How Sodium Acetate Promotes Resilient Infrastructure Materials?

Sodium Acetate in Infrastructure: Background and Objectives

Sodium acetate has emerged as a promising compound in the development of resilient infrastructure materials, marking a significant advancement in construction technology. The evolution of this field can be traced back to the early 2000s when researchers began exploring alternative additives to enhance the durability and performance of concrete and other building materials. As urbanization accelerated and infrastructure demands increased globally, the need for more robust and long-lasting materials became paramount.

The primary objective of incorporating sodium acetate into infrastructure materials is to improve their resilience against environmental stressors and extend their service life. This aligns with the broader goals of sustainable development and resource conservation in the construction industry. Sodium acetate, a salt formed by the combination of acetic acid and sodium hydroxide, has shown remarkable potential in addressing several key challenges faced by traditional infrastructure materials.

One of the most significant technical goals in this field is to enhance the freeze-thaw resistance of concrete. Sodium acetate acts as an anti-freezing agent, lowering the freezing point of water within the concrete matrix. This property is particularly crucial in regions experiencing severe winter conditions, where repeated freeze-thaw cycles can cause significant damage to infrastructure. By mitigating this issue, sodium acetate-enhanced materials can substantially reduce maintenance costs and extend the lifespan of structures.

Another important objective is to improve the self-healing capabilities of concrete. Sodium acetate has been found to promote the formation of calcium acetate, which can fill micro-cracks in concrete, effectively sealing them and preventing further deterioration. This self-healing property is a game-changer in infrastructure maintenance, potentially reducing the need for frequent repairs and interventions.

The integration of sodium acetate into infrastructure materials also aims to enhance their overall strength and durability. Research has shown that it can contribute to the formation of a more compact and less permeable concrete microstructure, thereby increasing resistance to chemical attacks and reducing the ingress of harmful substances like chlorides and sulfates.

As the field progresses, researchers are exploring the synergistic effects of combining sodium acetate with other advanced materials, such as nanomaterials and smart polymers. The goal is to develop next-generation infrastructure materials that not only exhibit superior resilience but also possess adaptive and responsive properties. This could lead to infrastructure capable of self-monitoring and self-repairing, revolutionizing the way we build and maintain our cities and transportation networks.

In conclusion, the incorporation of sodium acetate into infrastructure materials represents a significant leap forward in construction technology. By addressing critical issues such as freeze-thaw damage, material degradation, and maintenance costs, this innovation aligns perfectly with the global push towards more sustainable and resilient infrastructure. As research in this field continues to advance, it holds the promise of transforming our built environment, making it more durable, efficient, and adaptable to the challenges of the 21st century.

Market Analysis for Resilient Construction Materials

The market for resilient construction materials is experiencing significant growth, driven by increasing awareness of climate change impacts and the need for sustainable infrastructure. Sodium acetate, as a key component in promoting resilient infrastructure materials, is poised to play a crucial role in this expanding market.

The global construction industry is projected to reach $15.2 trillion by 2030, with a growing emphasis on sustainable and resilient building practices. Within this context, the market for resilient construction materials is expected to witness substantial growth. Factors such as urbanization, population growth, and the rising frequency of extreme weather events are fueling demand for materials that can withstand environmental stresses and maintain structural integrity over time.

Sodium acetate-enhanced construction materials offer several advantages that align with market needs. These include improved durability, increased resistance to freeze-thaw cycles, and enhanced self-healing properties. Such characteristics are particularly valuable in regions prone to harsh weather conditions or seismic activity, where infrastructure resilience is paramount.

The market for sodium acetate in construction applications is closely tied to the broader trends in green building and sustainable development. As governments and organizations worldwide implement stricter building codes and sustainability standards, the demand for innovative, resilient materials is expected to surge. This trend is further supported by initiatives such as the United Nations Sustainable Development Goals, which emphasize the importance of resilient infrastructure.

