Material Jetting Embedded Channels: Support Removal, Cleanliness And Verification

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting (MJ) technology has evolved significantly since its inception in the late 1990s, emerging as a sophisticated additive manufacturing process that precisely deposits photopolymer materials in a droplet-by-droplet fashion. This technology represents a pivotal advancement in the 3D printing landscape, offering exceptional dimensional accuracy, surface finish quality, and multi-material capabilities that traditional manufacturing methods cannot achieve.

The evolution of Material Jetting has been characterized by several key milestones, including the development of multi-material printing capabilities, improvements in material properties, and enhanced process control mechanisms. Initially limited to prototype visualization, the technology has progressively expanded to enable functional part production with embedded features such as channels and cavities, which are critical for applications in microfluidics, cooling systems, and sensor integration.

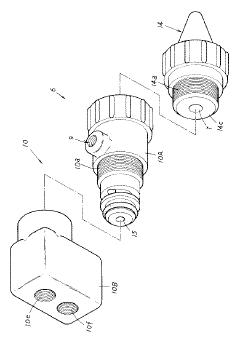

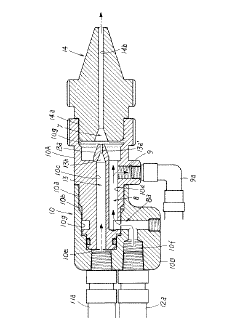

Current Material Jetting systems utilize piezoelectric print heads to deposit photopolymer droplets that are subsequently cured using ultraviolet light. This layer-by-layer approach allows for the creation of complex internal geometries, including embedded channels. However, the creation of these channels introduces significant technical challenges, particularly regarding support material removal, channel cleanliness verification, and quality assurance.

The primary technical objective in Material Jetting embedded channel development is to establish reliable methodologies for complete support material removal from internal channels without compromising structural integrity. This challenge is compounded by the limited accessibility of internal geometries and the risk of residual support material affecting fluid flow dynamics or causing system contamination in operational applications.

Additionally, there is a pressing need to develop non-destructive testing methods for verifying channel cleanliness and integrity post-processing. Current verification techniques often require destructive testing or are limited in their ability to detect residual support material in complex channel geometries, creating a significant barrier to widespread industrial adoption.

The technology aims to advance toward automated support removal systems that can handle increasingly complex channel geometries while maintaining consistent quality. Future developments are expected to focus on biodegradable or easily removable support materials, improved channel design guidelines to facilitate support removal, and advanced verification technologies utilizing ultrasonic or optical methods.

As industrial applications for embedded channels in Material Jetting continue to expand across sectors such as aerospace, automotive, and medical devices, addressing these technical challenges becomes increasingly critical to unlocking the full potential of this manufacturing approach for next-generation component design and production.

The evolution of Material Jetting has been characterized by several key milestones, including the development of multi-material printing capabilities, improvements in material properties, and enhanced process control mechanisms. Initially limited to prototype visualization, the technology has progressively expanded to enable functional part production with embedded features such as channels and cavities, which are critical for applications in microfluidics, cooling systems, and sensor integration.

Current Material Jetting systems utilize piezoelectric print heads to deposit photopolymer droplets that are subsequently cured using ultraviolet light. This layer-by-layer approach allows for the creation of complex internal geometries, including embedded channels. However, the creation of these channels introduces significant technical challenges, particularly regarding support material removal, channel cleanliness verification, and quality assurance.

The primary technical objective in Material Jetting embedded channel development is to establish reliable methodologies for complete support material removal from internal channels without compromising structural integrity. This challenge is compounded by the limited accessibility of internal geometries and the risk of residual support material affecting fluid flow dynamics or causing system contamination in operational applications.

Additionally, there is a pressing need to develop non-destructive testing methods for verifying channel cleanliness and integrity post-processing. Current verification techniques often require destructive testing or are limited in their ability to detect residual support material in complex channel geometries, creating a significant barrier to widespread industrial adoption.

The technology aims to advance toward automated support removal systems that can handle increasingly complex channel geometries while maintaining consistent quality. Future developments are expected to focus on biodegradable or easily removable support materials, improved channel design guidelines to facilitate support removal, and advanced verification technologies utilizing ultrasonic or optical methods.

