Material Jetting Post-Processing Chains: Cleaning, UV Cure, Thermal Condition And QA

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting (MJ) technology represents one of the most sophisticated additive manufacturing processes, evolving significantly since its inception in the late 1990s. Initially developed as a method for precise deposition of photopolymer materials, MJ has transformed from a prototyping tool into a viable manufacturing technology capable of producing end-use parts with exceptional detail and material properties.

The technological evolution of Material Jetting has been characterized by continuous improvements in printhead technology, material formulations, and process control systems. Early systems were limited by low resolution and restricted material options, whereas contemporary MJ platforms can achieve resolutions below 20 microns and support an expanding range of materials including rigid, flexible, transparent, and biocompatible photopolymers.

Current market trends indicate a growing demand for multi-material capabilities and functional parts with specific mechanical, thermal, and electrical properties. This has driven research toward developing new photopolymer formulations with enhanced performance characteristics and stability over time. The integration of digital manufacturing workflows has further accelerated MJ adoption across industries such as medical, consumer products, and aerospace.

Post-processing represents a critical yet often overlooked aspect of the Material Jetting workflow. Unlike some additive manufacturing technologies where parts emerge ready for use, MJ-produced components require systematic post-processing to achieve optimal mechanical properties and surface quality. This chain typically includes support removal, cleaning, UV curing, thermal conditioning, and quality assurance steps.

The primary technical objective in MJ post-processing development is to establish standardized, efficient protocols that maximize part performance while minimizing manual intervention. Current challenges include inconsistent curing parameters, residual uncured resin management, dimensional stability during thermal post-treatment, and the development of non-destructive testing methodologies appropriate for complex geometries.

Research goals in this domain focus on optimizing each stage of the post-processing chain through scientific understanding of photopolymer curing kinetics, thermal behavior of printed materials, and the relationship between processing parameters and final part properties. Automation of post-processing steps represents another significant objective, with efforts directed toward developing integrated systems that can handle cleaning, curing, and conditioning with minimal human intervention.

The ultimate aim is to establish a comprehensive framework for MJ post-processing that ensures reproducible part quality, predictable material properties, and efficient workflow integration. This would enable broader industrial adoption of MJ technology and expand its application into more demanding sectors requiring certified production processes and validated quality assurance protocols.

The technological evolution of Material Jetting has been characterized by continuous improvements in printhead technology, material formulations, and process control systems. Early systems were limited by low resolution and restricted material options, whereas contemporary MJ platforms can achieve resolutions below 20 microns and support an expanding range of materials including rigid, flexible, transparent, and biocompatible photopolymers.

Current market trends indicate a growing demand for multi-material capabilities and functional parts with specific mechanical, thermal, and electrical properties. This has driven research toward developing new photopolymer formulations with enhanced performance characteristics and stability over time. The integration of digital manufacturing workflows has further accelerated MJ adoption across industries such as medical, consumer products, and aerospace.

Post-processing represents a critical yet often overlooked aspect of the Material Jetting workflow. Unlike some additive manufacturing technologies where parts emerge ready for use, MJ-produced components require systematic post-processing to achieve optimal mechanical properties and surface quality. This chain typically includes support removal, cleaning, UV curing, thermal conditioning, and quality assurance steps.

The primary technical objective in MJ post-processing development is to establish standardized, efficient protocols that maximize part performance while minimizing manual intervention. Current challenges include inconsistent curing parameters, residual uncured resin management, dimensional stability during thermal post-treatment, and the development of non-destructive testing methodologies appropriate for complex geometries.

Research goals in this domain focus on optimizing each stage of the post-processing chain through scientific understanding of photopolymer curing kinetics, thermal behavior of printed materials, and the relationship between processing parameters and final part properties. Automation of post-processing steps represents another significant objective, with efforts directed toward developing integrated systems that can handle cleaning, curing, and conditioning with minimal human intervention.

The ultimate aim is to establish a comprehensive framework for MJ post-processing that ensures reproducible part quality, predictable material properties, and efficient workflow integration. This would enable broader industrial adoption of MJ technology and expand its application into more demanding sectors requiring certified production processes and validated quality assurance protocols.

