Material Jetting In Harsh Chemicals: Stress Cracking, Solvent Exposure And Property Retention

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting technology has evolved significantly since its inception in the late 1990s as a subset of additive manufacturing processes. Initially developed for rapid prototyping applications, this technology has progressively expanded into functional part production across various industries including aerospace, automotive, medical, and consumer products. Material Jetting operates on the principle of selectively depositing droplets of build material in a precise layer-by-layer approach, similar to traditional inkjet printing but in three dimensions.

The evolution trajectory shows a clear shift from single-material capabilities to multi-material and multi-property printing, enabling the creation of complex parts with varying mechanical and chemical properties within a single build process. Recent technological advancements have focused on expanding the range of compatible materials beyond traditional photopolymers to include ceramics, metals, and specialized composites, significantly broadening application possibilities.

Current market trends indicate growing interest in utilizing Material Jetting for components exposed to harsh chemical environments, where traditional manufacturing methods face limitations in producing complex geometries with appropriate chemical resistance. This presents both opportunities and challenges, as printed parts must maintain structural integrity and functional properties when exposed to aggressive chemicals, solvents, and varying environmental conditions.

The primary technical objective in advancing Material Jetting for harsh chemical applications is to overcome the inherent vulnerability of printed materials to stress cracking and degradation when exposed to solvents and aggressive chemicals. This requires developing new material formulations with enhanced chemical resistance while maintaining printability and dimensional accuracy during the jetting process.

Secondary objectives include improving the long-term property retention of printed parts under chemical exposure, developing predictive models for material behavior in specific chemical environments, and establishing standardized testing protocols to evaluate chemical resistance of jetted materials. These advancements would enable more reliable qualification of parts for critical applications in chemical processing, oil and gas, pharmaceutical manufacturing, and other industries where harsh chemical exposure is common.

The technology aims to bridge the gap between the geometric freedom offered by additive manufacturing and the chemical resistance typically associated with specialized conventional materials and processes. Success in this domain would represent a significant step forward in expanding the application envelope of Material Jetting technology beyond current limitations, potentially disrupting traditional manufacturing approaches for chemically-resistant components.

The evolution trajectory shows a clear shift from single-material capabilities to multi-material and multi-property printing, enabling the creation of complex parts with varying mechanical and chemical properties within a single build process. Recent technological advancements have focused on expanding the range of compatible materials beyond traditional photopolymers to include ceramics, metals, and specialized composites, significantly broadening application possibilities.

Current market trends indicate growing interest in utilizing Material Jetting for components exposed to harsh chemical environments, where traditional manufacturing methods face limitations in producing complex geometries with appropriate chemical resistance. This presents both opportunities and challenges, as printed parts must maintain structural integrity and functional properties when exposed to aggressive chemicals, solvents, and varying environmental conditions.

The primary technical objective in advancing Material Jetting for harsh chemical applications is to overcome the inherent vulnerability of printed materials to stress cracking and degradation when exposed to solvents and aggressive chemicals. This requires developing new material formulations with enhanced chemical resistance while maintaining printability and dimensional accuracy during the jetting process.

Secondary objectives include improving the long-term property retention of printed parts under chemical exposure, developing predictive models for material behavior in specific chemical environments, and establishing standardized testing protocols to evaluate chemical resistance of jetted materials. These advancements would enable more reliable qualification of parts for critical applications in chemical processing, oil and gas, pharmaceutical manufacturing, and other industries where harsh chemical exposure is common.

The technology aims to bridge the gap between the geometric freedom offered by additive manufacturing and the chemical resistance typically associated with specialized conventional materials and processes. Success in this domain would represent a significant step forward in expanding the application envelope of Material Jetting technology beyond current limitations, potentially disrupting traditional manufacturing approaches for chemically-resistant components.

