How to Minimize Heat Dissipation in PNP Transistor Circuits?

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PNP Transistor Heat Dissipation Background and Objectives

PNP transistors have been a fundamental component in electronic circuits since their inception in the mid-20th century. These devices, along with their NPN counterparts, form the backbone of many analog and digital circuits. However, as electronic devices become increasingly compact and powerful, heat dissipation has emerged as a critical challenge in PNP transistor circuits. This issue has gained prominence due to the growing demand for high-performance, energy-efficient electronics in various applications, from consumer gadgets to industrial equipment.

The evolution of PNP transistor technology has been marked by continuous improvements in performance and efficiency. Early PNP transistors were primarily made of germanium, which had limitations in terms of heat tolerance and switching speed. The transition to silicon-based transistors in the 1960s brought about significant advancements in thermal stability and overall performance. Despite these improvements, heat dissipation remains a persistent concern, especially as circuit densities increase and power requirements become more demanding.

In recent years, the focus on minimizing heat dissipation in PNP transistor circuits has intensified due to several factors. The proliferation of portable electronic devices has driven the need for more efficient power management and longer battery life. Additionally, the rise of Internet of Things (IoT) devices and wearable technology has further emphasized the importance of thermal management in compact, low-power circuits. These trends have pushed researchers and engineers to explore innovative solutions for heat reduction in PNP transistor designs.

The primary objective of minimizing heat dissipation in PNP transistor circuits is to enhance overall system performance and reliability. Excessive heat can lead to reduced efficiency, decreased lifespan of components, and potential system failures. By addressing this challenge, engineers aim to improve the power efficiency of electronic devices, extend their operational life, and enable the development of more compact and powerful systems.

To achieve these goals, researchers are exploring various approaches, including advanced materials science, novel circuit designs, and improved thermal management techniques. The development of new semiconductor materials with better thermal properties is one avenue being pursued. Additionally, innovative circuit topologies that optimize current flow and reduce power consumption are being investigated. Thermal management solutions, such as advanced heat sinks and active cooling systems, are also being integrated into circuit designs to mitigate heat-related issues.

As we delve deeper into this technical challenge, it is crucial to understand the underlying physics of heat generation in PNP transistors, the current state of the art in heat dissipation techniques, and the potential future directions for research and development in this field. By addressing the heat dissipation issue, we can pave the way for more efficient, reliable, and compact electronic systems that will drive innovation across multiple industries.

The evolution of PNP transistor technology has been marked by continuous improvements in performance and efficiency. Early PNP transistors were primarily made of germanium, which had limitations in terms of heat tolerance and switching speed. The transition to silicon-based transistors in the 1960s brought about significant advancements in thermal stability and overall performance. Despite these improvements, heat dissipation remains a persistent concern, especially as circuit densities increase and power requirements become more demanding.

In recent years, the focus on minimizing heat dissipation in PNP transistor circuits has intensified due to several factors. The proliferation of portable electronic devices has driven the need for more efficient power management and longer battery life. Additionally, the rise of Internet of Things (IoT) devices and wearable technology has further emphasized the importance of thermal management in compact, low-power circuits. These trends have pushed researchers and engineers to explore innovative solutions for heat reduction in PNP transistor designs.

The primary objective of minimizing heat dissipation in PNP transistor circuits is to enhance overall system performance and reliability. Excessive heat can lead to reduced efficiency, decreased lifespan of components, and potential system failures. By addressing this challenge, engineers aim to improve the power efficiency of electronic devices, extend their operational life, and enable the development of more compact and powerful systems.

To achieve these goals, researchers are exploring various approaches, including advanced materials science, novel circuit designs, and improved thermal management techniques. The development of new semiconductor materials with better thermal properties is one avenue being pursued. Additionally, innovative circuit topologies that optimize current flow and reduce power consumption are being investigated. Thermal management solutions, such as advanced heat sinks and active cooling systems, are also being integrated into circuit designs to mitigate heat-related issues.

As we delve deeper into this technical challenge, it is crucial to understand the underlying physics of heat generation in PNP transistors, the current state of the art in heat dissipation techniques, and the potential future directions for research and development in this field. By addressing the heat dissipation issue, we can pave the way for more efficient, reliable, and compact electronic systems that will drive innovation across multiple industries.

Market Demand for Efficient PNP Transistor Circuits

The market demand for efficient PNP transistor circuits has been steadily growing across various industries, driven by the increasing need for energy-efficient and compact electronic devices. As power consumption and heat dissipation become critical factors in circuit design, the demand for PNP transistors with improved thermal management capabilities has surged.

In the consumer electronics sector, manufacturers are constantly seeking ways to enhance battery life and reduce device temperatures. This has led to a significant increase in the adoption of PNP transistors with minimized heat dissipation in smartphones, tablets, and wearable devices. The market for these efficient circuits is expected to expand further as consumers demand longer-lasting and cooler-running gadgets.

The automotive industry has also emerged as a major driver for efficient PNP transistor circuits. With the rise of electric and hybrid vehicles, there is a growing need for power management solutions that can handle high currents while maintaining low heat generation. This trend is pushing automotive manufacturers to invest in advanced PNP transistor technologies that offer superior thermal performance.

In the industrial automation sector, the demand for efficient PNP transistor circuits is being fueled by the need for more reliable and long-lasting control systems. Factory equipment and robotics require circuits that can operate continuously under varying load conditions without overheating. This has created a substantial market for heat-optimized PNP transistor solutions in industrial applications.

