How to Incorporate PNP Transistors in Sensor Technology?

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PNP Transistors in Sensors: Background and Objectives

PNP transistors have played a crucial role in the evolution of sensor technology since their inception in the mid-20th century. These semiconductor devices, characterized by their ability to amplify and switch electronic signals, have become integral components in various sensing applications. The journey of incorporating PNP transistors into sensor technology began with the recognition of their potential to enhance signal processing and improve overall sensor performance.

The primary objective of integrating PNP transistors into sensor technology is to leverage their unique properties for more efficient and accurate sensing mechanisms. By utilizing PNP transistors, sensor designers aim to achieve higher sensitivity, improved signal-to-noise ratios, and enhanced power efficiency. These goals align with the broader trend in sensor technology towards miniaturization, increased functionality, and reduced power consumption.

As sensor technology has advanced, the role of PNP transistors has evolved from simple amplification to more complex functions. Modern sensor systems often employ PNP transistors in conjunction with other semiconductor devices to create sophisticated sensing circuits. These circuits can perform tasks such as temperature compensation, signal conditioning, and even basic data processing directly at the sensor level.

The incorporation of PNP transistors in sensor technology has been driven by several key technological trends. The continuous miniaturization of electronic components has allowed for the integration of multiple PNP transistors within compact sensor packages. Additionally, advancements in semiconductor manufacturing processes have led to the development of PNP transistors with improved performance characteristics, such as lower noise levels and higher operating frequencies.

Looking ahead, the future of PNP transistors in sensor technology is closely tied to emerging fields such as the Internet of Things (IoT) and wearable devices. These applications demand sensors that are not only highly sensitive and accurate but also energy-efficient and capable of operating in diverse environmental conditions. PNP transistors are expected to play a vital role in meeting these requirements, particularly in the development of smart sensors that can adapt to changing conditions and communicate with other devices seamlessly.

The ongoing research in materials science and nanotechnology is also expected to influence the incorporation of PNP transistors in sensor technology. Novel materials and fabrication techniques may lead to the creation of PNP transistors with enhanced properties, potentially revolutionizing their application in sensing devices. As such, the exploration of how to effectively incorporate PNP transistors in sensor technology remains a dynamic and promising area of study, with significant implications for the future of sensing applications across various industries.

The primary objective of integrating PNP transistors into sensor technology is to leverage their unique properties for more efficient and accurate sensing mechanisms. By utilizing PNP transistors, sensor designers aim to achieve higher sensitivity, improved signal-to-noise ratios, and enhanced power efficiency. These goals align with the broader trend in sensor technology towards miniaturization, increased functionality, and reduced power consumption.

As sensor technology has advanced, the role of PNP transistors has evolved from simple amplification to more complex functions. Modern sensor systems often employ PNP transistors in conjunction with other semiconductor devices to create sophisticated sensing circuits. These circuits can perform tasks such as temperature compensation, signal conditioning, and even basic data processing directly at the sensor level.

The incorporation of PNP transistors in sensor technology has been driven by several key technological trends. The continuous miniaturization of electronic components has allowed for the integration of multiple PNP transistors within compact sensor packages. Additionally, advancements in semiconductor manufacturing processes have led to the development of PNP transistors with improved performance characteristics, such as lower noise levels and higher operating frequencies.

Looking ahead, the future of PNP transistors in sensor technology is closely tied to emerging fields such as the Internet of Things (IoT) and wearable devices. These applications demand sensors that are not only highly sensitive and accurate but also energy-efficient and capable of operating in diverse environmental conditions. PNP transistors are expected to play a vital role in meeting these requirements, particularly in the development of smart sensors that can adapt to changing conditions and communicate with other devices seamlessly.

