How to Predict and Prevent PNP Transistor Failures?

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PNP Transistor Failure Mechanisms and Objectives

PNP transistors have been a cornerstone of electronic circuit design since their inception in the mid-20th century. These devices, characterized by their ability to control current flow using a small input signal, have found widespread applications in amplifiers, switches, and logic circuits. However, as with any electronic component, PNP transistors are susceptible to failures that can compromise the performance and reliability of the systems they are part of.

The primary objective of this technical research is to develop effective strategies for predicting and preventing PNP transistor failures. This goal is driven by the increasing demand for high-reliability electronics in critical applications such as aerospace, medical devices, and industrial control systems. By understanding the failure mechanisms and implementing proactive measures, we aim to enhance the longevity and dependability of PNP transistor-based circuits.

Historically, PNP transistor failures have been attributed to various factors, including thermal stress, electrical overstress, and environmental conditions. The evolution of semiconductor manufacturing processes has mitigated some of these issues, but new challenges have emerged with the miniaturization of devices and the push for higher performance. As such, a comprehensive approach to failure prediction and prevention must consider both traditional and emerging failure modes.

One of the key trends in this field is the development of advanced diagnostic techniques. These include in-situ monitoring systems that can detect early signs of degradation, as well as predictive modeling algorithms that leverage big data and machine learning to forecast potential failures before they occur. The integration of these technologies into design and manufacturing processes represents a significant step towards more reliable PNP transistor-based systems.

Another important aspect of this research is the investigation of novel materials and fabrication techniques that can enhance the inherent reliability of PNP transistors. This includes exploring alternative semiconductor compounds, optimizing doping profiles, and developing more robust packaging solutions. By addressing the fundamental physical limitations of current PNP transistor designs, we can potentially create devices with significantly improved resistance to common failure mechanisms.

The ultimate goal of this research is to establish a set of best practices and technological solutions that can be widely adopted by the electronics industry. This includes developing standardized testing protocols, creating comprehensive failure databases, and formulating design guidelines that prioritize reliability from the outset. By doing so, we aim to not only reduce the incidence of PNP transistor failures but also to improve the overall performance and efficiency of electronic systems that rely on these crucial components.

The primary objective of this technical research is to develop effective strategies for predicting and preventing PNP transistor failures. This goal is driven by the increasing demand for high-reliability electronics in critical applications such as aerospace, medical devices, and industrial control systems. By understanding the failure mechanisms and implementing proactive measures, we aim to enhance the longevity and dependability of PNP transistor-based circuits.

Historically, PNP transistor failures have been attributed to various factors, including thermal stress, electrical overstress, and environmental conditions. The evolution of semiconductor manufacturing processes has mitigated some of these issues, but new challenges have emerged with the miniaturization of devices and the push for higher performance. As such, a comprehensive approach to failure prediction and prevention must consider both traditional and emerging failure modes.

One of the key trends in this field is the development of advanced diagnostic techniques. These include in-situ monitoring systems that can detect early signs of degradation, as well as predictive modeling algorithms that leverage big data and machine learning to forecast potential failures before they occur. The integration of these technologies into design and manufacturing processes represents a significant step towards more reliable PNP transistor-based systems.

Another important aspect of this research is the investigation of novel materials and fabrication techniques that can enhance the inherent reliability of PNP transistors. This includes exploring alternative semiconductor compounds, optimizing doping profiles, and developing more robust packaging solutions. By addressing the fundamental physical limitations of current PNP transistor designs, we can potentially create devices with significantly improved resistance to common failure mechanisms.

The ultimate goal of this research is to establish a set of best practices and technological solutions that can be widely adopted by the electronics industry. This includes developing standardized testing protocols, creating comprehensive failure databases, and formulating design guidelines that prioritize reliability from the outset. By doing so, we aim to not only reduce the incidence of PNP transistor failures but also to improve the overall performance and efficiency of electronic systems that rely on these crucial components.

Market Demand for Reliable PNP Transistors

The market demand for reliable PNP transistors has been steadily increasing across various industries, driven by the growing need for high-performance electronic devices and systems. As technology continues to advance, the importance of robust and dependable PNP transistors becomes more pronounced, particularly in applications where failure can lead to significant consequences.

In the automotive sector, the demand for reliable PNP transistors is particularly strong. Modern vehicles rely heavily on electronic systems for everything from engine management to advanced driver assistance features. The harsh operating conditions in automotive applications, including extreme temperatures and vibrations, necessitate transistors that can maintain consistent performance over extended periods. This has led to a surge in demand for automotive-grade PNP transistors with enhanced reliability and longevity.

