PNP Transistors in Precision Instrumentation: Enhancing Accuracy

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PNP Transistor Evolution

The evolution of PNP transistors in precision instrumentation has been a journey of continuous refinement and innovation. Initially developed in the early 1950s, PNP transistors quickly found their place in analog circuits due to their ability to control current flow with high precision.

In the 1960s and 1970s, the focus shifted towards improving the manufacturing processes of PNP transistors. This era saw the introduction of epitaxial growth techniques, which allowed for better control of impurity concentrations and junction depths. These advancements led to PNP transistors with higher gain, lower noise, and improved temperature stability, making them increasingly suitable for precision instrumentation applications.

The 1980s marked a significant milestone in PNP transistor evolution with the development of complementary bipolar processes. This technology enabled the integration of high-performance PNP and NPN transistors on the same chip, paving the way for more complex and accurate analog circuits. The improved matching between PNP and NPN devices resulted in better offset voltage and temperature drift characteristics, crucial for precision instrumentation.

Throughout the 1990s and early 2000s, efforts were directed towards reducing parasitic capacitances and improving frequency response. The introduction of self-aligned structures and advanced isolation techniques, such as trench isolation, significantly enhanced the high-frequency performance of PNP transistors. These improvements expanded their use in high-speed precision measurement systems and data acquisition devices.

In recent years, the evolution of PNP transistors has focused on addressing the challenges posed by shrinking device geometries. Advanced lithography techniques and novel materials have been employed to maintain and improve device characteristics at smaller scales. This has led to the development of PNP transistors with lower noise, higher linearity, and better matching properties, further enhancing their suitability for precision instrumentation.

The advent of silicon-germanium (SiGe) technology has brought about a new era in PNP transistor performance. SiGe PNP transistors offer significantly higher current gain, lower noise, and improved high-frequency characteristics compared to their silicon counterparts. This breakthrough has enabled the design of precision instrumentation with unprecedented accuracy and bandwidth.

Looking ahead, the evolution of PNP transistors in precision instrumentation is likely to continue along several paths. Research is ongoing in the areas of advanced materials, such as III-V semiconductors, which promise even higher performance. Additionally, the integration of PNP transistors with other technologies, such as MEMS sensors and advanced packaging techniques, is expected to lead to more compact and capable precision measurement systems.

In the 1960s and 1970s, the focus shifted towards improving the manufacturing processes of PNP transistors. This era saw the introduction of epitaxial growth techniques, which allowed for better control of impurity concentrations and junction depths. These advancements led to PNP transistors with higher gain, lower noise, and improved temperature stability, making them increasingly suitable for precision instrumentation applications.

The 1980s marked a significant milestone in PNP transistor evolution with the development of complementary bipolar processes. This technology enabled the integration of high-performance PNP and NPN transistors on the same chip, paving the way for more complex and accurate analog circuits. The improved matching between PNP and NPN devices resulted in better offset voltage and temperature drift characteristics, crucial for precision instrumentation.

Throughout the 1990s and early 2000s, efforts were directed towards reducing parasitic capacitances and improving frequency response. The introduction of self-aligned structures and advanced isolation techniques, such as trench isolation, significantly enhanced the high-frequency performance of PNP transistors. These improvements expanded their use in high-speed precision measurement systems and data acquisition devices.

In recent years, the evolution of PNP transistors has focused on addressing the challenges posed by shrinking device geometries. Advanced lithography techniques and novel materials have been employed to maintain and improve device characteristics at smaller scales. This has led to the development of PNP transistors with lower noise, higher linearity, and better matching properties, further enhancing their suitability for precision instrumentation.

The advent of silicon-germanium (SiGe) technology has brought about a new era in PNP transistor performance. SiGe PNP transistors offer significantly higher current gain, lower noise, and improved high-frequency characteristics compared to their silicon counterparts. This breakthrough has enabled the design of precision instrumentation with unprecedented accuracy and bandwidth.

