Material Jetting Qualification Artifacts: Geometry Sets, Calibration And Proof

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting (MJ) has emerged as a pivotal additive manufacturing technology since its inception in the late 1990s. This process, which selectively deposits droplets of build materials onto a substrate using inkjet print heads, has evolved from simple prototyping applications to a sophisticated manufacturing method capable of producing multi-material, multi-color parts with exceptional resolution. The technology draws its foundations from traditional inkjet printing but has been adapted to handle a diverse range of materials including photopolymers, waxes, and even certain metals.

The evolution of Material Jetting technology has been marked by significant advancements in printhead technology, material science, and process control systems. Early systems were limited by material compatibility issues and dimensional accuracy concerns. However, recent developments have dramatically improved these aspects, enabling the production of parts with micron-level precision and increasingly complex material compositions.

Current Material Jetting systems operate by depositing ultraviolet (UV) curable photopolymers or thermoplastic materials layer by layer, with immediate curing through UV light exposure or thermal processes. This approach allows for the creation of parts with gradient material properties and embedded functionality, representing a significant advancement over traditional manufacturing methods.

The primary objective of Material Jetting qualification artifacts research is to establish standardized methodologies for evaluating and validating the performance of MJ systems. This includes developing comprehensive geometry sets that can effectively test various aspects of the printing process, creating reliable calibration procedures to ensure consistent output quality, and implementing proof mechanisms to verify that printed parts meet specified requirements.

These qualification artifacts serve multiple critical purposes: they enable manufacturers to assess and optimize their MJ systems, provide end-users with confidence in the technology's capabilities, and establish a foundation for industry-wide standards. The development of such artifacts is particularly important as Material Jetting transitions from primarily prototyping applications to end-use part production in industries such as aerospace, medical devices, and consumer electronics.

Looking forward, the trajectory of Material Jetting technology points toward increased material compatibility, higher resolution capabilities, faster build speeds, and more sophisticated multi-material applications. The qualification artifacts being developed today will play a crucial role in facilitating this evolution by providing the necessary tools to validate these advancements and ensure they meet the increasingly demanding requirements of industrial applications.

The evolution of Material Jetting technology has been marked by significant advancements in printhead technology, material science, and process control systems. Early systems were limited by material compatibility issues and dimensional accuracy concerns. However, recent developments have dramatically improved these aspects, enabling the production of parts with micron-level precision and increasingly complex material compositions.

Current Material Jetting systems operate by depositing ultraviolet (UV) curable photopolymers or thermoplastic materials layer by layer, with immediate curing through UV light exposure or thermal processes. This approach allows for the creation of parts with gradient material properties and embedded functionality, representing a significant advancement over traditional manufacturing methods.

The primary objective of Material Jetting qualification artifacts research is to establish standardized methodologies for evaluating and validating the performance of MJ systems. This includes developing comprehensive geometry sets that can effectively test various aspects of the printing process, creating reliable calibration procedures to ensure consistent output quality, and implementing proof mechanisms to verify that printed parts meet specified requirements.

These qualification artifacts serve multiple critical purposes: they enable manufacturers to assess and optimize their MJ systems, provide end-users with confidence in the technology's capabilities, and establish a foundation for industry-wide standards. The development of such artifacts is particularly important as Material Jetting transitions from primarily prototyping applications to end-use part production in industries such as aerospace, medical devices, and consumer electronics.

Looking forward, the trajectory of Material Jetting technology points toward increased material compatibility, higher resolution capabilities, faster build speeds, and more sophisticated multi-material applications. The qualification artifacts being developed today will play a crucial role in facilitating this evolution by providing the necessary tools to validate these advancements and ensure they meet the increasingly demanding requirements of industrial applications.

Market Analysis for Material Jetting Applications

The material jetting market has witnessed substantial growth in recent years, driven by increasing demand for high-precision manufacturing across multiple industries. Current market valuations place the global material jetting sector at approximately $2.3 billion, with projections indicating a compound annual growth rate of 18% through 2028. This growth trajectory significantly outpaces traditional manufacturing methods, reflecting the technology's expanding application scope.