Market Analysis for Material Jetting Applications

The material jetting market has experienced significant growth in recent years, driven by increasing demand for high-precision manufacturing processes across various industries. The global material jetting market was valued at approximately $2.5 billion in 2022 and is projected to reach $4.7 billion by 2028, representing a compound annual growth rate of 11.2% during the forecast period.

The healthcare and dental sectors currently dominate material jetting applications, accounting for nearly 35% of the total market share. The ability to produce patient-specific anatomical models, surgical guides, and dental prosthetics with high accuracy has positioned material jetting as a preferred technology in these fields. The dental industry, in particular, has embraced material jetting for the production of clear aligners, crowns, and bridges.

Aerospace and automotive industries represent the second-largest application segment, collectively contributing approximately 28% of market revenue. These sectors leverage material jetting for prototyping complex components, producing functional parts with specific mechanical properties, and manufacturing tooling with intricate geometries. The demand for lightweight components with enhanced performance characteristics continues to drive adoption in these industries.

Consumer electronics manufacturers have increasingly incorporated material jetting into their production processes, particularly for creating multi-material prototypes and functional components. This sector accounts for roughly 18% of the market and is expected to grow at the fastest rate among all application segments due to the increasing complexity of electronic devices and the need for rapid product development cycles.

Jewelry and luxury goods production represents an emerging application area, currently holding about 8% of the market share. The ability to create intricate designs with exceptional surface finish makes material jetting particularly suitable for this sector. Additionally, the technology enables the production of customized pieces with reduced material waste compared to traditional manufacturing methods.

The remaining market share is distributed across various industries including architecture, education, and research institutions. These sectors primarily utilize material jetting for conceptual modeling, educational purposes, and experimental research applications where high precision and material versatility are required.

Geographically, North America leads the material jetting market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing industrialization, government initiatives supporting advanced manufacturing technologies, and growing adoption across various sectors.

The healthcare and dental sectors currently dominate material jetting applications, accounting for nearly 35% of the total market share. The ability to produce patient-specific anatomical models, surgical guides, and dental prosthetics with high accuracy has positioned material jetting as a preferred technology in these fields. The dental industry, in particular, has embraced material jetting for the production of clear aligners, crowns, and bridges.

Aerospace and automotive industries represent the second-largest application segment, collectively contributing approximately 28% of market revenue. These sectors leverage material jetting for prototyping complex components, producing functional parts with specific mechanical properties, and manufacturing tooling with intricate geometries. The demand for lightweight components with enhanced performance characteristics continues to drive adoption in these industries.

Consumer electronics manufacturers have increasingly incorporated material jetting into their production processes, particularly for creating multi-material prototypes and functional components. This sector accounts for roughly 18% of the market and is expected to grow at the fastest rate among all application segments due to the increasing complexity of electronic devices and the need for rapid product development cycles.

Jewelry and luxury goods production represents an emerging application area, currently holding about 8% of the market share. The ability to create intricate designs with exceptional surface finish makes material jetting particularly suitable for this sector. Additionally, the technology enables the production of customized pieces with reduced material waste compared to traditional manufacturing methods.

The remaining market share is distributed across various industries including architecture, education, and research institutions. These sectors primarily utilize material jetting for conceptual modeling, educational purposes, and experimental research applications where high precision and material versatility are required.

Geographically, North America leads the material jetting market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing industrialization, government initiatives supporting advanced manufacturing technologies, and growing adoption across various sectors.

Current Post-Processing Challenges

Material jetting technology faces several significant post-processing challenges that impact product quality, production efficiency, and overall manufacturing costs. The cleaning phase presents difficulties in removing support materials completely without damaging the printed parts, especially for complex geometries with internal channels or intricate features. Current solvent-based cleaning methods often require extended immersion times and may not fully remove residual support materials from hard-to-reach areas, leading to quality inconsistencies.

