PNP Transistor Reliability: Long-Term Usage Insights

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PNP Transistor Evolution

The evolution of PNP transistors has been a significant journey in the field of electronics, marked by continuous improvements in reliability and performance. Initially developed in the early 1950s, PNP transistors have undergone several transformations to address the challenges of long-term usage and reliability.

In the early stages, germanium was the primary material used for PNP transistors. These devices were prone to thermal runaway and had limited temperature ranges, which significantly impacted their long-term reliability. The 1960s saw a shift towards silicon-based PNP transistors, which offered better thermal stability and higher operating temperatures.

The 1970s and 1980s brought about advancements in manufacturing processes, leading to the development of epitaxial PNP transistors. These devices featured improved current gain and frequency response, enhancing their reliability in various applications. The introduction of ion implantation techniques further refined the control over doping profiles, resulting in more consistent and reliable PNP transistors.

The 1990s witnessed the emergence of complementary bipolar processes, allowing the integration of high-performance PNP transistors alongside NPN devices on the same chip. This development significantly improved the overall reliability of integrated circuits incorporating PNP transistors.

In the 2000s, the focus shifted towards reducing parasitic effects and improving high-frequency performance. Advanced isolation techniques, such as deep trench isolation, were implemented to minimize substrate coupling and enhance the long-term stability of PNP transistors in mixed-signal applications.

Recent years have seen a renewed interest in PNP transistors for power applications, particularly in automotive and industrial sectors. The development of high-voltage PNP transistors with improved safe operating areas has addressed reliability concerns in these demanding environments.

Ongoing research in materials science has led to the exploration of wide-bandgap semiconductors, such as silicon carbide and gallium nitride, for PNP transistor fabrication. These materials offer the potential for higher temperature operation and improved reliability under extreme conditions.

The evolution of PNP transistors has also been influenced by advancements in packaging technologies. Improved heat dissipation and protection against environmental factors have contributed to enhanced long-term reliability, especially in harsh operating conditions.

As we look towards the future, the evolution of PNP transistors continues to focus on addressing the challenges of miniaturization, power efficiency, and reliability in emerging applications such as Internet of Things (IoT) devices and wearable technology. The ongoing development of novel materials and fabrication techniques promises to further improve the long-term reliability and performance of PNP transistors in the years to come.

In the early stages, germanium was the primary material used for PNP transistors. These devices were prone to thermal runaway and had limited temperature ranges, which significantly impacted their long-term reliability. The 1960s saw a shift towards silicon-based PNP transistors, which offered better thermal stability and higher operating temperatures.

The 1970s and 1980s brought about advancements in manufacturing processes, leading to the development of epitaxial PNP transistors. These devices featured improved current gain and frequency response, enhancing their reliability in various applications. The introduction of ion implantation techniques further refined the control over doping profiles, resulting in more consistent and reliable PNP transistors.

The 1990s witnessed the emergence of complementary bipolar processes, allowing the integration of high-performance PNP transistors alongside NPN devices on the same chip. This development significantly improved the overall reliability of integrated circuits incorporating PNP transistors.

In the 2000s, the focus shifted towards reducing parasitic effects and improving high-frequency performance. Advanced isolation techniques, such as deep trench isolation, were implemented to minimize substrate coupling and enhance the long-term stability of PNP transistors in mixed-signal applications.

Recent years have seen a renewed interest in PNP transistors for power applications, particularly in automotive and industrial sectors. The development of high-voltage PNP transistors with improved safe operating areas has addressed reliability concerns in these demanding environments.

Ongoing research in materials science has led to the exploration of wide-bandgap semiconductors, such as silicon carbide and gallium nitride, for PNP transistor fabrication. These materials offer the potential for higher temperature operation and improved reliability under extreme conditions.

The evolution of PNP transistors has also been influenced by advancements in packaging technologies. Improved heat dissipation and protection against environmental factors have contributed to enhanced long-term reliability, especially in harsh operating conditions.

As we look towards the future, the evolution of PNP transistors continues to focus on addressing the challenges of miniaturization, power efficiency, and reliability in emerging applications such as Internet of Things (IoT) devices and wearable technology. The ongoing development of novel materials and fabrication techniques promises to further improve the long-term reliability and performance of PNP transistors in the years to come.

Market Demand Analysis

The market demand for reliable PNP transistors in long-term usage scenarios continues to grow across various industries. As electronic devices become more prevalent and integrated into critical systems, the need for components that can maintain consistent performance over extended periods has become paramount.