Chemical Resistance Market Demand Analysis

The chemical resistance market for material jetting technologies is experiencing significant growth driven by increasing demands across multiple industries. The global market for chemical-resistant materials and components is projected to reach $36.5 billion by 2027, with a compound annual growth rate of 5.8% from 2022. This growth is primarily fueled by expanding applications in harsh chemical environments where traditional materials fail due to stress cracking and property degradation.

The oil and gas industry represents one of the largest market segments, accounting for approximately 28% of the total demand for chemical-resistant materials. Equipment used in extraction, processing, and transportation must withstand exposure to corrosive substances including hydrogen sulfide, carbon dioxide, and various hydrocarbon mixtures. Material jetting technologies that can produce components with superior chemical resistance are increasingly sought after to reduce maintenance costs and extend equipment lifespan.

Chemical processing industries contribute another 23% to market demand, requiring materials that maintain structural integrity when exposed to acids, bases, and organic solvents. The ability to jet materials that resist stress cracking under chemical exposure represents a critical competitive advantage in this sector, with companies reporting maintenance cost reductions of up to 40% when implementing chemically resistant components.

Pharmaceutical manufacturing presents a rapidly growing market segment with 17% annual growth in demand for chemical-resistant materials. The stringent requirements for purity and contamination prevention necessitate materials that can withstand aggressive cleaning agents and process chemicals without leaching or degradation. Material jetting technologies capable of producing components with certified biocompatibility and chemical resistance command premium pricing in this sector.

Semiconductor fabrication represents another high-value market segment, with manufacturers willing to pay 30-50% price premiums for components with exceptional chemical resistance. The extreme purity requirements and use of aggressive etching chemicals create unique challenges that only specialized materials can address.

Regional analysis reveals that North America leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth at 7.2% annually, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies.

Customer surveys indicate that 76% of industrial users rank chemical resistance as a "critical" or "very important" property when selecting materials for harsh environment applications. Furthermore, 62% of respondents reported willingness to invest in higher-cost materials that demonstrate superior long-term property retention under chemical exposure, indicating strong market potential for advanced material jetting solutions.

The oil and gas industry represents one of the largest market segments, accounting for approximately 28% of the total demand for chemical-resistant materials. Equipment used in extraction, processing, and transportation must withstand exposure to corrosive substances including hydrogen sulfide, carbon dioxide, and various hydrocarbon mixtures. Material jetting technologies that can produce components with superior chemical resistance are increasingly sought after to reduce maintenance costs and extend equipment lifespan.

Chemical processing industries contribute another 23% to market demand, requiring materials that maintain structural integrity when exposed to acids, bases, and organic solvents. The ability to jet materials that resist stress cracking under chemical exposure represents a critical competitive advantage in this sector, with companies reporting maintenance cost reductions of up to 40% when implementing chemically resistant components.

Pharmaceutical manufacturing presents a rapidly growing market segment with 17% annual growth in demand for chemical-resistant materials. The stringent requirements for purity and contamination prevention necessitate materials that can withstand aggressive cleaning agents and process chemicals without leaching or degradation. Material jetting technologies capable of producing components with certified biocompatibility and chemical resistance command premium pricing in this sector.

Semiconductor fabrication represents another high-value market segment, with manufacturers willing to pay 30-50% price premiums for components with exceptional chemical resistance. The extreme purity requirements and use of aggressive etching chemicals create unique challenges that only specialized materials can address.

Regional analysis reveals that North America leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth at 7.2% annually, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies.

Customer surveys indicate that 76% of industrial users rank chemical resistance as a "critical" or "very important" property when selecting materials for harsh environment applications. Furthermore, 62% of respondents reported willingness to invest in higher-cost materials that demonstrate superior long-term property retention under chemical exposure, indicating strong market potential for advanced material jetting solutions.

Current Challenges in Harsh Chemical Environments

Material jetting in harsh chemical environments faces significant challenges that limit its industrial applications. The primary concern is stress cracking, which occurs when printed materials are exposed to aggressive chemicals under mechanical load. This phenomenon is particularly problematic in industries such as chemical processing, oil and gas, and pharmaceutical manufacturing where components must maintain structural integrity despite constant chemical exposure.

