How to Achieve Better Thermal Stability in PNP Transistor Applications?

JUL 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PNP Transistor Thermal Stability Background

PNP transistors have been a cornerstone of electronic circuit design since their inception in the mid-20th century. These devices, characterized by their ability to control current flow using a small input signal, have found widespread applications in various fields, including amplifiers, switches, and voltage regulators. However, one of the persistent challenges in PNP transistor applications has been achieving and maintaining thermal stability.

Thermal stability in PNP transistors refers to the device's ability to maintain consistent performance characteristics across a range of operating temperatures. This is crucial because transistor behavior is inherently temperature-dependent, with factors such as current gain, leakage current, and threshold voltage all varying with temperature changes. As electronic devices become more compact and powerful, the issue of thermal management becomes increasingly critical.

The quest for better thermal stability in PNP transistors has its roots in the fundamental physics of semiconductor devices. As temperature increases, the mobility of charge carriers in the semiconductor material decreases, while the number of intrinsic carriers increases. This interplay leads to complex changes in transistor behavior, often resulting in undesirable performance variations or even device failure in extreme cases.

Historically, early attempts to address thermal stability focused on external compensation techniques, such as using temperature-sensitive resistors or diodes in the biasing network. While these methods provided some improvement, they often fell short in achieving precise and reliable temperature compensation across a wide range of operating conditions.

As semiconductor technology advanced, more sophisticated approaches to thermal stability emerged. These included the development of improved semiconductor materials with better thermal characteristics, the implementation of advanced packaging techniques to enhance heat dissipation, and the integration of on-chip temperature sensing and compensation circuits.

The importance of thermal stability in PNP transistor applications cannot be overstated. In precision analog circuits, such as those found in instrumentation and measurement equipment, even small temperature-induced variations can lead to significant errors. In power electronics, where PNP transistors may handle substantial currents, thermal instability can result in reduced efficiency, reliability issues, or even catastrophic failure.

The ongoing evolution of electronic systems, particularly in areas like automotive electronics, aerospace applications, and industrial control systems, has further heightened the need for thermally stable PNP transistors. These applications often involve operation in harsh environments with wide temperature fluctuations, making thermal stability a critical design consideration.

Thermal stability in PNP transistors refers to the device's ability to maintain consistent performance characteristics across a range of operating temperatures. This is crucial because transistor behavior is inherently temperature-dependent, with factors such as current gain, leakage current, and threshold voltage all varying with temperature changes. As electronic devices become more compact and powerful, the issue of thermal management becomes increasingly critical.

The quest for better thermal stability in PNP transistors has its roots in the fundamental physics of semiconductor devices. As temperature increases, the mobility of charge carriers in the semiconductor material decreases, while the number of intrinsic carriers increases. This interplay leads to complex changes in transistor behavior, often resulting in undesirable performance variations or even device failure in extreme cases.

Historically, early attempts to address thermal stability focused on external compensation techniques, such as using temperature-sensitive resistors or diodes in the biasing network. While these methods provided some improvement, they often fell short in achieving precise and reliable temperature compensation across a wide range of operating conditions.

As semiconductor technology advanced, more sophisticated approaches to thermal stability emerged. These included the development of improved semiconductor materials with better thermal characteristics, the implementation of advanced packaging techniques to enhance heat dissipation, and the integration of on-chip temperature sensing and compensation circuits.

The importance of thermal stability in PNP transistor applications cannot be overstated. In precision analog circuits, such as those found in instrumentation and measurement equipment, even small temperature-induced variations can lead to significant errors. In power electronics, where PNP transistors may handle substantial currents, thermal instability can result in reduced efficiency, reliability issues, or even catastrophic failure.

The ongoing evolution of electronic systems, particularly in areas like automotive electronics, aerospace applications, and industrial control systems, has further heightened the need for thermally stable PNP transistors. These applications often involve operation in harsh environments with wide temperature fluctuations, making thermal stability a critical design consideration.