Industrial manufacturing represents the largest market segment, accounting for roughly 42% of material jetting applications. The automotive and aerospace sectors have emerged as particularly strong adopters, utilizing material jetting for prototyping complex components and producing functional parts with specific material properties. These industries value the technology's ability to create qualification artifacts with precise geometrical specifications that meet stringent industry standards.

The medical and dental sectors constitute the fastest-growing application area, with a 24% year-over-year increase. The demand for patient-specific devices, anatomical models, and dental prosthetics has created a robust market for material jetting technologies capable of producing biocompatible parts with exceptional dimensional accuracy. Qualification artifacts in these applications serve critical roles in ensuring consistent production quality for medical-grade components.

Consumer products and electronics manufacturers have also embraced material jetting, particularly for creating multi-material and multi-color prototypes. This segment represents approximately 18% of the current market, with growth driven by shortened product development cycles and increasing customization demands. The ability to calibrate material jetting systems for consistent color reproduction and material property distribution has become a key competitive advantage.

Geographically, North America leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth rate at 22% annually, fueled by rapid industrialization and significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

The market for qualification artifacts specifically designed for material jetting calibration and verification is emerging as a specialized sub-segment. Industry analysis indicates this niche market is growing at 15% annually, driven by increasing quality assurance requirements and the need for standardized testing methodologies across the additive manufacturing ecosystem. Organizations developing geometry sets and calibration tools for material jetting systems are experiencing strong demand, particularly from regulated industries where process validation is mandatory.

Industrial manufacturing represents the largest market segment, accounting for roughly 42% of material jetting applications. The automotive and aerospace sectors have emerged as particularly strong adopters, utilizing material jetting for prototyping complex components and producing functional parts with specific material properties. These industries value the technology's ability to create qualification artifacts with precise geometrical specifications that meet stringent industry standards.

The medical and dental sectors constitute the fastest-growing application area, with a 24% year-over-year increase. The demand for patient-specific devices, anatomical models, and dental prosthetics has created a robust market for material jetting technologies capable of producing biocompatible parts with exceptional dimensional accuracy. Qualification artifacts in these applications serve critical roles in ensuring consistent production quality for medical-grade components.

Consumer products and electronics manufacturers have also embraced material jetting, particularly for creating multi-material and multi-color prototypes. This segment represents approximately 18% of the current market, with growth driven by shortened product development cycles and increasing customization demands. The ability to calibrate material jetting systems for consistent color reproduction and material property distribution has become a key competitive advantage.

Geographically, North America leads the market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth rate at 22% annually, fueled by rapid industrialization and significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

The market for qualification artifacts specifically designed for material jetting calibration and verification is emerging as a specialized sub-segment. Industry analysis indicates this niche market is growing at 15% annually, driven by increasing quality assurance requirements and the need for standardized testing methodologies across the additive manufacturing ecosystem. Organizations developing geometry sets and calibration tools for material jetting systems are experiencing strong demand, particularly from regulated industries where process validation is mandatory.

Current Challenges in Material Jetting Qualification

Material jetting technology faces several significant challenges that impede its widespread industrial adoption and reliability. The qualification process for material jetting systems remains inconsistent across the industry, with no universally accepted standards for evaluating print quality, dimensional accuracy, and material properties. This lack of standardization creates difficulties in comparing results between different machines and materials, hindering the technology's maturation.

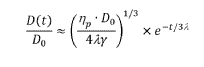

A primary technical challenge involves the complex rheological requirements for printable materials. The viscosity, surface tension, and curing properties must fall within narrow operational windows to achieve successful deposition. Materials that meet these specific requirements are limited, restricting the technology's application scope. Additionally, many available materials exhibit post-processing instability, with printed parts showing dimensional changes or property degradation over time due to continued polymerization or environmental factors.

