Material Jetting Multi-Material Interfaces: Delamination Risks And Gradient Design

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Technology Background and Objectives

Material Jetting technology has evolved significantly since its inception in the late 1990s, emerging as a pivotal additive manufacturing process capable of depositing build materials in a droplet-by-droplet fashion. This technology draws its fundamental principles from traditional inkjet printing, adapting them to accommodate various materials including photopolymers, waxes, and composites. The evolution trajectory has been marked by progressive improvements in resolution capabilities, material compatibility, and multi-material integration systems.

The current technological landscape of Material Jetting demonstrates remarkable precision, with layer thicknesses as fine as 16 microns and XY resolution approaching 42 microns in advanced systems. This exceptional dimensional accuracy positions Material Jetting as a preferred method for applications requiring intricate geometries and smooth surface finishes. The technology's distinctive ability to simultaneously process multiple materials has catalyzed its adoption across diverse sectors including medical modeling, consumer products, and industrial prototyping.

Despite these advancements, the interface between different materials in multi-material jetting applications presents significant challenges, particularly regarding delamination risks. Delamination—the separation of material layers at interfaces—remains a critical limitation that compromises structural integrity and functional performance of printed components. This phenomenon is exacerbated by disparities in material properties such as thermal expansion coefficients, curing behaviors, and mechanical characteristics.

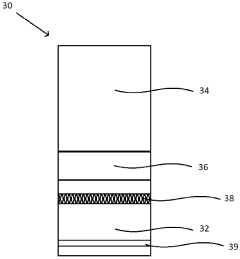

The primary objective of current research and development efforts is to mitigate these delamination risks through innovative gradient design approaches. These strategies aim to create seamless transitions between dissimilar materials by establishing gradual property variations across interfaces rather than abrupt boundaries. Such gradient interfaces potentially offer enhanced adhesion strength, improved stress distribution, and superior overall performance in multi-material printed structures.

Future technological goals include developing advanced computational models that can accurately predict interface behavior, creating new materials specifically engineered for gradient applications, and establishing standardized testing methodologies for interface quality assessment. Additionally, there is significant interest in expanding the range of compatible materials to include functional components such as conductive, magnetic, and thermally responsive elements that can be integrated without compromising interface integrity.

The trajectory of Material Jetting technology is increasingly focused on transitioning from purely aesthetic multi-material applications toward functional, performance-oriented components with reliable material interfaces. This shift necessitates fundamental research into material interaction mechanisms at the molecular level, as well as practical engineering solutions for gradient design implementation in commercial systems.

The current technological landscape of Material Jetting demonstrates remarkable precision, with layer thicknesses as fine as 16 microns and XY resolution approaching 42 microns in advanced systems. This exceptional dimensional accuracy positions Material Jetting as a preferred method for applications requiring intricate geometries and smooth surface finishes. The technology's distinctive ability to simultaneously process multiple materials has catalyzed its adoption across diverse sectors including medical modeling, consumer products, and industrial prototyping.

Despite these advancements, the interface between different materials in multi-material jetting applications presents significant challenges, particularly regarding delamination risks. Delamination—the separation of material layers at interfaces—remains a critical limitation that compromises structural integrity and functional performance of printed components. This phenomenon is exacerbated by disparities in material properties such as thermal expansion coefficients, curing behaviors, and mechanical characteristics.

The primary objective of current research and development efforts is to mitigate these delamination risks through innovative gradient design approaches. These strategies aim to create seamless transitions between dissimilar materials by establishing gradual property variations across interfaces rather than abrupt boundaries. Such gradient interfaces potentially offer enhanced adhesion strength, improved stress distribution, and superior overall performance in multi-material printed structures.

Future technological goals include developing advanced computational models that can accurately predict interface behavior, creating new materials specifically engineered for gradient applications, and establishing standardized testing methodologies for interface quality assessment. Additionally, there is significant interest in expanding the range of compatible materials to include functional components such as conductive, magnetic, and thermally responsive elements that can be integrated without compromising interface integrity.