Solvent exposure represents another critical challenge, as many industrial chemicals can penetrate the molecular structure of jetted materials, causing swelling, plasticization, and eventual degradation. Research indicates that even materials marketed as chemically resistant often show significant property deterioration after prolonged exposure to harsh chemicals, with some experiencing up to 30% reduction in mechanical strength within weeks of deployment.

Temperature fluctuations in industrial environments exacerbate these challenges, as higher temperatures typically accelerate chemical attack and degradation processes. Studies have shown that for every 10°C increase in operating temperature, the rate of chemical degradation can double, significantly reducing component lifespan in harsh environments.

Current material jetting technologies struggle with limited material compatibility options for harsh chemical applications. While traditional manufacturing methods can utilize specialized alloys and composites with proven chemical resistance, material jetting is restricted to a narrower range of printable materials, many of which lack sufficient chemical resistance properties for extreme environments.

The interface between different printed materials presents particular vulnerability to chemical attack. Multi-material jetting, while offering design flexibility, creates potential weak points where dissimilar materials meet. These interfaces often become initiation sites for chemical degradation, leading to premature component failure even when individual materials might perform adequately.

Long-term property retention remains poorly understood, with limited data available on how jetted materials perform after years of chemical exposure. This knowledge gap creates significant uncertainty for industries considering additive manufacturing for critical components in chemical processing applications, where replacement cycles of 5-10 years are standard.

Surface finish quality also impacts chemical resistance, with rougher surfaces providing more attack sites for chemical degradation. Current material jetting technologies still struggle to achieve the smooth surface finishes that would maximize chemical resistance without requiring extensive post-processing, which adds cost and complexity to the manufacturing process.

Solvent exposure represents another critical challenge, as many industrial chemicals can penetrate the molecular structure of jetted materials, causing swelling, plasticization, and eventual degradation. Research indicates that even materials marketed as chemically resistant often show significant property deterioration after prolonged exposure to harsh chemicals, with some experiencing up to 30% reduction in mechanical strength within weeks of deployment.

Temperature fluctuations in industrial environments exacerbate these challenges, as higher temperatures typically accelerate chemical attack and degradation processes. Studies have shown that for every 10°C increase in operating temperature, the rate of chemical degradation can double, significantly reducing component lifespan in harsh environments.

Current material jetting technologies struggle with limited material compatibility options for harsh chemical applications. While traditional manufacturing methods can utilize specialized alloys and composites with proven chemical resistance, material jetting is restricted to a narrower range of printable materials, many of which lack sufficient chemical resistance properties for extreme environments.

The interface between different printed materials presents particular vulnerability to chemical attack. Multi-material jetting, while offering design flexibility, creates potential weak points where dissimilar materials meet. These interfaces often become initiation sites for chemical degradation, leading to premature component failure even when individual materials might perform adequately.

Long-term property retention remains poorly understood, with limited data available on how jetted materials perform after years of chemical exposure. This knowledge gap creates significant uncertainty for industries considering additive manufacturing for critical components in chemical processing applications, where replacement cycles of 5-10 years are standard.

Surface finish quality also impacts chemical resistance, with rougher surfaces providing more attack sites for chemical degradation. Current material jetting technologies still struggle to achieve the smooth surface finishes that would maximize chemical resistance without requiring extensive post-processing, which adds cost and complexity to the manufacturing process.

