatentInactiveEP1453682A1

Innovation

- A method and system utilizing an absorbent member and a scraper member arranged in specific geometric relationships to form a cleaning assembly, where the scraper member scrapes the material outlet device simultaneously with absorption by the absorbent member, ensuring a perfect cleanliness state without complex mechanisms.

Material jet spray head cleaning

PatentWO2003045697A1

Innovation

- A method and system utilizing an absorbent member and a scraper member arranged in specific geometric relationships to form a cleaning assembly, where the scraper member scrapes the material outlet device while the absorbent member absorbs the material, allowing for simultaneous cleaning and material recovery without complex mechanisms.

Environmental Impact of Material Jetting Repair Processes

Material jetting repair processes, while offering significant advantages in additive manufacturing, present notable environmental considerations that warrant careful examination. The chemicals utilized in these processes, particularly photopolymers and support materials, often contain potentially hazardous components that may impact both human health and ecological systems when improperly managed. These substances can release volatile organic compounds (VOCs) during curing and cleaning operations, contributing to air quality degradation in manufacturing environments.

The cleaning phase of material jetting repair processes presents particular environmental challenges. Solvents commonly employed for removing uncured resin residues and support materials frequently contain isopropyl alcohol, acetone, or specialized proprietary solutions with varying degrees of environmental persistence. These cleaning agents require proper containment, handling, and disposal protocols to prevent contamination of water systems and soil.

Energy consumption represents another significant environmental factor in material jetting repair operations. The UV curing systems essential for solidifying deposited materials demand considerable electrical power, especially when multiple curing cycles are necessary during repair procedures. This energy footprint extends to the operation of precision heating elements required to maintain optimal material viscosity and flow characteristics throughout the repair process.

Waste generation constitutes a substantial environmental concern, with failed repairs, support materials, and contaminated cleaning solutions contributing to the overall environmental impact. The composite nature of many jetted materials complicates recycling efforts, as these materials often combine polymers with various additives, colorants, and functional components that are difficult to separate for conventional recycling streams.

Recent industry developments have focused on mitigating these environmental impacts through several approaches. Manufacturers are increasingly developing water-soluble support materials that reduce dependence on chemical solvents during the cleaning phase. Additionally, material formulations with lower toxicity profiles and reduced VOC emissions are emerging as environmentally preferable alternatives for repair applications.

Closed-loop recycling systems for cleaning solvents represent another promising development, allowing for the capture, filtration, and reuse of cleaning agents to minimize waste generation and resource consumption. Similarly, energy-efficient curing technologies utilizing LED-based systems rather than traditional mercury vapor lamps offer reduced power requirements while maintaining effective polymerization performance.

The implementation of comprehensive environmental management systems specifically tailored to material jetting repair operations can significantly reduce ecological impacts while potentially offering economic benefits through reduced material consumption and waste management costs.

The cleaning phase of material jetting repair processes presents particular environmental challenges. Solvents commonly employed for removing uncured resin residues and support materials frequently contain isopropyl alcohol, acetone, or specialized proprietary solutions with varying degrees of environmental persistence. These cleaning agents require proper containment, handling, and disposal protocols to prevent contamination of water systems and soil.

Energy consumption represents another significant environmental factor in material jetting repair operations. The UV curing systems essential for solidifying deposited materials demand considerable electrical power, especially when multiple curing cycles are necessary during repair procedures. This energy footprint extends to the operation of precision heating elements required to maintain optimal material viscosity and flow characteristics throughout the repair process.

Waste generation constitutes a substantial environmental concern, with failed repairs, support materials, and contaminated cleaning solutions contributing to the overall environmental impact. The composite nature of many jetted materials complicates recycling efforts, as these materials often combine polymers with various additives, colorants, and functional components that are difficult to separate for conventional recycling streams.

Recent industry developments have focused on mitigating these environmental impacts through several approaches. Manufacturers are increasingly developing water-soluble support materials that reduce dependence on chemical solvents during the cleaning phase. Additionally, material formulations with lower toxicity profiles and reduced VOC emissions are emerging as environmentally preferable alternatives for repair applications.