The telecommunications industry represents another major market for reliable PNP transistors. With the ongoing rollout of 5G networks and the increasing complexity of communication systems, the need for high-quality transistors that can operate efficiently at high frequencies while maintaining signal integrity has never been greater. Telecom equipment manufacturers are actively seeking PNP transistors with improved reliability to ensure uninterrupted service and reduce maintenance costs.

In the industrial automation sector, the trend towards Industry 4.0 and smart manufacturing has created a substantial demand for reliable PNP transistors. These components play a crucial role in sensor systems, motor controls, and other critical industrial applications where downtime due to component failure can result in significant production losses. As a result, manufacturers are willing to invest in higher-quality transistors to improve overall system reliability and reduce maintenance requirements.

The consumer electronics market also contributes significantly to the demand for reliable PNP transistors. With the proliferation of smartphones, tablets, and other portable devices, consumers expect longer battery life and improved performance. This has led to a focus on more efficient and reliable transistors that can operate at lower voltages while maintaining stability over the device's lifetime.

In the aerospace and defense sectors, the demand for ultra-reliable PNP transistors is particularly acute. These industries require components that can withstand extreme conditions and operate flawlessly in mission-critical applications. The high cost of failure in these sectors drives the need for transistors with exceptional reliability and predictable performance characteristics.

As the Internet of Things (IoT) continues to expand, the market for reliable PNP transistors in sensor and actuator applications is also growing. IoT devices often need to operate for extended periods on limited power sources, making the efficiency and reliability of transistors a critical factor in their design and implementation.

In the automotive sector, the demand for reliable PNP transistors is particularly strong. Modern vehicles rely heavily on electronic systems for everything from engine management to advanced driver assistance features. The harsh operating conditions in automotive applications, including extreme temperatures and vibrations, necessitate transistors that can maintain consistent performance over extended periods. This has led to a surge in demand for automotive-grade PNP transistors with enhanced reliability and longevity.

The telecommunications industry represents another major market for reliable PNP transistors. With the ongoing rollout of 5G networks and the increasing complexity of communication systems, the need for high-quality transistors that can operate efficiently at high frequencies while maintaining signal integrity has never been greater. Telecom equipment manufacturers are actively seeking PNP transistors with improved reliability to ensure uninterrupted service and reduce maintenance costs.

In the industrial automation sector, the trend towards Industry 4.0 and smart manufacturing has created a substantial demand for reliable PNP transistors. These components play a crucial role in sensor systems, motor controls, and other critical industrial applications where downtime due to component failure can result in significant production losses. As a result, manufacturers are willing to invest in higher-quality transistors to improve overall system reliability and reduce maintenance requirements.

The consumer electronics market also contributes significantly to the demand for reliable PNP transistors. With the proliferation of smartphones, tablets, and other portable devices, consumers expect longer battery life and improved performance. This has led to a focus on more efficient and reliable transistors that can operate at lower voltages while maintaining stability over the device's lifetime.

In the aerospace and defense sectors, the demand for ultra-reliable PNP transistors is particularly acute. These industries require components that can withstand extreme conditions and operate flawlessly in mission-critical applications. The high cost of failure in these sectors drives the need for transistors with exceptional reliability and predictable performance characteristics.

As the Internet of Things (IoT) continues to expand, the market for reliable PNP transistors in sensor and actuator applications is also growing. IoT devices often need to operate for extended periods on limited power sources, making the efficiency and reliability of transistors a critical factor in their design and implementation.

Current Challenges in PNP Transistor Reliability

PNP transistor reliability remains a critical concern in the semiconductor industry, presenting several challenges that demand innovative solutions. One of the primary issues is the susceptibility of PNP transistors to thermal runaway, particularly in high-power applications. This phenomenon occurs when increased temperature leads to higher current flow, which in turn generates more heat, creating a potentially destructive feedback loop.

Another significant challenge is the impact of environmental factors on PNP transistor performance. Extreme temperatures, humidity, and radiation exposure can all contribute to degradation of the device's characteristics over time. This is especially problematic in aerospace and automotive applications, where transistors must operate reliably under harsh conditions for extended periods.

The issue of current gain instability in PNP transistors also poses a considerable challenge. Fluctuations in current gain can lead to unpredictable behavior in circuits, affecting overall system performance and reliability. This instability is often exacerbated by temperature variations and aging effects, making it difficult to maintain consistent performance over the device's lifetime.