The ongoing research in materials science and nanotechnology is also expected to influence the incorporation of PNP transistors in sensor technology. Novel materials and fabrication techniques may lead to the creation of PNP transistors with enhanced properties, potentially revolutionizing their application in sensing devices. As such, the exploration of how to effectively incorporate PNP transistors in sensor technology remains a dynamic and promising area of study, with significant implications for the future of sensing applications across various industries.

Market Demand Analysis for PNP-based Sensors

The market demand for PNP-based sensors has been steadily growing, driven by the increasing need for high-performance sensing solutions across various industries. PNP transistors, known for their ability to amplify small electrical signals and their low noise characteristics, have found significant applications in sensor technology, particularly in areas requiring precise measurements and high sensitivity.

In the automotive sector, PNP-based sensors are gaining traction for applications such as engine management systems, tire pressure monitoring, and advanced driver assistance systems (ADAS). The automotive industry's shift towards electric and autonomous vehicles has further accelerated the demand for these sensors, as they play a crucial role in ensuring vehicle safety and efficiency.

The consumer electronics market has also shown a strong appetite for PNP-based sensors. With the proliferation of smartphones, wearables, and smart home devices, there is a growing need for compact, energy-efficient sensors capable of detecting various environmental parameters. PNP transistors, with their low power consumption and high sensitivity, are well-suited for these applications, driving market growth in this sector.

In the industrial sector, PNP-based sensors are increasingly being adopted for process control, automation, and condition monitoring. The push towards Industry 4.0 and the Industrial Internet of Things (IIoT) has created a demand for sensors that can provide accurate, real-time data in harsh industrial environments. PNP transistors' robustness and reliability make them ideal for such applications.

The healthcare and medical devices market represents another significant growth area for PNP-based sensors. These sensors are being utilized in various medical equipment, including patient monitoring systems, diagnostic devices, and wearable health trackers. The aging population and the trend towards personalized healthcare are expected to further boost demand in this sector.

Environmental monitoring and smart city initiatives have also contributed to the increasing market demand for PNP-based sensors. These sensors are being deployed in air quality monitoring systems, weather stations, and smart infrastructure projects, helping to collect valuable data for urban planning and environmental protection efforts.

As the Internet of Things (IoT) continues to expand, the demand for PNP-based sensors is expected to grow even further. The ability of these sensors to provide accurate, low-power sensing capabilities makes them ideal for the vast network of interconnected devices that form the backbone of IoT ecosystems.

In the automotive sector, PNP-based sensors are gaining traction for applications such as engine management systems, tire pressure monitoring, and advanced driver assistance systems (ADAS). The automotive industry's shift towards electric and autonomous vehicles has further accelerated the demand for these sensors, as they play a crucial role in ensuring vehicle safety and efficiency.

The consumer electronics market has also shown a strong appetite for PNP-based sensors. With the proliferation of smartphones, wearables, and smart home devices, there is a growing need for compact, energy-efficient sensors capable of detecting various environmental parameters. PNP transistors, with their low power consumption and high sensitivity, are well-suited for these applications, driving market growth in this sector.

In the industrial sector, PNP-based sensors are increasingly being adopted for process control, automation, and condition monitoring. The push towards Industry 4.0 and the Industrial Internet of Things (IIoT) has created a demand for sensors that can provide accurate, real-time data in harsh industrial environments. PNP transistors' robustness and reliability make them ideal for such applications.

The healthcare and medical devices market represents another significant growth area for PNP-based sensors. These sensors are being utilized in various medical equipment, including patient monitoring systems, diagnostic devices, and wearable health trackers. The aging population and the trend towards personalized healthcare are expected to further boost demand in this sector.

Environmental monitoring and smart city initiatives have also contributed to the increasing market demand for PNP-based sensors. These sensors are being deployed in air quality monitoring systems, weather stations, and smart infrastructure projects, helping to collect valuable data for urban planning and environmental protection efforts.

As the Internet of Things (IoT) continues to expand, the demand for PNP-based sensors is expected to grow even further. The ability of these sensors to provide accurate, low-power sensing capabilities makes them ideal for the vast network of interconnected devices that form the backbone of IoT ecosystems.

