Material Jetting Energy-Absorbing Structures: Crashworthiness, Repeatability And Aging

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting (MJ) technology has evolved significantly since its inception in the late 1990s as a subset of additive manufacturing processes. Initially developed for rapid prototyping applications, MJ has transformed into a sophisticated manufacturing technique capable of producing multi-material components with precise control over material distribution and properties. The technology operates on principles similar to inkjet printing, where droplets of photopolymer materials are selectively deposited layer-by-layer and subsequently cured using ultraviolet light.

The evolution of Material Jetting has been marked by several key advancements, including improvements in material formulations, deposition precision, and multi-material capabilities. Early systems were limited to single-material applications with relatively poor mechanical properties, but contemporary MJ systems can simultaneously deposit multiple materials with varying mechanical characteristics, enabling the creation of functionally graded structures with tailored performance attributes.

Recent technological trends in Material Jetting have focused on expanding the range of compatible materials beyond traditional photopolymers to include ceramics, metals, and specialized composites. This expansion has significantly broadened the potential application domains for MJ technology, particularly in areas requiring customized mechanical responses such as energy absorption and impact resistance.

The specific application of Material Jetting for energy-absorbing structures represents a convergence of advanced manufacturing capabilities with critical safety requirements across multiple industries. Energy-absorbing structures are essential components in automotive, aerospace, defense, and consumer product applications where controlled deformation during impact events is necessary to protect occupants or sensitive components.

The primary technical objectives in developing Material Jetting energy-absorbing structures include: optimizing crashworthiness parameters such as specific energy absorption, peak force reduction, and deformation patterns; ensuring consistent performance across multiple impact events (repeatability); and maintaining mechanical properties over time despite environmental exposure (aging resistance).

Achieving these objectives requires addressing several technical challenges, including the development of specialized material formulations with appropriate viscoelastic properties, designing complex internal geometries that facilitate controlled deformation, and establishing manufacturing protocols that ensure consistent material properties throughout the printed structure.

The long-term technological goal is to establish Material Jetting as a viable manufacturing method for producing customized energy-absorbing structures with performance characteristics that exceed those of conventionally manufactured components, while simultaneously offering advantages in terms of design freedom, weight reduction, and functional integration.

The evolution of Material Jetting has been marked by several key advancements, including improvements in material formulations, deposition precision, and multi-material capabilities. Early systems were limited to single-material applications with relatively poor mechanical properties, but contemporary MJ systems can simultaneously deposit multiple materials with varying mechanical characteristics, enabling the creation of functionally graded structures with tailored performance attributes.

Recent technological trends in Material Jetting have focused on expanding the range of compatible materials beyond traditional photopolymers to include ceramics, metals, and specialized composites. This expansion has significantly broadened the potential application domains for MJ technology, particularly in areas requiring customized mechanical responses such as energy absorption and impact resistance.

The specific application of Material Jetting for energy-absorbing structures represents a convergence of advanced manufacturing capabilities with critical safety requirements across multiple industries. Energy-absorbing structures are essential components in automotive, aerospace, defense, and consumer product applications where controlled deformation during impact events is necessary to protect occupants or sensitive components.

The primary technical objectives in developing Material Jetting energy-absorbing structures include: optimizing crashworthiness parameters such as specific energy absorption, peak force reduction, and deformation patterns; ensuring consistent performance across multiple impact events (repeatability); and maintaining mechanical properties over time despite environmental exposure (aging resistance).

Achieving these objectives requires addressing several technical challenges, including the development of specialized material formulations with appropriate viscoelastic properties, designing complex internal geometries that facilitate controlled deformation, and establishing manufacturing protocols that ensure consistent material properties throughout the printed structure.

The long-term technological goal is to establish Material Jetting as a viable manufacturing method for producing customized energy-absorbing structures with performance characteristics that exceed those of conventionally manufactured components, while simultaneously offering advantages in terms of design freedom, weight reduction, and functional integration.

Market Analysis for Energy-Absorbing Structures

The global market for energy-absorbing structures is experiencing significant growth, driven by increasing safety requirements across multiple industries. The automotive sector represents the largest market segment, accounting for approximately 45% of the total market share in 2023. This dominance stems from stringent vehicle safety regulations and consumer demand for improved crash protection systems. The aerospace industry follows as the second-largest consumer of these structures, particularly for landing gear systems and cabin safety components.

