PNP Transistor Use in Battery Management Systems: Latest Developments

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PNP Transistor Evolution in BMS

The evolution of PNP transistors in Battery Management Systems (BMS) has been a crucial factor in the advancement of energy storage technologies. Initially, PNP transistors were primarily used for basic switching and amplification functions in BMS circuits. However, as battery technologies became more sophisticated, the role of PNP transistors expanded significantly.

In the early stages of BMS development, PNP transistors were employed for simple voltage regulation and current control. Their ability to handle moderate power levels made them suitable for managing the charging and discharging processes of early battery systems. As BMS requirements grew more complex, PNP transistors were integrated into more advanced circuits, such as temperature sensing and cell balancing systems.

The mid-2000s saw a significant shift in PNP transistor usage within BMS. With the rise of lithium-ion batteries in portable electronics and electric vehicles, BMS designs required more precise control and monitoring capabilities. PNP transistors were then utilized in high-side current sensing circuits, providing accurate measurements of battery current flow. This development was crucial for improving battery life estimation and preventing overcharging or over-discharging.

As BMS technologies continued to evolve, PNP transistors found new applications in protection circuits. Their ability to quickly respond to voltage and current fluctuations made them ideal for implementing safety features such as short-circuit protection and overvoltage cutoff. The integration of PNP transistors in these critical safety systems significantly enhanced the reliability and safety of battery packs in various applications.

Recent years have seen further advancements in PNP transistor technology specifically tailored for BMS applications. Manufacturers have developed PNP transistors with lower on-resistance and improved thermal characteristics, allowing for more efficient operation in high-power BMS circuits. These enhancements have been particularly beneficial in electric vehicle applications, where power management and thermal control are critical.

The latest developments in PNP transistor use for BMS include their integration into smart battery management ICs. These advanced chips combine multiple functions, including voltage regulation, current sensing, and cell balancing, with PNP transistors playing a key role in analog signal processing and power control. This integration has led to more compact and efficient BMS designs, crucial for the development of smaller and more energy-dense battery systems.

Looking forward, the evolution of PNP transistors in BMS is expected to continue, with a focus on improving energy efficiency, reducing form factors, and enhancing overall system performance. As battery technologies advance, PNP transistors will likely play an even more critical role in enabling the next generation of energy storage solutions.

In the early stages of BMS development, PNP transistors were employed for simple voltage regulation and current control. Their ability to handle moderate power levels made them suitable for managing the charging and discharging processes of early battery systems. As BMS requirements grew more complex, PNP transistors were integrated into more advanced circuits, such as temperature sensing and cell balancing systems.

The mid-2000s saw a significant shift in PNP transistor usage within BMS. With the rise of lithium-ion batteries in portable electronics and electric vehicles, BMS designs required more precise control and monitoring capabilities. PNP transistors were then utilized in high-side current sensing circuits, providing accurate measurements of battery current flow. This development was crucial for improving battery life estimation and preventing overcharging or over-discharging.

As BMS technologies continued to evolve, PNP transistors found new applications in protection circuits. Their ability to quickly respond to voltage and current fluctuations made them ideal for implementing safety features such as short-circuit protection and overvoltage cutoff. The integration of PNP transistors in these critical safety systems significantly enhanced the reliability and safety of battery packs in various applications.

Recent years have seen further advancements in PNP transistor technology specifically tailored for BMS applications. Manufacturers have developed PNP transistors with lower on-resistance and improved thermal characteristics, allowing for more efficient operation in high-power BMS circuits. These enhancements have been particularly beneficial in electric vehicle applications, where power management and thermal control are critical.

The latest developments in PNP transistor use for BMS include their integration into smart battery management ICs. These advanced chips combine multiple functions, including voltage regulation, current sensing, and cell balancing, with PNP transistors playing a key role in analog signal processing and power control. This integration has led to more compact and efficient BMS designs, crucial for the development of smaller and more energy-dense battery systems.