As industrial applications for embedded channels in Material Jetting continue to expand across sectors such as aerospace, automotive, and medical devices, addressing these technical challenges becomes increasingly critical to unlocking the full potential of this manufacturing approach for next-generation component design and production.

Market Applications for Embedded Channel Structures

Embedded channel structures are revolutionizing multiple industries through their ability to integrate fluid, gas, or electrical pathways within solid components. The healthcare sector represents one of the most promising application areas, with microfluidic devices enabling point-of-care diagnostics, drug delivery systems, and lab-on-a-chip technologies. These applications benefit from the precise control of minute fluid volumes, allowing for faster analysis, reduced reagent consumption, and portable medical testing capabilities.

In aerospace and automotive industries, embedded channels provide significant weight reduction while maintaining structural integrity. Cooling systems for high-performance engines and electronic components can be integrated directly into structural elements, eliminating the need for separate cooling apparatus. This integration results in more compact designs, improved thermal management, and enhanced fuel efficiency.

The electronics sector leverages embedded channels for advanced thermal management solutions in increasingly dense computing environments. As electronic components continue to miniaturize while generating more heat, integrated cooling channels within circuit boards and semiconductor packages offer superior heat dissipation compared to traditional cooling methods. This application is particularly critical for data centers, high-performance computing, and next-generation mobile devices.

Consumer products represent another expanding market, with embedded channels enabling novel functionalities in everyday items. Examples include sports equipment with integrated cooling systems, wearable technology with fluid-based sensing capabilities, and household appliances with improved thermal regulation features.

Industrial manufacturing benefits from embedded channel structures in tooling applications, particularly injection molding. Conformal cooling channels that follow the contours of mold cavities enable more uniform cooling, reducing cycle times by up to 40% while improving part quality and consistency. This application alone represents a significant market opportunity as manufacturers seek to optimize production efficiency.

Energy systems constitute another promising application area, with embedded channels enhancing heat exchangers, fuel cells, and battery thermal management systems. The ability to create complex internal geometries allows for more efficient energy transfer and storage solutions, contributing to advancements in renewable energy technologies and electric vehicle performance.

Research institutions and academic laboratories represent a growing market segment, utilizing embedded channel structures for experimental apparatus, custom scientific instruments, and educational models. The rapid prototyping capabilities of material jetting technologies enable iterative design improvements and specialized equipment development that would be prohibitively expensive through traditional manufacturing methods.

In aerospace and automotive industries, embedded channels provide significant weight reduction while maintaining structural integrity. Cooling systems for high-performance engines and electronic components can be integrated directly into structural elements, eliminating the need for separate cooling apparatus. This integration results in more compact designs, improved thermal management, and enhanced fuel efficiency.

The electronics sector leverages embedded channels for advanced thermal management solutions in increasingly dense computing environments. As electronic components continue to miniaturize while generating more heat, integrated cooling channels within circuit boards and semiconductor packages offer superior heat dissipation compared to traditional cooling methods. This application is particularly critical for data centers, high-performance computing, and next-generation mobile devices.

Consumer products represent another expanding market, with embedded channels enabling novel functionalities in everyday items. Examples include sports equipment with integrated cooling systems, wearable technology with fluid-based sensing capabilities, and household appliances with improved thermal regulation features.

Industrial manufacturing benefits from embedded channel structures in tooling applications, particularly injection molding. Conformal cooling channels that follow the contours of mold cavities enable more uniform cooling, reducing cycle times by up to 40% while improving part quality and consistency. This application alone represents a significant market opportunity as manufacturers seek to optimize production efficiency.

Energy systems constitute another promising application area, with embedded channels enhancing heat exchangers, fuel cells, and battery thermal management systems. The ability to create complex internal geometries allows for more efficient energy transfer and storage solutions, contributing to advancements in renewable energy technologies and electric vehicle performance.

Research institutions and academic laboratories represent a growing market segment, utilizing embedded channel structures for experimental apparatus, custom scientific instruments, and educational models. The rapid prototyping capabilities of material jetting technologies enable iterative design improvements and specialized equipment development that would be prohibitively expensive through traditional manufacturing methods.