Existing Solutions for Chemical Resistance

01 Additives for stress crack prevention in material jetting

Various additives can be incorporated into materials used in jetting processes to prevent stress cracking and maintain property retention. These additives work by enhancing the molecular structure of the material, reducing internal stresses during solidification, and improving overall mechanical stability. The formulations typically include stabilizers, plasticizers, and reinforcing agents that work synergistically to prevent crack formation while maintaining the desired physical properties of the jetted material.- Additives to prevent stress cracking in material jetting: Various additives can be incorporated into material jetting formulations to prevent stress cracking and improve property retention. These additives work by enhancing the molecular structure of the printed material, reducing internal stresses during solidification, and improving the overall mechanical stability. The additives can include stabilizers, plasticizers, and reinforcing agents that help maintain the structural integrity of the jetted material under stress conditions.

- Material composition optimization for property retention: Optimizing the composition of materials used in jetting processes can significantly improve property retention and reduce stress cracking. This includes selecting appropriate polymer blends, adjusting the molecular weight distribution, and incorporating specific functional groups that enhance cross-linking. These optimizations help maintain mechanical properties over time and under various environmental conditions, resulting in printed parts with improved durability and resistance to stress-induced failures.

- Process parameters to control stress development: Controlling process parameters during material jetting can significantly reduce stress cracking and improve property retention. Key parameters include jetting temperature, curing conditions, layer thickness, and cooling rates. By optimizing these parameters, internal stresses can be minimized during the printing process, resulting in parts with improved mechanical properties and reduced susceptibility to cracking under load or environmental exposure.

- Post-processing techniques for stress reduction: Various post-processing techniques can be applied to material-jetted parts to reduce residual stresses and improve property retention. These techniques include thermal annealing, controlled cooling, surface treatments, and specialized curing methods. By implementing appropriate post-processing steps, internal stresses can be relieved, molecular orientation can be optimized, and the overall mechanical properties and resistance to stress cracking can be significantly improved.

- Testing and characterization methods for stress cracking: Advanced testing and characterization methods are essential for evaluating stress cracking susceptibility and property retention in material-jetted parts. These methods include accelerated aging tests, environmental stress cracking resistance (ESCR) tests, mechanical property measurements under various conditions, and microstructural analysis. By implementing comprehensive testing protocols, manufacturers can better understand the factors affecting stress cracking and develop more effective strategies to maintain property retention in jetted materials.

02 Material composition optimization for property retention

Optimizing the composition of materials used in jetting processes is crucial for maintaining desired properties and preventing stress cracking. This involves careful selection of polymer blends, resins, and other base materials that exhibit superior resistance to environmental stressors while maintaining dimensional stability. The molecular weight distribution, crystallinity, and cross-linking density of these materials can be tailored to achieve an optimal balance between processability during jetting and mechanical performance in the final product.Expand Specific Solutions03 Process parameter control for stress reduction

Controlling process parameters during material jetting significantly impacts stress cracking and property retention. Parameters such as jetting temperature, curing conditions, cooling rates, and layer thickness can be optimized to minimize internal stresses in the printed parts. Gradual cooling processes and controlled solidification rates help prevent the formation of residual stresses that could lead to cracking. Additionally, proper calibration of jetting pressure and speed ensures uniform material deposition, reducing stress concentration points.Expand Specific Solutions04 Post-processing techniques for property enhancement

Various post-processing techniques can be applied to jetted materials to enhance their resistance to stress cracking and improve property retention. These techniques include thermal annealing, UV curing optimization, and surface treatments that relieve internal stresses and enhance molecular bonding. Post-curing processes can be tailored to specific material compositions to achieve optimal cross-linking density and mechanical stability, resulting in improved long-term performance and resistance to environmental factors that might otherwise induce stress cracking.Expand Specific Solutions05 Environmental conditioning for stress crack resistance

Environmental conditioning methods can be employed to improve the stress crack resistance and property retention of jetted materials. These methods involve exposing the materials to controlled environmental conditions such as specific humidity levels, temperature cycles, or chemical treatments that enhance their molecular structure and resistance to cracking. Conditioning processes can be integrated into the manufacturing workflow to stabilize the material properties before the part enters service conditions, thereby extending the useful life of jetted components and maintaining their mechanical integrity under stress.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The material jetting market for harsh chemical applications is in a growth phase, with increasing demand for stress-cracking and solvent-resistant materials. The market is projected to expand significantly as industrial applications requiring chemical resistance grow. Leading players like Stratasys and Seiko Epson are advancing the technology's maturity through specialized material development, while chemical companies including Mitsui Chemicals and DSM IP Assets are contributing expertise in polymer formulations resistant to harsh environments. Industrial giants such as Siemens, General Electric, and Nippon Steel are driving application-specific solutions, particularly in sectors requiring components with high chemical resistance and property retention under extreme conditions.