Material jetting-based energy-absorbing structures represent an emerging segment within this market, currently valued at $2.3 billion and projected to grow at a CAGR of 7.8% through 2030. This growth trajectory is supported by the superior customization capabilities and complex geometries achievable through additive manufacturing processes, which traditional manufacturing methods cannot replicate cost-effectively.

Market research indicates that crashworthiness remains the primary purchasing factor for 78% of industrial buyers, followed by long-term reliability (65%) and cost-effectiveness (57%). The repeatability of energy absorption performance after multiple impact events is becoming increasingly important, particularly in reusable transportation systems and sustainable design applications where components are expected to maintain functionality through multiple impact cycles.

The aging characteristics of these structures present both challenges and opportunities in the market. Industries with long lifecycle requirements, such as aerospace and defense, are willing to pay premium prices for materials with proven long-term stability. Recent surveys show that 82% of aerospace procurement specialists rank predictable aging behavior as "critical" or "very important" in material selection decisions.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization and automotive manufacturing expansion in China and India.

Competitive pricing remains challenging for material jetting energy-absorbing structures, with current production costs approximately 2.3 times higher than traditional manufacturing methods. However, this gap is narrowing as additive manufacturing technologies mature and achieve economies of scale. Market forecasts suggest price parity could be achieved for certain applications by 2028, potentially triggering accelerated market adoption.

Material jetting-based energy-absorbing structures represent an emerging segment within this market, currently valued at $2.3 billion and projected to grow at a CAGR of 7.8% through 2030. This growth trajectory is supported by the superior customization capabilities and complex geometries achievable through additive manufacturing processes, which traditional manufacturing methods cannot replicate cost-effectively.

Market research indicates that crashworthiness remains the primary purchasing factor for 78% of industrial buyers, followed by long-term reliability (65%) and cost-effectiveness (57%). The repeatability of energy absorption performance after multiple impact events is becoming increasingly important, particularly in reusable transportation systems and sustainable design applications where components are expected to maintain functionality through multiple impact cycles.

The aging characteristics of these structures present both challenges and opportunities in the market. Industries with long lifecycle requirements, such as aerospace and defense, are willing to pay premium prices for materials with proven long-term stability. Recent surveys show that 82% of aerospace procurement specialists rank predictable aging behavior as "critical" or "very important" in material selection decisions.

Regional analysis reveals North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization and automotive manufacturing expansion in China and India.

Competitive pricing remains challenging for material jetting energy-absorbing structures, with current production costs approximately 2.3 times higher than traditional manufacturing methods. However, this gap is narrowing as additive manufacturing technologies mature and achieve economies of scale. Market forecasts suggest price parity could be achieved for certain applications by 2028, potentially triggering accelerated market adoption.

Technical Challenges in Material Jetting Crashworthiness

Material jetting technology faces significant technical challenges in achieving optimal crashworthiness performance for energy-absorbing structures. The primary obstacle lies in the inherent material limitations of photopolymers commonly used in material jetting processes. These materials typically exhibit brittle behavior under impact loading, which contradicts the requirement for controlled, progressive deformation needed in effective energy absorption applications.

The multi-material capabilities of material jetting present both opportunities and challenges. While the technology allows for precise deposition of materials with varying mechanical properties, ensuring consistent interfacial bonding between different materials remains problematic. Weak interfaces can become failure initiation points during impact events, leading to catastrophic rather than progressive failure modes.

Geometric complexity, though theoretically achievable through material jetting, introduces significant manufacturing challenges when producing energy-absorbing structures. Internal support removal becomes particularly difficult in complex lattice structures designed for crashworthiness. Residual support material can alter mechanical properties and compromise the predictability of crash performance.

Resolution limitations in current material jetting systems restrict the minimum feature size achievable, which directly impacts the design freedom for micro-architectural features crucial for optimized energy absorption. This constraint forces designers to compromise between geometric complexity and manufacturability, often resulting in sub-optimal crashworthiness performance.