Looking forward, the evolution of PNP transistors in BMS is expected to continue, with a focus on improving energy efficiency, reducing form factors, and enhancing overall system performance. As battery technologies advance, PNP transistors will likely play an even more critical role in enabling the next generation of energy storage solutions.

BMS Market Demand Analysis

The Battery Management System (BMS) market has been experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. As the demand for more efficient and reliable energy storage solutions continues to rise, the BMS market is expected to expand further in the coming years.

The automotive sector, particularly the EV segment, is a major driver of BMS market demand. With governments worldwide implementing stricter emissions regulations and offering incentives for EV adoption, the demand for advanced BMS solutions has surged. These systems play a crucial role in optimizing battery performance, extending battery life, and ensuring safety in EVs.

In addition to the automotive sector, the renewable energy industry is another key contributor to BMS market growth. As solar and wind power installations increase, the need for efficient energy storage systems with robust BMS capabilities has become more pronounced. These systems help manage large-scale battery arrays, ensuring optimal performance and longevity of energy storage installations.

The consumer electronics sector also plays a significant role in driving BMS market demand. With the proliferation of smartphones, laptops, and other portable devices, there is a growing need for advanced battery management solutions to improve device performance and battery life.

Market research indicates that the global BMS market is projected to grow at a compound annual growth rate (CAGR) of over 15% from 2021 to 2026. This growth is attributed to factors such as increasing EV sales, growing renewable energy installations, and the rising demand for smart grid systems.

Geographically, Asia-Pacific is expected to dominate the BMS market, driven by the rapid adoption of EVs in countries like China and Japan, as well as the presence of major battery manufacturers in the region. North America and Europe are also significant markets, with strong growth potential due to supportive government policies and increasing investments in renewable energy infrastructure.

The demand for more advanced BMS solutions is also evident in the industrial sector, where the need for reliable power backup systems and uninterruptible power supplies (UPS) is growing. This trend is particularly prominent in data centers, telecommunications, and manufacturing facilities, where continuous power supply is critical.

As the BMS market continues to evolve, there is an increasing focus on developing more sophisticated and intelligent systems. This includes the integration of artificial intelligence and machine learning algorithms to optimize battery performance, predict maintenance needs, and enhance overall system efficiency. The demand for BMS solutions that can handle higher voltage and current levels is also on the rise, particularly in the EV and renewable energy sectors.

The automotive sector, particularly the EV segment, is a major driver of BMS market demand. With governments worldwide implementing stricter emissions regulations and offering incentives for EV adoption, the demand for advanced BMS solutions has surged. These systems play a crucial role in optimizing battery performance, extending battery life, and ensuring safety in EVs.

In addition to the automotive sector, the renewable energy industry is another key contributor to BMS market growth. As solar and wind power installations increase, the need for efficient energy storage systems with robust BMS capabilities has become more pronounced. These systems help manage large-scale battery arrays, ensuring optimal performance and longevity of energy storage installations.

The consumer electronics sector also plays a significant role in driving BMS market demand. With the proliferation of smartphones, laptops, and other portable devices, there is a growing need for advanced battery management solutions to improve device performance and battery life.

Market research indicates that the global BMS market is projected to grow at a compound annual growth rate (CAGR) of over 15% from 2021 to 2026. This growth is attributed to factors such as increasing EV sales, growing renewable energy installations, and the rising demand for smart grid systems.

Geographically, Asia-Pacific is expected to dominate the BMS market, driven by the rapid adoption of EVs in countries like China and Japan, as well as the presence of major battery manufacturers in the region. North America and Europe are also significant markets, with strong growth potential due to supportive government policies and increasing investments in renewable energy infrastructure.

The demand for more advanced BMS solutions is also evident in the industrial sector, where the need for reliable power backup systems and uninterruptible power supplies (UPS) is growing. This trend is particularly prominent in data centers, telecommunications, and manufacturing facilities, where continuous power supply is critical.