Technical Challenges in Support Material Removal

Support material removal in material jetting processes with embedded channels presents significant technical challenges that require innovative solutions. The primary difficulty lies in the complete extraction of support materials from complex internal geometries, particularly narrow channels with intricate paths. Current removal methods often leave residual material in hard-to-reach areas, compromising both functionality and performance of the final parts.

The viscosity characteristics of support materials create a fundamental dilemma. Materials must be fluid enough during printing to fill complex geometries but solid enough to provide structural support. This balance becomes particularly challenging when designing support materials that can later be efficiently removed from confined spaces without damaging the primary structure.

Chemical dissolution methods, while effective for surface-accessible support structures, face significant limitations with embedded channels. Solvents must penetrate through potentially long, narrow pathways with limited access points. Diffusion rates decrease dramatically in confined spaces, leading to incomplete dissolution in channel centers. Additionally, dissolved material must be transported out of the channels, creating a secondary removal challenge that often results in channel blockages.

Thermal removal techniques encounter similar difficulties. Heat transfer through printed parts is often non-uniform, creating uneven melting patterns that can trap support material in cooler regions. The expansion and contraction of materials during heating and cooling cycles may also cause structural deformations in delicate channel architectures.

Mechanical removal methods, including pressurized fluid flushing and vibration techniques, face limitations in reaching high-aspect-ratio channels with multiple bends. The force required to dislodge support material must be carefully balanced against the structural integrity of the printed part, particularly for thin-walled channel designs.

Verification of complete support removal represents another significant technical hurdle. Non-destructive testing methods such as micro-CT scanning provide detailed visualization but are time-consuming and expensive for production environments. Simpler methods like fluid flow testing may not detect partial blockages until they cause functional failures in the final application.

Cross-contamination between build and support materials during the removal process can compromise surface finish quality and dimensional accuracy of internal channels. This is particularly problematic in applications requiring high precision or specific surface characteristics, such as microfluidic devices or heat exchangers where surface roughness directly impacts performance.

The viscosity characteristics of support materials create a fundamental dilemma. Materials must be fluid enough during printing to fill complex geometries but solid enough to provide structural support. This balance becomes particularly challenging when designing support materials that can later be efficiently removed from confined spaces without damaging the primary structure.

Chemical dissolution methods, while effective for surface-accessible support structures, face significant limitations with embedded channels. Solvents must penetrate through potentially long, narrow pathways with limited access points. Diffusion rates decrease dramatically in confined spaces, leading to incomplete dissolution in channel centers. Additionally, dissolved material must be transported out of the channels, creating a secondary removal challenge that often results in channel blockages.

Thermal removal techniques encounter similar difficulties. Heat transfer through printed parts is often non-uniform, creating uneven melting patterns that can trap support material in cooler regions. The expansion and contraction of materials during heating and cooling cycles may also cause structural deformations in delicate channel architectures.

Mechanical removal methods, including pressurized fluid flushing and vibration techniques, face limitations in reaching high-aspect-ratio channels with multiple bends. The force required to dislodge support material must be carefully balanced against the structural integrity of the printed part, particularly for thin-walled channel designs.

Verification of complete support removal represents another significant technical hurdle. Non-destructive testing methods such as micro-CT scanning provide detailed visualization but are time-consuming and expensive for production environments. Simpler methods like fluid flow testing may not detect partial blockages until they cause functional failures in the final application.

Cross-contamination between build and support materials during the removal process can compromise surface finish quality and dimensional accuracy of internal channels. This is particularly problematic in applications requiring high precision or specific surface characteristics, such as microfluidic devices or heat exchangers where surface roughness directly impacts performance.