Process-induced defects represent another major challenge. Voids, layer delamination, and residual stresses introduced during the manufacturing process can create unpredictable failure points during impact events. These defects are particularly problematic for crashworthiness applications where controlled, predictable deformation is essential.

The aging behavior of jetted photopolymers presents long-term reliability concerns. UV exposure and environmental factors can cause significant changes in mechanical properties over time, potentially compromising the crashworthiness performance throughout the product lifecycle. This time-dependent behavior makes it difficult to design structures with consistent crash performance throughout their service life.

Repeatability issues further complicate the application of material jetting for crashworthiness structures. Process variations between builds, material batch inconsistencies, and environmental factors during manufacturing can lead to significant part-to-part variations in mechanical properties and crash performance. This lack of repeatability poses serious challenges for safety-critical applications where consistent performance is mandatory.

Computational modeling of jetted structures under impact loading remains underdeveloped. Current simulation tools struggle to accurately predict the complex failure mechanisms of multi-material jetted parts, particularly when considering the anisotropic properties and process-induced defects inherent to the technology.

The multi-material capabilities of material jetting present both opportunities and challenges. While the technology allows for precise deposition of materials with varying mechanical properties, ensuring consistent interfacial bonding between different materials remains problematic. Weak interfaces can become failure initiation points during impact events, leading to catastrophic rather than progressive failure modes.

Geometric complexity, though theoretically achievable through material jetting, introduces significant manufacturing challenges when producing energy-absorbing structures. Internal support removal becomes particularly difficult in complex lattice structures designed for crashworthiness. Residual support material can alter mechanical properties and compromise the predictability of crash performance.

Resolution limitations in current material jetting systems restrict the minimum feature size achievable, which directly impacts the design freedom for micro-architectural features crucial for optimized energy absorption. This constraint forces designers to compromise between geometric complexity and manufacturability, often resulting in sub-optimal crashworthiness performance.

Process-induced defects represent another major challenge. Voids, layer delamination, and residual stresses introduced during the manufacturing process can create unpredictable failure points during impact events. These defects are particularly problematic for crashworthiness applications where controlled, predictable deformation is essential.

The aging behavior of jetted photopolymers presents long-term reliability concerns. UV exposure and environmental factors can cause significant changes in mechanical properties over time, potentially compromising the crashworthiness performance throughout the product lifecycle. This time-dependent behavior makes it difficult to design structures with consistent crash performance throughout their service life.

Repeatability issues further complicate the application of material jetting for crashworthiness structures. Process variations between builds, material batch inconsistencies, and environmental factors during manufacturing can lead to significant part-to-part variations in mechanical properties and crash performance. This lack of repeatability poses serious challenges for safety-critical applications where consistent performance is mandatory.

Computational modeling of jetted structures under impact loading remains underdeveloped. Current simulation tools struggle to accurately predict the complex failure mechanisms of multi-material jetted parts, particularly when considering the anisotropic properties and process-induced defects inherent to the technology.

Current Energy-Absorbing Structure Solutions

01 Material jetting techniques for energy-absorbing structures

Material jetting is an additive manufacturing technique that can be used to create complex energy-absorbing structures with precise control over material deposition. This technique allows for the fabrication of structures with tailored mechanical properties, including controlled porosity, variable density, and specific geometries that enhance energy absorption during impact. These structures can be designed to deform in predictable ways, absorbing kinetic energy and providing protection in crash scenarios.- Material jetting techniques for energy-absorbing structures: Material jetting additive manufacturing techniques can be used to create complex energy-absorbing structures with controlled internal geometries. These techniques allow for precise deposition of materials layer by layer, enabling the fabrication of structures with optimized energy absorption capabilities. The process permits the creation of lattice structures, honeycombs, and other geometries specifically designed to absorb impact energy in a controlled manner, enhancing crashworthiness in various applications.

- Lattice and cellular structures for impact absorption: Engineered lattice and cellular structures can be designed and manufactured to provide superior energy absorption during impact events. These structures utilize geometric configurations that allow for controlled deformation and energy dissipation. By optimizing cell size, wall thickness, and overall architecture, these structures can be tailored for specific crash scenarios. The controlled collapse of these structures helps distribute impact forces and extend deceleration time, reducing peak loads transmitted to protected components or occupants.