As the BMS market continues to evolve, there is an increasing focus on developing more sophisticated and intelligent systems. This includes the integration of artificial intelligence and machine learning algorithms to optimize battery performance, predict maintenance needs, and enhance overall system efficiency. The demand for BMS solutions that can handle higher voltage and current levels is also on the rise, particularly in the EV and renewable energy sectors.

PNP Transistor Challenges in BMS

PNP transistors play a crucial role in Battery Management Systems (BMS), but their implementation faces several challenges that impact system performance and reliability. One of the primary issues is the thermal management of PNP transistors in BMS applications. As battery systems become more powerful and compact, the heat generated by these transistors can lead to efficiency losses and potential safety hazards. Engineers must develop innovative cooling solutions and optimize transistor placement to mitigate these thermal concerns.

Another significant challenge is the voltage limitations of PNP transistors in high-voltage battery systems. As electric vehicles and energy storage systems push for higher voltages to improve efficiency, traditional PNP transistors may struggle to handle these increased voltage levels. This necessitates the development of new transistor designs or the implementation of alternative semiconductor technologies that can withstand higher voltages while maintaining the desired switching characteristics.

The speed and switching performance of PNP transistors also present challenges in modern BMS applications. As battery systems require faster response times and more precise control, the inherent limitations of PNP transistors in terms of switching speed and current handling capabilities become more apparent. This has led to a push for the development of faster, more efficient transistor technologies or the exploration of alternative switching devices.

Miniaturization is another key challenge facing PNP transistors in BMS. As battery systems become more compact and integrated, there is a growing need for smaller transistor packages that can deliver the same or improved performance. This miniaturization effort must balance size reduction with thermal management and electrical performance considerations.

The reliability and lifespan of PNP transistors in BMS applications also pose significant challenges. Battery systems often operate in harsh environments with wide temperature fluctuations and potential exposure to vibration and shock. Ensuring that PNP transistors can maintain consistent performance and longevity under these conditions is crucial for the overall reliability of the BMS.

Lastly, the cost-effectiveness of PNP transistors in large-scale BMS production remains a challenge. As the demand for electric vehicles and energy storage systems grows, manufacturers must find ways to reduce the cost of PNP transistors without compromising on performance or reliability. This may involve exploring new manufacturing techniques, materials, or alternative transistor technologies that offer a better balance of cost and performance for BMS applications.

Another significant challenge is the voltage limitations of PNP transistors in high-voltage battery systems. As electric vehicles and energy storage systems push for higher voltages to improve efficiency, traditional PNP transistors may struggle to handle these increased voltage levels. This necessitates the development of new transistor designs or the implementation of alternative semiconductor technologies that can withstand higher voltages while maintaining the desired switching characteristics.

The speed and switching performance of PNP transistors also present challenges in modern BMS applications. As battery systems require faster response times and more precise control, the inherent limitations of PNP transistors in terms of switching speed and current handling capabilities become more apparent. This has led to a push for the development of faster, more efficient transistor technologies or the exploration of alternative switching devices.

Miniaturization is another key challenge facing PNP transistors in BMS. As battery systems become more compact and integrated, there is a growing need for smaller transistor packages that can deliver the same or improved performance. This miniaturization effort must balance size reduction with thermal management and electrical performance considerations.

The reliability and lifespan of PNP transistors in BMS applications also pose significant challenges. Battery systems often operate in harsh environments with wide temperature fluctuations and potential exposure to vibration and shock. Ensuring that PNP transistors can maintain consistent performance and longevity under these conditions is crucial for the overall reliability of the BMS.

Lastly, the cost-effectiveness of PNP transistors in large-scale BMS production remains a challenge. As the demand for electric vehicles and energy storage systems grows, manufacturers must find ways to reduce the cost of PNP transistors without compromising on performance or reliability. This may involve exploring new manufacturing techniques, materials, or alternative transistor technologies that offer a better balance of cost and performance for BMS applications.

