Material Jetting Dimensional Tolerances For Press-Fit And Seal Interfaces

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting (MJ) technology has evolved significantly since its inception in the early 1990s as a promising additive manufacturing method. Initially developed as an extension of inkjet printing technology, Material Jetting has transformed from simple prototype visualization to a sophisticated manufacturing process capable of producing functional parts with multi-material capabilities. The technology's evolution has been marked by continuous improvements in material formulations, deposition precision, and curing mechanisms, enabling increasingly complex applications across various industries.

The fundamental principle of Material Jetting involves the selective deposition of photopolymer droplets onto a build platform, followed by immediate UV curing to solidify the material layer by layer. This approach offers distinct advantages in achieving smooth surface finishes and high-resolution features compared to other additive manufacturing technologies. Over the past decade, significant advancements have been made in printhead technology, material chemistry, and process control systems, collectively enhancing the dimensional accuracy and repeatability of MJ processes.

Current technological trends in Material Jetting are focused on expanding material compatibility, improving build speed, and enhancing dimensional stability. Particularly relevant to press-fit and seal interfaces is the industry's push toward tighter tolerances and better prediction of post-processing dimensional changes. Research indicates that while MJ can achieve nominal tolerances of ±0.1mm for general features, achieving consistent dimensional accuracy for precision interfaces remains challenging due to factors including material shrinkage, thermal effects, and aging characteristics.

The primary objective of Material Jetting technology development for press-fit and seal interfaces is to establish reliable manufacturing protocols that can consistently produce functional mechanical connections and fluid-tight seals. This requires not only improving the base technology but also developing comprehensive understanding of how material properties, process parameters, and post-processing treatments affect the final dimensional accuracy of critical interface features.

Industry stakeholders aim to achieve dimensional tolerances comparable to traditional manufacturing methods (±0.05mm or better) for press-fit applications while maintaining the design freedom inherent to additive manufacturing. For sealing interfaces, the goals extend beyond dimensional accuracy to include surface quality and material performance characteristics such as elasticity, compression set resistance, and long-term stability under various environmental conditions.

The technology roadmap for Material Jetting in precision applications emphasizes the development of advanced simulation tools to predict part behavior, in-process monitoring systems for real-time quality control, and specialized materials engineered specifically for interface applications. These developments collectively support the broader objective of transitioning Material Jetting from primarily prototyping applications to end-use production of functional assemblies with reliable mechanical and fluidic connections.

The fundamental principle of Material Jetting involves the selective deposition of photopolymer droplets onto a build platform, followed by immediate UV curing to solidify the material layer by layer. This approach offers distinct advantages in achieving smooth surface finishes and high-resolution features compared to other additive manufacturing technologies. Over the past decade, significant advancements have been made in printhead technology, material chemistry, and process control systems, collectively enhancing the dimensional accuracy and repeatability of MJ processes.

Current technological trends in Material Jetting are focused on expanding material compatibility, improving build speed, and enhancing dimensional stability. Particularly relevant to press-fit and seal interfaces is the industry's push toward tighter tolerances and better prediction of post-processing dimensional changes. Research indicates that while MJ can achieve nominal tolerances of ±0.1mm for general features, achieving consistent dimensional accuracy for precision interfaces remains challenging due to factors including material shrinkage, thermal effects, and aging characteristics.

The primary objective of Material Jetting technology development for press-fit and seal interfaces is to establish reliable manufacturing protocols that can consistently produce functional mechanical connections and fluid-tight seals. This requires not only improving the base technology but also developing comprehensive understanding of how material properties, process parameters, and post-processing treatments affect the final dimensional accuracy of critical interface features.

Industry stakeholders aim to achieve dimensional tolerances comparable to traditional manufacturing methods (±0.05mm or better) for press-fit applications while maintaining the design freedom inherent to additive manufacturing. For sealing interfaces, the goals extend beyond dimensional accuracy to include surface quality and material performance characteristics such as elasticity, compression set resistance, and long-term stability under various environmental conditions.

The technology roadmap for Material Jetting in precision applications emphasizes the development of advanced simulation tools to predict part behavior, in-process monitoring systems for real-time quality control, and specialized materials engineered specifically for interface applications. These developments collectively support the broader objective of transitioning Material Jetting from primarily prototyping applications to end-use production of functional assemblies with reliable mechanical and fluidic connections.

