PNP Transistors for Aerospace Applications: Challenges and Innovations

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace PNP Transistor Evolution and Objectives

PNP transistors have played a crucial role in aerospace applications since the early days of space exploration. The evolution of these devices has been closely tied to the increasing demands of space-based electronics, which require components capable of withstanding extreme temperatures, radiation, and other harsh environmental conditions.

In the 1960s, during the initial stages of space programs, germanium-based PNP transistors were commonly used due to their low noise characteristics and ability to operate at lower voltages. However, these devices had limitations in terms of temperature stability and radiation hardness, which prompted the development of silicon-based alternatives.

The 1970s and 1980s saw significant advancements in silicon PNP transistor technology, with improvements in manufacturing processes leading to enhanced performance and reliability. These developments included the introduction of epitaxial growth techniques and ion implantation, which allowed for better control of doping profiles and reduced parasitic capacitances.

As space missions became more complex and long-duration, the need for radiation-hardened PNP transistors became paramount. The 1990s witnessed the emergence of specialized fabrication techniques, such as silicon-on-insulator (SOI) technology, which greatly improved the radiation tolerance of these devices.

In recent years, the focus has shifted towards developing PNP transistors with higher power handling capabilities, improved thermal management, and enhanced reliability for extended space missions. This has led to the exploration of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), which offer superior performance in extreme environments.

The primary objectives for PNP transistors in aerospace applications continue to evolve. Current goals include further miniaturization to reduce payload weight, increased energy efficiency to optimize power consumption in space-based systems, and improved radiation hardness to withstand the harsh space environment for longer durations.

Additionally, there is a growing emphasis on developing PNP transistors that can operate reliably in a wider temperature range, from the extreme cold of deep space to the high temperatures encountered during atmospheric re-entry. This requires innovative materials and packaging solutions to ensure consistent performance across diverse thermal conditions.

Another key objective is to enhance the integration capabilities of PNP transistors with other semiconductor devices, enabling the creation of more compact and sophisticated aerospace electronic systems. This includes the development of advanced bipolar-CMOS (BiCMOS) processes that combine the strengths of both bipolar and CMOS technologies.

In the 1960s, during the initial stages of space programs, germanium-based PNP transistors were commonly used due to their low noise characteristics and ability to operate at lower voltages. However, these devices had limitations in terms of temperature stability and radiation hardness, which prompted the development of silicon-based alternatives.

The 1970s and 1980s saw significant advancements in silicon PNP transistor technology, with improvements in manufacturing processes leading to enhanced performance and reliability. These developments included the introduction of epitaxial growth techniques and ion implantation, which allowed for better control of doping profiles and reduced parasitic capacitances.

As space missions became more complex and long-duration, the need for radiation-hardened PNP transistors became paramount. The 1990s witnessed the emergence of specialized fabrication techniques, such as silicon-on-insulator (SOI) technology, which greatly improved the radiation tolerance of these devices.

In recent years, the focus has shifted towards developing PNP transistors with higher power handling capabilities, improved thermal management, and enhanced reliability for extended space missions. This has led to the exploration of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), which offer superior performance in extreme environments.

The primary objectives for PNP transistors in aerospace applications continue to evolve. Current goals include further miniaturization to reduce payload weight, increased energy efficiency to optimize power consumption in space-based systems, and improved radiation hardness to withstand the harsh space environment for longer durations.

Additionally, there is a growing emphasis on developing PNP transistors that can operate reliably in a wider temperature range, from the extreme cold of deep space to the high temperatures encountered during atmospheric re-entry. This requires innovative materials and packaging solutions to ensure consistent performance across diverse thermal conditions.

Another key objective is to enhance the integration capabilities of PNP transistors with other semiconductor devices, enabling the creation of more compact and sophisticated aerospace electronic systems. This includes the development of advanced bipolar-CMOS (BiCMOS) processes that combine the strengths of both bipolar and CMOS technologies.