In the automotive sector, the push towards electric and hybrid vehicles has significantly increased the demand for high-reliability PNP transistors. These components play crucial roles in power management systems, motor controls, and battery management units. The automotive industry's stringent requirements for longevity and reliability under harsh conditions have driven manufacturers to seek transistors with enhanced long-term stability.

The industrial automation market also presents a substantial demand for reliable PNP transistors. As factories and manufacturing plants increasingly adopt smart technologies and IoT solutions, the need for durable electronic components has surged. PNP transistors are essential in control systems, sensors, and actuators that must operate continuously for years without failure.

In the aerospace and defense sectors, where component reliability is critical, the demand for high-performance PNP transistors remains strong. These industries require transistors that can withstand extreme temperatures, radiation, and mechanical stress while maintaining consistent performance over decades of operation.

The medical device industry represents another significant market for reliable PNP transistors. With the increasing sophistication of implantable devices and diagnostic equipment, the need for components that can function reliably within the human body for extended periods has grown. This demand has spurred research into biocompatible materials and advanced packaging techniques for PNP transistors.

Consumer electronics, while often associated with shorter product lifecycles, also contribute to the demand for reliable PNP transistors. As consumers expect longer-lasting devices and manufacturers aim to reduce electronic waste, there is a growing emphasis on using components that can withstand years of daily use.

The telecommunications infrastructure sector, particularly with the ongoing rollout of 5G networks, requires PNP transistors that can operate reliably in base stations and network equipment for extended periods. The high costs associated with maintenance and replacement in remote or hard-to-reach locations drive the demand for components with exceptional long-term reliability.

Market analysts project that the global demand for high-reliability PNP transistors will continue to expand, driven by these key industries and the overall trend towards more durable and sustainable electronic products. This growth is expected to fuel further research and development efforts aimed at improving PNP transistor reliability and longevity, potentially leading to new materials, designs, and manufacturing processes in the coming years.

In the automotive sector, the push towards electric and hybrid vehicles has significantly increased the demand for high-reliability PNP transistors. These components play crucial roles in power management systems, motor controls, and battery management units. The automotive industry's stringent requirements for longevity and reliability under harsh conditions have driven manufacturers to seek transistors with enhanced long-term stability.

The industrial automation market also presents a substantial demand for reliable PNP transistors. As factories and manufacturing plants increasingly adopt smart technologies and IoT solutions, the need for durable electronic components has surged. PNP transistors are essential in control systems, sensors, and actuators that must operate continuously for years without failure.

In the aerospace and defense sectors, where component reliability is critical, the demand for high-performance PNP transistors remains strong. These industries require transistors that can withstand extreme temperatures, radiation, and mechanical stress while maintaining consistent performance over decades of operation.

The medical device industry represents another significant market for reliable PNP transistors. With the increasing sophistication of implantable devices and diagnostic equipment, the need for components that can function reliably within the human body for extended periods has grown. This demand has spurred research into biocompatible materials and advanced packaging techniques for PNP transistors.

Consumer electronics, while often associated with shorter product lifecycles, also contribute to the demand for reliable PNP transistors. As consumers expect longer-lasting devices and manufacturers aim to reduce electronic waste, there is a growing emphasis on using components that can withstand years of daily use.

The telecommunications infrastructure sector, particularly with the ongoing rollout of 5G networks, requires PNP transistors that can operate reliably in base stations and network equipment for extended periods. The high costs associated with maintenance and replacement in remote or hard-to-reach locations drive the demand for components with exceptional long-term reliability.

Market analysts project that the global demand for high-reliability PNP transistors will continue to expand, driven by these key industries and the overall trend towards more durable and sustainable electronic products. This growth is expected to fuel further research and development efforts aimed at improving PNP transistor reliability and longevity, potentially leading to new materials, designs, and manufacturing processes in the coming years.

Current Challenges

PNP transistors, despite their long-standing presence in the electronics industry, continue to face several challenges in terms of long-term reliability. One of the primary concerns is the degradation of electrical characteristics over time, particularly in high-temperature and high-voltage applications. This phenomenon, known as hot carrier injection, can lead to a gradual shift in the transistor's threshold voltage and a decrease in its current gain, ultimately affecting the overall performance of the circuit.