Current State and Challenges of PNP Integration

The integration of PNP transistors in sensor technology has made significant strides in recent years, yet it still faces several challenges. Currently, PNP transistors are widely used in various sensor applications, particularly in temperature sensors, light sensors, and pressure sensors. Their ability to amplify small signals and operate at low voltages makes them ideal for these applications.

One of the primary challenges in PNP integration is the issue of power consumption. While PNP transistors generally consume less power than their NPN counterparts, further optimization is needed to meet the increasing demands for energy-efficient sensors in IoT and wearable devices. Researchers are exploring novel materials and fabrication techniques to reduce the power consumption of PNP-based sensors without compromising their performance.

Another significant challenge lies in the miniaturization of PNP transistors for sensor applications. As sensors become smaller and more compact, integrating PNP transistors while maintaining their performance characteristics becomes increasingly difficult. This challenge is particularly evident in the development of MEMS (Micro-Electro-Mechanical Systems) sensors, where space constraints are a critical factor.

The temperature sensitivity of PNP transistors also presents a challenge in sensor technology. While this property is advantageous for temperature sensing applications, it can lead to accuracy issues in other types of sensors. Developing compensation techniques and temperature-stable designs is an ongoing area of research to improve the reliability of PNP-based sensors across various environmental conditions.

Integration of PNP transistors with other sensor components and circuitry is another area that requires attention. Achieving seamless integration while minimizing interference and noise is crucial for optimal sensor performance. This challenge becomes more pronounced as sensors incorporate multiple functionalities and require more complex circuitry.

The manufacturing process of PNP transistors for sensor applications also faces challenges. Ensuring consistency and reliability in large-scale production, especially for high-precision sensors, remains a concern. Advancements in semiconductor fabrication techniques are being pursued to address these manufacturing challenges and improve yield rates.

Lastly, the cost of integrating PNP transistors in sensor technology is a significant consideration. While PNP transistors offer several advantages, their integration must be cost-effective to be viable for mass-market sensor applications. Balancing performance improvements with cost considerations is an ongoing challenge for manufacturers and researchers in this field.

One of the primary challenges in PNP integration is the issue of power consumption. While PNP transistors generally consume less power than their NPN counterparts, further optimization is needed to meet the increasing demands for energy-efficient sensors in IoT and wearable devices. Researchers are exploring novel materials and fabrication techniques to reduce the power consumption of PNP-based sensors without compromising their performance.

Another significant challenge lies in the miniaturization of PNP transistors for sensor applications. As sensors become smaller and more compact, integrating PNP transistors while maintaining their performance characteristics becomes increasingly difficult. This challenge is particularly evident in the development of MEMS (Micro-Electro-Mechanical Systems) sensors, where space constraints are a critical factor.

The temperature sensitivity of PNP transistors also presents a challenge in sensor technology. While this property is advantageous for temperature sensing applications, it can lead to accuracy issues in other types of sensors. Developing compensation techniques and temperature-stable designs is an ongoing area of research to improve the reliability of PNP-based sensors across various environmental conditions.

Integration of PNP transistors with other sensor components and circuitry is another area that requires attention. Achieving seamless integration while minimizing interference and noise is crucial for optimal sensor performance. This challenge becomes more pronounced as sensors incorporate multiple functionalities and require more complex circuitry.

The manufacturing process of PNP transistors for sensor applications also faces challenges. Ensuring consistency and reliability in large-scale production, especially for high-precision sensors, remains a concern. Advancements in semiconductor fabrication techniques are being pursued to address these manufacturing challenges and improve yield rates.

Lastly, the cost of integrating PNP transistors in sensor technology is a significant consideration. While PNP transistors offer several advantages, their integration must be cost-effective to be viable for mass-market sensor applications. Balancing performance improvements with cost considerations is an ongoing challenge for manufacturers and researchers in this field.