Market Analysis for Aerospace-Grade PNP Transistors

The aerospace-grade PNP transistor market is experiencing significant growth driven by the increasing demand for reliable electronic components in space and aviation applications. This market segment is characterized by stringent performance requirements, including radiation hardness, temperature tolerance, and long-term reliability under extreme conditions. The global aerospace industry's expansion, particularly in satellite communications, earth observation, and space exploration missions, is fueling the demand for high-performance PNP transistors.

Key market drivers include the growing number of satellite launches, the development of advanced avionics systems, and the increasing adoption of electronic warfare technologies in military aircraft. The commercial aviation sector also contributes to market growth through the integration of more sophisticated electronic systems in modern aircraft. Additionally, the emergence of new space companies and the trend towards smaller, more cost-effective satellites are creating opportunities for innovative PNP transistor designs.

Market analysis reveals that North America currently dominates the aerospace-grade PNP transistor market, followed by Europe and Asia-Pacific. This regional distribution aligns with the concentration of major aerospace and defense companies in these areas. However, emerging markets in Asia, particularly China and India, are showing rapid growth potential due to their expanding space programs and increasing investments in aerospace technologies.

The market is segmented based on application areas, including satellite systems, aircraft avionics, missile guidance systems, and space exploration vehicles. Each segment has unique requirements, influencing the development and production of specialized PNP transistors. For instance, satellite applications demand transistors with enhanced radiation tolerance, while aircraft avionics require components with excellent thermal management capabilities.

Pricing trends in the aerospace-grade PNP transistor market reflect the high-value nature of these components. The cost per unit is significantly higher compared to commercial-grade transistors due to the extensive testing, qualification processes, and specialized manufacturing techniques required. Despite the higher costs, the market shows steady growth, indicating the critical nature of these components in aerospace applications.

Market forecasts suggest a compound annual growth rate (CAGR) in the mid-single digits for the aerospace-grade PNP transistor market over the next five years. This growth is supported by ongoing technological advancements, increasing space missions, and the modernization of military and commercial aircraft fleets. The market is also influenced by geopolitical factors and defense spending trends in major economies.

Key market drivers include the growing number of satellite launches, the development of advanced avionics systems, and the increasing adoption of electronic warfare technologies in military aircraft. The commercial aviation sector also contributes to market growth through the integration of more sophisticated electronic systems in modern aircraft. Additionally, the emergence of new space companies and the trend towards smaller, more cost-effective satellites are creating opportunities for innovative PNP transistor designs.

Market analysis reveals that North America currently dominates the aerospace-grade PNP transistor market, followed by Europe and Asia-Pacific. This regional distribution aligns with the concentration of major aerospace and defense companies in these areas. However, emerging markets in Asia, particularly China and India, are showing rapid growth potential due to their expanding space programs and increasing investments in aerospace technologies.

The market is segmented based on application areas, including satellite systems, aircraft avionics, missile guidance systems, and space exploration vehicles. Each segment has unique requirements, influencing the development and production of specialized PNP transistors. For instance, satellite applications demand transistors with enhanced radiation tolerance, while aircraft avionics require components with excellent thermal management capabilities.

Pricing trends in the aerospace-grade PNP transistor market reflect the high-value nature of these components. The cost per unit is significantly higher compared to commercial-grade transistors due to the extensive testing, qualification processes, and specialized manufacturing techniques required. Despite the higher costs, the market shows steady growth, indicating the critical nature of these components in aerospace applications.

Market forecasts suggest a compound annual growth rate (CAGR) in the mid-single digits for the aerospace-grade PNP transistor market over the next five years. This growth is supported by ongoing technological advancements, increasing space missions, and the modernization of military and commercial aircraft fleets. The market is also influenced by geopolitical factors and defense spending trends in major economies.

Current Challenges in Aerospace PNP Transistor Technology

The aerospace industry faces several critical challenges in the development and implementation of PNP transistors for high-reliability applications. One of the primary concerns is the susceptibility of these devices to radiation-induced damage in space environments. Cosmic rays and solar radiation can cause single-event effects (SEEs) and total ionizing dose (TID) damage, leading to performance degradation or complete failure of the transistors.