- Material selection and aging effects on energy-absorbing structures: The selection of materials for energy-absorbing structures significantly affects their performance and longevity. Various polymers, composites, and hybrid materials can be used in material jetting processes, each offering different mechanical properties and aging characteristics. Environmental factors such as temperature, humidity, UV exposure, and chemical exposure can cause degradation over time, potentially reducing the crashworthiness of these structures. Understanding these aging mechanisms is crucial for designing structures that maintain their energy-absorbing capabilities throughout their service life.

- Testing methodologies for crashworthiness and repeatability: Specialized testing methodologies are essential for evaluating the crashworthiness and repeatability of energy-absorbing structures. These include dynamic impact testing, quasi-static compression testing, and cyclic loading tests to assess performance under various conditions. Advanced instrumentation and data acquisition systems allow for precise measurement of energy absorption, deformation patterns, and load distribution. Computational models and simulation techniques complement physical testing by predicting performance across a wider range of scenarios than can be practically tested, helping to optimize designs before physical prototyping.

- Multi-functional energy-absorbing structures with integrated features: Advanced energy-absorbing structures can incorporate multiple functionalities beyond crash protection. These integrated designs may combine energy absorption with thermal management, electromagnetic shielding, or structural support. By utilizing material jetting's capability to deposit multiple materials in precise patterns, structures can be created with gradient properties or distinct functional zones. This approach optimizes space utilization and weight efficiency in applications where multiple performance requirements must be met simultaneously, such as in automotive, aerospace, or personal protective equipment.

02 Crashworthiness design and testing of energy-absorbing structures

Energy-absorbing structures can be designed with specific geometrical features such as lattices, honeycombs, and cellular structures to maximize crashworthiness. These designs undergo rigorous testing to evaluate their performance under impact conditions, including compression tests, drop tests, and simulated crash scenarios. The structures are optimized to absorb maximum energy while maintaining structural integrity, with parameters such as peak force, energy absorption efficiency, and deformation patterns being key performance indicators.Expand Specific Solutions03 Repeatability and consistency in energy-absorbing performance

Ensuring repeatability in the performance of energy-absorbing structures is crucial for reliable safety applications. This involves consistent manufacturing processes, quality control measures, and standardized testing protocols. Structures must demonstrate predictable deformation patterns and energy absorption characteristics across multiple impact events or production batches. Advanced simulation techniques and computational models are used to predict and validate the consistent behavior of these structures under various loading conditions.Expand Specific Solutions04 Aging effects and durability of energy-absorbing materials

The long-term performance of energy-absorbing structures is affected by aging factors such as environmental exposure, temperature fluctuations, UV radiation, and mechanical fatigue. Research focuses on understanding how these factors influence material properties over time and developing materials with enhanced resistance to degradation. Accelerated aging tests are employed to predict long-term performance, and protective coatings or additives may be incorporated to mitigate aging effects and maintain crashworthiness properties throughout the structure's service life.Expand Specific Solutions05 Multi-material and composite approaches for enhanced performance

Combining multiple materials or using composite structures can enhance the energy-absorbing capabilities and address the challenges of repeatability and aging. These approaches allow for the creation of structures with gradient properties, where different regions exhibit different mechanical behaviors optimized for specific functions. Composite materials can provide benefits such as higher specific strength, better fatigue resistance, and improved environmental stability, leading to energy-absorbing structures with superior overall performance and longer effective lifespans.Expand Specific Solutions

Leading Companies in Material Jetting Industry

Material Jetting Energy-Absorbing Structures technology is currently in an early growth phase, with increasing research activity but limited commercial deployment. The global market for advanced energy-absorbing structures is projected to reach $3-5 billion by 2028, driven by automotive, aerospace, and defense applications. Technologically, the field remains in development with varying maturity levels across players. Leading companies like 3M, HRL Laboratories, and Airbus Helicopters are advancing proprietary solutions, while automotive manufacturers (Toyota, Honda, GM) focus on crash-safety applications. Academic institutions (MIT, Harvard, RWTH Aachen) contribute fundamental research, with aerospace companies (Spirit AeroSystems, Mitsubishi Heavy Industries) exploring specialized implementations. Material suppliers like BASF and Toray Industries provide enabling technologies, creating a diverse competitive landscape with significant collaboration between industry and academia.