Leakage current is another area of concern in PNP transistor reliability. As devices continue to shrink in size, controlling leakage current becomes increasingly challenging. Excessive leakage can lead to increased power consumption, reduced battery life in portable devices, and potential thermal issues.

The phenomenon of hot carrier injection (HCI) presents a unique challenge for PNP transistors. HCI can cause degradation of the device's characteristics over time, leading to shifts in threshold voltage and reduced current drive capability. This effect is particularly pronounced in high-frequency applications and can significantly impact the long-term reliability of the transistor.

Electrostatic discharge (ESD) vulnerability remains a persistent challenge in PNP transistor design and manufacturing. ESD events can cause immediate failure or latent damage to the device, necessitating robust protection mechanisms and careful handling procedures throughout the production and integration processes.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, device physics, and circuit design. Improved modeling and simulation techniques are essential for predicting and mitigating failure modes, while novel fabrication processes and materials may offer enhanced resistance to degradation mechanisms. Additionally, the development of more sophisticated on-chip monitoring and compensation techniques could help maintain consistent performance over the device's lifetime, even in the face of changing environmental conditions and aging effects.

Another significant challenge is the impact of environmental factors on PNP transistor performance. Extreme temperatures, humidity, and radiation exposure can all contribute to degradation of the device's characteristics over time. This is especially problematic in aerospace and automotive applications, where transistors must operate reliably under harsh conditions for extended periods.

The issue of current gain instability in PNP transistors also poses a considerable challenge. Fluctuations in current gain can lead to unpredictable behavior in circuits, affecting overall system performance and reliability. This instability is often exacerbated by temperature variations and aging effects, making it difficult to maintain consistent performance over the device's lifetime.

Leakage current is another area of concern in PNP transistor reliability. As devices continue to shrink in size, controlling leakage current becomes increasingly challenging. Excessive leakage can lead to increased power consumption, reduced battery life in portable devices, and potential thermal issues.

The phenomenon of hot carrier injection (HCI) presents a unique challenge for PNP transistors. HCI can cause degradation of the device's characteristics over time, leading to shifts in threshold voltage and reduced current drive capability. This effect is particularly pronounced in high-frequency applications and can significantly impact the long-term reliability of the transistor.

Electrostatic discharge (ESD) vulnerability remains a persistent challenge in PNP transistor design and manufacturing. ESD events can cause immediate failure or latent damage to the device, necessitating robust protection mechanisms and careful handling procedures throughout the production and integration processes.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, device physics, and circuit design. Improved modeling and simulation techniques are essential for predicting and mitigating failure modes, while novel fabrication processes and materials may offer enhanced resistance to degradation mechanisms. Additionally, the development of more sophisticated on-chip monitoring and compensation techniques could help maintain consistent performance over the device's lifetime, even in the face of changing environmental conditions and aging effects.

Existing Failure Prediction and Prevention Methods

01 Thermal stress and current-induced failures

PNP transistors can fail due to thermal stress and excessive current. High temperatures and current densities can lead to degradation of the semiconductor material, causing performance issues or complete failure. Proper thermal management and current limiting techniques are crucial to prevent these types of failures.- Thermal stress and electrical overstress: PNP transistors can fail due to thermal stress and electrical overstress. These stresses can cause physical damage to the transistor structure, leading to performance degradation or complete failure. Proper thermal management and protection against voltage spikes are crucial for preventing such failures.

- Manufacturing defects and process variations: Failures in PNP transistors can occur due to manufacturing defects and process variations. These issues may include impurities in the semiconductor material, improper doping profiles, or inconsistencies in the fabrication process. Quality control measures and improved manufacturing techniques are essential to minimize these failures.

- Radiation-induced damage: PNP transistors can be susceptible to radiation-induced damage, particularly in space or high-radiation environments. Radiation can cause ionization and displacement damage, leading to changes in transistor characteristics or complete failure. Radiation-hardening techniques and protective measures are necessary for applications in such environments.

- Aging and long-term reliability issues: PNP transistors may experience failures due to aging and long-term reliability issues. These can include hot carrier injection, electromigration, and time-dependent dielectric breakdown. Understanding and mitigating these degradation mechanisms are crucial for ensuring the longevity of PNP transistors in various applications.