Looking ahead, the evolution of PNP transistors in precision instrumentation is likely to continue along several paths. Research is ongoing in the areas of advanced materials, such as III-V semiconductors, which promise even higher performance. Additionally, the integration of PNP transistors with other technologies, such as MEMS sensors and advanced packaging techniques, is expected to lead to more compact and capable precision measurement systems.

Precision Instrumentation Market Analysis

The precision instrumentation market has been experiencing significant growth in recent years, driven by increasing demand for high-accuracy measurement and control systems across various industries. This market segment encompasses a wide range of devices and equipment, including oscilloscopes, multimeters, signal generators, and data acquisition systems, all of which rely heavily on precise electronic components such as PNP transistors.

The global precision instrumentation market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily fueled by advancements in technology, particularly in the fields of semiconductors and microelectronics, which have enabled the development of more accurate and reliable instrumentation devices.

Key industries driving the demand for precision instrumentation include aerospace and defense, automotive, healthcare, and telecommunications. In the aerospace and defense sector, there is a growing need for highly accurate measurement tools for testing and calibration of critical systems. The automotive industry requires precision instruments for engine diagnostics, emissions testing, and quality control in manufacturing processes. In healthcare, precise measurements are crucial for medical imaging, patient monitoring, and laboratory equipment. The telecommunications sector relies on precision instruments for network testing and optimization.

The market for precision instrumentation is characterized by intense competition among established players and new entrants. Major companies in this space are continuously investing in research and development to enhance the accuracy and reliability of their products. The integration of PNP transistors in precision instrumentation has become a focal point for many manufacturers, as these components play a crucial role in improving the overall accuracy of measurement devices.

Geographically, North America and Europe have traditionally been the largest markets for precision instrumentation, owing to their well-established industrial bases and high adoption rates of advanced technologies. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, infrastructure development, and technological advancements in countries like China, Japan, and South Korea.

The trend towards Industry 4.0 and the Internet of Things (IoT) is expected to further boost the demand for precision instrumentation. As manufacturing processes become more automated and interconnected, the need for highly accurate sensors and measurement devices will continue to grow. This trend is likely to create new opportunities for innovations in PNP transistor technology, as manufacturers strive to develop more precise and reliable instrumentation solutions.

The global precision instrumentation market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily fueled by advancements in technology, particularly in the fields of semiconductors and microelectronics, which have enabled the development of more accurate and reliable instrumentation devices.

Key industries driving the demand for precision instrumentation include aerospace and defense, automotive, healthcare, and telecommunications. In the aerospace and defense sector, there is a growing need for highly accurate measurement tools for testing and calibration of critical systems. The automotive industry requires precision instruments for engine diagnostics, emissions testing, and quality control in manufacturing processes. In healthcare, precise measurements are crucial for medical imaging, patient monitoring, and laboratory equipment. The telecommunications sector relies on precision instruments for network testing and optimization.

The market for precision instrumentation is characterized by intense competition among established players and new entrants. Major companies in this space are continuously investing in research and development to enhance the accuracy and reliability of their products. The integration of PNP transistors in precision instrumentation has become a focal point for many manufacturers, as these components play a crucial role in improving the overall accuracy of measurement devices.

Geographically, North America and Europe have traditionally been the largest markets for precision instrumentation, owing to their well-established industrial bases and high adoption rates of advanced technologies. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, infrastructure development, and technological advancements in countries like China, Japan, and South Korea.

The trend towards Industry 4.0 and the Internet of Things (IoT) is expected to further boost the demand for precision instrumentation. As manufacturing processes become more automated and interconnected, the need for highly accurate sensors and measurement devices will continue to grow. This trend is likely to create new opportunities for innovations in PNP transistor technology, as manufacturers strive to develop more precise and reliable instrumentation solutions.

PNP Transistor Challenges

PNP transistors, while essential in precision instrumentation, face several significant challenges that impact their performance and reliability. One of the primary issues is their inherent sensitivity to temperature variations. As ambient temperature fluctuates, the transistor's characteristics can change, leading to drift in critical parameters such as current gain and base-emitter voltage. This temperature dependence can result in measurement inaccuracies, especially in applications requiring high precision over extended periods or in environments with varying thermal conditions.