Existing PNP Transistor Integration Solutions

01 Structure and fabrication of PNP transistors

PNP transistors are semiconductor devices with specific structures and fabrication methods. They typically consist of a p-type emitter, n-type base, and p-type collector. The fabrication process involves various steps such as doping, etching, and layering to create the desired structure and electrical characteristics.- PNP transistor structure and fabrication: This category covers the basic structure and fabrication methods of PNP transistors. It includes the design of emitter, base, and collector regions, as well as the processes used to create these structures on semiconductor substrates. Various techniques for doping, etching, and layering are discussed to achieve optimal PNP transistor performance.

- PNP transistor applications in integrated circuits: PNP transistors are crucial components in many integrated circuit designs. This category explores their use in various applications such as amplifiers, switches, and logic gates. It also covers the integration of PNP transistors with other semiconductor devices to create complex circuit functions and improve overall performance of integrated circuits.

- PNP transistor performance optimization: This category focuses on techniques to enhance the performance of PNP transistors. It includes methods to improve current gain, reduce noise, increase switching speed, and enhance thermal stability. Various design modifications and fabrication techniques are explored to achieve these performance improvements.

- PNP transistors in power applications: PNP transistors play a significant role in power electronics. This category covers the design and implementation of PNP transistors for high-power applications, including power amplifiers, voltage regulators, and switching circuits. It also discusses techniques to improve power handling capacity and efficiency of PNP transistors in these applications.

- PNP transistors in analog and mixed-signal circuits: This category explores the use of PNP transistors in analog and mixed-signal circuit designs. It covers applications such as current mirrors, differential amplifiers, and voltage references. The category also discusses techniques for matching PNP transistors with NPN transistors to create complementary circuits and improve overall circuit performance in analog and mixed-signal applications.

02 Applications of PNP transistors in electronic circuits

PNP transistors are widely used in various electronic circuits for amplification, switching, and signal processing. They are often employed in complementary circuits with NPN transistors, power supplies, and analog circuits. Their unique characteristics make them suitable for specific applications in electronic devices and systems.Expand Specific Solutions03 Performance optimization and characteristics of PNP transistors

Improving the performance of PNP transistors involves optimizing various parameters such as current gain, frequency response, and noise characteristics. This can be achieved through careful design of the device structure, doping profiles, and manufacturing processes. Understanding and controlling these characteristics is crucial for enhancing the overall performance of circuits using PNP transistors.Expand Specific Solutions04 Integration of PNP transistors in semiconductor devices

PNP transistors are often integrated with other semiconductor components to create complex integrated circuits and devices. This integration involves considerations such as layout design, thermal management, and compatibility with other components. The process of integrating PNP transistors can impact the overall performance and functionality of the semiconductor device.Expand Specific Solutions05 Testing and characterization of PNP transistors

Accurate testing and characterization of PNP transistors are essential for ensuring their proper functionality and performance in electronic circuits. This involves measuring various parameters such as current gain, breakdown voltage, and leakage current. Specialized testing equipment and methodologies are often employed to accurately assess the characteristics of PNP transistors.Expand Specific Solutions

Key Players in PNP Transistor Sensor Development

The incorporation of PNP transistors in sensor technology is currently in a mature stage of development, with a growing market driven by increasing demand for advanced sensing applications. The global market for PNP transistors in sensors is expected to expand significantly in the coming years, fueled by innovations in IoT, automotive, and consumer electronics sectors. Major players like IBM, Infineon Technologies, and Texas Instruments are at the forefront of this technology, leveraging their extensive R&D capabilities to develop high-performance, energy-efficient sensor solutions. These companies, along with others such as STMicroelectronics and Analog Devices, are continuously pushing the boundaries of PNP transistor integration in sensors, focusing on miniaturization, improved sensitivity, and enhanced power management.

International Business Machines Corp.