Market Demand Analysis

The market demand for improved thermal stability in PNP transistor applications has been steadily growing across various industries. This demand is primarily driven by the increasing need for high-performance electronic devices that can operate reliably under extreme temperature conditions.

In the automotive sector, there is a significant push for more robust and temperature-resistant electronic components. As vehicles incorporate more advanced driver assistance systems (ADAS) and move towards autonomous driving, the reliability of transistors under varying temperature conditions becomes crucial. The automotive electronics market, which heavily relies on PNP transistors, is projected to grow at a compound annual growth rate (CAGR) of 8% from 2021 to 2026.

The aerospace and defense industries also contribute substantially to the demand for thermally stable PNP transistors. These sectors require components that can withstand extreme temperature fluctuations encountered during flight or in military operations. The global aerospace and defense market is expected to reach $1,600 billion by 2025, with a significant portion allocated to electronic systems.

In the industrial automation sector, the need for PNP transistors with enhanced thermal stability is driven by the trend towards smart manufacturing and Industry 4.0. These applications often involve environments with high temperatures and require consistent performance from electronic components. The industrial automation market is forecasted to grow at a CAGR of 9.3% from 2020 to 2027.

The consumer electronics industry, particularly in the development of high-performance computing devices and smartphones, also contributes to the demand. As devices become more powerful and compact, managing heat dissipation and ensuring stable operation across temperature ranges becomes increasingly important. The global consumer electronics market is expected to reach $1,500 billion by 2026, with a substantial portion relying on advanced transistor technologies.

Emerging technologies such as 5G infrastructure and Internet of Things (IoT) devices are creating new market opportunities for thermally stable PNP transistors. These applications often require components that can operate reliably in outdoor environments with varying temperatures. The global 5G infrastructure market is projected to grow at a CAGR of 49.8% from 2021 to 2028.

The demand for improved thermal stability in PNP transistors is also influenced by the overall trend towards miniaturization and increased power density in electronic devices. As components become smaller and more tightly packed, the ability to maintain stable performance under higher operating temperatures becomes critical.

In conclusion, the market demand for PNP transistors with better thermal stability is robust and growing across multiple sectors. This demand is driven by the need for reliable performance in extreme conditions, the trend towards more advanced and compact electronic systems, and the emergence of new technologies that require high-performance components.

In the automotive sector, there is a significant push for more robust and temperature-resistant electronic components. As vehicles incorporate more advanced driver assistance systems (ADAS) and move towards autonomous driving, the reliability of transistors under varying temperature conditions becomes crucial. The automotive electronics market, which heavily relies on PNP transistors, is projected to grow at a compound annual growth rate (CAGR) of 8% from 2021 to 2026.

The aerospace and defense industries also contribute substantially to the demand for thermally stable PNP transistors. These sectors require components that can withstand extreme temperature fluctuations encountered during flight or in military operations. The global aerospace and defense market is expected to reach $1,600 billion by 2025, with a significant portion allocated to electronic systems.

In the industrial automation sector, the need for PNP transistors with enhanced thermal stability is driven by the trend towards smart manufacturing and Industry 4.0. These applications often involve environments with high temperatures and require consistent performance from electronic components. The industrial automation market is forecasted to grow at a CAGR of 9.3% from 2020 to 2027.

The consumer electronics industry, particularly in the development of high-performance computing devices and smartphones, also contributes to the demand. As devices become more powerful and compact, managing heat dissipation and ensuring stable operation across temperature ranges becomes increasingly important. The global consumer electronics market is expected to reach $1,500 billion by 2026, with a substantial portion relying on advanced transistor technologies.

Emerging technologies such as 5G infrastructure and Internet of Things (IoT) devices are creating new market opportunities for thermally stable PNP transistors. These applications often require components that can operate reliably in outdoor environments with varying temperatures. The global 5G infrastructure market is projected to grow at a CAGR of 49.8% from 2021 to 2028.

The demand for improved thermal stability in PNP transistors is also influenced by the overall trend towards miniaturization and increased power density in electronic devices. As components become smaller and more tightly packed, the ability to maintain stable performance under higher operating temperatures becomes critical.