Another significant challenge is the susceptibility of PNP transistors to radiation-induced damage, especially in aerospace and nuclear applications. Exposure to ionizing radiation can cause displacement damage and ionization effects, leading to increased leakage currents and altered device characteristics. This vulnerability necessitates the development of radiation-hardened PNP transistors or alternative solutions for critical applications in harsh environments.

The issue of thermal management remains a persistent challenge for PNP transistors, particularly in high-power applications. As the device operates, heat generation can lead to thermal runaway, potentially causing permanent damage or failure. This problem is exacerbated in compact designs where heat dissipation is limited, requiring innovative cooling solutions and thermal management strategies to ensure long-term reliability.

Electromigration is another concern that affects the long-term reliability of PNP transistors, especially in integrated circuits with high current densities. This phenomenon can cause the gradual movement of metal atoms in the device's interconnects, potentially leading to voids or short circuits over time. As transistor sizes continue to shrink, the impact of electromigration becomes more pronounced, necessitating advanced materials and design techniques to mitigate its effects.

The increasing demand for high-frequency applications poses additional challenges for PNP transistors. Their inherently lower switching speeds compared to NPN transistors can limit their usefulness in certain high-speed circuits. This limitation has led to ongoing research into improving the frequency response of PNP transistors through novel device structures and materials.

Lastly, the manufacturing process for PNP transistors presents its own set of challenges. Achieving consistent performance across large production runs requires precise control over doping profiles, junction depths, and other critical parameters. Variations in these factors can lead to device-to-device inconsistencies, impacting the overall reliability and yield of PNP transistor-based circuits.

Another significant challenge is the susceptibility of PNP transistors to radiation-induced damage, especially in aerospace and nuclear applications. Exposure to ionizing radiation can cause displacement damage and ionization effects, leading to increased leakage currents and altered device characteristics. This vulnerability necessitates the development of radiation-hardened PNP transistors or alternative solutions for critical applications in harsh environments.

The issue of thermal management remains a persistent challenge for PNP transistors, particularly in high-power applications. As the device operates, heat generation can lead to thermal runaway, potentially causing permanent damage or failure. This problem is exacerbated in compact designs where heat dissipation is limited, requiring innovative cooling solutions and thermal management strategies to ensure long-term reliability.

Electromigration is another concern that affects the long-term reliability of PNP transistors, especially in integrated circuits with high current densities. This phenomenon can cause the gradual movement of metal atoms in the device's interconnects, potentially leading to voids or short circuits over time. As transistor sizes continue to shrink, the impact of electromigration becomes more pronounced, necessitating advanced materials and design techniques to mitigate its effects.

The increasing demand for high-frequency applications poses additional challenges for PNP transistors. Their inherently lower switching speeds compared to NPN transistors can limit their usefulness in certain high-speed circuits. This limitation has led to ongoing research into improving the frequency response of PNP transistors through novel device structures and materials.

Lastly, the manufacturing process for PNP transistors presents its own set of challenges. Achieving consistent performance across large production runs requires precise control over doping profiles, junction depths, and other critical parameters. Variations in these factors can lead to device-to-device inconsistencies, impacting the overall reliability and yield of PNP transistor-based circuits.

Existing Reliability Solutions

01 Improved PNP transistor structure

Enhancing the reliability of PNP transistors through structural improvements, such as optimizing the base-emitter junction, reducing parasitic capacitances, and implementing advanced isolation techniques. These modifications can lead to better performance, increased stability, and improved longevity of the transistor.- Improved PNP transistor structure: Enhancing PNP transistor reliability through structural improvements, such as optimizing the base-emitter junction, reducing parasitic capacitances, and implementing advanced isolation techniques. These modifications can lead to better performance and increased longevity of the transistor.

- Temperature compensation techniques: Implementing temperature compensation methods to improve PNP transistor reliability across various operating conditions. This includes designing circuits that can adjust for temperature-induced variations in transistor characteristics, ensuring consistent performance and extended lifespan.

- Enhanced fabrication processes: Developing advanced fabrication techniques to improve PNP transistor reliability. This involves optimizing doping profiles, implementing precise control of impurity concentrations, and utilizing high-quality materials to reduce defects and enhance overall transistor performance.

- Protection against electrical stress: Incorporating protection mechanisms to enhance PNP transistor reliability against electrical stress. This includes implementing voltage clamping circuits, current limiting features, and electrostatic discharge (ESD) protection structures to prevent damage from voltage spikes and overcurrent conditions.

- Reliability testing and modeling: Developing comprehensive reliability testing procedures and accurate modeling techniques for PNP transistors. This involves creating accelerated life tests, stress tests, and simulation models to predict and improve long-term reliability under various operating conditions.