The trajectory of Material Jetting technology is increasingly focused on transitioning from purely aesthetic multi-material applications toward functional, performance-oriented components with reliable material interfaces. This shift necessitates fundamental research into material interaction mechanisms at the molecular level, as well as practical engineering solutions for gradient design implementation in commercial systems.

Multi-Material Interface Market Applications

The multi-material interface market is experiencing significant growth across various industries due to the unique capabilities offered by material jetting technologies. Aerospace and defense sectors have emerged as primary adopters, utilizing multi-material interfaces for lightweight components with selective mechanical properties. These applications include structural elements requiring both flexibility and rigidity, thermal management systems with gradient thermal conductivity, and vibration dampening components that integrate hard and soft materials.

In the medical device industry, multi-material interfaces enable the production of patient-specific implants and prosthetics that mimic biological tissue gradients. The market for these applications is particularly promising as they allow for better integration with human tissue, reducing rejection risks and improving patient outcomes. Dental applications, specifically for crowns and bridges with gradient properties that transition from hard enamel-like surfaces to more flexible dentin-like structures, represent another high-value segment.

Consumer electronics manufacturers are increasingly exploring multi-material interfaces for smart devices that require both rigid structural components and flexible user interface elements. This market segment values the ability to create seamless transitions between different material properties without mechanical fasteners or adhesives, resulting in more durable and aesthetically pleasing products.

The automotive industry represents another substantial market opportunity, particularly for interior components that combine hard structural elements with soft touch surfaces. Additionally, there is growing interest in using multi-material interfaces for functional components like seals and gaskets where gradient properties can enhance performance and durability.

Research institutions and advanced manufacturing facilities constitute a smaller but technologically sophisticated market segment. These organizations utilize multi-material interfaces for prototyping complex systems and developing next-generation materials with precisely engineered property gradients.

The market for architectural and construction applications is emerging, with potential uses in facade elements that require varying degrees of transparency, thermal insulation, and structural integrity. Similarly, the sports equipment industry is beginning to explore multi-material interfaces for performance gear that adapts to different body zones and movement patterns.

Market growth is primarily constrained by concerns regarding long-term interface stability, particularly delamination risks under environmental stress. Companies that can demonstrate reliable gradient design methodologies that minimize these risks stand to capture significant market share across these diverse application domains.

In the medical device industry, multi-material interfaces enable the production of patient-specific implants and prosthetics that mimic biological tissue gradients. The market for these applications is particularly promising as they allow for better integration with human tissue, reducing rejection risks and improving patient outcomes. Dental applications, specifically for crowns and bridges with gradient properties that transition from hard enamel-like surfaces to more flexible dentin-like structures, represent another high-value segment.

Consumer electronics manufacturers are increasingly exploring multi-material interfaces for smart devices that require both rigid structural components and flexible user interface elements. This market segment values the ability to create seamless transitions between different material properties without mechanical fasteners or adhesives, resulting in more durable and aesthetically pleasing products.

The automotive industry represents another substantial market opportunity, particularly for interior components that combine hard structural elements with soft touch surfaces. Additionally, there is growing interest in using multi-material interfaces for functional components like seals and gaskets where gradient properties can enhance performance and durability.

Research institutions and advanced manufacturing facilities constitute a smaller but technologically sophisticated market segment. These organizations utilize multi-material interfaces for prototyping complex systems and developing next-generation materials with precisely engineered property gradients.

The market for architectural and construction applications is emerging, with potential uses in facade elements that require varying degrees of transparency, thermal insulation, and structural integrity. Similarly, the sports equipment industry is beginning to explore multi-material interfaces for performance gear that adapts to different body zones and movement patterns.

Market growth is primarily constrained by concerns regarding long-term interface stability, particularly delamination risks under environmental stress. Companies that can demonstrate reliable gradient design methodologies that minimize these risks stand to capture significant market share across these diverse application domains.