Geographically, North America and Europe currently lead the market for resilient construction materials, owing to their advanced infrastructure and stringent building regulations. However, rapid urbanization and infrastructure development in Asia-Pacific and Latin America are creating new growth opportunities. These regions are increasingly adopting resilient building practices to mitigate the impacts of natural disasters and climate change.

The market landscape is characterized by a mix of established construction material manufacturers and innovative startups focusing on advanced materials. Key players are investing in research and development to enhance the performance of sodium acetate-based solutions and expand their application range. Collaborations between academic institutions and industry partners are also driving innovation in this space.

Despite the promising outlook, challenges remain. The higher initial cost of resilient materials compared to traditional options can be a barrier to widespread adoption, particularly in cost-sensitive markets. Additionally, the construction industry's conservative nature and slow adoption of new technologies may hinder rapid market penetration. However, as the long-term benefits of resilient materials become more apparent, including reduced maintenance costs and extended infrastructure lifespan, these barriers are expected to diminish.

Current Challenges in Infrastructure Resilience

Infrastructure resilience faces numerous challenges in the modern era, with increasing demands for durability, sustainability, and adaptability. One of the primary issues is the deterioration of materials due to environmental factors, such as extreme weather conditions, chemical exposure, and mechanical stress. Traditional construction materials often struggle to maintain their integrity over extended periods, leading to frequent repairs and replacements that burden both economic resources and environmental sustainability.

Another significant challenge is the need for infrastructure to withstand unpredictable and increasingly severe natural disasters. Climate change has amplified the frequency and intensity of events like hurricanes, floods, and earthquakes, putting unprecedented stress on existing structures. The ability of infrastructure to resist damage and recover quickly from these events is crucial for maintaining societal functions and minimizing economic losses.

The growing urbanization trend presents additional challenges for infrastructure resilience. As cities expand and populations increase, there is mounting pressure on existing infrastructure systems to accommodate higher loads and more complex usage patterns. This intensification of use accelerates wear and tear, potentially shortening the lifespan of critical components and increasing the risk of failure.

Moreover, the integration of smart technologies into infrastructure systems, while offering potential benefits, introduces new vulnerabilities. Cybersecurity concerns and the need for seamless integration of digital and physical components add layers of complexity to the resilience equation. Ensuring that these smart systems can withstand both physical and digital threats is a pressing challenge for modern infrastructure design and management.

The financial constraints faced by many governments and organizations further complicate efforts to enhance infrastructure resilience. Limited budgets often lead to deferred maintenance and delayed upgrades, exacerbating existing vulnerabilities and potentially increasing long-term costs. Balancing immediate financial considerations with the need for long-term resilience investments remains a persistent challenge.

Lastly, the development of sustainable and environmentally friendly infrastructure materials that do not compromise on strength and durability is an ongoing challenge. There is a growing demand for materials that can reduce carbon footprints, minimize resource consumption, and still provide the necessary resilience against various stressors. Finding innovative solutions that meet these multiple, often competing, criteria is a complex task that requires interdisciplinary approaches and continuous research efforts.

Existing Sodium Acetate-Based Solutions

01 Sodium acetate in heat storage materials

Sodium acetate is used in heat storage materials due to its phase change properties. It can absorb and release heat during phase transitions, making it suitable for thermal energy storage applications. These materials can be used in various industries for temperature regulation and energy conservation.- Sodium acetate in heat storage materials: Sodium acetate is used in heat storage materials due to its phase change properties. It can absorb and release heat during phase transitions, making it useful for thermal energy storage applications. These materials can be incorporated into various products to provide temperature regulation and heat retention capabilities.

- Sodium acetate in resilient compositions: Sodium acetate is utilized in resilient compositions, such as cushioning materials or impact-absorbing structures. These compositions can provide enhanced shock absorption and energy dissipation properties, making them suitable for protective equipment, packaging, or construction applications.

- Sodium acetate in chemical processes: Sodium acetate plays a role in various chemical processes, including as a buffering agent, pH regulator, or catalyst. It can be used in the production of other chemicals, pharmaceuticals, or in industrial applications where precise control of acidity or alkalinity is required.