In conclusion, the market demand for PNP transistors with better thermal stability is robust and growing across multiple sectors. This demand is driven by the need for reliable performance in extreme conditions, the trend towards more advanced and compact electronic systems, and the emergence of new technologies that require high-performance components.

Current Challenges in PNP Thermal Stability

PNP transistors, while essential in many electronic applications, face significant challenges in maintaining thermal stability. One of the primary issues is the inherent temperature sensitivity of these devices. As the temperature increases, the current gain (hFE) of PNP transistors tends to decrease, leading to performance degradation and potential circuit instability.

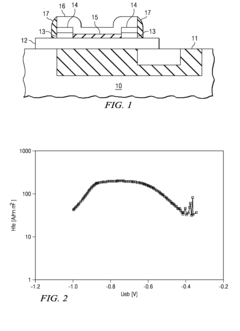

The base-emitter voltage (VBE) of PNP transistors is also highly temperature-dependent, typically decreasing by about 2mV per degree Celsius rise in temperature. This variation can cause undesirable shifts in operating points and affect the overall circuit behavior, especially in analog applications where precise biasing is crucial.

Thermal runaway is another critical concern in PNP transistor applications. As the device heats up, its collector current increases, which in turn generates more heat. This positive feedback loop can lead to device failure if not properly managed. The problem is exacerbated in high-power applications where significant heat is generated during normal operation.

Self-heating effects pose additional challenges to thermal stability. The heat generated within the transistor itself can cause localized temperature increases, leading to non-uniform thermal distribution across the device. This non-uniformity can result in unpredictable behavior and reduced reliability, particularly in compact designs where heat dissipation is limited.

The packaging and thermal management of PNP transistors also present significant hurdles. Inadequate heat sinking or poor thermal design can lead to hotspots and accelerated aging of the device. In multi-transistor circuits or integrated circuits, thermal coupling between adjacent devices can further complicate the thermal management process.

Leakage currents in PNP transistors are another temperature-dependent factor that affects stability. As temperature rises, reverse leakage currents increase exponentially, potentially leading to unwanted conduction and circuit malfunction. This is particularly problematic in high-temperature environments or applications with stringent power consumption requirements.

The variation in transistor parameters across different manufacturing batches and the effects of aging over time add another layer of complexity to achieving consistent thermal stability. These variations can lead to inconsistent performance across different units of the same circuit design, making it challenging to maintain uniform thermal characteristics in mass-produced applications.

Addressing these challenges requires a multifaceted approach, combining circuit design techniques, thermal management strategies, and careful component selection. Innovations in semiconductor materials, device structures, and packaging technologies are continually being pursued to enhance the thermal stability of PNP transistors and expand their applicability in demanding environments.

The base-emitter voltage (VBE) of PNP transistors is also highly temperature-dependent, typically decreasing by about 2mV per degree Celsius rise in temperature. This variation can cause undesirable shifts in operating points and affect the overall circuit behavior, especially in analog applications where precise biasing is crucial.

Thermal runaway is another critical concern in PNP transistor applications. As the device heats up, its collector current increases, which in turn generates more heat. This positive feedback loop can lead to device failure if not properly managed. The problem is exacerbated in high-power applications where significant heat is generated during normal operation.

Self-heating effects pose additional challenges to thermal stability. The heat generated within the transistor itself can cause localized temperature increases, leading to non-uniform thermal distribution across the device. This non-uniformity can result in unpredictable behavior and reduced reliability, particularly in compact designs where heat dissipation is limited.

The packaging and thermal management of PNP transistors also present significant hurdles. Inadequate heat sinking or poor thermal design can lead to hotspots and accelerated aging of the device. In multi-transistor circuits or integrated circuits, thermal coupling between adjacent devices can further complicate the thermal management process.

Leakage currents in PNP transistors are another temperature-dependent factor that affects stability. As temperature rises, reverse leakage currents increase exponentially, potentially leading to unwanted conduction and circuit malfunction. This is particularly problematic in high-temperature environments or applications with stringent power consumption requirements.