Calibration procedures represent another significant hurdle. Current calibration methods often rely on visual inspection or basic geometric measurements that fail to capture the full range of variables affecting print quality. The industry lacks robust, automated calibration protocols that can account for nozzle-to-nozzle variations, printhead alignment, and drop placement accuracy across the entire build platform.

The qualification artifacts themselves present challenges in design and implementation. Existing test geometries frequently fail to adequately represent real-world applications or stress the capabilities of material jetting systems in meaningful ways. Many test artifacts focus on single aspects of performance rather than providing comprehensive evaluation across multiple quality dimensions simultaneously.

Multi-material jetting introduces additional complexities in qualification. Interface characteristics between different materials, color bleeding, and material compatibility issues require specialized test artifacts and measurement protocols that are still evolving. The industry has yet to develop standardized methods for evaluating these multi-material interactions effectively.

Measurement and metrology challenges further complicate qualification efforts. The high-resolution features possible with material jetting often approach the limits of conventional measurement techniques. Non-destructive evaluation methods capable of assessing internal structures and material distribution remain limited, making comprehensive quality assessment difficult.

Environmental factors also impact qualification processes, as temperature, humidity, and ambient conditions can significantly affect material jetting outcomes. Current qualification approaches rarely account for these variables systematically, leading to inconsistent results across different manufacturing environments and limiting process repeatability.

A primary technical challenge involves the complex rheological requirements for printable materials. The viscosity, surface tension, and curing properties must fall within narrow operational windows to achieve successful deposition. Materials that meet these specific requirements are limited, restricting the technology's application scope. Additionally, many available materials exhibit post-processing instability, with printed parts showing dimensional changes or property degradation over time due to continued polymerization or environmental factors.

Calibration procedures represent another significant hurdle. Current calibration methods often rely on visual inspection or basic geometric measurements that fail to capture the full range of variables affecting print quality. The industry lacks robust, automated calibration protocols that can account for nozzle-to-nozzle variations, printhead alignment, and drop placement accuracy across the entire build platform.

The qualification artifacts themselves present challenges in design and implementation. Existing test geometries frequently fail to adequately represent real-world applications or stress the capabilities of material jetting systems in meaningful ways. Many test artifacts focus on single aspects of performance rather than providing comprehensive evaluation across multiple quality dimensions simultaneously.

Multi-material jetting introduces additional complexities in qualification. Interface characteristics between different materials, color bleeding, and material compatibility issues require specialized test artifacts and measurement protocols that are still evolving. The industry has yet to develop standardized methods for evaluating these multi-material interactions effectively.

Measurement and metrology challenges further complicate qualification efforts. The high-resolution features possible with material jetting often approach the limits of conventional measurement techniques. Non-destructive evaluation methods capable of assessing internal structures and material distribution remain limited, making comprehensive quality assessment difficult.

Environmental factors also impact qualification processes, as temperature, humidity, and ambient conditions can significantly affect material jetting outcomes. Current qualification approaches rarely account for these variables systematically, leading to inconsistent results across different manufacturing environments and limiting process repeatability.

Current Qualification Artifact Solutions

01 Calibration artifacts for material jetting systems

Specialized calibration artifacts are used in material jetting systems to ensure accuracy and precision. These artifacts have specific geometric features designed to test and calibrate various parameters of the printing system. The calibration process involves measuring the printed artifacts and comparing them to reference values to adjust the system accordingly. This ensures consistent quality and dimensional accuracy in the final printed parts.- Calibration artifacts for material jetting systems: Specific calibration artifacts are designed for material jetting systems to ensure accuracy and precision. These artifacts have standardized geometry sets that allow for consistent measurement and validation of the printing process. The calibration artifacts help in adjusting various parameters of the material jetting system, ensuring that the printed objects meet the required specifications and quality standards.