Thermal management presents another significant challenge. Aerospace applications often involve extreme temperature fluctuations, ranging from cryogenic conditions to high heat scenarios. PNP transistors must maintain stable performance across this wide temperature range, which requires advanced materials and design techniques to mitigate thermal stress and ensure consistent electrical characteristics.

The demand for miniaturization in aerospace electronics poses additional difficulties for PNP transistor technology. As spacecraft and satellite systems become more compact, there is a growing need for smaller, lighter transistors that can deliver high performance in limited space. This miniaturization trend conflicts with the requirement for robust radiation shielding, creating a complex design trade-off.

Reliability and longevity are paramount in aerospace applications, where component replacement is often impossible or prohibitively expensive. PNP transistors must demonstrate exceptional durability and consistent performance over extended periods, sometimes spanning decades. This necessitates rigorous testing and qualification processes, which can be time-consuming and costly.

The aerospace industry also grapples with the challenge of obsolescence management. As commercial semiconductor manufacturers continually evolve their product lines, aerospace-grade PNP transistors may become discontinued, forcing engineers to find suitable replacements or redesign entire systems. This issue is compounded by the long development cycles and stringent certification requirements in the aerospace sector.

Power efficiency is another critical concern, particularly in satellite and space probe applications where energy resources are limited. PNP transistors must operate with minimal power consumption while maintaining high performance, a balance that becomes increasingly difficult to achieve as other requirements, such as radiation hardness, are addressed.

Lastly, the aerospace industry faces challenges related to the supply chain and manufacturing of specialized PNP transistors. The limited market size for aerospace-grade components can lead to higher costs and longer lead times. Additionally, ensuring a secure and reliable supply chain for these critical components is essential, given the sensitive nature of many aerospace applications and the potential for counterfeit parts to enter the market.

Thermal management presents another significant challenge. Aerospace applications often involve extreme temperature fluctuations, ranging from cryogenic conditions to high heat scenarios. PNP transistors must maintain stable performance across this wide temperature range, which requires advanced materials and design techniques to mitigate thermal stress and ensure consistent electrical characteristics.

The demand for miniaturization in aerospace electronics poses additional difficulties for PNP transistor technology. As spacecraft and satellite systems become more compact, there is a growing need for smaller, lighter transistors that can deliver high performance in limited space. This miniaturization trend conflicts with the requirement for robust radiation shielding, creating a complex design trade-off.

Reliability and longevity are paramount in aerospace applications, where component replacement is often impossible or prohibitively expensive. PNP transistors must demonstrate exceptional durability and consistent performance over extended periods, sometimes spanning decades. This necessitates rigorous testing and qualification processes, which can be time-consuming and costly.

The aerospace industry also grapples with the challenge of obsolescence management. As commercial semiconductor manufacturers continually evolve their product lines, aerospace-grade PNP transistors may become discontinued, forcing engineers to find suitable replacements or redesign entire systems. This issue is compounded by the long development cycles and stringent certification requirements in the aerospace sector.

Power efficiency is another critical concern, particularly in satellite and space probe applications where energy resources are limited. PNP transistors must operate with minimal power consumption while maintaining high performance, a balance that becomes increasingly difficult to achieve as other requirements, such as radiation hardness, are addressed.

Lastly, the aerospace industry faces challenges related to the supply chain and manufacturing of specialized PNP transistors. The limited market size for aerospace-grade components can lead to higher costs and longer lead times. Additionally, ensuring a secure and reliable supply chain for these critical components is essential, given the sensitive nature of many aerospace applications and the potential for counterfeit parts to enter the market.

Existing Solutions for Aerospace PNP Transistor Design

01 PNP transistor structure and fabrication

This category covers the basic structure and fabrication methods of PNP transistors. It includes techniques for creating the emitter, base, and collector regions, as well as methods for optimizing the transistor's performance through doping profiles and layer thicknesses.- PNP transistor structure and fabrication: This category covers the basic structure and fabrication methods of PNP transistors. It includes the design of emitter, base, and collector regions, as well as the processes used to create these structures on semiconductor substrates. Various techniques for doping, etching, and layer deposition are discussed to achieve optimal PNP transistor performance.