UV curing processes exhibit challenges related to achieving uniform curing throughout the entire part volume. Parts with varying thicknesses or complex geometries may experience uneven curing, resulting in differential mechanical properties and potential warping. The energy distribution in UV chambers is frequently non-uniform, creating zones of over-curing and under-curing within the same part. Additionally, the relationship between UV exposure time, intensity, and resulting material properties remains difficult to standardize across different part geometries and material formulations.

Thermal conditioning processes face similar uniformity issues, with temperature gradients causing internal stresses that can lead to dimensional inaccuracies or part failure. The optimal thermal profiles for different materials and geometries are often determined through trial and error rather than systematic approaches, creating inefficiencies in process development and scaling.

Quality assurance represents perhaps the most significant challenge in the post-processing chain. Current inspection methods struggle to detect internal defects or incomplete curing without destructive testing. Non-destructive testing technologies such as CT scanning provide comprehensive analysis but are time-consuming and cost-prohibitive for routine production. The lack of in-line monitoring capabilities during post-processing stages means that defects are often discovered only after significant value has been added to the parts.

Integration of these post-processing steps into a cohesive, automated workflow remains problematic. Most current implementations require manual handling between stages, introducing variability and increasing labor costs. The disconnected nature of these processes also creates challenges in traceability and process optimization, as data from one stage rarely informs adjustments in subsequent stages.

Environmental and safety concerns further complicate post-processing operations. Many cleaning solvents pose health risks and environmental hazards, while UV curing systems require careful shielding and operator protection. These factors add regulatory compliance burdens and additional operational costs to material jetting manufacturing operations.

UV curing processes exhibit challenges related to achieving uniform curing throughout the entire part volume. Parts with varying thicknesses or complex geometries may experience uneven curing, resulting in differential mechanical properties and potential warping. The energy distribution in UV chambers is frequently non-uniform, creating zones of over-curing and under-curing within the same part. Additionally, the relationship between UV exposure time, intensity, and resulting material properties remains difficult to standardize across different part geometries and material formulations.

Thermal conditioning processes face similar uniformity issues, with temperature gradients causing internal stresses that can lead to dimensional inaccuracies or part failure. The optimal thermal profiles for different materials and geometries are often determined through trial and error rather than systematic approaches, creating inefficiencies in process development and scaling.

Quality assurance represents perhaps the most significant challenge in the post-processing chain. Current inspection methods struggle to detect internal defects or incomplete curing without destructive testing. Non-destructive testing technologies such as CT scanning provide comprehensive analysis but are time-consuming and cost-prohibitive for routine production. The lack of in-line monitoring capabilities during post-processing stages means that defects are often discovered only after significant value has been added to the parts.

Integration of these post-processing steps into a cohesive, automated workflow remains problematic. Most current implementations require manual handling between stages, introducing variability and increasing labor costs. The disconnected nature of these processes also creates challenges in traceability and process optimization, as data from one stage rarely informs adjustments in subsequent stages.

Environmental and safety concerns further complicate post-processing operations. Many cleaning solvents pose health risks and environmental hazards, while UV curing systems require careful shielding and operator protection. These factors add regulatory compliance burdens and additional operational costs to material jetting manufacturing operations.

Current Post-Processing Solutions Analysis

01 UV Curing Processes for Material Jetting

UV curing is a critical post-processing step for material jetting that involves exposing printed parts to ultraviolet light to initiate photopolymerization. This process solidifies liquid photopolymers into durable solids, enhancing mechanical properties and dimensional stability. Advanced UV curing systems may incorporate specific wavelength ranges, intensity controls, and exposure times optimized for different materials to ensure complete curing throughout the part volume while minimizing warping or shrinkage.- UV Curing Processes in Material Jetting: UV curing is a critical post-processing step in material jetting that involves exposing printed parts to ultraviolet light to initiate photopolymerization. This process solidifies liquid photopolymers into their final state, enhancing mechanical properties and dimensional stability. Advanced UV curing systems may incorporate specific wavelength ranges, intensity controls, and exposure times optimized for different materials to ensure complete polymerization throughout the part while minimizing warping or internal stresses.