Current Support Removal Techniques and Protocols

01 Support removal techniques for embedded channels in material jetting

Various techniques are employed for removing support materials from embedded channels created through material jetting processes. These methods ensure that channels remain unobstructed after printing. Techniques include dissolution using specific solvents, mechanical removal methods, and thermal processing to melt away sacrificial support materials. Effective support removal is critical for maintaining the functionality of microfluidic channels and internal passages in 3D printed components.- Support removal techniques for embedded channels in material jetting: Various techniques are employed for removing support materials from embedded channels created through material jetting processes. These methods include using soluble supports that can be dissolved with specific solvents, mechanical removal techniques, and specialized tools designed to access and clear internal channels without damaging the primary structure. Effective support removal is critical for ensuring channel functionality in applications such as microfluidics and cooling systems.

- Channel cleanliness verification methods: Verification of channel cleanliness after support removal is essential for ensuring proper functionality. Methods include optical inspection systems that can visualize internal channels, pressure testing to confirm unobstructed flow, fluid flow testing with colored or fluorescent markers, and advanced imaging techniques such as micro-CT scanning. These verification methods help ensure that channels are completely clear of support material residue and meet design specifications.

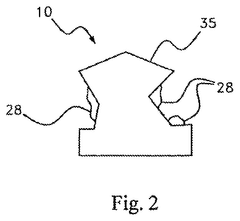

- Design considerations for removable supports in complex channels: Specific design considerations are implemented to facilitate support removal from complex embedded channels. These include designing appropriate access points, optimizing channel geometry to avoid sharp turns or constrictions that might trap support material, incorporating flushing ports, and creating breakaway support structures. The design phase must account for both the printing process and the subsequent support removal to ensure manufacturability.

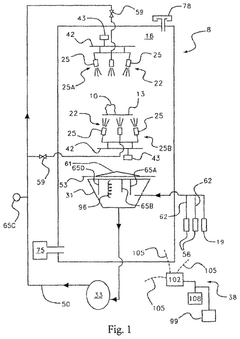

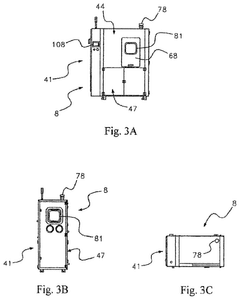

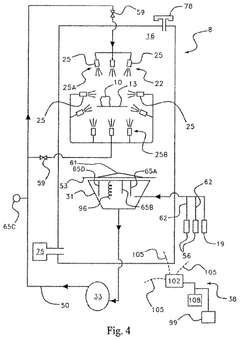

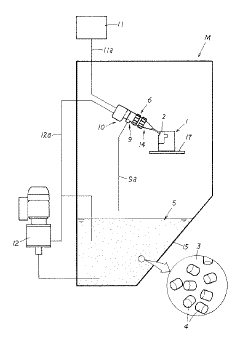

- Automated systems for support removal and channel cleaning: Automated systems have been developed to streamline the process of support removal and channel cleaning in material jetted parts. These systems include specialized washing stations with programmable pressure cycles, ultrasonic cleaning equipment, automated flushing systems that can circulate solvents through complex channel networks, and robotic systems for consistent and thorough cleaning of internal features without human intervention.

- Quality control and testing protocols for embedded channels: Comprehensive quality control and testing protocols are essential for validating embedded channels in material jetted parts. These include standardized procedures for measuring channel dimensions, flow rate testing, pressure drop analysis, leak testing, and durability assessment. Advanced monitoring techniques may incorporate sensors to verify channel integrity during operation, ensuring that the channels maintain their designed functionality throughout the product lifecycle.

02 Channel cleanliness verification methods

Various methods are used to verify the cleanliness of embedded channels after support material removal. These include optical inspection techniques, fluid flow testing, pressure testing, and imaging technologies. Advanced verification methods may incorporate sensors to detect residual materials or blockages within channels. Ensuring channel cleanliness is essential for applications requiring precise fluid flow, such as microfluidics and cooling systems.Expand Specific Solutions03 Design considerations for removable supports in complex channel structures

Specific design considerations are necessary when creating embedded channels with removable supports in material jetting processes. These include channel geometry optimization, support structure placement, access point design for support removal, and consideration of material compatibility between build and support materials. Proper design ensures that support structures can be completely removed while maintaining the structural integrity of the printed part and the functionality of the embedded channels.Expand Specific Solutions04 Material selection for support structures in channel fabrication