Closed-loop recycling systems for cleaning solvents represent another promising development, allowing for the capture, filtration, and reuse of cleaning agents to minimize waste generation and resource consumption. Similarly, energy-efficient curing technologies utilizing LED-based systems rather than traditional mercury vapor lamps offer reduced power requirements while maintaining effective polymerization performance.

The implementation of comprehensive environmental management systems specifically tailored to material jetting repair operations can significantly reduce ecological impacts while potentially offering economic benefits through reduced material consumption and waste management costs.

Quality Assurance Standards for Repaired Components

Quality assurance standards for repaired components in material jetting processes require comprehensive frameworks to ensure that reworked parts meet or exceed original specifications. Industry standards such as ISO 9001, ASTM F2971, and ASTM F3122 provide foundational guidelines for quality management systems specifically tailored to additive manufacturing processes, including material jetting repair operations.

These standards emphasize the importance of establishing robust testing protocols for repaired components. Non-destructive testing methods, including ultrasonic inspection, X-ray computed tomography, and optical coherence tomography, have emerged as preferred techniques for evaluating the structural integrity of repaired interfaces without compromising the component's functionality. These methods can detect internal voids, delamination, or insufficient bonding between original and repaired sections.

Mechanical property verification represents another critical aspect of quality assurance. Repaired components must undergo systematic testing to confirm that tensile strength, flexural properties, and impact resistance match the original specifications. This often involves comparative analysis between control samples and repaired specimens to quantify any potential degradation in performance characteristics.

Dimensional accuracy verification has become increasingly important, particularly for high-precision applications. Advanced metrology techniques, including laser scanning and structured light systems, enable verification that repaired components maintain geometric tolerances within acceptable ranges. Deviation analysis between pre-repair and post-repair measurements provides quantitative evidence of dimensional stability.

Surface quality assessment protocols focus on evaluating the seamless integration between original and repaired sections. Parameters such as surface roughness, color matching, and texture consistency must be quantified using standardized measurement techniques. The development of specialized surface analysis tools has enhanced the ability to detect subtle variations that might affect functional performance or aesthetic qualities.

Accelerated aging tests represent a forward-looking component of quality assurance standards. These protocols subject repaired components to simulated environmental conditions to predict long-term performance. Factors such as UV exposure, thermal cycling, and humidity variations help identify potential degradation mechanisms specific to the interface between original and repaired materials.

Documentation requirements have evolved significantly, with current standards mandating comprehensive records of repair procedures, material batch information, curing parameters, and quality verification results. This documentation chain ensures traceability throughout the component's lifecycle and facilitates continuous improvement of repair methodologies based on performance data analysis.

These standards emphasize the importance of establishing robust testing protocols for repaired components. Non-destructive testing methods, including ultrasonic inspection, X-ray computed tomography, and optical coherence tomography, have emerged as preferred techniques for evaluating the structural integrity of repaired interfaces without compromising the component's functionality. These methods can detect internal voids, delamination, or insufficient bonding between original and repaired sections.

Mechanical property verification represents another critical aspect of quality assurance. Repaired components must undergo systematic testing to confirm that tensile strength, flexural properties, and impact resistance match the original specifications. This often involves comparative analysis between control samples and repaired specimens to quantify any potential degradation in performance characteristics.

Dimensional accuracy verification has become increasingly important, particularly for high-precision applications. Advanced metrology techniques, including laser scanning and structured light systems, enable verification that repaired components maintain geometric tolerances within acceptable ranges. Deviation analysis between pre-repair and post-repair measurements provides quantitative evidence of dimensional stability.

Surface quality assessment protocols focus on evaluating the seamless integration between original and repaired sections. Parameters such as surface roughness, color matching, and texture consistency must be quantified using standardized measurement techniques. The development of specialized surface analysis tools has enhanced the ability to detect subtle variations that might affect functional performance or aesthetic qualities.

Accelerated aging tests represent a forward-looking component of quality assurance standards. These protocols subject repaired components to simulated environmental conditions to predict long-term performance. Factors such as UV exposure, thermal cycling, and humidity variations help identify potential degradation mechanisms specific to the interface between original and repaired materials.

Documentation requirements have evolved significantly, with current standards mandating comprehensive records of repair procedures, material batch information, curing parameters, and quality verification results. This documentation chain ensures traceability throughout the component's lifecycle and facilitates continuous improvement of repair methodologies based on performance data analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!