- PNP transistor applications in integrated circuits: PNP transistors play crucial roles in various integrated circuit designs. This category explores their use in analog and digital circuits, including amplifiers, current mirrors, and logic gates. It also covers their integration with other semiconductor devices to create complex circuit functions and improve overall performance of integrated systems.

- PNP transistor performance optimization: This category focuses on techniques to enhance PNP transistor performance. It includes methods to improve current gain, reduce parasitic capacitances, and minimize leakage currents. Advanced doping profiles, novel materials, and structural modifications are explored to achieve better frequency response, power handling, and thermal stability in PNP transistors.

- PNP transistors in power electronics: PNP transistors find applications in power electronics circuits. This category covers their use in high-voltage and high-current applications, such as power supplies, motor drivers, and voltage regulators. It includes design considerations for improved heat dissipation, breakdown voltage, and safe operating area to ensure reliable operation in power electronic systems.

- PNP transistors in analog and RF circuits: This category explores the use of PNP transistors in analog and radio frequency (RF) circuit applications. It covers their implementation in low-noise amplifiers, mixers, and oscillators. The focus is on optimizing PNP transistor characteristics for high-frequency operation, improved linearity, and reduced noise figure in analog and RF circuit designs.

02 PNP transistor applications in integrated circuits

This point focuses on the use of PNP transistors in various integrated circuit designs. It includes applications in analog and digital circuits, such as amplifiers, current mirrors, and logic gates, as well as their integration with other semiconductor devices.Expand Specific Solutions03 PNP transistor performance optimization

This category covers techniques for improving PNP transistor performance, including methods to enhance gain, reduce noise, increase switching speed, and improve temperature stability. It also includes innovations in device geometry and materials to achieve better electrical characteristics.Expand Specific Solutions04 PNP transistors in power applications

This point addresses the use of PNP transistors in power electronics and high-current applications. It includes designs for power amplifiers, voltage regulators, and switching circuits, as well as methods for improving heat dissipation and current handling capabilities.Expand Specific Solutions05 PNP transistors in specialized semiconductor devices

This category covers the integration of PNP transistors in specialized semiconductor devices such as thyristors, silicon-controlled rectifiers (SCRs), and other multi-layer structures. It includes novel device configurations that leverage PNP transistor characteristics for specific applications.Expand Specific Solutions

Key Players in Aerospace Semiconductor Industry

The PNP transistor market for aerospace applications is in a mature growth stage, with a steady but moderate expansion driven by increasing demand in satellite communications, avionics, and space exploration. The global market size is estimated to be in the hundreds of millions of dollars, reflecting the specialized nature of aerospace-grade components. Technologically, PNP transistors for aerospace applications are highly advanced, with companies like IBM, Infineon Technologies, and Texas Instruments leading innovations in radiation hardening, high-temperature performance, and miniaturization. These advancements are crucial for meeting the stringent reliability and durability requirements of aerospace environments, pushing the boundaries of semiconductor technology in extreme conditions.

International Business Machines Corp.

Technical Solution: IBM has developed advanced PNP transistors for aerospace applications using Silicon-Germanium (SiGe) technology. Their SiGe heterojunction bipolar transistors (HBTs) offer improved performance in extreme environments. The company's latest PNP transistors feature a novel vertical profile design, enhancing radiation hardness and thermal stability[1]. IBM's process integrates these transistors with CMOS technology, allowing for highly integrated mixed-signal circuits suitable for aerospace systems[2]. The transistors demonstrate a cutoff frequency of over 30 GHz and breakdown voltages exceeding 5V, making them ideal for high-frequency, high-power applications in satellite communications and radar systems[3].

Strengths: Superior radiation hardness, high-frequency performance, and thermal stability. Integration with CMOS technology enables compact, power-efficient designs. Weaknesses: Higher production costs compared to standard silicon processes, and potential supply chain complexities for aerospace-grade components.