The selection of appropriate materials for support structures is crucial in material jetting processes involving embedded channels. Ideal support materials are those that can be easily removed through dissolution, melting, or mechanical means without damaging the main structure. Water-soluble supports, thermoplastic materials with lower melting points than the build material, and materials with different chemical resistances are commonly used. The compatibility between build and support materials significantly impacts the efficiency of the support removal process and the quality of the final embedded channels.Expand Specific Solutions05 Automated systems for support removal and channel verification

Automated systems have been developed to streamline the process of support removal and verification of embedded channels in material jetted parts. These systems incorporate automated cleaning stations, robotic handling of parts, integrated inspection technologies, and software solutions for process monitoring and quality control. Automation improves consistency in support removal, reduces the risk of channel damage, and enables efficient verification of channel cleanliness and functionality, particularly for complex or high-volume production scenarios.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Material Jetting Embedded Channels technology is currently in an early growth phase, with the market expanding as industries recognize its potential for creating complex internal structures in 3D printed components. The global market size is estimated to reach $2.5 billion by 2027, driven by applications in microfluidics, electronics, and medical devices. From a technical maturity perspective, the field shows varied development levels across key players. Companies like Optomec and Fujifilm Dimatix lead in printhead technology, while Mycronic AB and TRUMPF demonstrate advanced capabilities in precision deposition systems. Lam Research and Intel contribute significant innovations in semiconductor applications, with Fraunhofer-Gesellschaft providing important research foundations. Support removal techniques and channel verification methods remain challenging areas requiring further development to achieve widespread industrial adoption.

Seiko Epson Corp.

Technical Solution: Seiko Epson has developed sophisticated Material Jetting technology for embedded channels through their PrecisionCore printhead technology. Their approach utilizes multi-nozzle piezoelectric printheads capable of jetting both structural and support materials with micron-level precision. For embedded channel applications, Epson has engineered water-soluble support materials specifically formulated for complete dissolution even in complex internal geometries. Their support removal process employs a combination of specialized solvent circulation systems with controlled temperature and pressure parameters to ensure complete material extraction from narrow channels. For particularly complex geometries, Epson utilizes ultrasonic agitation with precisely controlled frequencies to dislodge support material without damaging the primary channel structures. Channel cleanliness verification is accomplished through their proprietary optical inspection system that combines high-resolution imaging with computational analysis to detect any remaining support material or contaminants. Additionally, Epson has developed specialized testing protocols that utilize calibrated flow measurements to verify channel patency and identify any remaining blockages that might affect fluid dynamics in the final application.

Strengths: Exceptional precision with their PrecisionCore technology enables highly consistent channel geometries with minimal variation between production runs. Their integrated hardware and materials approach ensures compatibility throughout the process chain. Weaknesses: Their systems have limitations with certain high-temperature materials that may be required for specialized industrial applications, and the cleaning process can require significant optimization for each new channel geometry.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed comprehensive solutions for Material Jetting Embedded Channels focusing on industrial applications. Their approach integrates multi-material printing capabilities with specialized support structures designed specifically for complex internal channel geometries. For support removal, Fraunhofer employs a combination of thermally-responsive and solvent-soluble support materials that can be extracted from channels through controlled thermal cycling followed by solvent flushing. Their research has yielded proprietary support material formulations that maintain structural integrity during printing but undergo controlled degradation during post-processing. For channel cleanliness verification, Fraunhofer utilizes advanced non-destructive testing methods including micro-CT scanning with specialized algorithms to detect residual support material down to 10 microns. Their process also incorporates ultrasonic cleaning techniques with precisely controlled frequency modulation to dislodge stubborn support material in hard-to-reach channel sections. The verification process includes flow testing with calibrated pressure sensors to confirm channel patency and identify any remaining blockages that might affect fluid dynamics in the final application.

Strengths: Comprehensive end-to-end solution covering material development, process optimization, and quality verification. Their multi-disciplinary approach integrates materials science with process engineering for robust industrial applications. Weaknesses: The complexity of their approach requires significant process optimization for each new application, potentially increasing development time and costs for novel channel geometries.