Market Demand for Precision Press-Fit Components

The global market for precision press-fit components has experienced significant growth in recent years, driven primarily by increasing demands in automotive, aerospace, medical device, and consumer electronics industries. These sectors require components with increasingly tight tolerances to ensure proper functionality, reliability, and longevity of assembled products.

In the automotive industry, the transition toward electric vehicles has intensified the need for high-precision components that can maintain electrical connections while withstanding vibration and thermal cycling. Market research indicates that the automotive segment alone accounts for approximately 35% of the precision press-fit component market, with projected annual growth rates exceeding 7% through 2028.

The aerospace sector demands components with exceptional dimensional accuracy for critical applications where failure is not an option. This industry values the elimination of fasteners and welding through precise press-fit connections, reducing weight while maintaining structural integrity. The aerospace precision component market segment is currently valued at several billion dollars with steady growth projections.

Medical device manufacturing represents another significant market driver, with stringent requirements for biocompatible components that maintain precise fits for implantable devices and diagnostic equipment. The medical sector's demand for micro-precision components has grown at double-digit rates annually as minimally invasive procedures become standard practice.

Consumer electronics manufacturers continue to push the boundaries of miniaturization while increasing functionality, creating substantial demand for micro-scale press-fit components with tolerances measured in microns rather than millimeters. This sector's rapid product development cycles also necessitate manufacturing processes that can quickly adapt to new designs while maintaining precision.

Industrial equipment manufacturers represent a stable market segment requiring robust press-fit components that can withstand harsh operating environments while maintaining sealing integrity. The industrial automation trend has further accelerated demand for precision components that enable reliable operation of increasingly complex machinery.

Market analysis reveals that manufacturers are willing to pay premium prices for components that consistently meet tight tolerance specifications, as the cost of failure in assembly or field operation far exceeds the component cost differential. This value proposition has created opportunities for advanced manufacturing technologies that can deliver higher precision than traditional methods.

The market increasingly demands customization capabilities, with shorter production runs and faster turnaround times. This trend favors digital manufacturing approaches that can efficiently produce precision components without the tooling costs and lead times associated with traditional manufacturing methods.

In the automotive industry, the transition toward electric vehicles has intensified the need for high-precision components that can maintain electrical connections while withstanding vibration and thermal cycling. Market research indicates that the automotive segment alone accounts for approximately 35% of the precision press-fit component market, with projected annual growth rates exceeding 7% through 2028.

The aerospace sector demands components with exceptional dimensional accuracy for critical applications where failure is not an option. This industry values the elimination of fasteners and welding through precise press-fit connections, reducing weight while maintaining structural integrity. The aerospace precision component market segment is currently valued at several billion dollars with steady growth projections.

Medical device manufacturing represents another significant market driver, with stringent requirements for biocompatible components that maintain precise fits for implantable devices and diagnostic equipment. The medical sector's demand for micro-precision components has grown at double-digit rates annually as minimally invasive procedures become standard practice.

Consumer electronics manufacturers continue to push the boundaries of miniaturization while increasing functionality, creating substantial demand for micro-scale press-fit components with tolerances measured in microns rather than millimeters. This sector's rapid product development cycles also necessitate manufacturing processes that can quickly adapt to new designs while maintaining precision.

Industrial equipment manufacturers represent a stable market segment requiring robust press-fit components that can withstand harsh operating environments while maintaining sealing integrity. The industrial automation trend has further accelerated demand for precision components that enable reliable operation of increasingly complex machinery.

Market analysis reveals that manufacturers are willing to pay premium prices for components that consistently meet tight tolerance specifications, as the cost of failure in assembly or field operation far exceeds the component cost differential. This value proposition has created opportunities for advanced manufacturing technologies that can deliver higher precision than traditional methods.

The market increasingly demands customization capabilities, with shorter production runs and faster turnaround times. This trend favors digital manufacturing approaches that can efficiently produce precision components without the tooling costs and lead times associated with traditional manufacturing methods.