- Thermal Conditioning Techniques: Thermal conditioning represents an important post-processing step for material jetted parts, involving controlled heating and cooling cycles to relieve internal stresses, improve mechanical properties, and enhance dimensional stability. This process can include annealing, tempering, or other heat treatment methods tailored to specific materials. Proper thermal conditioning can significantly improve part durability, reduce warping, and ensure consistent material properties throughout the printed object.

- Cleaning and Support Removal Methods: Cleaning processes for material jetted parts involve the removal of uncured resin, support materials, and other contaminants from the printed object. This may include solvent baths, water jetting, ultrasonic cleaning, or mechanical removal techniques. Effective cleaning ensures proper surface finish and prevents contamination that could affect subsequent processing steps. Advanced cleaning systems may incorporate automated processes with controlled parameters to optimize removal efficiency while preserving part integrity.

- Quality Assurance and Testing Protocols: Quality assurance for material jetted parts encompasses various inspection and testing methods to verify dimensional accuracy, surface quality, mechanical properties, and overall part integrity. This includes visual inspection, dimensional measurement, mechanical testing, and non-destructive evaluation techniques. Advanced QA systems may incorporate automated vision systems, CT scanning, or other technologies to detect defects, ensure consistency, and validate that parts meet required specifications before final use.

- Integrated Post-Processing Workflows: Integrated post-processing workflows combine multiple treatment steps into cohesive, often automated systems that enhance efficiency and consistency. These workflows may include sequential cleaning, curing, thermal treatment, and quality inspection stations with controlled material handling between steps. Advanced systems incorporate process monitoring, feedback control, and data logging to ensure repeatability and traceability throughout the post-processing chain, optimizing both quality and production efficiency for material jetted parts.

02 Cleaning Techniques for Material Jetted Parts

Post-processing cleaning is essential for removing uncured resin, support materials, and contaminants from material jetted parts. Techniques include solvent baths, ultrasonic cleaning, water jet systems, and specialized cleaning solutions designed for specific materials. Proper cleaning improves surface finish, prevents contamination of subsequent processing steps, and ensures accurate dimensional specifications. The cleaning process must be carefully controlled to avoid damaging delicate features while effectively removing all residual materials.Expand Specific Solutions03 Thermal Conditioning and Heat Treatment

Thermal conditioning involves subjecting material jetted parts to controlled temperature environments to enhance material properties and dimensional stability. Heat treatment processes can include annealing, tempering, and stress relief to reduce internal stresses, improve mechanical properties, and ensure dimensional accuracy. Temperature profiles must be carefully controlled to prevent warping, cracking, or degradation of the printed materials. Thermal conditioning can also be used to achieve specific material characteristics such as increased flexibility or hardness.Expand Specific Solutions04 Quality Assurance and Testing Methods

Quality assurance for material jetted parts involves comprehensive testing and inspection methods to verify dimensional accuracy, surface quality, mechanical properties, and functional performance. Techniques include optical scanning, coordinate measuring machines, CT scanning, mechanical testing, and visual inspection. Automated systems may incorporate machine vision and AI algorithms to detect defects and ensure consistency. QA processes often involve comparing parts against CAD models and predefined specifications to identify deviations and ensure parts meet required standards.Expand Specific Solutions05 Integrated Post-Processing Workflows

Integrated post-processing workflows combine cleaning, UV curing, thermal conditioning, and quality assurance into streamlined, often automated systems. These workflows optimize the sequence and parameters of each post-processing step to enhance efficiency and consistency. Advanced systems may incorporate sensors and feedback mechanisms to adjust parameters in real-time based on material properties and part geometry. Integrated approaches reduce handling between steps, minimize contamination risks, and ensure consistent quality across production batches.Expand Specific Solutions

Leading Material Jetting Equipment Manufacturers

Material Jetting post-processing technology is currently in a growth phase, with the market expected to reach significant expansion as additive manufacturing adoption increases. The competitive landscape features established players like 3D Systems, HP Development, and Stratasys leading innovation in automated post-processing solutions, while specialty chemical companies including DuPont, BASF, and DSM IP Assets are advancing material formulations specifically for UV curing and thermal conditioning. Emerging players like Inkbit are disrupting the space with vision-based quality assurance systems. Technical maturity varies across the ecosystem, with cleaning and UV curing technologies being more established, while integrated quality assurance systems represent the frontier of development. The industry is moving toward more automated, integrated post-processing chains to improve consistency and reduce labor costs.