02 Temperature compensation techniques

Implementing temperature compensation methods to maintain stable PNP transistor performance across varying operating conditions. This includes designing circuits with temperature-dependent components, utilizing feedback mechanisms, and incorporating thermal management strategies to mitigate the effects of temperature fluctuations on transistor reliability.Expand Specific Solutions03 Enhanced fabrication processes

Developing and refining fabrication processes to improve PNP transistor reliability. This involves optimizing doping profiles, implementing advanced lithography techniques, and utilizing high-quality materials to reduce defects and enhance overall transistor performance and longevity.Expand Specific Solutions04 Circuit design for reliability

Designing circuits that enhance the reliability of PNP transistors by implementing protective measures, such as current limiting, voltage clamping, and proper biasing techniques. These circuit-level approaches can help prevent overstress and ensure stable operation of the transistors under various conditions.Expand Specific Solutions05 Reliability testing and modeling

Developing comprehensive reliability testing methodologies and accurate modeling techniques for PNP transistors. This includes accelerated life testing, stress testing under extreme conditions, and creating detailed simulation models to predict long-term performance and identify potential failure modes.Expand Specific Solutions

Key Industry Players

The PNP transistor reliability market is in a mature stage, with established players and well-understood technology. The global market size for PNP transistors is significant, driven by their widespread use in various electronic applications. Technologically, PNP transistors are well-developed, with ongoing research focusing on long-term reliability improvements. Key players like International Business Machines Corp., Texas Instruments Incorporated, and Infineon Technologies AG are at the forefront of innovation, leveraging their extensive experience and R&D capabilities. Other notable companies such as NXP Semiconductors, STMicroelectronics, and ROHM Co., Ltd. also contribute significantly to advancements in PNP transistor technology, particularly in areas of performance optimization and reliability enhancement for extended usage scenarios.

International Business Machines Corp.

Technical Solution: IBM has developed advanced PNP transistor reliability techniques for long-term usage. Their approach involves utilizing silicon-on-insulator (SOI) technology to enhance transistor performance and reliability[1]. IBM's PNP transistors feature a unique buried oxide layer that reduces parasitic capacitance and improves isolation, leading to better long-term stability[2]. The company has also implemented advanced stress testing methodologies, including accelerated life testing and electromigration studies, to predict and improve PNP transistor reliability over extended periods[3]. Furthermore, IBM has introduced novel dopant profiling techniques to optimize carrier mobility and reduce hot carrier effects, which are critical for maintaining transistor performance over time[4].

Strengths: Advanced SOI technology, comprehensive stress testing, and optimized dopant profiling. Weaknesses: Potentially higher manufacturing costs and complexity compared to standard bipolar transistors.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has made significant strides in PNP transistor reliability for long-term usage. Their approach focuses on advanced packaging technologies and innovative circuit design techniques. TI has developed a proprietary BiCMOS process that integrates high-performance PNP transistors with CMOS logic, improving overall reliability and reducing power consumption[5]. The company's PNP transistors feature optimized emitter geometry and base width control, resulting in enhanced current gain stability over time[6]. TI has also implemented advanced thermal management techniques, including the use of copper heat spreaders and improved die attach materials, to mitigate temperature-related degradation mechanisms[7]. Additionally, TI employs sophisticated modeling and simulation tools to predict long-term transistor behavior under various operating conditions, enabling more accurate reliability projections[8].

Strengths: Integration of PNP transistors with CMOS logic, advanced thermal management, and sophisticated modeling tools. Weaknesses: Potential trade-offs between performance and long-term reliability in some applications.