Another challenge lies in the device's noise characteristics. PNP transistors typically exhibit higher noise levels compared to their NPN counterparts, particularly at low frequencies. This increased noise can manifest as 1/f noise or flicker noise, which becomes more pronounced in low-frequency applications. The presence of excess noise can significantly degrade the signal-to-noise ratio in sensitive measurement circuits, limiting the overall accuracy and resolution of the instrumentation system.

Matching issues between PNP transistors also present a considerable challenge in precision applications. Even transistors from the same manufacturing batch can exhibit slight variations in their electrical characteristics. These mismatches can lead to offset errors and gain imbalances in differential amplifier configurations, which are common in precision instrumentation. Achieving tight matching between PNP devices often requires careful selection and pairing processes, adding complexity and cost to the manufacturing process.

The frequency response of PNP transistors is another area of concern. Generally, PNP transistors have lower bandwidth compared to NPN types due to their slower carrier mobility. This limitation can restrict their use in high-frequency precision applications, where rapid signal processing is crucial. The reduced frequency response can lead to signal distortion and phase shifts, compromising the accuracy of measurements in dynamic systems.

Leakage currents pose yet another challenge in PNP transistor applications. These unwanted currents, which flow even when the transistor is supposed to be in the off state, can introduce errors in low-level current measurements. In precision instrumentation, where detecting and measuring minute signals is often required, even small leakage currents can significantly impact the accuracy and reliability of the measurements.

Lastly, the base-emitter voltage (VBE) of PNP transistors exhibits a logarithmic dependence on collector current, known as the Early effect. This non-linear behavior can introduce distortion in analog circuits, particularly in applications requiring high linearity. Compensating for this effect often requires additional circuitry or sophisticated design techniques, adding to the complexity of precision instrument design.

Another challenge lies in the device's noise characteristics. PNP transistors typically exhibit higher noise levels compared to their NPN counterparts, particularly at low frequencies. This increased noise can manifest as 1/f noise or flicker noise, which becomes more pronounced in low-frequency applications. The presence of excess noise can significantly degrade the signal-to-noise ratio in sensitive measurement circuits, limiting the overall accuracy and resolution of the instrumentation system.

Matching issues between PNP transistors also present a considerable challenge in precision applications. Even transistors from the same manufacturing batch can exhibit slight variations in their electrical characteristics. These mismatches can lead to offset errors and gain imbalances in differential amplifier configurations, which are common in precision instrumentation. Achieving tight matching between PNP devices often requires careful selection and pairing processes, adding complexity and cost to the manufacturing process.

The frequency response of PNP transistors is another area of concern. Generally, PNP transistors have lower bandwidth compared to NPN types due to their slower carrier mobility. This limitation can restrict their use in high-frequency precision applications, where rapid signal processing is crucial. The reduced frequency response can lead to signal distortion and phase shifts, compromising the accuracy of measurements in dynamic systems.

Leakage currents pose yet another challenge in PNP transistor applications. These unwanted currents, which flow even when the transistor is supposed to be in the off state, can introduce errors in low-level current measurements. In precision instrumentation, where detecting and measuring minute signals is often required, even small leakage currents can significantly impact the accuracy and reliability of the measurements.

Lastly, the base-emitter voltage (VBE) of PNP transistors exhibits a logarithmic dependence on collector current, known as the Early effect. This non-linear behavior can introduce distortion in analog circuits, particularly in applications requiring high linearity. Compensating for this effect often requires additional circuitry or sophisticated design techniques, adding to the complexity of precision instrument design.

Current PNP Transistor Designs

01 Improved PNP transistor structure

Advancements in PNP transistor design focus on enhancing accuracy through structural modifications. These improvements include optimized base-emitter regions, refined doping profiles, and innovative fabrication techniques to reduce parasitic effects and improve overall performance.- Improved PNP transistor structure: Advancements in PNP transistor design focus on enhancing accuracy through structural modifications. These improvements include optimized base-emitter regions, refined doping profiles, and innovative fabrication techniques to reduce parasitic effects and improve overall performance.