Current PNP Transistor BMS Solutions

01 PNP transistor structure and fabrication

This category focuses on the physical structure and manufacturing processes of PNP transistors. It includes innovations in transistor design, such as improved emitter, base, and collector configurations, as well as novel fabrication techniques to enhance performance and reduce size.- PNP transistor structure and fabrication: This category focuses on the physical structure and manufacturing processes of PNP transistors. It includes innovations in transistor design, such as improved emitter, base, and collector configurations, as well as novel fabrication techniques to enhance performance and reduce size.

- PNP transistor applications in circuits: This point covers the various applications of PNP transistors in electronic circuits. It includes their use in amplifiers, switches, logic gates, and other specialized circuits where PNP transistors offer unique advantages over other semiconductor devices.

- PNP transistor performance optimization: This category deals with methods and techniques to improve the performance of PNP transistors. It includes strategies for enhancing gain, reducing noise, improving frequency response, and optimizing other key parameters to meet specific application requirements.

- Integration of PNP transistors in semiconductor devices: This point focuses on the integration of PNP transistors with other semiconductor components to create more complex devices and integrated circuits. It covers techniques for combining PNP transistors with NPN transistors, CMOS structures, and other elements on a single chip.

- PNP transistor modeling and simulation: This category encompasses the development of accurate models and simulation techniques for PNP transistors. It includes methods for characterizing transistor behavior, creating mathematical models, and implementing these models in computer-aided design tools for circuit analysis and optimization.

02 PNP transistor applications in circuits

This point covers the various applications of PNP transistors in electronic circuits. It includes their use in amplifiers, switches, logic gates, and other circuit configurations. The focus is on how PNP transistors are integrated into larger systems to achieve specific functions.Expand Specific Solutions03 PNP transistor performance optimization

This category deals with methods and techniques to improve the performance of PNP transistors. It includes strategies for enhancing parameters such as gain, switching speed, power handling, and temperature stability. The focus is on optimizing the transistor's characteristics for specific applications.Expand Specific Solutions04 Integration of PNP transistors in semiconductor devices

This point addresses the integration of PNP transistors with other semiconductor components. It covers topics such as combining PNP transistors with NPN transistors to create complementary circuits, integrating them into ICs, and developing new semiconductor device architectures that incorporate PNP transistors.Expand Specific Solutions05 PNP transistor modeling and simulation

This category focuses on the development of accurate models and simulation techniques for PNP transistors. It includes creating mathematical models, computer-aided design tools, and simulation software to predict and analyze PNP transistor behavior in various operating conditions and circuit configurations.Expand Specific Solutions

Key BMS Manufacturers and Suppliers

The PNP transistor market in Battery Management Systems (BMS) is experiencing significant growth, driven by the expanding electric vehicle and renewable energy sectors. The industry is in a mature stage, with established players like Infineon Technologies, Texas Instruments, and Panasonic Holdings dominating the market. However, emerging companies such as ABLIC and Nuvoton Technology are introducing innovative solutions, intensifying competition. The global BMS market size is projected to reach $10 billion by 2025, with PNP transistors playing a crucial role. Technological advancements focus on improving efficiency, reducing power consumption, and enhancing thermal management, with major players like Robert Bosch and Siemens AG investing heavily in R&D to maintain their competitive edge.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced Battery Management Systems (BMS) utilizing PNP transistors for enhanced efficiency and safety. Their latest BMS incorporates intelligent cell balancing techniques, employing PNP transistors in a flyback topology to redistribute energy between cells[1]. This approach allows for precise control of individual cell voltages, extending battery life and improving overall performance. Bosch's system also features high-precision current sensing using PNP transistors in a current mirror configuration, enabling accurate state-of-charge estimation[2]. Additionally, they have implemented a novel thermal management solution using PNP transistors for temperature sensing and control, ensuring optimal battery operating conditions[3].

Strengths: Comprehensive BMS solution with advanced cell balancing and thermal management. Weaknesses: Potentially higher cost due to complex implementation and specialized components.