- Sodium acetate in textile and fiber treatment: Sodium acetate is employed in textile and fiber treatment processes. It can be used as a mordant in dyeing, a finishing agent for fabrics, or in the production of synthetic fibers. These applications can improve the color fastness, texture, or other properties of textiles and fibers.

- Sodium acetate in food and beverage applications: Sodium acetate finds use in food and beverage applications as a preservative, flavoring agent, or acidity regulator. It can help extend shelf life, enhance taste profiles, or maintain desired pH levels in various food products and beverages.

02 Sodium acetate in resilient compositions

Sodium acetate is incorporated into resilient compositions to enhance their mechanical properties. These compositions can be used in various applications where resilience and durability are required, such as in construction materials, automotive parts, or consumer products.Expand Specific Solutions03 Sodium acetate in chemical processes

Sodium acetate is utilized in various chemical processes as a reagent, buffer, or catalyst. It plays a role in reactions such as esterification, saponification, and neutralization. The compound's properties make it valuable in industrial chemistry and laboratory applications.Expand Specific Solutions04 Sodium acetate in food and pharmaceutical applications

Sodium acetate is used as a food additive and in pharmaceutical formulations. It serves as a preservative, pH regulator, and flavoring agent in food products. In pharmaceuticals, it can be used as an excipient or in drug formulations for various therapeutic purposes.Expand Specific Solutions05 Sodium acetate in environmental applications

Sodium acetate is employed in environmental applications such as wastewater treatment and air pollution control. It can be used as a deicer for roads and runways, offering a more environmentally friendly alternative to traditional deicing agents. The compound's biodegradability and low toxicity make it suitable for these applications.Expand Specific Solutions

Key Players in Sodium Acetate and Construction Industries

The development of sodium acetate-based resilient infrastructure materials is in an emerging phase, with growing market potential driven by the increasing demand for sustainable and durable construction solutions. The global market for advanced construction materials is expanding, though the specific segment for sodium acetate-based products is still developing. Technologically, the field is progressing rapidly, with companies like Wacker Chemie AG, FMC Corp., and Sika Technology AG leading research efforts. Academic institutions such as Clemson University and Northeastern University are also contributing significantly to advancing the technology. While not yet fully mature, the technology shows promise in enhancing infrastructure resilience, with ongoing collaborations between industry and academia driving innovation and practical applications.

Wacker Chemie AG

China Petroleum & Chemical Corp.

Core Innovations in Sodium Acetate Technology

- A solution of calcium acetoacetate is applied to the surface of the material, penetrating into its pores where it transforms into calcium carbonate, effectively reinforcing the material without the drawbacks of known methods, using water or alcohol as solvents and potentially repeating the application for deeper penetration.

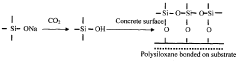

- The development of Protekta Base, a viscous liquid formulation combining silicates of sodium, zirconium, and calcium with proprietary biochemical additives, which penetrates concrete to form a sub-surface barrier, reducing permeability and porosity, and enhancing chemical resistance by reacting with free calcium to form Calcium Silicate Hydrate, thus providing a multi-functional waterproofing and hardening treatment.

Environmental Impact of Sodium Acetate Use

The use of sodium acetate in infrastructure materials has significant environmental implications that warrant careful consideration. As a de-icing agent and concrete additive, sodium acetate interacts with the environment in various ways, both positive and negative.

One of the primary environmental benefits of sodium acetate is its lower corrosivity compared to traditional de-icing salts like sodium chloride. This reduced corrosiveness helps preserve infrastructure and vehicles, potentially extending their lifespan and reducing the need for frequent replacements or repairs. Consequently, this can lead to a decrease in resource consumption and waste generation associated with infrastructure maintenance.

However, the introduction of sodium acetate into the environment is not without concerns. When used as a de-icing agent, it can accumulate in soil and water systems. While less harmful than chloride-based alternatives, high concentrations of acetate can still impact aquatic ecosystems by altering pH levels and potentially promoting algal growth. This could lead to eutrophication in water bodies, affecting biodiversity and water quality.