- Precision current mirror circuits: Implementing precision current mirror circuits using PNP transistors can significantly improve accuracy in analog applications. These circuits utilize matched PNP transistors to provide stable and accurate current ratios, enhancing the overall performance of analog systems.

- Temperature compensation techniques: Various temperature compensation techniques are employed to maintain PNP transistor accuracy across a wide range of operating temperatures. These methods include the use of bandgap reference circuits, thermal feedback loops, and specialized biasing schemes to minimize temperature-induced variations.

- Fabrication process optimization: Improving PNP transistor accuracy through optimized fabrication processes involves refining epitaxial growth techniques, enhancing ion implantation methods, and developing advanced annealing procedures. These process improvements result in more consistent and precise transistor characteristics.

- Integrated circuit design considerations: Enhancing PNP transistor accuracy in integrated circuits requires careful consideration of layout techniques, parasitic element minimization, and optimal device sizing. Advanced circuit design methodologies and simulation tools are utilized to achieve high-precision PNP transistor performance in complex IC environments.

02 Temperature compensation techniques

Various methods are employed to compensate for temperature-induced variations in PNP transistor performance. These techniques involve the use of temperature-sensitive components, feedback circuits, and specialized biasing schemes to maintain consistent operation across a wide temperature range, thereby improving accuracy.Expand Specific Solutions03 Precision current mirror configurations

Implementing precise current mirror configurations using PNP transistors enhances accuracy in analog circuits. These designs focus on matching transistor characteristics, minimizing offset voltages, and reducing the effects of process variations to achieve highly accurate current replication.Expand Specific Solutions04 Noise reduction techniques

Various approaches are developed to minimize noise in PNP transistors, improving their accuracy in low-level signal applications. These techniques include optimized layout designs, advanced isolation methods, and specialized biasing schemes to reduce both thermal and flicker noise contributions.Expand Specific Solutions05 Calibration and trimming methods

Calibration and trimming techniques are employed to enhance PNP transistor accuracy post-fabrication. These methods involve adjusting device parameters through laser trimming, digital calibration, or on-chip compensation circuits to minimize manufacturing variations and achieve higher precision in critical applications.Expand Specific Solutions

Key Semiconductor Manufacturers

The PNP transistor market in precision instrumentation is in a mature stage, characterized by steady growth and established players. The market size is substantial, driven by increasing demand for high-accuracy measurement devices across various industries. Technologically, PNP transistors for precision applications have reached a high level of sophistication, with companies like Texas Instruments, Infineon Technologies, and STMicroelectronics leading innovation. These firms, along with others such as QUALCOMM and GlobalFoundries, are continuously improving transistor performance, focusing on enhancing accuracy, reducing noise, and increasing temperature stability. The competitive landscape is intense, with both specialized semiconductor manufacturers and diversified technology conglomerates vying for market share through product differentiation and technological advancements.

Infineon Technologies AG

Technical Solution: Infineon Technologies has made significant strides in PNP transistor technology for precision instrumentation. Their approach focuses on developing high-performance, low-noise PNP transistors with excellent linearity and temperature stability. Infineon's PNP transistors for precision applications feature ultra-low 1/f noise, typically below 1 nV/√Hz at 1 kHz [2], crucial for accurate low-frequency measurements. They have implemented advanced silicon-germanium (SiGe) processes to achieve higher current gain and improved frequency response, with some models offering transition frequencies exceeding 5 GHz [4]. Infineon has also developed proprietary surface passivation techniques to enhance long-term stability and reliability, critical for precision instrumentation in harsh environments [6].

Strengths: Excellent noise performance, high-frequency capability, and robust design for harsh environments. Weaknesses: Potentially higher production costs and limited availability in some package options.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced PNP transistors for precision instrumentation, focusing on enhancing accuracy in analog circuits. Their approach includes implementing low-noise, high-gain PNP transistors with improved current gain and frequency response. TI's precision PNP transistors feature reduced base-emitter voltage temperature coefficients, typically less than 1 μV/°C [1], which significantly improves measurement accuracy across varying temperatures. They have also introduced innovative packaging techniques to minimize thermal gradients and reduce offset voltages, crucial for high-precision applications [3]. TI's PNP transistors incorporate advanced epitaxial processes to achieve better matching and lower noise characteristics, essential for instrumentation amplifiers and other precision analog circuits [5].