Core Innovations

Supply voltage control

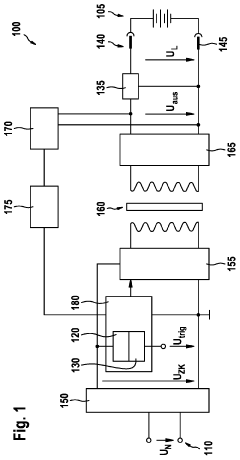

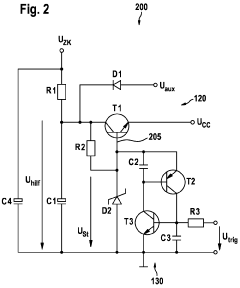

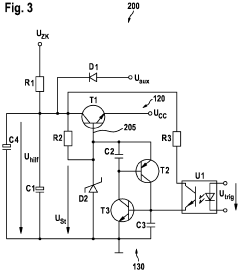

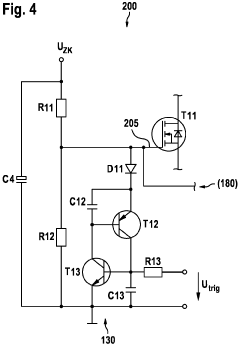

PatentWO2012123177A1

Innovation

- A non-destructive switch-off mechanism using a circuit with PNP and NPN transistors, a control voltage connection, and capacitors to safely shut down a switched-mode power supply, allowing it to remain off for a longer period, enhancing safety and operational reliability.

Failure Mode Analysis

Failure mode analysis is a critical aspect of understanding PNP transistor reliability in long-term usage scenarios. This analysis involves identifying and categorizing the various ways in which these semiconductor devices can degrade or fail over extended periods of operation.

One of the primary failure modes observed in PNP transistors is thermal runaway. This occurs when the device's temperature increases, leading to a higher collector current, which in turn causes further temperature rise. If unchecked, this positive feedback loop can result in catastrophic failure. Factors contributing to thermal runaway include inadequate heat dissipation, improper biasing, and environmental stress.

Another significant failure mode is hot carrier injection (HCI). This phenomenon involves charge carriers gaining sufficient energy to overcome potential barriers and becoming trapped in the gate oxide. Over time, HCI can lead to threshold voltage shifts, transconductance degradation, and increased leakage currents, ultimately compromising the transistor's performance and reliability.

Electromigration is a failure mechanism that becomes particularly relevant in long-term usage scenarios. It involves the gradual movement of metal ions in the transistor's interconnects due to high current densities. This can result in voids or hillocks in the metal layers, potentially causing open or short circuits and affecting the device's electrical characteristics.

Time-dependent dielectric breakdown (TDDB) is another crucial failure mode to consider. This occurs when defects accumulate in the gate oxide over time, eventually leading to a conductive path formation and gate oxide breakdown. TDDB is exacerbated by factors such as high electric fields, elevated temperatures, and the presence of contaminants.

Surface-related failures, including surface charge accumulation and interface state generation, can also impact PNP transistor reliability. These phenomena can alter the device's electrical characteristics, leading to increased leakage currents and shifts in threshold voltage.

Mechanical stress-induced failures are particularly relevant in applications involving thermal cycling or vibration. These stresses can cause issues such as die cracking, package delamination, or wire bond fatigue, all of which can compromise the transistor's long-term reliability.

Understanding these failure modes is essential for developing effective strategies to enhance PNP transistor reliability. By identifying the dominant failure mechanisms in specific applications, engineers can implement appropriate design modifications, process improvements, and operating guidelines to mitigate these risks and extend the useful life of PNP transistors in long-term usage scenarios.

One of the primary failure modes observed in PNP transistors is thermal runaway. This occurs when the device's temperature increases, leading to a higher collector current, which in turn causes further temperature rise. If unchecked, this positive feedback loop can result in catastrophic failure. Factors contributing to thermal runaway include inadequate heat dissipation, improper biasing, and environmental stress.

Another significant failure mode is hot carrier injection (HCI). This phenomenon involves charge carriers gaining sufficient energy to overcome potential barriers and becoming trapped in the gate oxide. Over time, HCI can lead to threshold voltage shifts, transconductance degradation, and increased leakage currents, ultimately compromising the transistor's performance and reliability.

Electromigration is a failure mechanism that becomes particularly relevant in long-term usage scenarios. It involves the gradual movement of metal ions in the transistor's interconnects due to high current densities. This can result in voids or hillocks in the metal layers, potentially causing open or short circuits and affecting the device's electrical characteristics.

Time-dependent dielectric breakdown (TDDB) is another crucial failure mode to consider. This occurs when defects accumulate in the gate oxide over time, eventually leading to a conductive path formation and gate oxide breakdown. TDDB is exacerbated by factors such as high electric fields, elevated temperatures, and the presence of contaminants.

Surface-related failures, including surface charge accumulation and interface state generation, can also impact PNP transistor reliability. These phenomena can alter the device's electrical characteristics, leading to increased leakage currents and shifts in threshold voltage.

Mechanical stress-induced failures are particularly relevant in applications involving thermal cycling or vibration. These stresses can cause issues such as die cracking, package delamination, or wire bond fatigue, all of which can compromise the transistor's long-term reliability.