The variation in transistor parameters across different manufacturing batches and the effects of aging over time add another layer of complexity to achieving consistent thermal stability. These variations can lead to inconsistent performance across different units of the same circuit design, making it challenging to maintain uniform thermal characteristics in mass-produced applications.

Addressing these challenges requires a multifaceted approach, combining circuit design techniques, thermal management strategies, and careful component selection. Innovations in semiconductor materials, device structures, and packaging technologies are continually being pursued to enhance the thermal stability of PNP transistors and expand their applicability in demanding environments.

Existing Thermal Stability Solutions

01 Thermal compensation techniques

Various thermal compensation techniques are employed to enhance the thermal stability of PNP transistors. These may include using temperature-sensitive resistors, diodes, or other components to counteract the effects of temperature changes on transistor performance. Such techniques help maintain consistent operation across a wide temperature range.- Thermal compensation techniques: Various thermal compensation techniques are employed to enhance the thermal stability of PNP transistors. These may include using temperature-sensitive resistors, diodes, or other components to counteract the effects of temperature changes on transistor performance. Such techniques help maintain consistent operation across a wide temperature range.

- Improved transistor structure design: Advancements in PNP transistor structure design focus on enhancing thermal stability. This includes optimizing the layout, doping profiles, and materials used in the transistor construction. These improvements aim to reduce temperature-induced variations in electrical characteristics and increase overall device reliability.

- Integration of temperature sensing elements: Incorporating temperature sensing elements within or near PNP transistors allows for real-time monitoring and adjustment of operating parameters. This approach enables dynamic compensation for temperature fluctuations, maintaining stable performance across varying thermal conditions.

- Advanced packaging and heat dissipation: Innovative packaging techniques and improved heat dissipation methods are utilized to enhance the thermal stability of PNP transistors. These may include advanced materials, heat spreaders, or novel package designs that efficiently remove heat from the transistor, reducing thermal-induced performance variations.

- Bias circuit optimization: Optimizing bias circuits for PNP transistors plays a crucial role in maintaining thermal stability. This involves designing bias networks that are less sensitive to temperature changes or that can actively adjust bias conditions to compensate for thermal variations, ensuring consistent transistor operation across different temperatures.

02 Improved transistor structure design

Advancements in PNP transistor structure design focus on enhancing thermal stability. This includes optimizing the layout, doping profiles, and materials used in the transistor construction. These improvements aim to reduce temperature-induced variations in electrical characteristics and increase overall device reliability.Expand Specific Solutions03 Integration of temperature sensing elements

Incorporating temperature sensing elements within or near PNP transistors allows for real-time monitoring and adjustment of operating parameters. This approach enables dynamic compensation for temperature fluctuations, maintaining stable performance across varying thermal conditions.Expand Specific Solutions04 Advanced packaging and heat dissipation

Innovative packaging techniques and improved heat dissipation methods are developed to enhance the thermal stability of PNP transistors. These may include advanced materials for better heat conduction, optimized package designs for efficient heat removal, and integration of heat sinks or other cooling mechanisms.Expand Specific Solutions05 Circuit-level thermal management

Implementing circuit-level thermal management strategies to improve PNP transistor stability. This includes designing bias circuits that are less sensitive to temperature variations, using feedback mechanisms to adjust operating points, and employing temperature-compensated current sources or voltage references in conjunction with PNP transistors.Expand Specific Solutions

Key Players in PNP Transistor Industry

The thermal stability of PNP transistors remains a critical challenge in the semiconductor industry, with the market currently in a mature growth phase. The global market for transistors, including PNP types, is substantial, driven by increasing demand in various electronic applications. Key players like Texas Instruments, Analog Devices, and Infineon Technologies are at the forefront of addressing thermal stability issues through advanced research and development. These companies, along with others such as NXP and STMicroelectronics, are investing in innovative technologies to enhance the performance and reliability of PNP transistors under varying temperature conditions. The competition is fierce, with each company striving to develop proprietary solutions that offer superior thermal management and overall efficiency.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced thermal management techniques for PNP transistors, including the use of silicon-germanium (SiGe) heterojunction bipolar transistors (HBTs). These HBTs offer improved thermal stability due to their wider bandgap and reduced base resistance[1]. TI also implements advanced packaging solutions, such as flip-chip technology, which allows for better heat dissipation[2]. Additionally, they utilize precision trimming techniques to compensate for temperature-induced variations in transistor characteristics[3]. TI's approach also includes the integration of on-chip temperature sensors and compensation circuits to dynamically adjust bias conditions, ensuring stable performance across a wide temperature range[4].