Delamination Challenges in Material Jetting

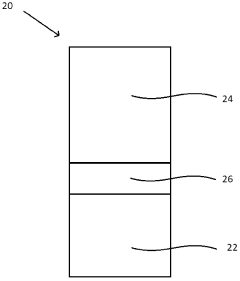

Material jetting technology faces significant delamination challenges at multi-material interfaces, which represent one of the primary failure modes in additively manufactured parts. Delamination occurs when adjacent layers or different materials separate due to insufficient bonding, creating structural weaknesses that compromise the mechanical integrity and functionality of printed components. This phenomenon is particularly prevalent in multi-material interfaces where materials with dissimilar physical and chemical properties meet.

The fundamental causes of delamination in material jetting processes stem from several interrelated factors. Material incompatibility represents a primary challenge, as polymers with different chemical compositions may exhibit poor intermolecular bonding at interfaces. This incompatibility is exacerbated by differences in thermal expansion coefficients, where materials expand and contract at different rates during curing and cooling cycles, generating internal stresses that can exceed the interfacial bond strength.

Surface energy mismatches between adjacent materials further complicate adhesion, as materials with significantly different surface energies may resist proper wetting and bonding. The layer-by-layer nature of material jetting introduces inherent weaknesses at layer boundaries, creating natural planes for crack initiation and propagation when subjected to mechanical loads.

Process parameters significantly influence delamination risk. Insufficient UV curing energy may result in incomplete polymerization at interfaces, while improper droplet spacing can create voids or excessive material accumulation. Platform temperature variations during printing can induce thermal stresses that manifest as delamination during post-processing or in-service conditions.

Environmental factors also play a crucial role in delamination behavior. Humidity during printing can affect polymerization kinetics and interfacial bonding quality. Post-processing treatments, including cleaning solvents and heat treatments, may introduce additional stresses or chemical degradation at material interfaces, further compromising bond integrity.

Recent research has identified several critical interface scenarios particularly prone to delamination. Rigid-flexible material combinations present significant challenges due to the mechanical property mismatch, while transparent-opaque material interfaces often require different curing parameters that can lead to bonding inconsistencies. Support material interfaces represent another vulnerable area, as temporary structures must maintain sufficient adhesion during printing while allowing clean removal afterward.

Understanding these delamination mechanisms is essential for developing effective mitigation strategies and advancing multi-material material jetting capabilities toward more reliable and functional applications in industries ranging from medical devices to consumer electronics.

The fundamental causes of delamination in material jetting processes stem from several interrelated factors. Material incompatibility represents a primary challenge, as polymers with different chemical compositions may exhibit poor intermolecular bonding at interfaces. This incompatibility is exacerbated by differences in thermal expansion coefficients, where materials expand and contract at different rates during curing and cooling cycles, generating internal stresses that can exceed the interfacial bond strength.

Surface energy mismatches between adjacent materials further complicate adhesion, as materials with significantly different surface energies may resist proper wetting and bonding. The layer-by-layer nature of material jetting introduces inherent weaknesses at layer boundaries, creating natural planes for crack initiation and propagation when subjected to mechanical loads.

Process parameters significantly influence delamination risk. Insufficient UV curing energy may result in incomplete polymerization at interfaces, while improper droplet spacing can create voids or excessive material accumulation. Platform temperature variations during printing can induce thermal stresses that manifest as delamination during post-processing or in-service conditions.

Environmental factors also play a crucial role in delamination behavior. Humidity during printing can affect polymerization kinetics and interfacial bonding quality. Post-processing treatments, including cleaning solvents and heat treatments, may introduce additional stresses or chemical degradation at material interfaces, further compromising bond integrity.

Recent research has identified several critical interface scenarios particularly prone to delamination. Rigid-flexible material combinations present significant challenges due to the mechanical property mismatch, while transparent-opaque material interfaces often require different curing parameters that can lead to bonding inconsistencies. Support material interfaces represent another vulnerable area, as temporary structures must maintain sufficient adhesion during printing while allowing clean removal afterward.

Understanding these delamination mechanisms is essential for developing effective mitigation strategies and advancing multi-material material jetting capabilities toward more reliable and functional applications in industries ranging from medical devices to consumer electronics.