Current Capabilities and Challenges in Dimensional Accuracy

Material jetting technology currently achieves dimensional tolerances of approximately ±0.1% of the part dimension with a lower bound of ±0.05 mm for small features. This represents a significant improvement over earlier generations of the technology but still falls short of the precision required for high-performance press-fit and seal interfaces, which often demand tolerances of ±0.025 mm or better. The accuracy limitations stem from multiple factors in the manufacturing process chain.

The primary challenge lies in the material deposition process itself. Droplet placement accuracy is affected by printhead movement precision, jetting consistency, and material flow dynamics. Even minor variations in droplet trajectory or volume can accumulate into measurable dimensional deviations, particularly for features requiring tight tolerances such as O-ring grooves or precision press-fits.

Post-processing shrinkage presents another significant hurdle. Most photopolymers used in material jetting experience volumetric shrinkage during curing, typically ranging from 1-6% depending on the specific material formulation. While manufacturers attempt to compensate for this shrinkage through scaling factors in the printing process, the shrinkage is not always uniform across different geometries and feature sizes, making it difficult to predict and control precisely.

Environmental factors further complicate dimensional accuracy. Temperature and humidity variations during printing and curing can affect material properties and dimensional stability. Studies have shown that parts produced in controlled environments exhibit up to 40% better dimensional consistency compared to those manufactured in fluctuating conditions.

The anisotropic nature of the printing process introduces directional dependencies in dimensional accuracy. Z-axis resolution (layer thickness) typically ranges from 16-32 microns, while XY resolution is determined by the printhead's native resolution, usually 600-1600 DPI. This disparity creates inherent differences in accuracy between vertical and horizontal features, complicating the design of circular sealing interfaces and cylindrical press-fits.

Material limitations also impact dimensional accuracy capabilities. Current photopolymer formulations balance multiple competing properties including viscosity for jetting, curing speed, mechanical strength, and dimensional stability. Materials optimized specifically for dimensional accuracy often compromise on other mechanical properties, creating a challenging trade-off for applications requiring both precise dimensions and specific performance characteristics.

Advanced industrial systems have begun implementing real-time monitoring and closed-loop feedback systems to improve dimensional accuracy, but these technologies remain in early adoption phases and have not yet demonstrated consistent sub-50-micron tolerances required for critical sealing applications.

The primary challenge lies in the material deposition process itself. Droplet placement accuracy is affected by printhead movement precision, jetting consistency, and material flow dynamics. Even minor variations in droplet trajectory or volume can accumulate into measurable dimensional deviations, particularly for features requiring tight tolerances such as O-ring grooves or precision press-fits.

Post-processing shrinkage presents another significant hurdle. Most photopolymers used in material jetting experience volumetric shrinkage during curing, typically ranging from 1-6% depending on the specific material formulation. While manufacturers attempt to compensate for this shrinkage through scaling factors in the printing process, the shrinkage is not always uniform across different geometries and feature sizes, making it difficult to predict and control precisely.

Environmental factors further complicate dimensional accuracy. Temperature and humidity variations during printing and curing can affect material properties and dimensional stability. Studies have shown that parts produced in controlled environments exhibit up to 40% better dimensional consistency compared to those manufactured in fluctuating conditions.

The anisotropic nature of the printing process introduces directional dependencies in dimensional accuracy. Z-axis resolution (layer thickness) typically ranges from 16-32 microns, while XY resolution is determined by the printhead's native resolution, usually 600-1600 DPI. This disparity creates inherent differences in accuracy between vertical and horizontal features, complicating the design of circular sealing interfaces and cylindrical press-fits.

Material limitations also impact dimensional accuracy capabilities. Current photopolymer formulations balance multiple competing properties including viscosity for jetting, curing speed, mechanical strength, and dimensional stability. Materials optimized specifically for dimensional accuracy often compromise on other mechanical properties, creating a challenging trade-off for applications requiring both precise dimensions and specific performance characteristics.

Advanced industrial systems have begun implementing real-time monitoring and closed-loop feedback systems to improve dimensional accuracy, but these technologies remain in early adoption phases and have not yet demonstrated consistent sub-50-micron tolerances required for critical sealing applications.