Infineon Technologies AG

Technical Solution: Infineon has made significant strides in PNP transistor technology for Battery Management Systems. Their latest developments include a high-voltage PNP transistor array specifically designed for BMS applications[4]. This array features low on-resistance and high current capability, making it ideal for cell balancing and protection circuits. Infineon has also introduced a novel bipolar-CMOS (BiCMOS) process that integrates PNP transistors with advanced CMOS logic, allowing for more compact and efficient BMS designs[5]. Furthermore, they have developed a smart power stage using PNP transistors for battery disconnect and reverse polarity protection, enhancing overall system reliability[6].

Strengths: High integration capabilities, advanced manufacturing processes, and specialized PNP transistor designs for BMS. Weaknesses: Potential limitations in extreme temperature environments.

PNP Transistor Innovations for BMS

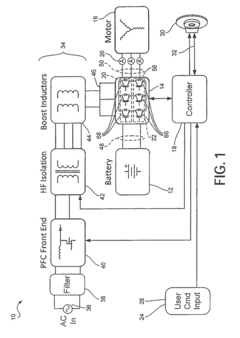

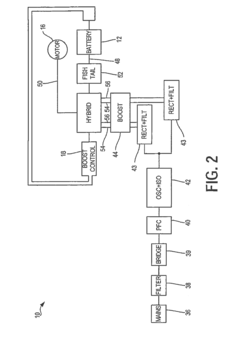

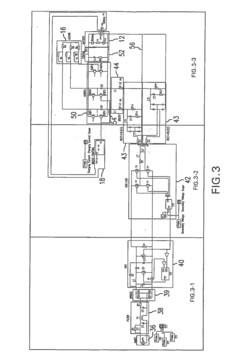

Combination charger and motive power device

PatentActiveUS20140340004A1

Innovation

- A combined battery charger and motor driver circuit assembly that includes a PNP transistor array and a charging source configured to provide pulse-width-modulated power, allowing for efficient energy transfer and regenerative braking, while minimizing waste heat and thermal spikes.

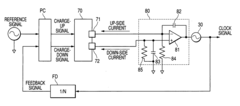

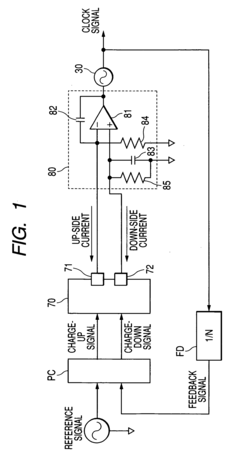

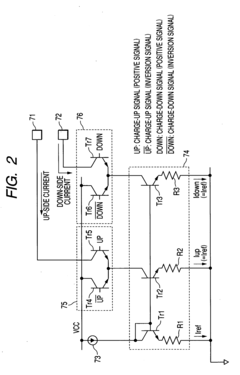

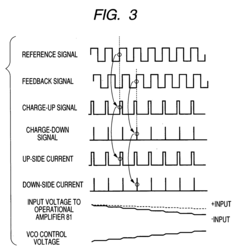

Charge pump circuit and PLL circuit using the same

PatentInactiveUS20050195301A1

Innovation

- A charge pump circuit utilizing npn bipolar transistors or n-channel MOS-FETs for symmetric current switching, with current mirror circuits and phase offset control, ensuring fast and precise operation without asymmetry, thereby reducing circuit scale and maintaining high symmetry between up-side and down-side currents.

BMS Regulatory Compliance

Battery Management Systems (BMS) are subject to a complex web of regulatory requirements that ensure safety, reliability, and performance standards are met. These regulations vary across different regions and industries, but generally focus on electrical safety, electromagnetic compatibility, environmental protection, and specific battery-related standards.

In the automotive sector, the United Nations Economic Commission for Europe (UNECE) Regulation No. 100 sets safety requirements for electric power train of vehicles, including BMS. This regulation covers aspects such as protection against electrical shock, functional safety, and thermal management. Similarly, ISO 26262 addresses functional safety for automotive electrical and electronic systems, with specific implications for BMS design and implementation.