Key Innovations in Channel Cleaning Technologies

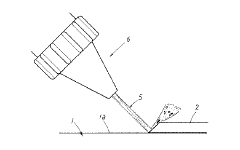

Method and apparatus for support removal using directed atomized and semi-atomized fluid

PatentActiveUS12194682B2

Innovation

- An apparatus and method using atomized or semi-atomized fluid, chemical dissolution, and pressurized fluid to automatically remove support material and smooth surfaces of additively manufactured parts, featuring a chamber with nozzles and a tank for recycling the fluid, and a diverter to prevent foaming, allowing for adjustable parameters to tailor the process to specific parts.

Support material removing method

PatentInactiveJP2012192679A

Innovation

- A method using a slurry of abrasive grains mixed with a liquid, injected via a slurry injection body with compressed air, effectively removes support material by collision and shaving action, eliminating the need for chemical treatment.

Quality Assurance Standards for Embedded Channels

Quality assurance for embedded channels in material jetting processes requires comprehensive standards to ensure functionality and reliability. These standards must address the unique challenges of support removal, cleanliness verification, and channel integrity validation in complex internal geometries that are often inaccessible for direct inspection.

The foundation of quality assurance standards begins with dimensional accuracy specifications. Embedded channels must conform to design tolerances, typically within ±50-100 microns depending on channel diameter and application requirements. Cross-sectional geometry consistency must be maintained throughout the channel length, with particular attention to areas where channels change direction or intersect.

Surface roughness parameters constitute another critical quality metric. For fluid-carrying channels, Ra values below 10 μm are typically required to prevent flow disruption and particle accumulation. Higher precision applications may demand even smoother surfaces, necessitating post-processing techniques compatible with internal geometries.

Cleanliness verification protocols form a cornerstone of embedded channel QA standards. These include quantitative measurements of residual support material, with acceptable thresholds typically below 0.1% of channel volume. Standardized flushing procedures using specified solvents at controlled temperatures, pressures, and durations must be established based on channel geometry and support material properties.

Non-destructive testing methodologies represent essential components of comprehensive QA standards. These include micro-CT scanning with resolution capabilities of 5-10 microns, ultrasonic inspection techniques calibrated for specific material combinations, and pressure/flow testing protocols that establish baseline performance metrics for different channel configurations.

Statistical process control frameworks must be implemented to monitor key quality indicators across production batches. This includes tracking support removal efficiency, channel obstruction rates, and dimensional consistency to identify process drift before it impacts product quality.

Documentation requirements constitute the final element of robust QA standards. These include detailed records of cleaning procedures, verification test results, and traceability information linking specific channels to material batches, process parameters, and post-processing treatments. Such documentation enables root cause analysis when quality issues arise and facilitates continuous improvement of manufacturing processes.

The foundation of quality assurance standards begins with dimensional accuracy specifications. Embedded channels must conform to design tolerances, typically within ±50-100 microns depending on channel diameter and application requirements. Cross-sectional geometry consistency must be maintained throughout the channel length, with particular attention to areas where channels change direction or intersect.

Surface roughness parameters constitute another critical quality metric. For fluid-carrying channels, Ra values below 10 μm are typically required to prevent flow disruption and particle accumulation. Higher precision applications may demand even smoother surfaces, necessitating post-processing techniques compatible with internal geometries.

Cleanliness verification protocols form a cornerstone of embedded channel QA standards. These include quantitative measurements of residual support material, with acceptable thresholds typically below 0.1% of channel volume. Standardized flushing procedures using specified solvents at controlled temperatures, pressures, and durations must be established based on channel geometry and support material properties.

Non-destructive testing methodologies represent essential components of comprehensive QA standards. These include micro-CT scanning with resolution capabilities of 5-10 microns, ultrasonic inspection techniques calibrated for specific material combinations, and pressure/flow testing protocols that establish baseline performance metrics for different channel configurations.

Statistical process control frameworks must be implemented to monitor key quality indicators across production batches. This includes tracking support removal efficiency, channel obstruction rates, and dimensional consistency to identify process drift before it impacts product quality.