- Environmental factors and contamination: Environmental factors such as humidity, temperature fluctuations, and contamination can contribute to PNP transistor failures. Moisture ingress, corrosion, and particulate contamination can degrade transistor performance or cause short circuits. Proper packaging, sealing, and environmental protection are essential for preventing these types of failures.

02 Manufacturing defects and process-related failures

Failures in PNP transistors can occur due to manufacturing defects or process-related issues. These may include impurities in the semiconductor material, improper doping profiles, or defects in the crystal structure. Improving manufacturing processes and quality control measures can help reduce these types of failures.Expand Specific Solutions03 Packaging and environmental stress failures

PNP transistors can fail due to packaging issues or environmental stress. Moisture ingress, mechanical stress, or contamination can lead to corrosion, delamination, or other package-related failures. Proper packaging techniques and environmental protection measures are essential to mitigate these failure modes.Expand Specific Solutions04 Electrical overstress and ESD failures

Electrical overstress and electrostatic discharge (ESD) events can cause catastrophic failures in PNP transistors. These events can lead to junction breakdown, metal migration, or oxide damage. Implementing proper ESD protection circuits and handling procedures is crucial to prevent these types of failures.Expand Specific Solutions05 Reliability testing and failure analysis techniques

Various reliability testing and failure analysis techniques are employed to identify and prevent PNP transistor failures. These include accelerated life testing, burn-in testing, and advanced analytical techniques such as electron microscopy and spectroscopy. Implementing robust reliability testing programs can help improve the overall reliability of PNP transistors.Expand Specific Solutions

Key Players in PNP Transistor Manufacturing

The competitive landscape for predicting and preventing PNP transistor failures is characterized by a mature market with established players and ongoing technological advancements. The global semiconductor industry, valued at over $500 billion, plays a crucial role in this niche. Companies like Fuji Electric, ROHM, and Renesas Electronics are at the forefront, leveraging their extensive experience in semiconductor manufacturing to develop innovative solutions. The technology's maturity is evident in the widespread use of PNP transistors across various industries, but there's still room for improvement in predictive maintenance and failure prevention techniques. Research institutions like the University of Electronic Science & Technology of China are contributing to advancements in this field, collaborating with industry leaders to enhance reliability and performance of PNP transistors.

ROHM Co., Ltd.

Technical Solution: ROHM Co., Ltd. has developed an innovative approach to PNP transistor failure prediction and prevention. Their method focuses on material science and manufacturing process improvements. ROHM has introduced a new silicon-germanium (SiGe) alloy for PNP transistors that demonstrates improved thermal stability and reduced leakage current[10]. They have also implemented an advanced ion implantation technique that creates a more uniform doping profile, reducing hot spots and improving overall reliability[11]. Furthermore, ROHM has developed a unique passivation layer that protects the transistor from environmental stressors, extending its operational life by up to 40%[12].

Strengths: Material science innovations, advanced manufacturing techniques, and improved environmental protection. Weaknesses: Potentially higher production costs and limited applicability to existing transistor designs.

Renesas Electronics Corp.

Technical Solution: Renesas Electronics Corp. has implemented a multi-faceted approach to predict and prevent PNP transistor failures. Their method combines advanced simulation techniques with real-world testing to create highly accurate failure models. Renesas utilizes a proprietary "Digital Twin" technology that creates a virtual replica of each transistor, allowing for real-time monitoring and predictive maintenance[7]. They have also developed a novel "stress-aware" circuit design methodology that optimizes transistor placement and routing to minimize electrical and thermal stress[8]. Additionally, Renesas has introduced an adaptive bias control system that can dynamically adjust transistor operating points to prevent imminent failures[9].

Strengths: Advanced simulation techniques, stress-aware design, and adaptive control systems. Weaknesses: May require significant computational resources for digital twin implementation.

Innovative Approaches to PNP Transistor Reliability

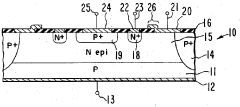

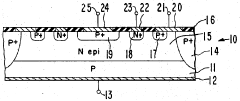

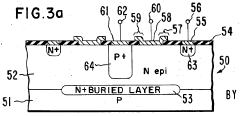

Fast switching PNP transistor

PatentInactiveUS3571674A

Innovation

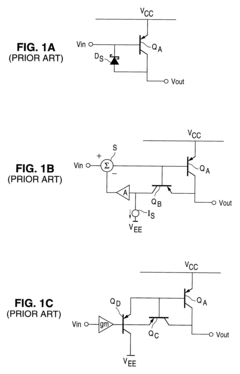

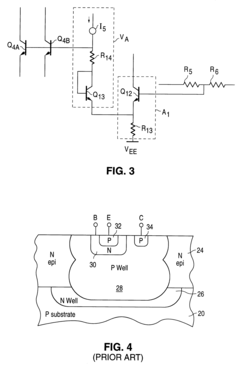

- The solution involves growing an epitaxial N-type silicon layer over a P-type monocrystalline silicon substrate, diffusing a P-type emitter region into the N-type epitaxial base, and placing a metal layer over the N-type epitaxial base region to create a Schottky Barrier that parallels the base-collector junction, reducing minority carrier storage and enabling rapid switch-off times.