Current Tolerance Achievement Methods for Interface Applications

01 Achieving high precision in material jetting processes

Material jetting technologies can achieve high dimensional accuracy through precise control of droplet deposition. Advanced systems incorporate real-time monitoring and feedback mechanisms to adjust parameters during printing, ensuring dimensional tolerances are maintained. Calibration techniques and compensation algorithms help correct for material shrinkage, thermal expansion, and other factors that could affect dimensional accuracy.- Precision control in material jetting processes: Material jetting technologies require precise control mechanisms to achieve tight dimensional tolerances. These systems incorporate advanced positioning systems, feedback controls, and calibration methods to ensure accurate deposition of materials. By controlling parameters such as droplet size, ejection velocity, and positioning accuracy, manufacturers can achieve consistent dimensional tolerances in the final printed parts. These precision control systems are essential for applications requiring high accuracy and repeatability.

- Material formulation for improved dimensional accuracy: The composition and properties of jetted materials significantly impact dimensional tolerances. Specialized formulations with controlled viscosity, surface tension, and curing characteristics help minimize shrinkage and deformation during printing and post-processing. Advanced materials incorporate additives that enhance stability during deposition and solidification, resulting in more predictable dimensional outcomes. These formulations are particularly important for maintaining tight tolerances in complex geometries and fine features.

- Process parameter optimization for tolerance control: Achieving tight dimensional tolerances in material jetting requires optimization of various process parameters. These include printing speed, layer thickness, curing conditions, and environmental factors such as temperature and humidity. Sophisticated algorithms and modeling techniques help determine optimal parameter combinations for specific geometries and materials. By systematically adjusting these parameters based on part requirements, manufacturers can significantly improve dimensional accuracy and consistency across production runs.

- Post-processing techniques for enhancing dimensional accuracy: Various post-processing methods can be employed to improve the dimensional tolerances of material-jetted parts. These include controlled thermal treatments, surface finishing operations, and precision machining of critical features. Some approaches involve compensating for known shrinkage patterns by adjusting the initial design dimensions. Advanced post-processing techniques can help achieve tolerances that might not be possible through the printing process alone, particularly for high-precision applications.

- Quality control and inspection systems for dimensional verification: Maintaining consistent dimensional tolerances in material jetting processes requires sophisticated quality control and inspection systems. These include in-situ monitoring technologies, machine vision systems, and advanced metrology equipment for verifying dimensional accuracy. Real-time feedback mechanisms can detect deviations and make adjustments during the printing process. Comprehensive inspection protocols help identify tolerance issues early, allowing for process adjustments before significant production runs are affected.

02 Material formulation for improved dimensional stability

The composition of jetting materials significantly impacts dimensional tolerances. Specialized formulations with controlled viscosity, surface tension, and curing properties help maintain dimensional accuracy during deposition and solidification. Additives can be incorporated to reduce shrinkage, prevent warping, and enhance structural integrity, resulting in printed parts with tighter tolerances and better reproducibility.Expand Specific Solutions03 Process parameter optimization for dimensional control

Optimizing process parameters such as jetting temperature, droplet size, deposition rate, and curing conditions is essential for achieving tight dimensional tolerances. Systematic approaches to parameter selection based on material properties and part geometry help maintain consistency across production runs. Advanced algorithms can predict and compensate for dimensional variations based on specific printing conditions.Expand Specific Solutions04 Post-processing techniques to enhance dimensional accuracy

Various post-processing methods can be employed to improve the dimensional accuracy of material-jetted parts. These include controlled thermal treatments to relieve internal stresses, precision machining to achieve critical dimensions, and surface treatments to enhance finish quality. Post-processing steps can be integrated into the manufacturing workflow to consistently meet tight tolerance requirements.Expand Specific Solutions05 Quality control and inspection methods for dimensional verification

Advanced measurement and inspection techniques are crucial for verifying dimensional tolerances in material jetting processes. In-situ monitoring systems can detect deviations during printing, while sophisticated metrology equipment provides accurate post-production verification. Statistical process control methods help identify trends and variations, enabling continuous improvement of dimensional accuracy in material jetting manufacturing.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Material Jetting technology for dimensional tolerances in press-fit and seal interfaces is currently in a growth phase, with the market expanding as industrial applications increase. The global market is estimated to reach $500-700 million by 2025, driven by demand for precision components. Technologically, the field is approaching maturity with companies like Stratasys, HP Development, and DuPont leading innovation in high-precision material jetting solutions. Stratasys offers advanced multi-material capabilities, while HP focuses on industrial-scale production with tight tolerances. Robert Bosch and Boeing are implementing these technologies for critical seal interfaces, while companies like Sumitomo Electric and Saint-Gobain are developing specialized materials optimized for dimensional stability in press-fit applications.