Seiko Epson Corp.

Technical Solution: Epson has developed specialized material jetting solutions for harsh chemical environments through their PrecisionCore technology. Their approach focuses on multi-layer composite structures with chemically resistant outer shells protecting more functional inner cores. Epson's proprietary ink formulations incorporate siloxane-modified polymers that create highly hydrophobic surfaces resistant to aqueous chemical solutions. Their technology utilizes precision droplet placement to create gradient material transitions that optimize both chemical resistance and mechanical properties. Epson has also pioneered a multi-stage curing process where initial UV exposure is followed by thermal post-processing, creating more densely cross-linked structures with enhanced chemical resistance. Their materials incorporate specialized nanoparticle additives that act as chemical scavengers, neutralizing aggressive compounds before they can attack the polymer matrix.

Strengths: Exceptional precision in material deposition allows for optimized material distribution based on expected chemical exposure patterns. Their process offers excellent surface finish quality even with highly chemical-resistant materials. Weaknesses: More limited build volume compared to some competing technologies, and their specialized chemical-resistant materials typically require dedicated print heads to prevent cross-contamination.

Canon, Inc.

Technical Solution: Canon has developed advanced material jetting technology specifically addressing chemical resistance challenges through their proprietary UVgel technology. This approach utilizes specially formulated gel-state inks that undergo instantaneous UV curing upon deposition, creating highly cross-linked polymer structures with enhanced chemical resistance. Canon's technology incorporates fluorinated acrylate monomers that provide exceptional resistance to organic solvents while maintaining structural integrity. Their multi-layer jetting approach creates composite structures with specialized barrier layers that protect against chemical permeation. Canon has also developed a post-processing infiltration technique where printed parts are treated with chemical-resistant resins that penetrate the surface, creating a protective barrier against harsh environments while preserving dimensional accuracy and surface quality.

Strengths: Excellent balance between chemical resistance and mechanical properties, with parts maintaining over 90% of tensile strength after extended chemical exposure. Their process offers high throughput production capabilities suitable for industrial applications. Weaknesses: More limited material color options compared to standard inkjet materials, and the specialized formulations command premium pricing.

Critical Technologies for Stress Cracking Prevention

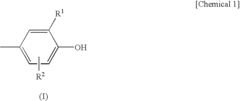

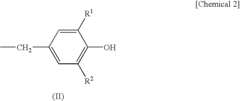

Environmental Stress Cracking Resistance Improver, and Resin Composition With Improved Environmental Stress Cracking Resistance Properties Containing the Same

PatentInactiveUS20090036584A1

Innovation

- A compound with a specific benzyl group and substituted aromatic ring is used as an environmental stress cracking resistance improver, added to olefin resins to enhance their resistance to cracking, specifically formulated to improve the properties of ethylene resins by incorporating 1 to 4 benzyl groups with a molecular weight of 300 to 2,000, and used in amounts ranging from 0.005 to 5 parts by weight per 100 parts of resin.

Regulatory Compliance for Chemical-Resistant Materials

The regulatory landscape for materials used in harsh chemical environments is complex and constantly evolving, requiring manufacturers to navigate multiple layers of compliance requirements. In the United States, the Environmental Protection Agency (EPA) under the Toxic Substances Control Act (TSCA) regulates chemical substances and mixtures that may present unreasonable risks to human health or the environment. Materials designed for chemical resistance must undergo rigorous testing to ensure they do not leach harmful substances when exposed to solvents or corrosive agents.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes even stricter requirements, mandating comprehensive documentation of chemical properties and potential risks. For material jetting applications involving harsh chemicals, manufacturers must provide detailed safety data sheets and technical documentation demonstrating compliance with these regulations.