Technical Solution: IBM has developed advanced PNP transistor technology for sensor applications, focusing on improving sensitivity and reducing power consumption. Their approach involves using silicon-germanium (SiGe) heterojunction bipolar transistors (HBTs) in sensor designs[1]. This technology allows for the creation of high-performance analog and mixed-signal circuits, which are crucial for sensor interfaces. IBM's PNP transistors in sensors feature reduced base width and optimized doping profiles, resulting in higher current gain and improved frequency response[2]. The company has also implemented vertical PNP structures in their sensor designs, which offer better isolation and reduced parasitic capacitance compared to lateral PNP transistors[3].

Strengths: Superior performance in analog and mixed-signal applications, reduced power consumption, and improved sensitivity. Weaknesses: Potentially higher manufacturing costs and complexity compared to standard CMOS processes.

Infineon Technologies AG

Technical Solution: Infineon has integrated PNP transistors into their sensor technology, particularly in the development of smart power devices and automotive sensors. Their approach combines PNP transistors with CMOS technology in a single chip, known as BCD (Bipolar-CMOS-DMOS) integration[4]. This allows for high-voltage capabilities, precise analog functions, and digital control on the same die. Infineon's PNP transistors in sensors are optimized for low noise and high linearity, making them suitable for precision measurement applications. The company has also developed vertical PNP structures with reduced collector resistance, improving the overall performance of their sensor systems[5].

Strengths: Excellent integration capabilities, high-voltage handling, and suitability for automotive applications. Weaknesses: Potentially higher production costs due to the complex integration process.

Core Innovations in PNP-based Sensor Design

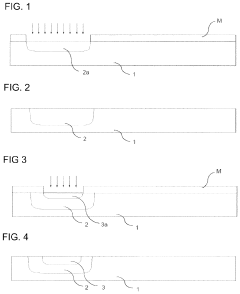

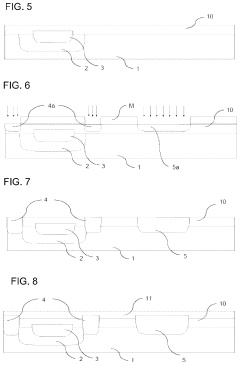

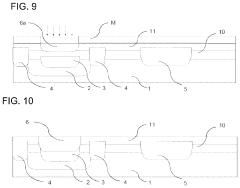

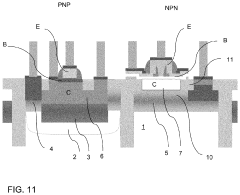

Device comprising a PNP bipolar transistor and NPN bipolar transistor for radiofrequency applications

PatentActiveUS11955481B2

Innovation

- A method involving the formation of two epitaxial semiconductor layers allows burying the P+ well deeper in the substrate without high-energy implantation, optimizing the performance of both PNP and NPN transistors by controlling the thickness and doping of these layers to prevent crystalline defects and enhance transistor speed.

Device for detecting a magnetic field, magnetic field measurer and current meter

PatentInactiveEP1256010A1

Innovation

- The use of complementary lateral magnetotransistors, specifically npn and pnp types, integrated on a semiconductor chip with a measuring bridge configuration that allows direct signal tapping without additional shunt resistors or external wiring, enhancing sensitivity and signal-to-noise ratio while enabling automatic offset and temperature compensation.

Environmental Impact of PNP Transistor Sensors

The incorporation of PNP transistors in sensor technology has significant environmental implications that warrant careful consideration. These devices, while essential for advancing sensor capabilities, also contribute to the broader environmental footprint of electronic systems. The production process of PNP transistors involves the use of various materials, including silicon, metals, and potentially harmful chemicals, which can have adverse effects on ecosystems if not properly managed.

One of the primary environmental concerns is the energy consumption associated with the manufacturing and operation of PNP transistor-based sensors. The fabrication of these components requires substantial energy inputs, contributing to greenhouse gas emissions and climate change. However, it is important to note that the integration of PNP transistors in sensors often leads to improved energy efficiency in the final products, potentially offsetting some of the initial environmental costs over the device's lifetime.