Strengths: Extensive experience in analog design, advanced packaging technologies, and integrated compensation techniques. Weaknesses: Potentially higher cost due to advanced materials and processes, may require redesign of existing circuits to fully utilize new technologies.

Analog Devices, Inc.

Technical Solution: Analog Devices focuses on improving thermal stability in PNP transistors through several innovative approaches. They employ advanced BiCMOS processes that integrate PNP transistors with better thermal characteristics[5]. ADI also utilizes proprietary dielectric isolation techniques to reduce thermal coupling between adjacent devices[6]. Their designs often incorporate chopper-stabilized amplifiers and auto-zero techniques to minimize temperature-induced offset voltages[7]. Furthermore, ADI has developed specialized current mirrors and bias circuits that maintain consistent performance over temperature variations[8]. They also implement advanced modeling and simulation techniques to predict and compensate for thermal effects in complex analog systems[9].

Strengths: Strong expertise in precision analog design, innovative isolation techniques, and advanced modeling capabilities. Weaknesses: Solutions may be more complex to implement, potentially increasing design time and cost for some applications.

Core Innovations in PNP Thermal Design

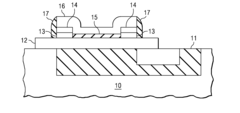

Method of manufacturing an electronic device including a PNP bipolar transistor

PatentActiveUS7888225B2

Innovation

- A nitride interface layer is introduced between the base and emitter layers in PNP transistors, providing stability against oxygen penetration and maintaining barrier properties, allowing for improved thermal stability and control of base current.

PTC conductive composition containing a low molecular weight polyethylene processing aid

PatentInactiveEP1490880A1

Innovation

- The use of polymeric PTC compositions comprising an organic polymer, a conductive filler, and a low molecular weight polyethylene processing aid, optionally with additives, to achieve high PTC effect and low initial resistivity, with the polymer having a melting point between 100°C to 250°C and a crystallinity of at least 10%, and the low molecular weight polyethylene processing aid improving processability.

Thermal Management Techniques

Thermal management techniques play a crucial role in achieving better thermal stability in PNP transistor applications. These techniques aim to dissipate heat effectively and maintain optimal operating temperatures, ensuring reliable performance and extended lifespan of the transistors.

One of the primary thermal management techniques is the use of heat sinks. Heat sinks are passive cooling devices that increase the surface area available for heat dissipation. They are typically made of materials with high thermal conductivity, such as aluminum or copper. When attached to the transistor package, heat sinks facilitate the transfer of heat from the device to the surrounding air, effectively reducing the operating temperature.

Active cooling methods, such as forced-air cooling and liquid cooling, can be employed for more demanding applications. Forced-air cooling utilizes fans or blowers to increase air circulation around the transistor, enhancing convective heat transfer. This method is particularly effective in enclosed spaces or high-density circuit designs. Liquid cooling systems, while more complex, offer superior heat dissipation capabilities by circulating a coolant through a heat exchanger in contact with the transistor.

Thermal interface materials (TIMs) are essential components in effective thermal management. These materials, such as thermal greases, pads, or adhesives, are applied between the transistor and the heat sink to improve thermal conductivity and reduce thermal resistance. TIMs fill microscopic air gaps and ensure efficient heat transfer from the device to the cooling solution.