Stratasys, Inc.

Technical Solution: Stratasys has developed advanced Material Jetting technology called PolyJet that achieves dimensional tolerances as precise as +/- 0.1mm for small features and +/- 0.3% for larger dimensions. Their system utilizes multi-material jetting capabilities with support materials that can be easily removed, enabling the creation of complex press-fit and seal interfaces with high precision. The company's J8 and J55 series printers employ a proprietary droplet placement technology that deposits photopolymer materials in layers as thin as 14 microns, allowing for exceptional surface finish quality critical for sealing applications. Stratasys has also developed specialized elastomeric materials (Agilus30 and TangoPlus) specifically engineered for gasket and seal applications, with shore hardness values ranging from 27-95A to accommodate various sealing requirements. Their Digital ABS Plus material offers high dimensional stability with heat deflection temperatures up to 80°C, making it suitable for functional press-fit components that maintain tolerances under thermal stress.

Strengths: Superior multi-material capabilities allowing for overmolded seals and gaskets in a single print process; exceptional surface finish quality; wide range of material properties from rigid to flexible. Weaknesses: Higher material costs compared to traditional manufacturing; limited build volume restricting the size of producible components; post-processing requirements for support removal can affect final dimensional accuracy.

HP Development Co. LP

Technical Solution: HP has pioneered Multi Jet Fusion (MJF) technology that achieves dimensional tolerances of ±0.2mm for features under 100mm, making it highly suitable for press-fit and seal interface applications. Their process utilizes a unique approach where a fusing agent is selectively applied to powder material and then activated by energy sources, resulting in parts with exceptional isotropy and minimal warpage. HP's 5200 series printers incorporate a closed-loop thermal control system that maintains consistent chamber temperatures within ±3°C, critical for achieving repeatable dimensional accuracy across production runs. For seal interfaces, HP has developed specialized TPU materials with shore hardness ranging from 75A to 90A that maintain elasticity while providing dimensional stability. Their proprietary voxel-level control technology allows for precise manipulation of material properties within parts, enabling the creation of variable stiffness regions within a single component - particularly valuable for complex sealing applications where different compression forces are required across the seal interface.

Strengths: Excellent repeatability across production runs; superior isotropy compared to other 3D printing technologies; good balance between dimensional accuracy and production speed. Weaknesses: Limited material selection compared to some competing technologies; challenges with very small feature sizes below 0.5mm; post-processing requirements for surface finish improvement in critical sealing applications.

Critical Patents and Research on Dimensional Control

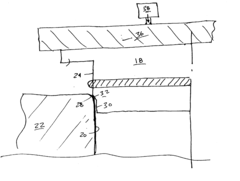

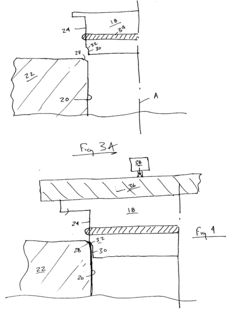

Stepped locating diameter for a press fit component

PatentInactiveUS20040146344A1

Innovation

- A press fit seal component with a locating diameter that provides a clearance fit in the bore, allowing for stable prepositioning and alignment, enabling simple press fitting without complex tooling, and a method where the locating diameter is initially placed into the bore to facilitate perpendicular indexing and sealing with a gasket material.

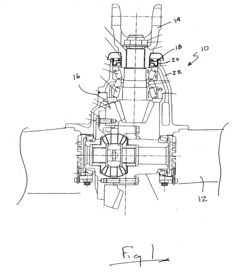

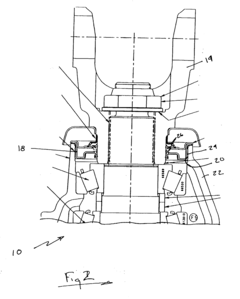

Creep resistant metal to plastic interconnection

PatentInactiveEP0589889A1

Innovation

- An insert molding or post-mold press fit of a metal sleeve into the inner diameter of a plastic part, followed by press fitting the plastic part into a rigid metal housing, enhances resistance to creep by allowing cold flow of plastic into surface imperfections in the metal housing.