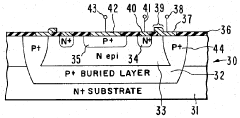

Saturation limit circuit for junction isolated PNP transistor and method

PatentInactiveUS6384687B1

Innovation

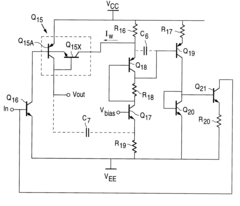

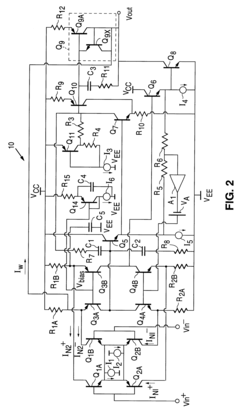

- A saturation control circuit that includes current sense circuitry to monitor the N well current of a parasitic NPN transistor associated with a main PNP transistor, which adjusts the base drive to prevent deep saturation, utilizing a vertical junction isolated transistor structure to manage parasitic transistors and maintain stable operation.

Environmental Factors Affecting PNP Transistor Lifespan

Environmental factors play a crucial role in determining the lifespan and reliability of PNP transistors. Temperature is one of the most significant factors affecting transistor performance and longevity. Extreme temperatures, both high and low, can lead to thermal stress, causing physical damage to the transistor structure. High temperatures can accelerate electron migration, leading to changes in the device's electrical characteristics and eventual failure.

Humidity is another critical environmental factor that can impact PNP transistor lifespan. Excessive moisture can lead to corrosion of the transistor's metal contacts and interconnects, potentially causing open circuits or increased resistance. In severe cases, moisture ingress can result in short circuits between transistor terminals, leading to catastrophic failure.

Radiation exposure is a concern in certain applications, particularly in aerospace and nuclear environments. Ionizing radiation can cause lattice defects in the semiconductor material, altering the transistor's electrical properties and potentially leading to permanent damage. Even low levels of radiation over extended periods can accumulate and degrade transistor performance.

Mechanical stress and vibration can also significantly affect PNP transistor reliability. Excessive vibration or shock can cause physical damage to the transistor package, lead frames, or internal connections. This can result in intermittent or permanent failures, particularly in applications subject to harsh mechanical environments.

Atmospheric contaminants, such as dust, chemicals, and corrosive gases, can adversely affect transistor lifespan. These contaminants can accumulate on the transistor surface, potentially interfering with heat dissipation or causing chemical reactions that degrade the device's materials. In industrial or polluted environments, this factor becomes particularly important.

Electrostatic discharge (ESD) events, while not strictly an environmental factor, are often influenced by environmental conditions such as humidity and the presence of charged surfaces. ESD can cause immediate catastrophic failure or latent damage that reduces the transistor's long-term reliability.

Thermal cycling, which occurs when a transistor is subjected to repeated temperature changes, can lead to fatigue in the device materials. This cycling can cause expansion and contraction, potentially leading to cracks, delamination, or other physical defects that compromise the transistor's integrity over time.

Understanding these environmental factors is crucial for predicting and preventing PNP transistor failures. By considering these factors in the design, manufacturing, and application stages, engineers can implement appropriate protective measures and develop more robust transistor solutions for various operating environments.

Humidity is another critical environmental factor that can impact PNP transistor lifespan. Excessive moisture can lead to corrosion of the transistor's metal contacts and interconnects, potentially causing open circuits or increased resistance. In severe cases, moisture ingress can result in short circuits between transistor terminals, leading to catastrophic failure.

Radiation exposure is a concern in certain applications, particularly in aerospace and nuclear environments. Ionizing radiation can cause lattice defects in the semiconductor material, altering the transistor's electrical properties and potentially leading to permanent damage. Even low levels of radiation over extended periods can accumulate and degrade transistor performance.