Infineon Technologies AG

Technical Solution: Infineon has developed a range of PNP transistors specifically designed for aerospace applications, focusing on reliability and performance in extreme conditions. Their latest offerings include high-voltage PNP transistors with breakdown voltages up to 100V and current capabilities exceeding 5A[4]. Infineon's aerospace-grade PNP transistors incorporate advanced packaging techniques to enhance thermal management and reduce parasitic effects. The company has also implemented unique doping profiles to improve the transistors' radiation tolerance, crucial for space applications[5]. Infineon's PNP transistors feature low saturation voltages and high current gain, optimized for power management and amplification in satellite systems and aircraft avionics[6].

Strengths: Wide range of voltage and current ratings, excellent thermal management, and radiation tolerance. Established presence in aerospace supply chains. Weaknesses: Higher cost compared to commercial-grade alternatives, and potential lead times for specialized aerospace components.

Core Innovations in Radiation-Hardened PNP Transistors

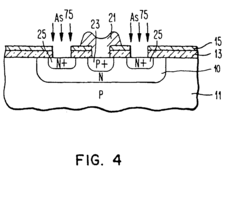

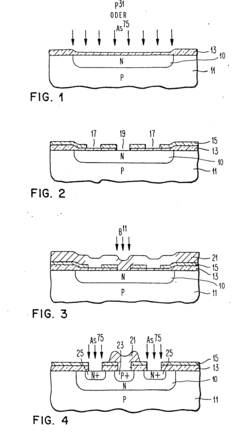

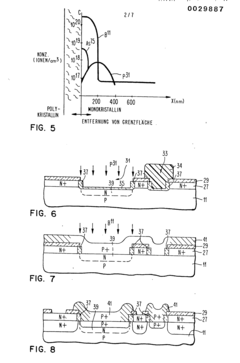

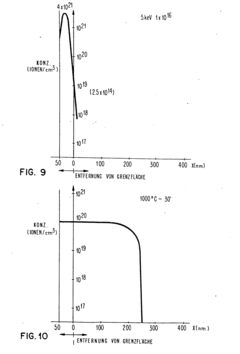

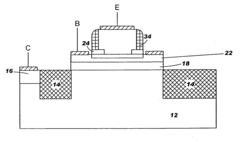

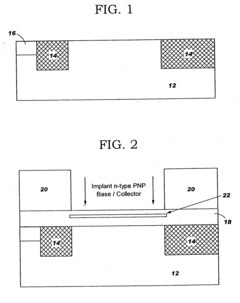

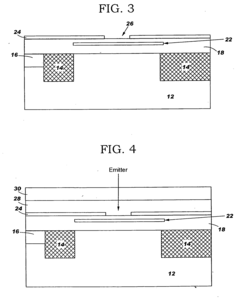

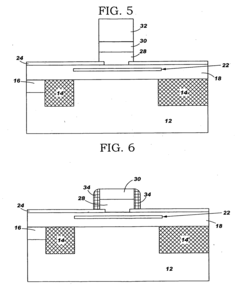

Process for producing a vertical PNP transistor and transistor so produced

PatentInactiveEP0029887A1

Innovation

- A method involving the application of a polycrystalline silicon layer with p-type conductivity-generating impurities implanted under specific conditions, followed by a heating process to form a flat P-doped emitter zone with a steep impurity gradient, minimizing defects and achieving optimal electrical properties.

High performance integrated vertical transistors and method of making the same

PatentInactiveUS20070001264A1

Innovation

- The use of a shared silicon germanium (SiGe) low temperature epitaxial (LTE) layer allows for the fabrication of vertically aligned complementary bipolar transistors, where the NPN and PNP transistors share the same epitaxial base and collector regions, with the PNP emitter layer acting as the NPN base layer, utilizing advanced epitaxial techniques like molecular beam epitaxy (MBE) and low temperature epitaxy (LTE) to ensure identical vertical profiles.

Reliability Testing and Qualification Standards

Reliability testing and qualification standards are crucial aspects of developing PNP transistors for aerospace applications. These processes ensure that the components can withstand the harsh conditions encountered in space and aviation environments. The aerospace industry adheres to stringent standards set by organizations such as NASA, ESA, and military agencies to guarantee the performance and longevity of electronic components.