Material Properties Impact on Seal Interface Performance

The material properties of components used in material jetting processes significantly influence the performance of seal interfaces. Polymer-based materials commonly used in material jetting exhibit viscoelastic behavior, which directly affects their sealing capabilities. This viscoelasticity results in time-dependent deformation under load, creating challenges for maintaining consistent seal performance over extended periods. The stress relaxation phenomenon, particularly prevalent in photopolymers, can lead to decreased sealing force over time, potentially compromising the integrity of sealed interfaces in critical applications.

Surface characteristics of jetted materials play a crucial role in seal effectiveness. The layer-by-layer deposition process inherent to material jetting creates microscopic surface irregularities that can impact sealing performance. These surface features, combined with the material's inherent wettability and surface energy, determine how effectively the seal can prevent fluid or gas penetration. Materials with higher surface energy typically form more effective seals due to stronger molecular interactions at the interface boundary.

Thermal properties of jetted materials present another significant consideration for seal interface performance. Coefficient of thermal expansion (CTE) mismatches between mating components can lead to seal gaps or excessive compression when operating across varying temperature environments. Most photopolymers used in material jetting exhibit relatively high CTEs compared to traditional engineering materials, necessitating careful design considerations for applications with temperature fluctuations.

Mechanical properties such as hardness, elastic modulus, and creep resistance directly influence seal performance. Softer materials may conform better to mating surfaces initially, creating effective seals, but may suffer from accelerated wear or permanent deformation. Conversely, harder materials maintain dimensional stability but may require higher precision to achieve effective sealing. The balance between compliance and resilience is particularly critical for dynamic seals where components experience relative motion.

Chemical compatibility between the seal material and the contained substance represents another vital consideration. Many photopolymers used in material jetting have limited resistance to certain chemicals, solvents, and oils. Exposure to incompatible substances can cause swelling, degradation, or embrittlement of the seal material, leading to premature failure. This limitation necessitates careful material selection based on the specific chemical environment of the intended application.

Aging and environmental effects further complicate seal performance predictions. UV exposure, humidity, and oxygen can degrade many photopolymers over time, altering their mechanical properties and dimensional stability. This degradation can manifest as reduced elasticity, increased brittleness, or dimensional changes that compromise seal effectiveness. Accelerated aging tests are essential for predicting long-term seal performance in various environmental conditions.

Surface characteristics of jetted materials play a crucial role in seal effectiveness. The layer-by-layer deposition process inherent to material jetting creates microscopic surface irregularities that can impact sealing performance. These surface features, combined with the material's inherent wettability and surface energy, determine how effectively the seal can prevent fluid or gas penetration. Materials with higher surface energy typically form more effective seals due to stronger molecular interactions at the interface boundary.

Thermal properties of jetted materials present another significant consideration for seal interface performance. Coefficient of thermal expansion (CTE) mismatches between mating components can lead to seal gaps or excessive compression when operating across varying temperature environments. Most photopolymers used in material jetting exhibit relatively high CTEs compared to traditional engineering materials, necessitating careful design considerations for applications with temperature fluctuations.

Mechanical properties such as hardness, elastic modulus, and creep resistance directly influence seal performance. Softer materials may conform better to mating surfaces initially, creating effective seals, but may suffer from accelerated wear or permanent deformation. Conversely, harder materials maintain dimensional stability but may require higher precision to achieve effective sealing. The balance between compliance and resilience is particularly critical for dynamic seals where components experience relative motion.

Chemical compatibility between the seal material and the contained substance represents another vital consideration. Many photopolymers used in material jetting have limited resistance to certain chemicals, solvents, and oils. Exposure to incompatible substances can cause swelling, degradation, or embrittlement of the seal material, leading to premature failure. This limitation necessitates careful material selection based on the specific chemical environment of the intended application.