- Geometry sets for qualification testing: Specialized geometry sets are used for qualification testing of material jetting processes. These sets include various shapes and structures designed to test different aspects of the printing process, such as dimensional accuracy, surface finish, and feature resolution. By analyzing the printed geometry sets, manufacturers can assess the capabilities and limitations of their material jetting systems and ensure they meet industry standards.

- Imaging and measurement techniques for verification: Advanced imaging and measurement techniques are employed to verify the quality of material jetted parts. These techniques include optical scanning, computed tomography, and laser measurement systems that can accurately capture the dimensions and features of printed artifacts. The data collected through these methods is used to compare the actual printed parts with the digital design, identifying any deviations or defects that may affect performance.

- Process validation and quality control methods: Comprehensive validation and quality control methods are implemented to ensure the reliability of material jetting processes. These methods involve systematic testing of printed artifacts against predefined specifications and standards. Statistical analysis of measurement data helps identify trends and potential issues in the printing process, allowing for continuous improvement and optimization of material jetting parameters.

- Thermal and environmental calibration considerations: Thermal and environmental factors significantly impact the performance of material jetting systems and must be carefully calibrated. Temperature variations can affect material viscosity and flow characteristics, while humidity and other environmental conditions can influence curing and solidification processes. Specialized artifacts and sensors are used to monitor and adjust for these factors, ensuring consistent print quality across different operating conditions.

02 Geometry sets for qualification testing

Standardized geometry sets are employed for qualification testing of material jetting systems. These sets include various geometric shapes and features designed to evaluate different aspects of the printing process, such as dimensional accuracy, surface finish, and feature resolution. By analyzing the printed geometry sets, manufacturers can verify that the material jetting system meets required specifications and identify areas for improvement in the printing process.Expand Specific Solutions03 Verification and proof methods for material jetting

Various verification and proof methods are used to validate the performance of material jetting systems. These methods involve printing test artifacts and analyzing them using specialized measurement techniques and imaging systems. The analysis results are compared against established standards to verify that the system meets required specifications. This process helps ensure the reliability and consistency of the material jetting process for production applications.Expand Specific Solutions04 Imaging and measurement systems for artifact analysis

Advanced imaging and measurement systems are essential for analyzing qualification artifacts in material jetting processes. These systems use various technologies, including optical scanning, computed tomography, and laser measurement, to capture detailed information about printed artifacts. The data collected is processed using specialized software to evaluate dimensional accuracy, surface quality, and internal features of the artifacts, providing comprehensive information about the performance of the material jetting system.Expand Specific Solutions05 Process parameter optimization using test artifacts

Test artifacts are used to optimize process parameters in material jetting systems. By printing specifically designed test artifacts under different processing conditions, manufacturers can identify the optimal parameters for achieving desired quality and performance. This approach involves systematic testing and analysis of various factors such as jetting temperature, material properties, and curing conditions. The results are used to establish process windows and operating guidelines for consistent production quality.Expand Specific Solutions

Key Industry Players in Material Jetting

Material Jetting Qualification is currently in a growth phase, with the market expanding as additive manufacturing adoption increases across industries. The global market shows promising development, driven by demand for high-precision manufacturing solutions. Technologically, the field is advancing from early maturity toward standardization, with companies like Stratasys, Renishaw, and Hexagon Metrology leading innovation in qualification artifacts and calibration methodologies. Other significant players include Siemens Industry Software and Nikon Metrology, who are developing integrated solutions for geometry validation and process verification. The competitive landscape features both established manufacturing technology providers and specialized additive manufacturing companies working to address challenges in repeatability, accuracy, and quality assurance for material jetting processes.