The use of rare earth elements and precious metals in PNP transistor production also raises sustainability issues. The extraction and processing of these materials can lead to habitat destruction, water pollution, and soil degradation in mining regions. As demand for sensors incorporating PNP transistors grows, responsible sourcing and recycling initiatives become increasingly crucial to mitigate these impacts.

Electronic waste (e-waste) is another significant environmental challenge associated with PNP transistor sensors. As these devices reach the end of their useful life, proper disposal and recycling are essential to prevent the release of toxic substances into the environment. Many countries have implemented e-waste regulations, but the global nature of the electronics industry necessitates a coordinated international approach to address this issue effectively.

On the positive side, PNP transistor sensors often enable more precise environmental monitoring and control systems. This can lead to improved resource management, reduced energy consumption, and enhanced pollution detection capabilities. For instance, in industrial settings, these sensors can optimize processes, resulting in lower emissions and waste generation.

The miniaturization trend in sensor technology, facilitated by advanced PNP transistor designs, also has environmental benefits. Smaller sensors require less material and energy to produce and operate, potentially reducing their overall environmental impact. Additionally, the increased durability and reliability of modern PNP transistor sensors can extend product lifespans, reducing the frequency of replacement and associated waste generation.

As the industry moves forward, there is a growing emphasis on developing more environmentally friendly manufacturing processes for PNP transistors and associated sensor technologies. This includes research into bio-based materials, green chemistry approaches, and design for recyclability. These efforts aim to create a more sustainable lifecycle for PNP transistor sensors, from production to disposal.

One of the primary environmental concerns is the energy consumption associated with the manufacturing and operation of PNP transistor-based sensors. The fabrication of these components requires substantial energy inputs, contributing to greenhouse gas emissions and climate change. However, it is important to note that the integration of PNP transistors in sensors often leads to improved energy efficiency in the final products, potentially offsetting some of the initial environmental costs over the device's lifetime.

The use of rare earth elements and precious metals in PNP transistor production also raises sustainability issues. The extraction and processing of these materials can lead to habitat destruction, water pollution, and soil degradation in mining regions. As demand for sensors incorporating PNP transistors grows, responsible sourcing and recycling initiatives become increasingly crucial to mitigate these impacts.

Electronic waste (e-waste) is another significant environmental challenge associated with PNP transistor sensors. As these devices reach the end of their useful life, proper disposal and recycling are essential to prevent the release of toxic substances into the environment. Many countries have implemented e-waste regulations, but the global nature of the electronics industry necessitates a coordinated international approach to address this issue effectively.

On the positive side, PNP transistor sensors often enable more precise environmental monitoring and control systems. This can lead to improved resource management, reduced energy consumption, and enhanced pollution detection capabilities. For instance, in industrial settings, these sensors can optimize processes, resulting in lower emissions and waste generation.

The miniaturization trend in sensor technology, facilitated by advanced PNP transistor designs, also has environmental benefits. Smaller sensors require less material and energy to produce and operate, potentially reducing their overall environmental impact. Additionally, the increased durability and reliability of modern PNP transistor sensors can extend product lifespans, reducing the frequency of replacement and associated waste generation.

As the industry moves forward, there is a growing emphasis on developing more environmentally friendly manufacturing processes for PNP transistors and associated sensor technologies. This includes research into bio-based materials, green chemistry approaches, and design for recyclability. These efforts aim to create a more sustainable lifecycle for PNP transistor sensors, from production to disposal.

Standardization and Compatibility Issues

The incorporation of PNP transistors in sensor technology has led to significant advancements in device performance and functionality. However, this integration also brings forth challenges related to standardization and compatibility issues that need to be addressed for widespread adoption and seamless integration across various systems.