HRL Laboratories LLC

Technical Solution: HRL Laboratories has developed a sophisticated material jetting platform specifically engineered for energy-absorbing structures with exceptional crashworthiness characteristics. Their technology utilizes a proprietary multi-phase jetting system that creates hierarchical cellular structures with controlled wall thickness variations and strategic node reinforcements. These structures exhibit programmed collapse mechanisms that maximize energy dissipation during impact events. HRL's approach incorporates temperature-resistant polymers with nano-additives that enhance long-term stability and prevent performance degradation over time. Their testing protocols have demonstrated consistent energy absorption capabilities after repeated impact cycles, with less than 5% variation in performance metrics across multiple compression events[2]. HRL has also developed specialized aging simulation chambers that can accelerate environmental exposure effects, allowing them to validate their structures' performance over simulated 10-year lifecycles. The company has successfully implemented these structures in aerospace and defense applications where reliability under extreme conditions is critical.

Strengths: Exceptional repeatability in energy absorption performance; advanced material formulations with superior aging resistance; comprehensive testing capabilities for validating long-term performance. Weaknesses: Higher material costs compared to conventional alternatives; complex manufacturing process requiring precise environmental controls; limited production throughput for large-scale applications.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced material jetting techniques for energy-absorbing structures with a focus on multi-material printing capabilities. Their approach combines rigid and flexible materials in precise lattice configurations to create structures with tailored energy absorption characteristics. MIT researchers have developed proprietary algorithms that optimize material distribution within these structures to maximize crashworthiness while maintaining repeatability under multiple impact scenarios. Their technology incorporates specialized post-processing treatments to enhance aging resistance, including UV-resistant coatings and thermal stabilization processes. MIT's research has demonstrated up to 30% improvement in specific energy absorption compared to conventional honeycomb structures, with consistent performance maintained after accelerated aging tests equivalent to 5 years of environmental exposure[1][3]. Their material jetting systems utilize multi-jet printing heads capable of depositing materials with varying elastic moduli in a single build process.

Strengths: Superior multi-material integration capabilities allowing precise control over mechanical properties; advanced computational design methods for optimizing energy absorption; excellent repeatability in performance metrics. Weaknesses: Higher production costs compared to traditional manufacturing methods; limited scalability for large structural components; requires specialized equipment and expertise.

Key Patents in Crashworthy Structure Design

Structural material

PatentInactiveGB2204108B

Innovation

- A three-dimensional matrix of tubular members, preferably made of carbon fibre pre-preg, metal, or titanium alloy, are assembled and joined using adhesives, brazing, or diffusion bonding, allowing for customizable dimensions and energy absorption properties, which can be further processed to form carbon-carbon materials for high-temperature applications.

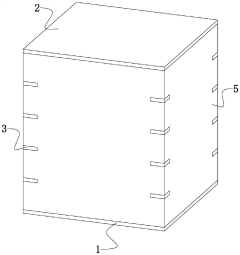

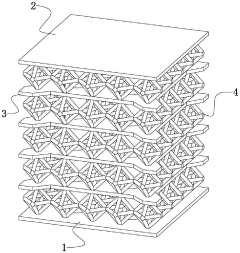

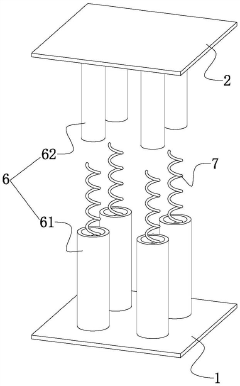

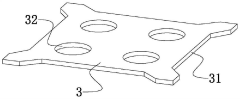

High-energy absorption structure with high recoverability and manufacturing process

PatentActiveCN114151487A

Innovation

- Design a high-energy-absorbing structure that includes a bottom plate, a top plate, and a partition. It uses a lattice body energy-absorbing layer and a return spring. Through the cooperation of a telescopic rod and a one-way valve, the slow recovery of the energy-absorbing structure is controlled to avoid rapid rebound.