Renishaw Plc

Technical Solution: Renishaw has developed a sophisticated approach to Material Jetting qualification through their metrology expertise. Their system centers on high-precision geometry sets that incorporate features specifically designed to test the limits of material jetting processes. These artifacts include stepped pyramids, thin-walled structures, and complex internal channels that challenge both the material deposition accuracy and post-processing capabilities. Renishaw's calibration methodology employs their renowned metrology systems, including coordinate measuring machines (CMMs) and optical measurement technologies, to achieve measurement accuracies down to 0.1 microns[2]. Their qualification process integrates in-situ monitoring with post-build verification, creating a closed-loop system that can detect and compensate for process variations in real-time. Renishaw's proof artifacts include standardized test coupons that undergo rigorous mechanical and thermal testing to validate not just dimensional accuracy but also functional performance characteristics of jetted materials[4]. Their approach emphasizes traceability to international standards, with all measurement protocols linked to NIST or equivalent reference standards.

Strengths: Exceptional measurement precision and traceability to international standards. Their integrated approach combines in-process monitoring with post-build verification for comprehensive quality assurance. Weaknesses: Their solutions tend to be high-cost and may require significant expertise to implement effectively. The system is optimized for high-value, precision applications rather than high-throughput production environments.

Nikon Metrology NV

Technical Solution: Nikon Metrology has developed a sophisticated Material Jetting qualification system that leverages their expertise in optical measurement technologies. Their approach centers on multi-scale geometry sets that incorporate features ranging from macro dimensions to micro-textures, enabling comprehensive evaluation of material jetting capabilities. These artifacts include precision lattice structures, thin-walled components, and surface texture reference patterns designed to challenge both the resolution and accuracy of material jetting systems. Nikon's calibration methodology employs their advanced optical CMM and laser scanning technologies to achieve measurement accuracies in the sub-micron range across entire build volumes[2]. Their qualification process incorporates automated measurement sequences that can rapidly assess hundreds of features on qualification artifacts, generating statistical process capability data. For proof testing, Nikon has developed specialized artifacts with optically traceable features that can be measured both in-situ and post-process to validate dimensional stability throughout the manufacturing and post-processing workflow. Their system includes specialized software tools that can identify and categorize defects based on their likely process origins, facilitating targeted process improvements[5]. Nikon's approach emphasizes the correlation between optical surface characteristics and functional performance, particularly for applications requiring precise optical or fluidic properties.

Strengths: Exceptional optical measurement capabilities with high throughput automated inspection systems. Their multi-scale approach effectively bridges the gap between micro and macro feature qualification. Weaknesses: Their solutions are primarily focused on optical measurement techniques, which may not fully characterize all material properties relevant to functional performance. Implementation requires significant expertise in optical metrology and data analysis.

Critical Geometry Set Design Innovations

Compositions and methods for high-temperature jetting of viscous thermosets to create solid articles via additive fabrication

PatentWO2019117723A1

Innovation

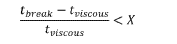

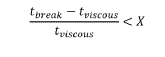

- The method involves ejecting droplets of highly viscous thermoset materials at elevated temperatures using a jetting system configured to operate at viscosities up to 60 cP, with a nozzle temperature ranging from 30°C to 180°C, and using a CaBER extensional rheology method to ensure suitable rheological characteristics, allowing for the formation of three-dimensional objects with enhanced mechanical properties.

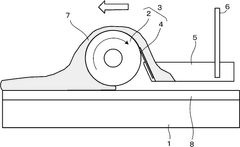

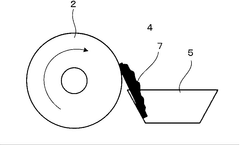

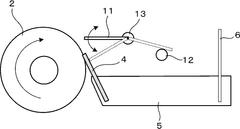

Three-dimensional object producing apparatus and three-dimensional object producing method

PatentWO2021187169A1

Innovation

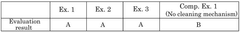

- A three-dimensional object producing apparatus is designed with a first removing unit to flatten object forming layers, a second unit to scrape away materials from the first unit, and a third unit, such as a rotating blade, suction nozzle, or cleaning liquid discharging unit, to regularly clean the second unit, preventing material accumulation and contamination.