For consumer electronics, IEC 62133 is a key standard that covers safety requirements for portable sealed secondary cells and batteries containing alkaline or other non-acid electrolytes. This standard directly impacts BMS design, particularly in areas of overcharge protection, short circuit protection, and thermal management.

In the aerospace industry, DO-311A provides guidance for rechargeable lithium batteries and battery systems in aerospace applications. This standard sets stringent requirements for BMS in terms of monitoring, control, and safety features.

Electromagnetic compatibility (EMC) regulations, such as IEC 61000 series and CISPR standards, are crucial for BMS compliance. These standards ensure that BMS do not generate electromagnetic interference that could affect other electronic systems, and are themselves resistant to external electromagnetic disturbances.

Environmental regulations also play a significant role in BMS compliance. The European Union's Restriction of Hazardous Substances (RoHS) Directive and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation impact the materials and components used in BMS manufacturing.

As the use of PNP transistors in BMS evolves, manufacturers must ensure that these developments align with existing regulations and anticipate future regulatory changes. This includes considering the impact of PNP transistor characteristics on overall system safety, reliability, and performance as defined by various standards.

Compliance testing and certification processes are integral to meeting these regulatory requirements. Manufacturers must conduct rigorous testing, including environmental stress testing, EMC testing, and safety testing, to demonstrate compliance with relevant standards. Documentation of compliance, including test reports and technical files, is typically required for market access in many jurisdictions.

In the automotive sector, the United Nations Economic Commission for Europe (UNECE) Regulation No. 100 sets safety requirements for electric power train of vehicles, including BMS. This regulation covers aspects such as protection against electrical shock, functional safety, and thermal management. Similarly, ISO 26262 addresses functional safety for automotive electrical and electronic systems, with specific implications for BMS design and implementation.

For consumer electronics, IEC 62133 is a key standard that covers safety requirements for portable sealed secondary cells and batteries containing alkaline or other non-acid electrolytes. This standard directly impacts BMS design, particularly in areas of overcharge protection, short circuit protection, and thermal management.

In the aerospace industry, DO-311A provides guidance for rechargeable lithium batteries and battery systems in aerospace applications. This standard sets stringent requirements for BMS in terms of monitoring, control, and safety features.

Electromagnetic compatibility (EMC) regulations, such as IEC 61000 series and CISPR standards, are crucial for BMS compliance. These standards ensure that BMS do not generate electromagnetic interference that could affect other electronic systems, and are themselves resistant to external electromagnetic disturbances.

Environmental regulations also play a significant role in BMS compliance. The European Union's Restriction of Hazardous Substances (RoHS) Directive and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation impact the materials and components used in BMS manufacturing.

As the use of PNP transistors in BMS evolves, manufacturers must ensure that these developments align with existing regulations and anticipate future regulatory changes. This includes considering the impact of PNP transistor characteristics on overall system safety, reliability, and performance as defined by various standards.

Compliance testing and certification processes are integral to meeting these regulatory requirements. Manufacturers must conduct rigorous testing, including environmental stress testing, EMC testing, and safety testing, to demonstrate compliance with relevant standards. Documentation of compliance, including test reports and technical files, is typically required for market access in many jurisdictions.

PNP Transistor Reliability in BMS

PNP transistors play a crucial role in Battery Management Systems (BMS), particularly in applications requiring high-side switching and current sensing. The reliability of these components is paramount to ensure the safe and efficient operation of battery systems in various applications, from consumer electronics to electric vehicles.

Recent developments in PNP transistor technology have significantly improved their reliability in BMS applications. Advanced manufacturing processes, such as the implementation of trench-gate structures and enhanced epitaxial layers, have led to reduced on-resistance and improved thermal performance. These advancements contribute to lower power dissipation and increased overall efficiency of the BMS.