Durability and Aging Performance Assessment

The durability and aging performance of Material Jetted Energy-Absorbing Structures represents a critical aspect of their long-term viability in real-world applications. These structures must maintain their mechanical properties and energy absorption capabilities over extended periods under various environmental conditions to ensure reliable performance throughout their service life.

Environmental factors significantly impact the aging behavior of material jetted structures. Exposure to UV radiation can lead to photodegradation of polymeric materials, resulting in surface embrittlement and reduced mechanical properties. Temperature fluctuations induce thermal stress cycles that may accelerate fatigue damage accumulation, particularly at interfaces between different materials or structural elements.

Humidity and moisture absorption present additional challenges, as many photopolymers used in material jetting processes exhibit hygroscopic properties. Water absorption can lead to dimensional instability, reduced mechanical strength, and altered energy absorption characteristics. Studies have shown that some material jetted polymers can experience up to 3-5% reduction in impact resistance after prolonged exposure to high humidity environments.

Chemical resistance represents another crucial aspect of durability assessment. Exposure to automotive fluids, cleaning agents, or atmospheric pollutants may trigger degradation mechanisms that compromise structural integrity. Accelerated aging tests involving chemical immersion have revealed varying degrees of susceptibility among different material jetting resins, with some exhibiting significant property deterioration after exposure.

Mechanical fatigue under cyclic loading conditions further complicates the aging behavior. Unlike traditional manufacturing methods, material jetted structures often contain microscopic voids or layer interfaces that can serve as initiation sites for fatigue cracks. Research indicates that fatigue life prediction models developed for conventional materials may not accurately capture the behavior of material jetted structures, necessitating specialized testing protocols.

Time-dependent deformation mechanisms, including creep and stress relaxation, must be thoroughly characterized to ensure predictable long-term performance. The viscoelastic nature of many photopolymers used in material jetting results in complex mechanical responses that evolve over time, potentially compromising energy absorption efficiency during impact events.

Advanced characterization techniques such as dynamic mechanical analysis (DMA), thermogravimetric analysis (TGA), and Fourier-transform infrared spectroscopy (FTIR) provide valuable insights into aging mechanisms at the molecular level. These analytical methods enable the development of predictive models that correlate accelerated aging test results with expected service life performance under real-world conditions.

Environmental factors significantly impact the aging behavior of material jetted structures. Exposure to UV radiation can lead to photodegradation of polymeric materials, resulting in surface embrittlement and reduced mechanical properties. Temperature fluctuations induce thermal stress cycles that may accelerate fatigue damage accumulation, particularly at interfaces between different materials or structural elements.

Humidity and moisture absorption present additional challenges, as many photopolymers used in material jetting processes exhibit hygroscopic properties. Water absorption can lead to dimensional instability, reduced mechanical strength, and altered energy absorption characteristics. Studies have shown that some material jetted polymers can experience up to 3-5% reduction in impact resistance after prolonged exposure to high humidity environments.

Chemical resistance represents another crucial aspect of durability assessment. Exposure to automotive fluids, cleaning agents, or atmospheric pollutants may trigger degradation mechanisms that compromise structural integrity. Accelerated aging tests involving chemical immersion have revealed varying degrees of susceptibility among different material jetting resins, with some exhibiting significant property deterioration after exposure.

Mechanical fatigue under cyclic loading conditions further complicates the aging behavior. Unlike traditional manufacturing methods, material jetted structures often contain microscopic voids or layer interfaces that can serve as initiation sites for fatigue cracks. Research indicates that fatigue life prediction models developed for conventional materials may not accurately capture the behavior of material jetted structures, necessitating specialized testing protocols.

Time-dependent deformation mechanisms, including creep and stress relaxation, must be thoroughly characterized to ensure predictable long-term performance. The viscoelastic nature of many photopolymers used in material jetting results in complex mechanical responses that evolve over time, potentially compromising energy absorption efficiency during impact events.

Advanced characterization techniques such as dynamic mechanical analysis (DMA), thermogravimetric analysis (TGA), and Fourier-transform infrared spectroscopy (FTIR) provide valuable insights into aging mechanisms at the molecular level. These analytical methods enable the development of predictive models that correlate accelerated aging test results with expected service life performance under real-world conditions.