Current Solutions for Interface Adhesion

01 Interface bonding techniques for multi-material jetting

Various bonding techniques can be employed to enhance the adhesion between different materials in material jetting processes. These techniques include surface treatments, adhesion promoters, and specialized interlayers that create stronger bonds at material interfaces. Proper bonding techniques are essential to prevent delamination risks when joining dissimilar materials with different physical and chemical properties.- Interface adhesion enhancement techniques: Various techniques can be employed to enhance adhesion between different materials in multi-material jetting processes, thereby reducing delamination risks. These techniques include surface treatments, use of adhesion promoters, and optimization of interface geometries. Proper surface preparation and treatment before material deposition can significantly improve the bonding strength at interfaces, while specialized adhesion promoters can create stronger chemical bonds between dissimilar materials.

- Material compatibility assessment and selection: Careful assessment and selection of compatible materials is crucial for minimizing delamination risks in multi-material jetting processes. This involves evaluating the chemical and physical properties of materials, including thermal expansion coefficients, surface energies, and molecular structures. Materials with similar properties or those specifically designed to bond with each other can significantly reduce interface failures and improve overall structural integrity of the printed components.

- Process parameter optimization for interface strength: Optimizing process parameters such as jetting temperature, curing conditions, layer thickness, and deposition speed can significantly impact the strength of interfaces between different materials. Controlled thermal management during printing and post-processing can reduce residual stresses that lead to delamination. Advanced algorithms and monitoring systems can be implemented to dynamically adjust these parameters based on material combinations and geometric features.

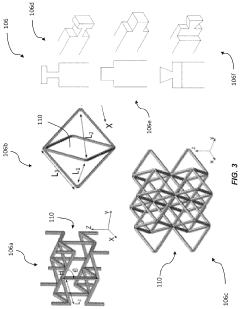

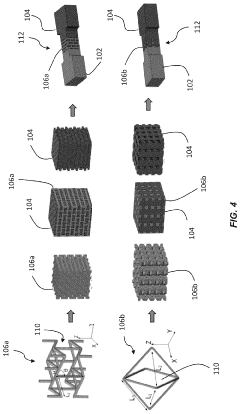

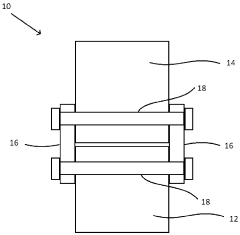

- Interface design and structural modifications: Strategic design of interfaces between different materials can significantly reduce delamination risks. This includes implementing gradual transitions between materials, creating mechanical interlocking features, and designing overlapping structures. Micro-texturing of interfaces and incorporation of reinforcement elements at critical junctions can distribute stresses more evenly and prevent crack propagation, thereby enhancing the overall durability of multi-material printed components.

- Post-processing treatments for interface strengthening: Various post-processing treatments can be applied to strengthen interfaces between different materials after the jetting process. These include thermal annealing, UV curing, chemical treatments, and pressure application. Such treatments can promote cross-linking between materials, reduce internal stresses, and enhance molecular diffusion across interfaces, resulting in stronger bonds and reduced delamination risks in multi-material printed structures.

02 Material compatibility assessment and selection

Careful assessment and selection of compatible materials is crucial for reducing delamination risks in multi-material jetting processes. This involves analyzing the chemical and physical properties of materials, including thermal expansion coefficients, surface energies, and molecular structures. By selecting materials with complementary properties, the risk of interface failure and delamination can be significantly reduced.Expand Specific Solutions03 Process parameter optimization for interface strength

Optimizing process parameters such as jetting temperature, curing conditions, layer thickness, and deposition speed can significantly impact the strength of multi-material interfaces. Proper calibration of these parameters helps ensure optimal material fusion and reduces internal stresses that could lead to delamination. Advanced monitoring systems can be used to maintain consistent process conditions throughout the manufacturing process.Expand Specific Solutions04 Interface design strategies to prevent delamination