Strengths: Superior temperature stability, excellent noise performance, and high gain. Weaknesses: Potentially higher cost compared to standard transistors, and may require specialized design considerations for optimal performance.

Innovative PNP Architectures

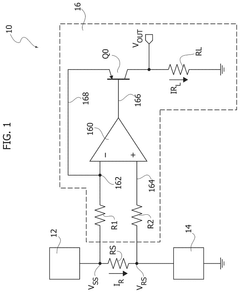

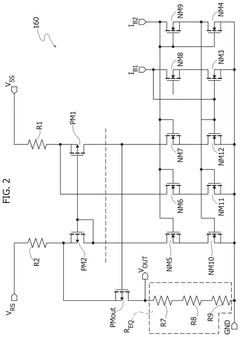

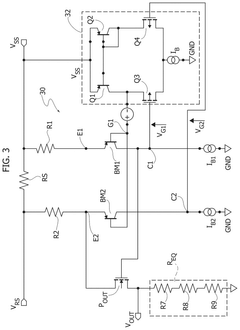

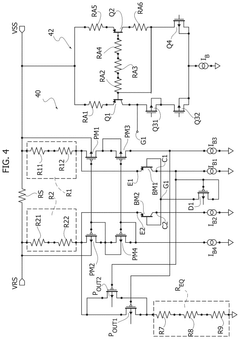

Current sensing circuits and method

PatentPendingUS20250208175A1

Innovation

- The introduction of an auxiliary amplification circuit with a pair of pnp BJT transistors and an auxiliary amplifier, coupled with a common control node, compensates for beta errors and maintains consistent voltage levels across the transistors, enhancing accuracy and speed while supporting wide common-mode voltage ranges.

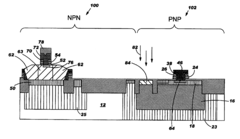

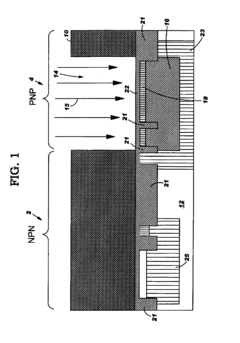

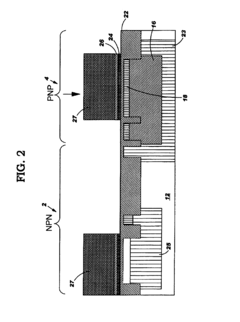

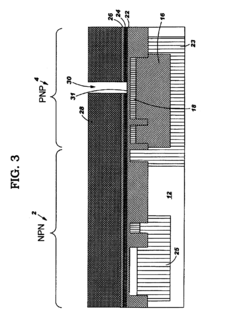

High performance vertical PNP transistor and method

PatentInactiveUS6909164B2

Innovation

- A method for fabricating high-performance vertical PNP transistors by incorporating an emitter region with silicon and germanium, sharing a single layer of silicon with the NPN transistor's base, and adding two additional masking steps to conventional CMOS and bipolar device fabrication processes, which enhances PNP device performance.

Noise Reduction Techniques

Noise reduction techniques play a crucial role in enhancing the accuracy of PNP transistors in precision instrumentation. These techniques aim to minimize unwanted electrical disturbances that can compromise the performance of sensitive measurement devices. One of the primary methods employed is shielding, which involves encasing the transistor and associated circuitry in a conductive material to block external electromagnetic interference. This approach is particularly effective in reducing high-frequency noise from nearby electronic equipment or power sources.

Another important technique is proper grounding, which helps to establish a stable reference point for the circuit and prevent ground loops. By implementing a single-point grounding system and using low-impedance connections, designers can significantly reduce noise induced by ground potential differences. Additionally, the use of bypass capacitors strategically placed near power supply pins helps to filter out high-frequency noise on the power rails, ensuring a cleaner supply voltage for the transistor.