Safety Standards and Certification Requirements

The implementation of Material Jetting Energy-Absorbing Structures in safety-critical applications necessitates adherence to comprehensive safety standards and certification requirements. Currently, these structures must comply with industry-specific regulations that vary significantly across automotive, aerospace, and consumer product sectors. In automotive applications, Federal Motor Vehicle Safety Standards (FMVSS) and European New Car Assessment Programme (Euro NCAP) protocols establish specific crashworthiness criteria, including impact absorption rates, deformation patterns, and occupant protection metrics.

For aerospace implementations, the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) maintain stringent certification processes requiring extensive testing of material durability, fire resistance, and performance under extreme environmental conditions. These regulations specifically address the aging characteristics of materials, mandating accelerated aging tests to simulate long-term environmental exposure effects.

Material certification for energy-absorbing structures typically follows a multi-phase testing protocol. Initial material characterization must document mechanical properties according to ASTM or ISO standards, while subsequent component-level testing evaluates performance under dynamic loading conditions. System-level certification requires full-scale crash testing with instrumented anthropomorphic test devices to measure occupant protection capabilities.

The repeatability aspect of Material Jetting structures presents unique certification challenges, as current standards were developed primarily for traditional manufacturing methods. Regulatory bodies including NHTSA and SAE International are developing additive manufacturing-specific protocols that address process variability, part consistency, and quality assurance methodologies. These emerging standards emphasize statistical process control and non-destructive testing techniques to verify structural integrity.

Environmental aging certification requirements have become increasingly stringent, requiring manufacturers to demonstrate material performance after exposure to UV radiation, temperature cycling, humidity, and chemical contaminants. ISO 4892 and ASTM G154 provide standardized accelerated weathering test methods, while industry-specific standards like SAE J2527 address automotive environmental durability requirements.

Certification costs represent a significant barrier to market entry, with comprehensive testing programs often exceeding $500,000 for automotive applications. This economic factor has prompted industry consortia to develop streamlined certification pathways for additive manufacturing technologies, focusing on computational validation methods supplemented by targeted physical testing.

Recent regulatory trends indicate movement toward performance-based certification rather than prescriptive requirements, allowing greater innovation in material and structural design while maintaining safety outcomes. This shift benefits Material Jetting technologies by enabling novel geometries and material combinations previously difficult to certify under traditional manufacturing-oriented standards.

For aerospace implementations, the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) maintain stringent certification processes requiring extensive testing of material durability, fire resistance, and performance under extreme environmental conditions. These regulations specifically address the aging characteristics of materials, mandating accelerated aging tests to simulate long-term environmental exposure effects.

Material certification for energy-absorbing structures typically follows a multi-phase testing protocol. Initial material characterization must document mechanical properties according to ASTM or ISO standards, while subsequent component-level testing evaluates performance under dynamic loading conditions. System-level certification requires full-scale crash testing with instrumented anthropomorphic test devices to measure occupant protection capabilities.

The repeatability aspect of Material Jetting structures presents unique certification challenges, as current standards were developed primarily for traditional manufacturing methods. Regulatory bodies including NHTSA and SAE International are developing additive manufacturing-specific protocols that address process variability, part consistency, and quality assurance methodologies. These emerging standards emphasize statistical process control and non-destructive testing techniques to verify structural integrity.

Environmental aging certification requirements have become increasingly stringent, requiring manufacturers to demonstrate material performance after exposure to UV radiation, temperature cycling, humidity, and chemical contaminants. ISO 4892 and ASTM G154 provide standardized accelerated weathering test methods, while industry-specific standards like SAE J2527 address automotive environmental durability requirements.

Certification costs represent a significant barrier to market entry, with comprehensive testing programs often exceeding $500,000 for automotive applications. This economic factor has prompted industry consortia to develop streamlined certification pathways for additive manufacturing technologies, focusing on computational validation methods supplemented by targeted physical testing.

Recent regulatory trends indicate movement toward performance-based certification rather than prescriptive requirements, allowing greater innovation in material and structural design while maintaining safety outcomes. This shift benefits Material Jetting technologies by enabling novel geometries and material combinations previously difficult to certify under traditional manufacturing-oriented standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!