Documentation requirements constitute the final element of robust QA standards. These include detailed records of cleaning procedures, verification test results, and traceability information linking specific channels to material batches, process parameters, and post-processing treatments. Such documentation enables root cause analysis when quality issues arise and facilitates continuous improvement of manufacturing processes.

Environmental Impact of Support Material Disposal

The disposal of support materials from material jetting processes presents significant environmental challenges that warrant careful consideration. These materials, often composed of wax-like substances or water-soluble polymers, contain various chemical additives that can potentially harm ecosystems if improperly managed. When removed from printed parts with embedded channels, these materials typically enter wastewater systems or solid waste streams, creating downstream environmental impacts.

Current disposal methods vary widely across manufacturing facilities, with many lacking standardized protocols for handling these specialized waste materials. Chemical solvents used in support removal processes compound the environmental concern, as they may contain volatile organic compounds (VOCs) and other hazardous substances that require specialized treatment before release into the environment.

Research indicates that water-soluble support materials can contribute to microplastic pollution when they enter aquatic ecosystems. These particles resist degradation and may accumulate in marine organisms, potentially entering the food chain. Studies have documented concentrations of these materials in wastewater treatment effluent, suggesting conventional filtration systems cannot fully capture these contaminants.

The energy consumption associated with support material removal processes also contributes to the environmental footprint. Heated ultrasonic baths and pressurized washing systems, commonly used for thorough support removal from complex channel geometries, require significant electricity, further increasing the carbon footprint of the manufacturing process.

Regulatory frameworks addressing these specific waste streams remain underdeveloped in many regions. The European Union's REACH regulations and similar initiatives in other jurisdictions have begun classifying certain support materials as substances of concern, but enforcement and compliance mechanisms are still evolving. Manufacturers face increasing pressure to document disposal practices and demonstrate environmental responsibility.

Several promising approaches are emerging to mitigate these environmental impacts. Bio-based support materials derived from renewable resources offer biodegradable alternatives to petroleum-based products. Closed-loop recycling systems that capture and reprocess support materials show potential for reducing waste volume. Additionally, advanced filtration technologies specifically designed to remove support material residues from wastewater streams are being developed and tested in industrial settings.

Life cycle assessment studies comparing different support material formulations and removal methods provide valuable insights for environmentally conscious manufacturing decisions. These analyses typically consider factors such as resource depletion, ecotoxicity, and global warming potential across the entire product lifecycle, enabling more informed material selection and process optimization.

Current disposal methods vary widely across manufacturing facilities, with many lacking standardized protocols for handling these specialized waste materials. Chemical solvents used in support removal processes compound the environmental concern, as they may contain volatile organic compounds (VOCs) and other hazardous substances that require specialized treatment before release into the environment.

Research indicates that water-soluble support materials can contribute to microplastic pollution when they enter aquatic ecosystems. These particles resist degradation and may accumulate in marine organisms, potentially entering the food chain. Studies have documented concentrations of these materials in wastewater treatment effluent, suggesting conventional filtration systems cannot fully capture these contaminants.

The energy consumption associated with support material removal processes also contributes to the environmental footprint. Heated ultrasonic baths and pressurized washing systems, commonly used for thorough support removal from complex channel geometries, require significant electricity, further increasing the carbon footprint of the manufacturing process.

Regulatory frameworks addressing these specific waste streams remain underdeveloped in many regions. The European Union's REACH regulations and similar initiatives in other jurisdictions have begun classifying certain support materials as substances of concern, but enforcement and compliance mechanisms are still evolving. Manufacturers face increasing pressure to document disposal practices and demonstrate environmental responsibility.

Several promising approaches are emerging to mitigate these environmental impacts. Bio-based support materials derived from renewable resources offer biodegradable alternatives to petroleum-based products. Closed-loop recycling systems that capture and reprocess support materials show potential for reducing waste volume. Additionally, advanced filtration technologies specifically designed to remove support material residues from wastewater streams are being developed and tested in industrial settings.

Life cycle assessment studies comparing different support material formulations and removal methods provide valuable insights for environmentally conscious manufacturing decisions. These analyses typically consider factors such as resource depletion, ecotoxicity, and global warming potential across the entire product lifecycle, enabling more informed material selection and process optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!