Specialized interface designs can be implemented to reduce delamination risks in multi-material jetting. These include creating gradient interfaces, interlocking geometries, and mechanical anchoring features that distribute stress more evenly across material boundaries. Such design approaches can significantly enhance the mechanical integrity of multi-material interfaces and prevent failure under mechanical or thermal loads.Expand Specific Solutions05 Post-processing treatments for enhanced interface durability

Various post-processing treatments can be applied to strengthen multi-material interfaces after the jetting process. These include thermal annealing, UV curing optimization, chemical treatments, and surface modifications that promote cross-linking between different materials. Such treatments can significantly improve the long-term durability of multi-material interfaces and reduce delamination risks under various environmental conditions.Expand Specific Solutions

Leading Material Jetting Industry Players

Material Jetting Multi-Material Interface technology is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market is expanding rapidly, projected to reach $2-3 billion by 2025, driven by applications in electronics, automotive, and medical sectors. Technologically, the field remains challenging, with companies addressing delamination risks through different approaches. Industry leaders like Intel, Samsung Electronics, and TSMC are developing advanced gradient design methodologies, while materials specialists such as Murata Manufacturing and Soitec are focusing on interface compatibility solutions. Academic institutions including Central South University and Jilin University are contributing fundamental research on multi-material bonding mechanisms. The technology is approaching commercial viability but requires further refinement in material compatibility and process control to achieve widespread industrial adoption.

Dai Nippon Printing Co., Ltd.

Technical Solution: Dai Nippon Printing has developed a sophisticated material jetting system called "InterfaceMax" that specifically addresses delamination challenges in multi-material printing. Their approach utilizes a proprietary gradient design methodology that creates seamless transitions between materials with differing mechanical and thermal properties. The system employs variable viscosity inks with custom-formulated coupling agents that enhance chemical bonding at interfaces. DNP's technology incorporates multi-layer interface design where material composition gradually shifts across several thin layers rather than creating a single boundary. Their process includes controlled environmental parameters during printing and curing to minimize residual stresses that contribute to delamination. The InterfaceMax system also features post-processing treatments including specialized thermal annealing protocols that strengthen interfacial bonds while relieving internal stresses.

Strengths: Exceptional print resolution at interface regions; superior adhesion between organic and inorganic materials; excellent long-term stability under varying environmental conditions. Weaknesses: Requires precise environmental control during fabrication; limited compatibility with certain high-performance polymers; higher material costs compared to conventional single-material printing.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered a multi-material jetting platform specifically addressing delamination challenges in electronic components. Their technology utilizes a proprietary "interlocking gradient architecture" where material transitions are designed with microscale mechanical interlocking features combined with chemical bonding agents. The system employs multiple print heads with varying viscosity materials that create functional gradients at interfaces. Samsung's approach incorporates machine learning algorithms that analyze historical delamination data to optimize printing parameters in real-time. Their solution includes post-processing treatments using controlled thermal cycling and UV curing to strengthen interfacial bonds. The technology enables creation of components with embedded electronics where material interfaces are reinforced through nanoscale additives that enhance adhesion between dissimilar materials.

Strengths: Excellent performance in high-temperature cycling environments; superior mechanical stability at interfaces; compatibility with existing electronics manufacturing. Weaknesses: Complex calibration requirements; limited material selection compared to single-material processes; higher production costs for small batch manufacturing.

Key Patents in Gradient Design Technology

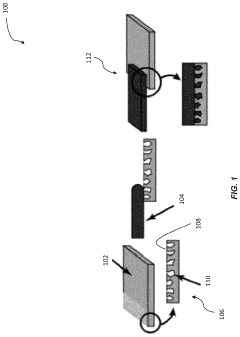

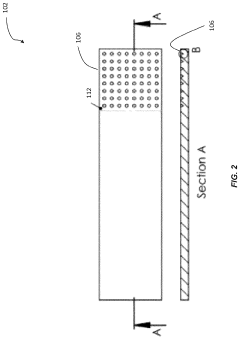

Design method for interlocking multi-material interface design

PatentPendingUS20240025128A1

Innovation

- The development of interlocking multi-material interfaces using mechanisms like protrusions and cavities formed by metallic powder deposition and molding, where the interlocking mechanisms can include re-entrant auxetic structures and geometric patterns, allowing for the use of non-compatible materials without additional bonding mechanisms.