One of the primary reliability tests for PNP transistors in aerospace applications is thermal cycling. This test subjects the transistors to extreme temperature variations, simulating the conditions experienced during orbital transitions or high-altitude flights. Typically, the temperature range spans from -55°C to +125°C, with hundreds or even thousands of cycles performed to assess the component's resilience to thermal stress.

Radiation hardness testing is another critical aspect of qualification for aerospace PNP transistors. These tests evaluate the transistor's ability to function correctly when exposed to various types of radiation, including gamma rays, protons, and heavy ions. Total Ionizing Dose (TID) tests measure the cumulative effects of radiation exposure over time, while Single Event Effects (SEE) tests assess the transistor's susceptibility to sudden radiation-induced malfunctions.

Vibration and shock testing are essential to ensure that PNP transistors can withstand the mechanical stresses encountered during launch and in-flight operations. These tests involve subjecting the components to high-frequency vibrations and sudden impacts, simulating the forces experienced during rocket launches or turbulent atmospheric conditions.

Hermetic seal testing is crucial for aerospace-grade PNP transistors, as it verifies the integrity of the component's packaging. This test ensures that the transistor remains protected from moisture, contaminants, and other environmental factors that could compromise its performance or reliability.

Long-term reliability testing, such as High-Temperature Operating Life (HTOL) tests, evaluates the transistor's performance over extended periods under elevated temperatures and electrical stress. These tests help predict the component's lifespan and identify potential failure modes that may occur during prolonged operation in aerospace environments.

Qualification standards for aerospace PNP transistors often include specific requirements for electrical performance, such as gain stability, leakage current, and switching speed, under various environmental conditions. These parameters must be consistently met throughout the qualification process to ensure the transistor's suitability for aerospace applications.

Documentation and traceability are integral parts of the qualification process. Manufacturers must maintain detailed records of all testing procedures, results, and any modifications made during the development and production of aerospace-grade PNP transistors. This documentation is essential for regulatory compliance and facilitates future improvements or troubleshooting efforts.

One of the primary reliability tests for PNP transistors in aerospace applications is thermal cycling. This test subjects the transistors to extreme temperature variations, simulating the conditions experienced during orbital transitions or high-altitude flights. Typically, the temperature range spans from -55°C to +125°C, with hundreds or even thousands of cycles performed to assess the component's resilience to thermal stress.

Radiation hardness testing is another critical aspect of qualification for aerospace PNP transistors. These tests evaluate the transistor's ability to function correctly when exposed to various types of radiation, including gamma rays, protons, and heavy ions. Total Ionizing Dose (TID) tests measure the cumulative effects of radiation exposure over time, while Single Event Effects (SEE) tests assess the transistor's susceptibility to sudden radiation-induced malfunctions.

Vibration and shock testing are essential to ensure that PNP transistors can withstand the mechanical stresses encountered during launch and in-flight operations. These tests involve subjecting the components to high-frequency vibrations and sudden impacts, simulating the forces experienced during rocket launches or turbulent atmospheric conditions.

Hermetic seal testing is crucial for aerospace-grade PNP transistors, as it verifies the integrity of the component's packaging. This test ensures that the transistor remains protected from moisture, contaminants, and other environmental factors that could compromise its performance or reliability.

Long-term reliability testing, such as High-Temperature Operating Life (HTOL) tests, evaluates the transistor's performance over extended periods under elevated temperatures and electrical stress. These tests help predict the component's lifespan and identify potential failure modes that may occur during prolonged operation in aerospace environments.

Qualification standards for aerospace PNP transistors often include specific requirements for electrical performance, such as gain stability, leakage current, and switching speed, under various environmental conditions. These parameters must be consistently met throughout the qualification process to ensure the transistor's suitability for aerospace applications.

Documentation and traceability are integral parts of the qualification process. Manufacturers must maintain detailed records of all testing procedures, results, and any modifications made during the development and production of aerospace-grade PNP transistors. This documentation is essential for regulatory compliance and facilitates future improvements or troubleshooting efforts.