3D Systems, Inc.

Technical Solution: 3D Systems has developed the Figure 4 technology platform with an integrated post-processing solution for material jetted parts. Their approach features a modular post-processing chain that can be configured based on production requirements. The cleaning phase employs a combination of solvent-based and mechanical methods, with their proprietary "Wash-R" system using environmentally friendly solvents that reduce VOC emissions by up to 75% compared to traditional cleaning agents[4]. For UV curing, 3D Systems utilizes their "Cure-R" technology with programmable UV intensity profiles (ranging from 20-100 mW/cm²) and rotating platforms to ensure uniform exposure across complex geometries. Their thermal conditioning process incorporates vacuum-assisted thermal chambers that can cycle between -20°C to 160°C to relieve internal stresses and enhance mechanical properties. The QA component includes their "3D Connect" software that provides real-time monitoring and statistical process control, with automated dimensional verification using optical metrology that can detect deviations as small as 25 microns[5]. The system also features material-specific post-processing recipes that automatically adjust parameters based on the specific resin chemistry.

Strengths: Highly modular system allows for customization based on production needs. Advanced material-specific processing parameters optimize mechanical properties. Comprehensive digital workflow integration enables traceability and process optimization. Weaknesses: Multiple separate modules can require more floor space than integrated solutions. Some specialized materials require manual parameter adjustments. Higher operating costs for certain specialty materials.

HP Development Co. LP

Technical Solution: HP's Multi Jet Fusion (MJF) technology incorporates a sophisticated post-processing chain for material jetted parts. Their approach centers on a "Processing Station" that handles multiple post-processing steps in an integrated manner. For cleaning, HP employs a combination of mechanical vibration and compressed air systems that remove up to 95% of unfused powder without chemical solvents. The UV curing process utilizes a proprietary multi-directional UV light array that ensures uniform curing throughout complex geometries, with wavelength-specific LEDs targeting different material properties. Thermal conditioning occurs in controlled cooling chambers with variable temperature gradients (5-150°C) that can be programmed based on part geometry and material requirements[2]. HP's quality assurance system incorporates machine vision technology that compares finished parts against CAD models with accuracy to 100 microns, and automatically flags deviations. Their system also features closed-loop material recycling that recovers and conditions unused powder, achieving material utilization rates of over 80%[3].

Strengths: High throughput capability with industrial-scale production focus. Advanced automation reduces operator intervention and improves consistency. Sophisticated thermal management systems provide excellent dimensional stability. Weaknesses: System complexity requires specialized training and maintenance. Higher initial capital investment compared to some competing technologies. Limited material portfolio compared to some specialized material jetting systems.

Key Innovations in Post-Processing Technologies

Compositions and methods for high-temperature jetting of viscous thermosets to create solid articles via additive fabrication

PatentWO2019117723A1

Innovation

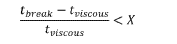

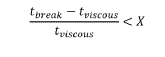

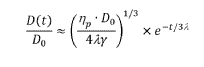

- The method involves ejecting droplets of highly viscous thermoset materials at elevated temperatures using a jetting system configured to operate at viscosities up to 60 cP, with a nozzle temperature ranging from 30°C to 180°C, and using a CaBER extensional rheology method to ensure suitable rheological characteristics, allowing for the formation of three-dimensional objects with enhanced mechanical properties.

Additive manufacturing components and methods

PatentPendingUS20210086266A1

Innovation

- A new method of binder jetting using functional binders that infiltrate and fuse powder bed particles in situ, eliminating the need for sacrificial binders and reducing porosity, allowing for the production of functional products with enhanced mechanical properties.