Differential signaling is another powerful noise reduction strategy. By using two complementary signals to transmit information, common-mode noise can be effectively cancelled out at the receiver end. This technique is particularly useful in environments with high electromagnetic interference or when dealing with long signal paths. In the context of PNP transistors, implementing differential pairs can greatly improve noise immunity and signal integrity.

Careful component selection and layout design also contribute significantly to noise reduction. Using low-noise PNP transistors specifically designed for precision applications is essential. These transistors often feature optimized internal structures and materials that minimize inherent noise generation. Furthermore, proper PCB layout techniques, such as separating analog and digital grounds, using guard rings around sensitive components, and minimizing trace lengths, can help reduce noise coupling and improve overall circuit performance.

Advanced filtering techniques, such as active low-pass filters or notch filters, can be employed to attenuate specific frequency bands of noise. These filters can be tailored to target known noise sources or to limit the bandwidth of the signal to only the frequencies of interest, thereby improving the signal-to-noise ratio. In some cases, chopper stabilization techniques may be used to modulate the input signal to a higher frequency, where 1/f noise is less prominent, before demodulating it back to the original frequency band.

Lastly, thermal management plays a crucial role in noise reduction for PNP transistors in precision instrumentation. Temperature fluctuations can lead to changes in transistor characteristics and introduce thermal noise. Implementing proper heat sinking, using temperature-compensated designs, and ensuring stable operating temperatures can significantly reduce thermally induced noise and drift, thereby enhancing the overall accuracy of the instrumentation system.

Another important technique is proper grounding, which helps to establish a stable reference point for the circuit and prevent ground loops. By implementing a single-point grounding system and using low-impedance connections, designers can significantly reduce noise induced by ground potential differences. Additionally, the use of bypass capacitors strategically placed near power supply pins helps to filter out high-frequency noise on the power rails, ensuring a cleaner supply voltage for the transistor.

Differential signaling is another powerful noise reduction strategy. By using two complementary signals to transmit information, common-mode noise can be effectively cancelled out at the receiver end. This technique is particularly useful in environments with high electromagnetic interference or when dealing with long signal paths. In the context of PNP transistors, implementing differential pairs can greatly improve noise immunity and signal integrity.

Careful component selection and layout design also contribute significantly to noise reduction. Using low-noise PNP transistors specifically designed for precision applications is essential. These transistors often feature optimized internal structures and materials that minimize inherent noise generation. Furthermore, proper PCB layout techniques, such as separating analog and digital grounds, using guard rings around sensitive components, and minimizing trace lengths, can help reduce noise coupling and improve overall circuit performance.

Advanced filtering techniques, such as active low-pass filters or notch filters, can be employed to attenuate specific frequency bands of noise. These filters can be tailored to target known noise sources or to limit the bandwidth of the signal to only the frequencies of interest, thereby improving the signal-to-noise ratio. In some cases, chopper stabilization techniques may be used to modulate the input signal to a higher frequency, where 1/f noise is less prominent, before demodulating it back to the original frequency band.

Lastly, thermal management plays a crucial role in noise reduction for PNP transistors in precision instrumentation. Temperature fluctuations can lead to changes in transistor characteristics and introduce thermal noise. Implementing proper heat sinking, using temperature-compensated designs, and ensuring stable operating temperatures can significantly reduce thermally induced noise and drift, thereby enhancing the overall accuracy of the instrumentation system.

Temperature Compensation Strategies

Temperature compensation is a critical aspect of enhancing accuracy in precision instrumentation using PNP transistors. As these devices are inherently sensitive to temperature variations, implementing effective compensation strategies is essential to maintain consistent performance across a wide range of operating conditions.

One of the primary temperature compensation techniques involves the use of thermistors or temperature-sensitive resistors. These components are strategically placed in close proximity to the PNP transistor to detect temperature changes. By incorporating thermistors into the circuit design, engineers can create a feedback loop that adjusts the bias voltage or current of the transistor in response to temperature fluctuations. This approach helps to maintain stable operating characteristics and minimize temperature-induced errors.