One of the primary concerns is the lack of uniform standards for PNP transistor-based sensors. Different manufacturers often employ proprietary designs and specifications, making it difficult for end-users to interchange components or integrate sensors from multiple vendors. This fragmentation in the market hinders interoperability and limits the potential for creating comprehensive sensor networks.

To address this issue, industry stakeholders are working towards establishing common standards for PNP transistor-based sensors. These efforts aim to define uniform specifications for key parameters such as sensitivity, response time, and power consumption. Standardization would not only facilitate easier integration but also promote healthy competition and innovation within the industry.

Compatibility issues also arise when incorporating PNP transistors into existing sensor systems. Many legacy systems are designed to work with specific types of sensors, and integrating PNP transistor-based sensors may require significant modifications to hardware and software interfaces. This can be particularly challenging in industries with long-standing infrastructure, such as industrial automation or automotive applications.

To mitigate these compatibility challenges, sensor manufacturers are developing adaptive interfaces and modular designs. These solutions allow PNP transistor-based sensors to be more easily integrated into a wide range of systems without requiring extensive modifications. Additionally, the development of middleware and software libraries that can translate between different sensor protocols is helping to bridge the gap between legacy systems and new PNP transistor-based sensors.

Another aspect of compatibility concerns the integration of PNP transistor-based sensors with emerging technologies such as Internet of Things (IoT) platforms and artificial intelligence systems. Ensuring that these sensors can seamlessly communicate and share data with cloud-based analytics tools and machine learning algorithms is crucial for realizing their full potential in next-generation applications.

As the adoption of PNP transistor-based sensors continues to grow, addressing these standardization and compatibility issues becomes increasingly important. Industry collaborations, open-source initiatives, and regulatory guidance are all playing crucial roles in developing solutions that promote interoperability and ease of integration. By overcoming these challenges, the sensor technology industry can unlock the full potential of PNP transistors, leading to more efficient, versatile, and interconnected sensing solutions across various domains.

One of the primary concerns is the lack of uniform standards for PNP transistor-based sensors. Different manufacturers often employ proprietary designs and specifications, making it difficult for end-users to interchange components or integrate sensors from multiple vendors. This fragmentation in the market hinders interoperability and limits the potential for creating comprehensive sensor networks.

To address this issue, industry stakeholders are working towards establishing common standards for PNP transistor-based sensors. These efforts aim to define uniform specifications for key parameters such as sensitivity, response time, and power consumption. Standardization would not only facilitate easier integration but also promote healthy competition and innovation within the industry.

Compatibility issues also arise when incorporating PNP transistors into existing sensor systems. Many legacy systems are designed to work with specific types of sensors, and integrating PNP transistor-based sensors may require significant modifications to hardware and software interfaces. This can be particularly challenging in industries with long-standing infrastructure, such as industrial automation or automotive applications.

To mitigate these compatibility challenges, sensor manufacturers are developing adaptive interfaces and modular designs. These solutions allow PNP transistor-based sensors to be more easily integrated into a wide range of systems without requiring extensive modifications. Additionally, the development of middleware and software libraries that can translate between different sensor protocols is helping to bridge the gap between legacy systems and new PNP transistor-based sensors.

Another aspect of compatibility concerns the integration of PNP transistor-based sensors with emerging technologies such as Internet of Things (IoT) platforms and artificial intelligence systems. Ensuring that these sensors can seamlessly communicate and share data with cloud-based analytics tools and machine learning algorithms is crucial for realizing their full potential in next-generation applications.

As the adoption of PNP transistor-based sensors continues to grow, addressing these standardization and compatibility issues becomes increasingly important. Industry collaborations, open-source initiatives, and regulatory guidance are all playing crucial roles in developing solutions that promote interoperability and ease of integration. By overcoming these challenges, the sensor technology industry can unlock the full potential of PNP transistors, leading to more efficient, versatile, and interconnected sensing solutions across various domains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!