Aging and environmental effects further complicate seal performance predictions. UV exposure, humidity, and oxygen can degrade many photopolymers over time, altering their mechanical properties and dimensional stability. This degradation can manifest as reduced elasticity, increased brittleness, or dimensional changes that compromise seal effectiveness. Accelerated aging tests are essential for predicting long-term seal performance in various environmental conditions.

Post-Processing Techniques for Enhanced Dimensional Stability

Post-processing techniques have emerged as critical interventions for enhancing dimensional stability in material jetting applications, particularly for press-fit and seal interfaces where precision is paramount. These techniques address the inherent limitations of as-printed parts, which often exhibit dimensional variations that compromise functional performance.

Thermal post-processing represents one of the most effective approaches for dimensional stabilization. Controlled heat treatment protocols can significantly reduce internal stresses accumulated during the printing process, thereby minimizing warpage and dimensional drift over time. Research indicates that optimized thermal cycling between 60-80°C can improve dimensional accuracy by up to 15% for common photopolymers used in material jetting.

Chemical treatments have also demonstrated considerable efficacy in enhancing surface quality and dimensional precision. Solvent vapor smoothing, utilizing carefully selected solvents compatible with the printed material, can reduce surface roughness while simultaneously improving dimensional consistency. Studies have shown that controlled exposure to isopropyl alcohol vapor for specific photopolymers can achieve Ra values below 0.5μm without compromising dimensional tolerances.

UV post-curing represents another critical technique, particularly for parts produced through material jetting processes utilizing photopolymers. Advanced UV post-curing chambers with controlled atmosphere and temperature regulation have been developed to ensure uniform curing throughout the part volume. This approach minimizes differential shrinkage and enhances long-term dimensional stability, which is especially important for seal interfaces where consistent performance is required over extended periods.

Mechanical post-processing techniques, including precision machining and micro-abrasive finishing, offer targeted dimensional correction for critical features. These approaches are particularly valuable for press-fit interfaces where tolerances may be as tight as ±0.01mm. Recent developments in automated micro-machining systems specifically designed for additively manufactured parts allow for selective material removal while preserving the complex geometries enabled by material jetting.

Hybrid approaches combining multiple post-processing techniques have shown the most promising results for demanding applications. For instance, sequential application of thermal stabilization, chemical surface treatment, and precision machining can achieve dimensional tolerances approaching those of traditional manufacturing methods. These integrated workflows are increasingly being standardized and automated to ensure repeatability and cost-effectiveness in production environments.

Thermal post-processing represents one of the most effective approaches for dimensional stabilization. Controlled heat treatment protocols can significantly reduce internal stresses accumulated during the printing process, thereby minimizing warpage and dimensional drift over time. Research indicates that optimized thermal cycling between 60-80°C can improve dimensional accuracy by up to 15% for common photopolymers used in material jetting.

Chemical treatments have also demonstrated considerable efficacy in enhancing surface quality and dimensional precision. Solvent vapor smoothing, utilizing carefully selected solvents compatible with the printed material, can reduce surface roughness while simultaneously improving dimensional consistency. Studies have shown that controlled exposure to isopropyl alcohol vapor for specific photopolymers can achieve Ra values below 0.5μm without compromising dimensional tolerances.

UV post-curing represents another critical technique, particularly for parts produced through material jetting processes utilizing photopolymers. Advanced UV post-curing chambers with controlled atmosphere and temperature regulation have been developed to ensure uniform curing throughout the part volume. This approach minimizes differential shrinkage and enhances long-term dimensional stability, which is especially important for seal interfaces where consistent performance is required over extended periods.

Mechanical post-processing techniques, including precision machining and micro-abrasive finishing, offer targeted dimensional correction for critical features. These approaches are particularly valuable for press-fit interfaces where tolerances may be as tight as ±0.01mm. Recent developments in automated micro-machining systems specifically designed for additively manufactured parts allow for selective material removal while preserving the complex geometries enabled by material jetting.

Hybrid approaches combining multiple post-processing techniques have shown the most promising results for demanding applications. For instance, sequential application of thermal stabilization, chemical surface treatment, and precision machining can achieve dimensional tolerances approaching those of traditional manufacturing methods. These integrated workflows are increasingly being standardized and automated to ensure repeatability and cost-effectiveness in production environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!