The production process of sodium acetate also carries environmental considerations. Manufacturing this compound typically involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. The energy requirements and potential emissions associated with these industrial processes contribute to the overall environmental footprint of sodium acetate use in infrastructure materials.

On a positive note, sodium acetate is biodegradable, which means it breaks down naturally in the environment over time. This characteristic reduces its long-term accumulation and persistent impact on ecosystems compared to non-biodegradable alternatives. Additionally, its lower freezing point depression compared to sodium chloride means that less material is required to achieve the same de-icing effect, potentially reducing overall chemical usage.

The use of sodium acetate in concrete as an accelerating admixture can also have indirect environmental benefits. By enhancing early strength development, it can potentially reduce curing times and energy requirements in concrete production. This could lead to more efficient construction processes and lower overall energy consumption in infrastructure development.

However, the long-term effects of sodium acetate on concrete durability and its potential leaching into the environment over time are areas that require further research. The interaction between sodium acetate and other components in infrastructure materials, as well as its behavior under various environmental conditions, needs to be thoroughly understood to assess its full environmental impact.

In conclusion, while sodium acetate offers several environmental advantages over traditional materials in promoting resilient infrastructure, its use must be carefully managed and monitored. Balancing its benefits against potential ecological risks is crucial for sustainable infrastructure development. Ongoing research and environmental assessments are necessary to optimize its application and mitigate any adverse effects on ecosystems.

Cost-Benefit Analysis of Sodium Acetate Implementation

The implementation of sodium acetate in infrastructure materials presents a complex cost-benefit scenario that requires careful analysis. Initial costs associated with incorporating sodium acetate into construction materials are generally higher than traditional alternatives. These expenses stem from the need for specialized production processes, potential modifications to existing manufacturing facilities, and the higher raw material costs of sodium acetate compared to conventional additives.

However, the long-term benefits of sodium acetate-enhanced materials can potentially outweigh these upfront investments. The increased durability and resilience of infrastructure materials containing sodium acetate lead to extended service life and reduced maintenance requirements. This translates to significant cost savings over the lifecycle of structures, particularly in harsh environments or areas prone to extreme weather conditions.

The self-healing properties of sodium acetate-infused materials contribute to reduced repair and replacement costs. By autonomously addressing minor cracks and damages, these materials minimize the need for manual interventions, thereby lowering labor costs and reducing downtime for infrastructure assets. This aspect is particularly valuable for critical structures where continuous operation is essential.

Energy efficiency improvements associated with sodium acetate implementation can result in operational cost reductions. For instance, in building applications, the thermal regulation properties of sodium acetate can lead to decreased heating and cooling expenses. Similarly, in road construction, the enhanced freeze-thaw resistance can reduce the frequency of surface treatments and resurfacing operations.

Environmental benefits, while challenging to quantify monetarily, should also be considered in the cost-benefit analysis. The increased longevity of infrastructure materials reduces the demand for raw materials and energy required for replacements, aligning with sustainability goals and potentially offering carbon credit opportunities or compliance with environmental regulations.

The scalability of sodium acetate implementation affects its cost-effectiveness. As adoption increases and production scales up, economies of scale are likely to reduce the per-unit cost of sodium acetate-enhanced materials. This trend could make the technology more accessible and economically viable for a broader range of applications over time.

Risk mitigation is another crucial factor in the cost-benefit equation. The improved resilience of infrastructure materials containing sodium acetate can reduce the likelihood of catastrophic failures, potentially leading to lower insurance premiums and decreased liability risks for infrastructure owners and operators.

In conclusion, while the initial costs of sodium acetate implementation may be higher, the long-term economic benefits, coupled with enhanced performance and sustainability advantages, present a compelling case for its adoption in resilient infrastructure materials. A comprehensive lifecycle cost analysis, taking into account both direct and indirect benefits, is essential for accurately assessing the true value proposition of this innovative technology.