Proper PCB design is another critical aspect of thermal management. Techniques such as using thicker copper layers, implementing thermal vias, and optimizing component placement can significantly improve heat dissipation. Thermal vias, which are plated through-holes in the PCB, provide a low-resistance path for heat to spread from the transistor to other layers of the board or to a heat sink on the opposite side.

Advanced packaging technologies, like flip-chip and direct bonded copper (DBC) substrates, can also enhance thermal performance. These technologies reduce thermal resistance by minimizing the distance between the transistor die and the cooling solution, allowing for more efficient heat transfer.

In some cases, thermoelectric coolers (TECs) or Peltier devices may be employed for precise temperature control. These solid-state devices can actively cool the transistor below ambient temperature, which is particularly useful in applications requiring stringent thermal stability.

Implementing thermal monitoring and feedback systems can further improve thermal stability. Temperature sensors and control circuits can be used to dynamically adjust operating conditions or activate additional cooling mechanisms when temperatures approach critical thresholds.

By combining these thermal management techniques and selecting the most appropriate methods for specific applications, engineers can significantly enhance the thermal stability of PNP transistors, ensuring optimal performance and reliability across a wide range of operating conditions.

One of the primary thermal management techniques is the use of heat sinks. Heat sinks are passive cooling devices that increase the surface area available for heat dissipation. They are typically made of materials with high thermal conductivity, such as aluminum or copper. When attached to the transistor package, heat sinks facilitate the transfer of heat from the device to the surrounding air, effectively reducing the operating temperature.

Active cooling methods, such as forced-air cooling and liquid cooling, can be employed for more demanding applications. Forced-air cooling utilizes fans or blowers to increase air circulation around the transistor, enhancing convective heat transfer. This method is particularly effective in enclosed spaces or high-density circuit designs. Liquid cooling systems, while more complex, offer superior heat dissipation capabilities by circulating a coolant through a heat exchanger in contact with the transistor.

Thermal interface materials (TIMs) are essential components in effective thermal management. These materials, such as thermal greases, pads, or adhesives, are applied between the transistor and the heat sink to improve thermal conductivity and reduce thermal resistance. TIMs fill microscopic air gaps and ensure efficient heat transfer from the device to the cooling solution.

Proper PCB design is another critical aspect of thermal management. Techniques such as using thicker copper layers, implementing thermal vias, and optimizing component placement can significantly improve heat dissipation. Thermal vias, which are plated through-holes in the PCB, provide a low-resistance path for heat to spread from the transistor to other layers of the board or to a heat sink on the opposite side.

Advanced packaging technologies, like flip-chip and direct bonded copper (DBC) substrates, can also enhance thermal performance. These technologies reduce thermal resistance by minimizing the distance between the transistor die and the cooling solution, allowing for more efficient heat transfer.

In some cases, thermoelectric coolers (TECs) or Peltier devices may be employed for precise temperature control. These solid-state devices can actively cool the transistor below ambient temperature, which is particularly useful in applications requiring stringent thermal stability.

Implementing thermal monitoring and feedback systems can further improve thermal stability. Temperature sensors and control circuits can be used to dynamically adjust operating conditions or activate additional cooling mechanisms when temperatures approach critical thresholds.

By combining these thermal management techniques and selecting the most appropriate methods for specific applications, engineers can significantly enhance the thermal stability of PNP transistors, ensuring optimal performance and reliability across a wide range of operating conditions.

Reliability Testing Methods

Reliability testing methods play a crucial role in ensuring the thermal stability of PNP transistors in various applications. These methods are designed to evaluate the performance and durability of transistors under different thermal conditions, simulating real-world scenarios and identifying potential failure modes.

One of the primary reliability testing methods for PNP transistors is thermal cycling. This process involves subjecting the transistor to alternating high and low temperatures, typically ranging from -55°C to 150°C, for a specified number of cycles. The test assesses the transistor's ability to withstand thermal stress and maintain its electrical characteristics over time. During thermal cycling, parameters such as collector-emitter voltage, base-emitter voltage, and collector current are monitored to detect any significant deviations.