Industry-specific standards further complicate the compliance landscape. The pharmaceutical industry, for example, follows FDA guidelines and USP Class VI testing protocols for materials that may come into contact with drugs or biological substances. These standards evaluate materials for biocompatibility, leachables, and extractables under various chemical exposure conditions.

ISO 10993 series standards are particularly relevant for materials used in medical devices that may be exposed to harsh cleaning agents or sterilization chemicals. These standards require extensive testing for cytotoxicity, sensitization, and irritation potential when materials are subjected to chemical stress.

For industrial applications, ASTM F1545 provides standardized test methods for evaluating the chemical resistance of polymers and other materials. Compliance with this standard often serves as a baseline requirement for materials intended for harsh chemical environments. Additionally, NACE (National Association of Corrosion Engineers) standards address materials used in corrosive industrial settings.

The food and beverage industry follows FDA 21 CFR 177 regulations for materials that may contact food products, including those exposed to cleaning chemicals. These regulations specify acceptable polymers and additives, along with extraction limits when materials are exposed to food-simulating solvents.

Emerging regulations are increasingly focusing on the environmental impact of chemical-resistant materials. The EU's Single-Use Plastics Directive and various circular economy initiatives are pushing manufacturers to develop materials that maintain their chemical resistance properties while being more environmentally sustainable or recyclable.

Compliance testing for stress cracking, solvent exposure, and property retention typically involves accelerated aging tests under chemical exposure conditions. These tests must be conducted according to standardized protocols such as ASTM D543 for chemical resistance or ISO 175 for determining the effects of liquid chemicals on plastics.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes even stricter requirements, mandating comprehensive documentation of chemical properties and potential risks. For material jetting applications involving harsh chemicals, manufacturers must provide detailed safety data sheets and technical documentation demonstrating compliance with these regulations.

Industry-specific standards further complicate the compliance landscape. The pharmaceutical industry, for example, follows FDA guidelines and USP Class VI testing protocols for materials that may come into contact with drugs or biological substances. These standards evaluate materials for biocompatibility, leachables, and extractables under various chemical exposure conditions.

ISO 10993 series standards are particularly relevant for materials used in medical devices that may be exposed to harsh cleaning agents or sterilization chemicals. These standards require extensive testing for cytotoxicity, sensitization, and irritation potential when materials are subjected to chemical stress.

For industrial applications, ASTM F1545 provides standardized test methods for evaluating the chemical resistance of polymers and other materials. Compliance with this standard often serves as a baseline requirement for materials intended for harsh chemical environments. Additionally, NACE (National Association of Corrosion Engineers) standards address materials used in corrosive industrial settings.

The food and beverage industry follows FDA 21 CFR 177 regulations for materials that may contact food products, including those exposed to cleaning chemicals. These regulations specify acceptable polymers and additives, along with extraction limits when materials are exposed to food-simulating solvents.

Emerging regulations are increasingly focusing on the environmental impact of chemical-resistant materials. The EU's Single-Use Plastics Directive and various circular economy initiatives are pushing manufacturers to develop materials that maintain their chemical resistance properties while being more environmentally sustainable or recyclable.

Compliance testing for stress cracking, solvent exposure, and property retention typically involves accelerated aging tests under chemical exposure conditions. These tests must be conducted according to standardized protocols such as ASTM D543 for chemical resistance or ISO 175 for determining the effects of liquid chemicals on plastics.