Multi-material joint

PatentWO2023208730A1

Innovation

- A method involving the creation of a transition member with transition layers made from aged Inconel or pure nickel and titanium-based materials, welded together using explosion, linear, or rotary friction welding, which securely joins nickel-based superalloy and titanium-based material members without fasteners, optionally with a diffusion barrier and additive manufacturing for improved bonding and thermal management.

Material Compatibility Matrix

The Material Compatibility Matrix for material jetting processes represents a critical analytical framework for understanding the interaction behaviors between different materials at their interfaces. This matrix systematically categorizes material pairs based on their chemical, mechanical, and thermal compatibility factors, providing essential guidance for multi-material design decisions.

Primary compatibility factors include chemical bonding potential, surface energy differentials, thermal expansion coefficient mismatches, and mechanical property gradients. When materials with similar chemical structures are paired, they typically exhibit stronger interfacial bonding. For instance, combinations within the same polymer family (such as different grades of acrylates) generally demonstrate higher compatibility than cross-family pairings (such as acrylates with silicones).

Surface energy variations between materials significantly impact wetting behaviors and adhesion quality. Materials with substantial surface energy differences often exhibit poor interfacial adhesion, leading to increased delamination risks. The matrix quantifies these relationships, typically using contact angle measurements and surface tension values as key indicators of potential compatibility issues.

Thermal expansion coefficient (CTE) matching represents another crucial dimension in the compatibility matrix. Materials with CTE differences exceeding 30% frequently develop significant internal stresses during cooling phases, substantially increasing delamination probability. The matrix maps these relationships across common material jetting polymers, highlighting particularly problematic combinations that should be avoided or managed through gradient interfaces.

Mechanical property transitions, particularly modulus and hardness differentials, form the fourth major dimension of the compatibility matrix. Abrupt transitions between rigid and flexible materials create stress concentration zones that become failure initiation points. The matrix provides quantitative thresholds for safe mechanical property gradients, suggesting optimal transition designs for various material combinations.

The compatibility matrix also incorporates processing parameter considerations, as optimal jetting temperatures and curing conditions often vary between materials. Compatible materials should ideally process within similar parameter windows to minimize residual stresses and ensure consistent interface quality. This dimension of the matrix helps identify combinations requiring specialized processing approaches to achieve reliable bonding.

Recent advancements have expanded the matrix to include time-dependent compatibility factors, accounting for aging effects and environmental exposure impacts on multi-material interfaces. This temporal dimension provides critical insights for applications requiring long-term stability under various operating conditions.

Primary compatibility factors include chemical bonding potential, surface energy differentials, thermal expansion coefficient mismatches, and mechanical property gradients. When materials with similar chemical structures are paired, they typically exhibit stronger interfacial bonding. For instance, combinations within the same polymer family (such as different grades of acrylates) generally demonstrate higher compatibility than cross-family pairings (such as acrylates with silicones).

Surface energy variations between materials significantly impact wetting behaviors and adhesion quality. Materials with substantial surface energy differences often exhibit poor interfacial adhesion, leading to increased delamination risks. The matrix quantifies these relationships, typically using contact angle measurements and surface tension values as key indicators of potential compatibility issues.

Thermal expansion coefficient (CTE) matching represents another crucial dimension in the compatibility matrix. Materials with CTE differences exceeding 30% frequently develop significant internal stresses during cooling phases, substantially increasing delamination probability. The matrix maps these relationships across common material jetting polymers, highlighting particularly problematic combinations that should be avoided or managed through gradient interfaces.

Mechanical property transitions, particularly modulus and hardness differentials, form the fourth major dimension of the compatibility matrix. Abrupt transitions between rigid and flexible materials create stress concentration zones that become failure initiation points. The matrix provides quantitative thresholds for safe mechanical property gradients, suggesting optimal transition designs for various material combinations.