Another essential method is the high-temperature operating life (HTOL) test. In this test, PNP transistors are operated at their maximum rated temperature for an extended period, often lasting several thousand hours. The HTOL test evaluates the long-term stability of the transistor's electrical parameters and helps identify potential degradation mechanisms that may occur during prolonged exposure to high temperatures.

Temperature humidity bias (THB) testing is employed to assess the transistor's resistance to moisture-induced degradation. This method involves exposing the device to high temperature and humidity conditions while applying electrical bias. The test typically runs for 1000 hours at 85°C and 85% relative humidity, simulating harsh environmental conditions that may accelerate corrosion or other moisture-related failure mechanisms.

Power cycling tests are particularly relevant for PNP transistors used in high-power applications. These tests involve rapidly switching the transistor on and off while monitoring its electrical and thermal characteristics. The goal is to evaluate the device's ability to handle thermal expansion and contraction stresses caused by power fluctuations, which can lead to fatigue and eventual failure.

To assess the transistor's resistance to electrostatic discharge (ESD), human body model (HBM) and charged device model (CDM) tests are conducted. These tests simulate different ESD events that may occur during handling or operation, ensuring that the transistor can withstand sudden voltage spikes without compromising its thermal stability or overall performance.

Accelerated life testing (ALT) methods are also employed to predict the long-term reliability of PNP transistors. These tests involve exposing the devices to stress conditions that exceed normal operating parameters, such as elevated temperatures or voltages, to induce failures more quickly. The results are then extrapolated to estimate the transistor's expected lifetime under normal operating conditions.

By employing these comprehensive reliability testing methods, manufacturers and engineers can identify potential weaknesses in PNP transistor designs, optimize their thermal stability, and ensure their long-term performance in various applications. The data gathered from these tests not only helps in improving current designs but also informs the development of more robust and thermally stable PNP transistors for future applications.

One of the primary reliability testing methods for PNP transistors is thermal cycling. This process involves subjecting the transistor to alternating high and low temperatures, typically ranging from -55°C to 150°C, for a specified number of cycles. The test assesses the transistor's ability to withstand thermal stress and maintain its electrical characteristics over time. During thermal cycling, parameters such as collector-emitter voltage, base-emitter voltage, and collector current are monitored to detect any significant deviations.

Another essential method is the high-temperature operating life (HTOL) test. In this test, PNP transistors are operated at their maximum rated temperature for an extended period, often lasting several thousand hours. The HTOL test evaluates the long-term stability of the transistor's electrical parameters and helps identify potential degradation mechanisms that may occur during prolonged exposure to high temperatures.

Temperature humidity bias (THB) testing is employed to assess the transistor's resistance to moisture-induced degradation. This method involves exposing the device to high temperature and humidity conditions while applying electrical bias. The test typically runs for 1000 hours at 85°C and 85% relative humidity, simulating harsh environmental conditions that may accelerate corrosion or other moisture-related failure mechanisms.

Power cycling tests are particularly relevant for PNP transistors used in high-power applications. These tests involve rapidly switching the transistor on and off while monitoring its electrical and thermal characteristics. The goal is to evaluate the device's ability to handle thermal expansion and contraction stresses caused by power fluctuations, which can lead to fatigue and eventual failure.

To assess the transistor's resistance to electrostatic discharge (ESD), human body model (HBM) and charged device model (CDM) tests are conducted. These tests simulate different ESD events that may occur during handling or operation, ensuring that the transistor can withstand sudden voltage spikes without compromising its thermal stability or overall performance.

Accelerated life testing (ALT) methods are also employed to predict the long-term reliability of PNP transistors. These tests involve exposing the devices to stress conditions that exceed normal operating parameters, such as elevated temperatures or voltages, to induce failures more quickly. The results are then extrapolated to estimate the transistor's expected lifetime under normal operating conditions.

By employing these comprehensive reliability testing methods, manufacturers and engineers can identify potential weaknesses in PNP transistor designs, optimize their thermal stability, and ensure their long-term performance in various applications. The data gathered from these tests not only helps in improving current designs but also informs the development of more robust and thermally stable PNP transistors for future applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!