One key factor affecting PNP transistor reliability in BMS is the ability to withstand high voltage spikes and transients. Modern PNP transistors now incorporate improved electrostatic discharge (ESD) protection and enhanced safe operating area (SOA) characteristics. These features enable the transistors to handle sudden voltage fluctuations without compromising their performance or lifespan.

Thermal management has also seen significant improvements, addressing a major concern in BMS applications. New packaging technologies, such as copper clip and dual-side cooling, have enhanced heat dissipation capabilities. This allows PNP transistors to operate more reliably under high current conditions, which is especially important in fast-charging scenarios for electric vehicle batteries.

The integration of advanced diagnostic features within PNP transistors has further bolstered their reliability in BMS. Real-time current sensing and temperature monitoring capabilities enable more precise control and protection mechanisms. These features allow the BMS to detect potential issues early and take preventive actions, thereby extending the overall lifespan of the battery system.

Radiation hardening techniques have also been applied to PNP transistors used in BMS for aerospace and satellite applications. These specialized transistors exhibit improved resistance to single-event effects and total ionizing dose, ensuring reliable operation in harsh radiation environments.

Long-term stability and aging characteristics of PNP transistors have been addressed through improved doping profiles and passivation techniques. These enhancements result in more consistent performance over time, reducing the risk of premature failure and extending the operational life of the BMS.

The automotive industry has driven significant advancements in PNP transistor reliability for BMS applications. Stringent automotive qualification standards, such as AEC-Q101, have led to the development of robust PNP transistors capable of withstanding extreme temperature cycles, humidity, and mechanical stress.

In conclusion, the reliability of PNP transistors in BMS has seen substantial improvements through various technological advancements. These developments have addressed key challenges such as thermal management, voltage handling, and long-term stability, making PNP transistors more suitable for demanding BMS applications across multiple industries.

Recent developments in PNP transistor technology have significantly improved their reliability in BMS applications. Advanced manufacturing processes, such as the implementation of trench-gate structures and enhanced epitaxial layers, have led to reduced on-resistance and improved thermal performance. These advancements contribute to lower power dissipation and increased overall efficiency of the BMS.

One key factor affecting PNP transistor reliability in BMS is the ability to withstand high voltage spikes and transients. Modern PNP transistors now incorporate improved electrostatic discharge (ESD) protection and enhanced safe operating area (SOA) characteristics. These features enable the transistors to handle sudden voltage fluctuations without compromising their performance or lifespan.

Thermal management has also seen significant improvements, addressing a major concern in BMS applications. New packaging technologies, such as copper clip and dual-side cooling, have enhanced heat dissipation capabilities. This allows PNP transistors to operate more reliably under high current conditions, which is especially important in fast-charging scenarios for electric vehicle batteries.

The integration of advanced diagnostic features within PNP transistors has further bolstered their reliability in BMS. Real-time current sensing and temperature monitoring capabilities enable more precise control and protection mechanisms. These features allow the BMS to detect potential issues early and take preventive actions, thereby extending the overall lifespan of the battery system.

Radiation hardening techniques have also been applied to PNP transistors used in BMS for aerospace and satellite applications. These specialized transistors exhibit improved resistance to single-event effects and total ionizing dose, ensuring reliable operation in harsh radiation environments.

Long-term stability and aging characteristics of PNP transistors have been addressed through improved doping profiles and passivation techniques. These enhancements result in more consistent performance over time, reducing the risk of premature failure and extending the operational life of the BMS.

The automotive industry has driven significant advancements in PNP transistor reliability for BMS applications. Stringent automotive qualification standards, such as AEC-Q101, have led to the development of robust PNP transistors capable of withstanding extreme temperature cycles, humidity, and mechanical stress.

In conclusion, the reliability of PNP transistors in BMS has seen substantial improvements through various technological advancements. These developments have addressed key challenges such as thermal management, voltage handling, and long-term stability, making PNP transistors more suitable for demanding BMS applications across multiple industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!