Metrology Systems for Material Jetting Validation

Metrology systems play a crucial role in validating material jetting processes, providing the necessary measurements and analysis to ensure printed parts meet design specifications. Current metrology solutions for material jetting validation encompass a range of technologies, from optical scanning systems to coordinate measuring machines (CMMs) and specialized microscopy tools.

Optical metrology systems represent the most widely adopted validation approach, utilizing structured light scanning, laser triangulation, and photogrammetry to capture comprehensive surface data of printed artifacts. These non-contact methods offer advantages in speed and preservation of delicate features, particularly important for material jetted parts with complex geometries or thin-walled sections.

High-precision CMMs provide tactile measurement capabilities with accuracy levels reaching sub-micron resolution. While slower than optical methods, CMMs remain the gold standard for dimensional validation in critical applications where absolute measurement certainty is required. Hybrid systems combining optical and tactile measurements have emerged to leverage the strengths of both approaches.

Specialized microscopy tools, including confocal microscopy and focus variation systems, enable detailed surface characterization at micro and nano scales. These systems are particularly valuable for evaluating surface texture, layer adhesion quality, and feature fidelity in material jetted parts where surface finish is a critical parameter.

Advanced software solutions have evolved alongside hardware systems, offering sophisticated analysis capabilities including geometric dimensioning and tolerancing (GD&T), deviation mapping, and statistical process control. Machine learning algorithms are increasingly integrated into these platforms to identify patterns in measurement data and predict potential process drift before defects occur.

Real-time monitoring systems represent the cutting edge of metrology for material jetting, incorporating in-situ cameras, sensors, and spectroscopic tools to capture process data during fabrication. These systems enable immediate detection of anomalies and can trigger corrective actions before defects propagate through multiple layers.

Calibration protocols for these metrology systems require specialized artifacts with known dimensions and surface characteristics. Traceability to national measurement standards ensures consistency across different measurement platforms and facilities, a critical consideration for distributed manufacturing environments.

The integration of metrology data with digital twins and process simulation tools is creating closed-loop validation systems that continuously refine material jetting parameters based on measured outcomes, accelerating the qualification of new materials and process parameters.

Optical metrology systems represent the most widely adopted validation approach, utilizing structured light scanning, laser triangulation, and photogrammetry to capture comprehensive surface data of printed artifacts. These non-contact methods offer advantages in speed and preservation of delicate features, particularly important for material jetted parts with complex geometries or thin-walled sections.

High-precision CMMs provide tactile measurement capabilities with accuracy levels reaching sub-micron resolution. While slower than optical methods, CMMs remain the gold standard for dimensional validation in critical applications where absolute measurement certainty is required. Hybrid systems combining optical and tactile measurements have emerged to leverage the strengths of both approaches.

Specialized microscopy tools, including confocal microscopy and focus variation systems, enable detailed surface characterization at micro and nano scales. These systems are particularly valuable for evaluating surface texture, layer adhesion quality, and feature fidelity in material jetted parts where surface finish is a critical parameter.

Advanced software solutions have evolved alongside hardware systems, offering sophisticated analysis capabilities including geometric dimensioning and tolerancing (GD&T), deviation mapping, and statistical process control. Machine learning algorithms are increasingly integrated into these platforms to identify patterns in measurement data and predict potential process drift before defects occur.

Real-time monitoring systems represent the cutting edge of metrology for material jetting, incorporating in-situ cameras, sensors, and spectroscopic tools to capture process data during fabrication. These systems enable immediate detection of anomalies and can trigger corrective actions before defects propagate through multiple layers.

Calibration protocols for these metrology systems require specialized artifacts with known dimensions and surface characteristics. Traceability to national measurement standards ensures consistency across different measurement platforms and facilities, a critical consideration for distributed manufacturing environments.

The integration of metrology data with digital twins and process simulation tools is creating closed-loop validation systems that continuously refine material jetting parameters based on measured outcomes, accelerating the qualification of new materials and process parameters.