Environmental Impact and Sustainability Considerations

Material jetting processes, while offering significant advantages in additive manufacturing, present notable environmental and sustainability challenges that require careful consideration. The post-processing chains—cleaning, UV curing, thermal conditioning, and quality assurance—each contribute to the environmental footprint of this technology. Chemical solvents used in cleaning processes often contain volatile organic compounds (VOCs) that pose risks to both human health and the environment, necessitating proper handling, storage, and disposal protocols to minimize ecological impact.

UV curing systems consume substantial energy and utilize UV lamps containing mercury, which requires specialized disposal procedures to prevent environmental contamination. The industry is increasingly transitioning toward more energy-efficient LED-based UV curing systems that eliminate mercury concerns while reducing power consumption by up to 80% compared to traditional mercury arc lamps.

Thermal conditioning processes similarly demand significant energy inputs, particularly when maintaining precise temperature controls for extended periods. Implementing heat recovery systems and optimizing thermal cycles can substantially reduce energy consumption, with some manufacturers reporting energy savings of 30-45% through advanced thermal management techniques.

Waste generation across the entire post-processing chain represents another critical sustainability concern. Material jetting typically produces support materials that require removal and disposal, while cleaning processes generate contaminated solvents. Implementing closed-loop recycling systems for both support materials and cleaning agents can significantly reduce waste volumes, with pioneering facilities achieving up to 85% reduction in liquid waste through solvent recovery systems.

Water consumption, particularly in cleaning operations, presents additional environmental challenges. Advanced water recycling systems and waterless cleaning technologies are emerging as promising solutions, with some systems demonstrating water usage reductions of 60-70% compared to conventional approaches.

The industry is increasingly adopting life cycle assessment (LCA) methodologies to quantify environmental impacts comprehensively. Recent LCA studies indicate that post-processing accounts for 15-30% of the total environmental impact of material jetting operations, highlighting the importance of sustainable post-processing strategies. Manufacturers are responding by developing biodegradable support materials, water-based cleaning solutions, and energy-efficient curing and conditioning equipment.

Regulatory frameworks worldwide are evolving to address these environmental concerns, with particular focus on VOC emissions, hazardous waste management, and energy efficiency standards. Companies implementing sustainable post-processing chains not only reduce environmental impact but often realize operational cost savings through reduced energy consumption, decreased waste disposal costs, and improved resource efficiency.

UV curing systems consume substantial energy and utilize UV lamps containing mercury, which requires specialized disposal procedures to prevent environmental contamination. The industry is increasingly transitioning toward more energy-efficient LED-based UV curing systems that eliminate mercury concerns while reducing power consumption by up to 80% compared to traditional mercury arc lamps.

Thermal conditioning processes similarly demand significant energy inputs, particularly when maintaining precise temperature controls for extended periods. Implementing heat recovery systems and optimizing thermal cycles can substantially reduce energy consumption, with some manufacturers reporting energy savings of 30-45% through advanced thermal management techniques.

Waste generation across the entire post-processing chain represents another critical sustainability concern. Material jetting typically produces support materials that require removal and disposal, while cleaning processes generate contaminated solvents. Implementing closed-loop recycling systems for both support materials and cleaning agents can significantly reduce waste volumes, with pioneering facilities achieving up to 85% reduction in liquid waste through solvent recovery systems.

Water consumption, particularly in cleaning operations, presents additional environmental challenges. Advanced water recycling systems and waterless cleaning technologies are emerging as promising solutions, with some systems demonstrating water usage reductions of 60-70% compared to conventional approaches.

The industry is increasingly adopting life cycle assessment (LCA) methodologies to quantify environmental impacts comprehensively. Recent LCA studies indicate that post-processing accounts for 15-30% of the total environmental impact of material jetting operations, highlighting the importance of sustainable post-processing strategies. Manufacturers are responding by developing biodegradable support materials, water-based cleaning solutions, and energy-efficient curing and conditioning equipment.

Regulatory frameworks worldwide are evolving to address these environmental concerns, with particular focus on VOC emissions, hazardous waste management, and energy efficiency standards. Companies implementing sustainable post-processing chains not only reduce environmental impact but often realize operational cost savings through reduced energy consumption, decreased waste disposal costs, and improved resource efficiency.