Mechanical stress and vibration can also significantly affect PNP transistor reliability. Excessive vibration or shock can cause physical damage to the transistor package, lead frames, or internal connections. This can result in intermittent or permanent failures, particularly in applications subject to harsh mechanical environments.

Atmospheric contaminants, such as dust, chemicals, and corrosive gases, can adversely affect transistor lifespan. These contaminants can accumulate on the transistor surface, potentially interfering with heat dissipation or causing chemical reactions that degrade the device's materials. In industrial or polluted environments, this factor becomes particularly important.

Electrostatic discharge (ESD) events, while not strictly an environmental factor, are often influenced by environmental conditions such as humidity and the presence of charged surfaces. ESD can cause immediate catastrophic failure or latent damage that reduces the transistor's long-term reliability.

Thermal cycling, which occurs when a transistor is subjected to repeated temperature changes, can lead to fatigue in the device materials. This cycling can cause expansion and contraction, potentially leading to cracks, delamination, or other physical defects that compromise the transistor's integrity over time.

Understanding these environmental factors is crucial for predicting and preventing PNP transistor failures. By considering these factors in the design, manufacturing, and application stages, engineers can implement appropriate protective measures and develop more robust transistor solutions for various operating environments.

Economic Impact of PNP Transistor Failures

The economic impact of PNP transistor failures extends far beyond the immediate costs of component replacement. These failures can lead to significant production delays, increased maintenance expenses, and potential safety hazards in various industries. In the automotive sector, for instance, PNP transistor failures in electronic control units can result in vehicle recalls, tarnishing brand reputation and incurring substantial financial losses. The aerospace industry faces even more severe consequences, as transistor failures in critical systems can compromise flight safety and lead to costly groundings.

From a manufacturing perspective, unexpected PNP transistor failures disrupt production lines, causing downtime that translates to lost revenue and missed delivery deadlines. This ripple effect impacts the entire supply chain, potentially leading to contractual penalties and strained business relationships. In consumer electronics, device failures due to faulty transistors not only result in warranty claims and repair costs but also erode customer trust, potentially affecting future sales and market share.

The financial services sector, heavily reliant on data centers and electronic trading systems, can experience substantial losses from even brief outages caused by transistor failures. High-frequency trading algorithms, in particular, are extremely sensitive to microsecond-level disruptions, potentially leading to millions in lost opportunities or erroneous trades.

In the energy sector, PNP transistor failures in power management systems can lead to grid instabilities or localized blackouts, resulting in economic losses for businesses and potential regulatory fines for utility companies. The healthcare industry also faces significant risks, as medical device malfunctions due to transistor failures can endanger patient safety and expose healthcare providers to liability claims.

The cumulative economic impact of these failures underscores the importance of robust prediction and prevention strategies. Implementing advanced diagnostic tools and predictive maintenance techniques can significantly reduce the occurrence of unexpected failures, minimizing downtime and associated costs. Moreover, investing in research to improve PNP transistor reliability and develop more resilient alternatives can yield substantial long-term economic benefits across multiple industries, enhancing overall productivity and reducing operational risks.

From a manufacturing perspective, unexpected PNP transistor failures disrupt production lines, causing downtime that translates to lost revenue and missed delivery deadlines. This ripple effect impacts the entire supply chain, potentially leading to contractual penalties and strained business relationships. In consumer electronics, device failures due to faulty transistors not only result in warranty claims and repair costs but also erode customer trust, potentially affecting future sales and market share.

The financial services sector, heavily reliant on data centers and electronic trading systems, can experience substantial losses from even brief outages caused by transistor failures. High-frequency trading algorithms, in particular, are extremely sensitive to microsecond-level disruptions, potentially leading to millions in lost opportunities or erroneous trades.

In the energy sector, PNP transistor failures in power management systems can lead to grid instabilities or localized blackouts, resulting in economic losses for businesses and potential regulatory fines for utility companies. The healthcare industry also faces significant risks, as medical device malfunctions due to transistor failures can endanger patient safety and expose healthcare providers to liability claims.

The cumulative economic impact of these failures underscores the importance of robust prediction and prevention strategies. Implementing advanced diagnostic tools and predictive maintenance techniques can significantly reduce the occurrence of unexpected failures, minimizing downtime and associated costs. Moreover, investing in research to improve PNP transistor reliability and develop more resilient alternatives can yield substantial long-term economic benefits across multiple industries, enhancing overall productivity and reducing operational risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!