Another widely adopted strategy is the implementation of differential amplifier configurations. By utilizing matched pairs of PNP transistors in a differential setup, common-mode temperature variations can be effectively cancelled out. This technique relies on the principle that both transistors in the pair will experience similar temperature changes, allowing the differential output to remain relatively stable. Careful layout and thermal management considerations are crucial to ensure optimal matching and thermal coupling between the transistor pairs.

Advanced temperature compensation methods often incorporate on-chip temperature sensors and digital calibration techniques. These approaches involve integrating temperature-sensing elements directly onto the semiconductor die, allowing for precise monitoring of the transistor's operating temperature. The sensor data is then processed by digital circuitry, which applies pre-programmed compensation algorithms to adjust the transistor's operating parameters in real-time. This dynamic compensation method offers superior accuracy and adaptability across a wide temperature range.

Bandgap reference circuits represent another important temperature compensation strategy in precision instrumentation. These circuits exploit the complementary temperature characteristics of base-emitter voltage and thermal voltage in bipolar transistors to generate a stable reference voltage that is largely independent of temperature variations. By utilizing this temperature-stable reference, the overall circuit can maintain consistent performance across different operating conditions.

In some applications, chopper stabilization techniques are employed to mitigate temperature-induced offset voltages. This method involves periodically switching the input signal polarity and demodulating the output, effectively cancelling out low-frequency noise and drift caused by temperature variations. While primarily used for offset reduction, chopper stabilization can indirectly contribute to improved temperature stability in PNP transistor-based precision instrumentation.

Implementing these temperature compensation strategies requires careful consideration of circuit design, component selection, and layout techniques. Engineers must balance the complexity and cost of compensation methods against the required level of accuracy for the specific application. As precision instrumentation continues to evolve, ongoing research and development in temperature compensation techniques will play a crucial role in pushing the boundaries of accuracy and reliability in PNP transistor-based systems.

One of the primary temperature compensation techniques involves the use of thermistors or temperature-sensitive resistors. These components are strategically placed in close proximity to the PNP transistor to detect temperature changes. By incorporating thermistors into the circuit design, engineers can create a feedback loop that adjusts the bias voltage or current of the transistor in response to temperature fluctuations. This approach helps to maintain stable operating characteristics and minimize temperature-induced errors.

Another widely adopted strategy is the implementation of differential amplifier configurations. By utilizing matched pairs of PNP transistors in a differential setup, common-mode temperature variations can be effectively cancelled out. This technique relies on the principle that both transistors in the pair will experience similar temperature changes, allowing the differential output to remain relatively stable. Careful layout and thermal management considerations are crucial to ensure optimal matching and thermal coupling between the transistor pairs.

Advanced temperature compensation methods often incorporate on-chip temperature sensors and digital calibration techniques. These approaches involve integrating temperature-sensing elements directly onto the semiconductor die, allowing for precise monitoring of the transistor's operating temperature. The sensor data is then processed by digital circuitry, which applies pre-programmed compensation algorithms to adjust the transistor's operating parameters in real-time. This dynamic compensation method offers superior accuracy and adaptability across a wide temperature range.

Bandgap reference circuits represent another important temperature compensation strategy in precision instrumentation. These circuits exploit the complementary temperature characteristics of base-emitter voltage and thermal voltage in bipolar transistors to generate a stable reference voltage that is largely independent of temperature variations. By utilizing this temperature-stable reference, the overall circuit can maintain consistent performance across different operating conditions.

In some applications, chopper stabilization techniques are employed to mitigate temperature-induced offset voltages. This method involves periodically switching the input signal polarity and demodulating the output, effectively cancelling out low-frequency noise and drift caused by temperature variations. While primarily used for offset reduction, chopper stabilization can indirectly contribute to improved temperature stability in PNP transistor-based precision instrumentation.

Implementing these temperature compensation strategies requires careful consideration of circuit design, component selection, and layout techniques. Engineers must balance the complexity and cost of compensation methods against the required level of accuracy for the specific application. As precision instrumentation continues to evolve, ongoing research and development in temperature compensation techniques will play a crucial role in pushing the boundaries of accuracy and reliability in PNP transistor-based systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!