Environmental Impact and Sustainability Considerations

The environmental impact of material jetting processes involving harsh chemicals presents significant sustainability challenges that require careful consideration. Traditional material jetting technologies often utilize chemicals with high toxicity profiles, including volatile organic compounds (VOCs) and hazardous solvents that contribute to air pollution, water contamination, and soil degradation. These environmental concerns are magnified when considering the entire lifecycle of jetted materials exposed to harsh chemical environments.

Chemical leaching from jetted materials represents a primary environmental concern, particularly when products are exposed to aggressive solvents or acidic environments during their operational lifetime. The degradation processes that occur—including stress cracking and property deterioration—can release microparticles and chemical compounds into surrounding ecosystems, potentially disrupting aquatic habitats and entering food chains.

Energy consumption associated with material jetting processes also contributes significantly to their environmental footprint. The production of specialized materials capable of withstanding harsh chemical environments typically requires energy-intensive manufacturing processes. Additionally, the need for frequent replacement of components that fail due to chemical exposure increases resource consumption and waste generation throughout the product lifecycle.

Waste management challenges are particularly acute for materials jetted for harsh chemical applications. End-of-life disposal presents complications as these materials often cannot be processed through conventional recycling streams due to contamination concerns and complex material compositions. This frequently results in landfilling or incineration, both of which carry their own environmental consequences.

Recent sustainability innovations in the field include the development of bio-based and biodegradable alternatives that maintain chemical resistance properties while reducing environmental persistence. These materials are designed to degrade safely after their useful life without releasing harmful byproducts. Additionally, closed-loop manufacturing systems are being implemented to capture and reuse solvents and other chemicals involved in the material jetting process.

Regulatory frameworks worldwide are increasingly addressing the environmental impacts of chemical-resistant materials. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia are establishing stricter requirements for chemical usage, emissions control, and end-of-life management for advanced manufacturing processes including material jetting.

Life Cycle Assessment (LCA) methodologies are becoming essential tools for evaluating the true environmental impact of materials designed for harsh chemical environments. These assessments consider raw material extraction, manufacturing processes, use phase durability, and end-of-life scenarios to provide a comprehensive understanding of environmental trade-offs and identify opportunities for sustainability improvements in next-generation material jetting technologies.

Chemical leaching from jetted materials represents a primary environmental concern, particularly when products are exposed to aggressive solvents or acidic environments during their operational lifetime. The degradation processes that occur—including stress cracking and property deterioration—can release microparticles and chemical compounds into surrounding ecosystems, potentially disrupting aquatic habitats and entering food chains.

Energy consumption associated with material jetting processes also contributes significantly to their environmental footprint. The production of specialized materials capable of withstanding harsh chemical environments typically requires energy-intensive manufacturing processes. Additionally, the need for frequent replacement of components that fail due to chemical exposure increases resource consumption and waste generation throughout the product lifecycle.

Waste management challenges are particularly acute for materials jetted for harsh chemical applications. End-of-life disposal presents complications as these materials often cannot be processed through conventional recycling streams due to contamination concerns and complex material compositions. This frequently results in landfilling or incineration, both of which carry their own environmental consequences.

Recent sustainability innovations in the field include the development of bio-based and biodegradable alternatives that maintain chemical resistance properties while reducing environmental persistence. These materials are designed to degrade safely after their useful life without releasing harmful byproducts. Additionally, closed-loop manufacturing systems are being implemented to capture and reuse solvents and other chemicals involved in the material jetting process.

Regulatory frameworks worldwide are increasingly addressing the environmental impacts of chemical-resistant materials. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia are establishing stricter requirements for chemical usage, emissions control, and end-of-life management for advanced manufacturing processes including material jetting.

Life Cycle Assessment (LCA) methodologies are becoming essential tools for evaluating the true environmental impact of materials designed for harsh chemical environments. These assessments consider raw material extraction, manufacturing processes, use phase durability, and end-of-life scenarios to provide a comprehensive understanding of environmental trade-offs and identify opportunities for sustainability improvements in next-generation material jetting technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!