The compatibility matrix also incorporates processing parameter considerations, as optimal jetting temperatures and curing conditions often vary between materials. Compatible materials should ideally process within similar parameter windows to minimize residual stresses and ensure consistent interface quality. This dimension of the matrix helps identify combinations requiring specialized processing approaches to achieve reliable bonding.

Recent advancements have expanded the matrix to include time-dependent compatibility factors, accounting for aging effects and environmental exposure impacts on multi-material interfaces. This temporal dimension provides critical insights for applications requiring long-term stability under various operating conditions.

Sustainability Considerations

Material jetting technology, while offering significant advantages in multi-material manufacturing, presents important sustainability considerations that must be addressed for responsible implementation. The environmental impact of material jetting processes begins with raw material sourcing, where the extraction and processing of photopolymers and support materials often involve energy-intensive procedures and potentially harmful chemicals. The carbon footprint associated with these materials can be substantial, particularly when considering global supply chains and transportation requirements.

The manufacturing process itself consumes considerable energy, primarily through the curing mechanisms that utilize UV light or other radiation sources. This energy consumption is further amplified when dealing with multi-material interfaces that may require specialized processing parameters or additional post-processing steps to ensure proper adhesion between different material types.

Waste generation represents another critical sustainability concern. Failed prints due to delamination issues at material interfaces contribute to material waste, while support structures necessary for complex geometries often become single-use disposables. The chemical composition of many photopolymers used in material jetting makes them challenging to recycle through conventional methods, further exacerbating end-of-life disposal problems.

The introduction of gradient designs at material interfaces offers promising sustainability improvements. By creating smoother transitions between different materials, these gradients can reduce stress concentrations and minimize delamination failures, thereby decreasing waste from rejected parts. Additionally, well-designed material gradients can potentially reduce the need for extensive support structures, further minimizing material consumption and waste generation.

Life cycle assessment (LCA) studies indicate that the operational phase of material jetting equipment contributes significantly to the overall environmental impact. Innovations in energy-efficient curing technologies and process optimization could substantially reduce this footprint. Furthermore, the development of bio-based and biodegradable photopolymers represents an emerging research direction with potential to address end-of-life concerns.

Regulatory frameworks worldwide are increasingly focusing on the environmental impact of manufacturing processes, with particular attention to chemical safety, waste management, and energy efficiency. Companies adopting material jetting technologies must navigate these evolving regulations while implementing sustainable practices throughout their operations. This includes establishing material recovery programs, optimizing process parameters for energy efficiency, and investing in research for more environmentally friendly material formulations.

The manufacturing process itself consumes considerable energy, primarily through the curing mechanisms that utilize UV light or other radiation sources. This energy consumption is further amplified when dealing with multi-material interfaces that may require specialized processing parameters or additional post-processing steps to ensure proper adhesion between different material types.

Waste generation represents another critical sustainability concern. Failed prints due to delamination issues at material interfaces contribute to material waste, while support structures necessary for complex geometries often become single-use disposables. The chemical composition of many photopolymers used in material jetting makes them challenging to recycle through conventional methods, further exacerbating end-of-life disposal problems.

The introduction of gradient designs at material interfaces offers promising sustainability improvements. By creating smoother transitions between different materials, these gradients can reduce stress concentrations and minimize delamination failures, thereby decreasing waste from rejected parts. Additionally, well-designed material gradients can potentially reduce the need for extensive support structures, further minimizing material consumption and waste generation.

Life cycle assessment (LCA) studies indicate that the operational phase of material jetting equipment contributes significantly to the overall environmental impact. Innovations in energy-efficient curing technologies and process optimization could substantially reduce this footprint. Furthermore, the development of bio-based and biodegradable photopolymers represents an emerging research direction with potential to address end-of-life concerns.

Regulatory frameworks worldwide are increasingly focusing on the environmental impact of manufacturing processes, with particular attention to chemical safety, waste management, and energy efficiency. Companies adopting material jetting technologies must navigate these evolving regulations while implementing sustainable practices throughout their operations. This includes establishing material recovery programs, optimizing process parameters for energy efficiency, and investing in research for more environmentally friendly material formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!