Sustainability Considerations in Material Jetting Processes

The environmental impact of material jetting processes has become increasingly significant as the technology gains wider adoption across industries. Material jetting qualification artifacts, while essential for calibration and proof of process capability, must be evaluated through a sustainability lens to align with global environmental objectives.

Material consumption represents a primary sustainability concern in material jetting processes. Traditional qualification artifacts often require substantial material usage, particularly when multiple iterations are needed for calibration purposes. The development of optimized geometry sets that maintain diagnostic capabilities while minimizing material consumption can reduce waste by up to 30%, according to recent industry studies.

Energy efficiency during the qualification process presents another critical sustainability factor. The power requirements for material jetting systems during calibration procedures can be substantial, especially when considering the cumulative impact across thousands of manufacturing facilities globally. Innovations in qualification methodologies that reduce processing time while maintaining accuracy can significantly decrease the carbon footprint associated with these operations.

End-of-life considerations for qualification artifacts remain largely unaddressed in current industry practices. Most calibration geometry sets are discarded after use, contributing to industrial waste streams. The incorporation of recyclable or biodegradable materials specifically designed for qualification purposes represents an emerging research direction with promising environmental benefits.

Water usage in material jetting processes, particularly for cleaning and support material removal from qualification artifacts, presents additional sustainability challenges. Advanced geometry designs that minimize support structures can reduce post-processing requirements and associated water consumption. Some manufacturers have reported water usage reductions of 40-60% through optimized artifact designs.

Chemical sustainability must also be considered, as many material jetting processes utilize potentially harmful substances during qualification procedures. The development of bio-based alternatives and environmentally friendly formulations for calibration materials could significantly reduce the ecological impact of these processes while maintaining the precision required for effective qualification.

Supply chain considerations extend the sustainability impact beyond the immediate manufacturing environment. Locally produced qualification artifacts can reduce transportation-related emissions, while digital distribution of standardized geometry sets enables on-demand production, minimizing inventory waste and associated environmental costs.

Human Resources: Sustainability Considerations in Material Jetting Processes

Material consumption represents a primary sustainability concern in material jetting processes. Traditional qualification artifacts often require substantial material usage, particularly when multiple iterations are needed for calibration purposes. The development of optimized geometry sets that maintain diagnostic capabilities while minimizing material consumption can reduce waste by up to 30%, according to recent industry studies.

Energy efficiency during the qualification process presents another critical sustainability factor. The power requirements for material jetting systems during calibration procedures can be substantial, especially when considering the cumulative impact across thousands of manufacturing facilities globally. Innovations in qualification methodologies that reduce processing time while maintaining accuracy can significantly decrease the carbon footprint associated with these operations.

End-of-life considerations for qualification artifacts remain largely unaddressed in current industry practices. Most calibration geometry sets are discarded after use, contributing to industrial waste streams. The incorporation of recyclable or biodegradable materials specifically designed for qualification purposes represents an emerging research direction with promising environmental benefits.

Water usage in material jetting processes, particularly for cleaning and support material removal from qualification artifacts, presents additional sustainability challenges. Advanced geometry designs that minimize support structures can reduce post-processing requirements and associated water consumption. Some manufacturers have reported water usage reductions of 40-60% through optimized artifact designs.

Chemical sustainability must also be considered, as many material jetting processes utilize potentially harmful substances during qualification procedures. The development of bio-based alternatives and environmentally friendly formulations for calibration materials could significantly reduce the ecological impact of these processes while maintaining the precision required for effective qualification.

Supply chain considerations extend the sustainability impact beyond the immediate manufacturing environment. Locally produced qualification artifacts can reduce transportation-related emissions, while digital distribution of standardized geometry sets enables on-demand production, minimizing inventory waste and associated environmental costs.

Human Resources: Sustainability Considerations in Material Jetting Processes

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!