Quality Assurance Standards and Certification

Quality assurance in Material Jetting (MJ) processes requires adherence to established standards and certifications to ensure consistent part quality and performance. The additive manufacturing industry has developed several standards specifically addressing post-processing quality control, with organizations like ASTM International, ISO, and industry consortia leading these efforts.

ASTM F3122 provides guidelines for evaluating mechanical properties of additively manufactured parts after post-processing, while ISO/ASTM 52901:2021 establishes requirements for purchased AM parts, including post-processing quality specifications. These standards define acceptable tolerances for dimensional accuracy, surface finish, and mechanical properties that must be verified through appropriate testing methodologies.

For Material Jetting specifically, ASTM F42 committee has developed standards addressing the unique characteristics of photopolymer-based processes, including protocols for testing UV-cured parts and evaluating thermal conditioning effectiveness. These standards specify measurement techniques for properties such as tensile strength, elongation, and hardness that may change significantly during post-processing operations.

Quality certification systems for MJ post-processing typically involve multi-stage verification processes. Initial certification requires demonstration of process capability through statistical process control methods, followed by periodic audits to ensure continued compliance. Organizations like UL and TÜV offer specialized certification programs for additive manufacturing processes that include post-processing validation protocols.

Documentation requirements form a critical component of quality assurance standards. Manufacturers must maintain detailed records of cleaning parameters, UV exposure times and intensities, thermal conditioning profiles, and all quality inspection results. This documentation chain ensures traceability throughout the post-processing workflow and facilitates root cause analysis when quality issues arise.

Emerging trends in quality assurance standards include the integration of real-time monitoring systems that track critical post-processing parameters and automatically flag deviations. Industry 4.0 principles are increasingly incorporated into certification requirements, with emphasis on digital thread continuity from design through post-processing and final inspection.

Regulatory bodies in medical, aerospace, and automotive sectors have begun adopting these standards as requirements for component qualification. The FDA's guidance on 3D printed medical devices specifically addresses post-processing validation, while aerospace manufacturers must comply with Nadcap special process certification requirements that include detailed post-processing quality protocols for additively manufactured components.

ASTM F3122 provides guidelines for evaluating mechanical properties of additively manufactured parts after post-processing, while ISO/ASTM 52901:2021 establishes requirements for purchased AM parts, including post-processing quality specifications. These standards define acceptable tolerances for dimensional accuracy, surface finish, and mechanical properties that must be verified through appropriate testing methodologies.

For Material Jetting specifically, ASTM F42 committee has developed standards addressing the unique characteristics of photopolymer-based processes, including protocols for testing UV-cured parts and evaluating thermal conditioning effectiveness. These standards specify measurement techniques for properties such as tensile strength, elongation, and hardness that may change significantly during post-processing operations.

Quality certification systems for MJ post-processing typically involve multi-stage verification processes. Initial certification requires demonstration of process capability through statistical process control methods, followed by periodic audits to ensure continued compliance. Organizations like UL and TÜV offer specialized certification programs for additive manufacturing processes that include post-processing validation protocols.

Documentation requirements form a critical component of quality assurance standards. Manufacturers must maintain detailed records of cleaning parameters, UV exposure times and intensities, thermal conditioning profiles, and all quality inspection results. This documentation chain ensures traceability throughout the post-processing workflow and facilitates root cause analysis when quality issues arise.

Emerging trends in quality assurance standards include the integration of real-time monitoring systems that track critical post-processing parameters and automatically flag deviations. Industry 4.0 principles are increasingly incorporated into certification requirements, with emphasis on digital thread continuity from design through post-processing and final inspection.

Regulatory bodies in medical, aerospace, and automotive sectors have begun adopting these standards as requirements for component qualification. The FDA's guidance on 3D printed medical devices specifically addresses post-processing validation, while aerospace manufacturers must comply with Nadcap special process certification requirements that include detailed post-processing quality protocols for additively manufactured components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!