Understanding these failure modes is essential for developing effective strategies to enhance PNP transistor reliability. By identifying the dominant failure mechanisms in specific applications, engineers can implement appropriate design modifications, process improvements, and operating guidelines to mitigate these risks and extend the useful life of PNP transistors in long-term usage scenarios.

Environmental Impact

The environmental impact of PNP transistors in long-term usage scenarios is a critical consideration for sustainable electronics design and manufacturing. These semiconductor devices, while essential for modern electronics, can have significant environmental implications throughout their lifecycle.

During the production phase, the manufacturing of PNP transistors involves energy-intensive processes and the use of various chemicals, some of which may be hazardous. The extraction and refinement of raw materials, particularly silicon and dopants, can lead to habitat disruption and contribute to greenhouse gas emissions. Additionally, the fabrication process requires ultra-pure water, potentially straining local water resources in manufacturing regions.

In the usage phase, PNP transistors generally have a low direct environmental impact due to their small size and low power consumption. However, their reliability and longevity play a crucial role in the overall environmental footprint of electronic devices. Transistors that degrade quickly or fail prematurely can lead to increased electronic waste, as entire devices may need replacement rather than repair.

The end-of-life stage presents significant environmental challenges. When electronic devices containing PNP transistors are discarded, they contribute to the growing problem of e-waste. Improper disposal can lead to the leaching of toxic substances into soil and water systems. While recycling efforts are increasing, the complex nature of modern electronics makes it difficult to fully recover and reuse all materials.

Long-term usage of PNP transistors can have both positive and negative environmental impacts. On the positive side, improved reliability and longer lifespans reduce the frequency of device replacement, thereby decreasing e-waste generation and the demand for new raw materials. Conversely, as transistors age, they may become less energy-efficient, potentially increasing the power consumption of devices over time.

Advancements in PNP transistor technology aimed at enhancing reliability can contribute to environmental sustainability. Innovations that extend transistor lifespan, improve energy efficiency, or facilitate easier recycling can significantly reduce the overall environmental impact. Furthermore, the development of bio-based or biodegradable transistor materials could revolutionize the industry's approach to sustainability.

As environmental concerns become increasingly prominent, the electronics industry is focusing more on the eco-design of components like PNP transistors. This includes efforts to reduce the use of harmful substances, improve energy efficiency, and enhance recyclability. The long-term reliability of PNP transistors is thus not only a technical challenge but also an environmental imperative, driving research towards more sustainable semiconductor technologies.

During the production phase, the manufacturing of PNP transistors involves energy-intensive processes and the use of various chemicals, some of which may be hazardous. The extraction and refinement of raw materials, particularly silicon and dopants, can lead to habitat disruption and contribute to greenhouse gas emissions. Additionally, the fabrication process requires ultra-pure water, potentially straining local water resources in manufacturing regions.

In the usage phase, PNP transistors generally have a low direct environmental impact due to their small size and low power consumption. However, their reliability and longevity play a crucial role in the overall environmental footprint of electronic devices. Transistors that degrade quickly or fail prematurely can lead to increased electronic waste, as entire devices may need replacement rather than repair.

The end-of-life stage presents significant environmental challenges. When electronic devices containing PNP transistors are discarded, they contribute to the growing problem of e-waste. Improper disposal can lead to the leaching of toxic substances into soil and water systems. While recycling efforts are increasing, the complex nature of modern electronics makes it difficult to fully recover and reuse all materials.

Long-term usage of PNP transistors can have both positive and negative environmental impacts. On the positive side, improved reliability and longer lifespans reduce the frequency of device replacement, thereby decreasing e-waste generation and the demand for new raw materials. Conversely, as transistors age, they may become less energy-efficient, potentially increasing the power consumption of devices over time.

Advancements in PNP transistor technology aimed at enhancing reliability can contribute to environmental sustainability. Innovations that extend transistor lifespan, improve energy efficiency, or facilitate easier recycling can significantly reduce the overall environmental impact. Furthermore, the development of bio-based or biodegradable transistor materials could revolutionize the industry's approach to sustainability.

As environmental concerns become increasingly prominent, the electronics industry is focusing more on the eco-design of components like PNP transistors. This includes efforts to reduce the use of harmful substances, improve energy efficiency, and enhance recyclability. The long-term reliability of PNP transistors is thus not only a technical challenge but also an environmental imperative, driving research towards more sustainable semiconductor technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!