Environmental Impact of Aerospace Electronics Manufacturing

The aerospace industry's electronics manufacturing processes have significant environmental implications, particularly in the production of PNP transistors for aerospace applications. These components, crucial for various aerospace systems, require specialized manufacturing techniques that often involve the use of hazardous materials and energy-intensive processes.

The production of PNP transistors typically involves the use of semiconductor materials, such as silicon or germanium, which are doped with specific impurities to create the desired electrical properties. This process often requires the use of toxic chemicals, including arsenic, phosphorus, and boron compounds. The handling and disposal of these materials pose potential risks to the environment if not managed properly.

Furthermore, the manufacturing of aerospace-grade PNP transistors demands stringent quality control measures and clean room environments. Maintaining these conditions requires substantial energy consumption, contributing to increased carbon emissions. The need for ultra-pure water in the manufacturing process also raises concerns about water usage and potential contamination of local water sources.

The etching and cleaning processes used in transistor production often involve the use of strong acids and solvents. These chemicals, if not properly treated or disposed of, can lead to soil and water pollution. Additionally, the production of specialized packaging materials for aerospace-grade transistors may involve the use of plastics and metals that have their own environmental footprint.

As the aerospace industry continues to grow and demand for high-performance electronics increases, the environmental impact of manufacturing these components becomes more pronounced. This has led to increased scrutiny and efforts to develop more sustainable manufacturing practices within the industry.

In response to these environmental concerns, many aerospace electronics manufacturers are exploring innovative approaches to reduce their ecological footprint. These include the development of more efficient manufacturing processes, the use of less toxic materials, and the implementation of advanced waste treatment and recycling systems.

Some companies are investing in research to develop alternative materials and manufacturing techniques that could potentially reduce the environmental impact of PNP transistor production. For instance, the exploration of organic semiconductors and the use of 3D printing technologies for certain components show promise in reducing both material waste and energy consumption.

The aerospace industry is also increasingly adopting lifecycle assessment approaches to evaluate and mitigate the environmental impact of their products, including electronic components like PNP transistors. This holistic view considers the environmental effects from raw material extraction through manufacturing, use, and eventual disposal or recycling of the components.

The production of PNP transistors typically involves the use of semiconductor materials, such as silicon or germanium, which are doped with specific impurities to create the desired electrical properties. This process often requires the use of toxic chemicals, including arsenic, phosphorus, and boron compounds. The handling and disposal of these materials pose potential risks to the environment if not managed properly.

Furthermore, the manufacturing of aerospace-grade PNP transistors demands stringent quality control measures and clean room environments. Maintaining these conditions requires substantial energy consumption, contributing to increased carbon emissions. The need for ultra-pure water in the manufacturing process also raises concerns about water usage and potential contamination of local water sources.

The etching and cleaning processes used in transistor production often involve the use of strong acids and solvents. These chemicals, if not properly treated or disposed of, can lead to soil and water pollution. Additionally, the production of specialized packaging materials for aerospace-grade transistors may involve the use of plastics and metals that have their own environmental footprint.

As the aerospace industry continues to grow and demand for high-performance electronics increases, the environmental impact of manufacturing these components becomes more pronounced. This has led to increased scrutiny and efforts to develop more sustainable manufacturing practices within the industry.

In response to these environmental concerns, many aerospace electronics manufacturers are exploring innovative approaches to reduce their ecological footprint. These include the development of more efficient manufacturing processes, the use of less toxic materials, and the implementation of advanced waste treatment and recycling systems.

Some companies are investing in research to develop alternative materials and manufacturing techniques that could potentially reduce the environmental impact of PNP transistor production. For instance, the exploration of organic semiconductors and the use of 3D printing technologies for certain components show promise in reducing both material waste and energy consumption.

The aerospace industry is also increasingly adopting lifecycle assessment approaches to evaluate and mitigate the environmental impact of their products, including electronic components like PNP transistors. This holistic view considers the environmental effects from raw material extraction through manufacturing, use, and eventual disposal or recycling of the components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!