The telecommunications industry is another key market for efficient PNP transistor circuits. As 5G networks continue to expand, there is an increasing demand for high-frequency transistors that can operate with minimal heat generation. This is crucial for maintaining the reliability and performance of base stations and other network infrastructure components.

The aerospace and defense sectors are also showing significant interest in PNP transistors with improved thermal characteristics. These industries require electronic components that can withstand extreme conditions while maintaining optimal performance. The demand for efficient PNP transistor circuits in this sector is driven by the need for lightweight, reliable, and heat-resistant electronics in aircraft and military equipment.

As the Internet of Things (IoT) continues to proliferate, the market for efficient PNP transistor circuits is expanding into new areas. Smart home devices, industrial sensors, and connected appliances all benefit from reduced heat dissipation, leading to increased reliability and longer product lifespans. This trend is expected to drive further innovation in PNP transistor design and manufacturing.

Overall, the market demand for efficient PNP transistor circuits is robust and diverse, spanning multiple industries and applications. As energy efficiency and thermal management remain top priorities for electronic device manufacturers, the development of innovative solutions to minimize heat dissipation in PNP transistor circuits will continue to be a key focus area for semiconductor companies and research institutions.

In the consumer electronics sector, manufacturers are constantly seeking ways to enhance battery life and reduce device temperatures. This has led to a significant increase in the adoption of PNP transistors with minimized heat dissipation in smartphones, tablets, and wearable devices. The market for these efficient circuits is expected to expand further as consumers demand longer-lasting and cooler-running gadgets.

The automotive industry has also emerged as a major driver for efficient PNP transistor circuits. With the rise of electric and hybrid vehicles, there is a growing need for power management solutions that can handle high currents while maintaining low heat generation. This trend is pushing automotive manufacturers to invest in advanced PNP transistor technologies that offer superior thermal performance.

In the industrial automation sector, the demand for efficient PNP transistor circuits is being fueled by the need for more reliable and long-lasting control systems. Factory equipment and robotics require circuits that can operate continuously under varying load conditions without overheating. This has created a substantial market for heat-optimized PNP transistor solutions in industrial applications.

The telecommunications industry is another key market for efficient PNP transistor circuits. As 5G networks continue to expand, there is an increasing demand for high-frequency transistors that can operate with minimal heat generation. This is crucial for maintaining the reliability and performance of base stations and other network infrastructure components.

The aerospace and defense sectors are also showing significant interest in PNP transistors with improved thermal characteristics. These industries require electronic components that can withstand extreme conditions while maintaining optimal performance. The demand for efficient PNP transistor circuits in this sector is driven by the need for lightweight, reliable, and heat-resistant electronics in aircraft and military equipment.

As the Internet of Things (IoT) continues to proliferate, the market for efficient PNP transistor circuits is expanding into new areas. Smart home devices, industrial sensors, and connected appliances all benefit from reduced heat dissipation, leading to increased reliability and longer product lifespans. This trend is expected to drive further innovation in PNP transistor design and manufacturing.

Overall, the market demand for efficient PNP transistor circuits is robust and diverse, spanning multiple industries and applications. As energy efficiency and thermal management remain top priorities for electronic device manufacturers, the development of innovative solutions to minimize heat dissipation in PNP transistor circuits will continue to be a key focus area for semiconductor companies and research institutions.

Current Challenges in PNP Transistor Heat Management

PNP transistor circuits face significant challenges in heat management, primarily due to the inherent characteristics of these semiconductor devices. As current flows through the transistor, power dissipation occurs, leading to temperature increases that can adversely affect performance and reliability. One of the main challenges is the thermal runaway effect, where increased temperature leads to higher current flow, further exacerbating heat generation in a positive feedback loop.

The miniaturization trend in electronic devices compounds this issue, as smaller form factors limit the available surface area for heat dissipation. This constraint makes it increasingly difficult to implement traditional cooling solutions effectively. Additionally, the demand for higher power density in modern applications puts further strain on thermal management systems, requiring more sophisticated approaches to heat dissipation.

Another significant challenge is the variability in thermal characteristics among different PNP transistor models and manufacturers. This inconsistency makes it challenging to develop standardized heat management solutions that can be universally applied across various circuit designs. Engineers must often tailor their thermal management strategies to specific transistor types and circuit configurations, adding complexity to the design process.

The integration of PNP transistors in multi-layer printed circuit boards (PCBs) presents additional thermal management difficulties. Heat generated by these components can become trapped between layers, creating localized hot spots that are difficult to address through conventional cooling methods. This issue is particularly pronounced in high-density circuit designs where multiple heat-generating components are in close proximity.

Power efficiency is another critical concern in PNP transistor heat management. As circuits become more complex and energy-conscious, there is a growing need to minimize power losses that contribute to heat generation. Balancing performance requirements with thermal constraints often requires trade-offs that can impact overall system efficiency and functionality.

Environmental factors also play a role in the challenges of PNP transistor heat management. Variations in ambient temperature and humidity can significantly affect the thermal behavior of these devices, necessitating robust thermal management solutions that can adapt to changing operating conditions. This is especially crucial for applications in harsh or unpredictable environments.

Lastly, the cost and complexity of implementing advanced thermal management solutions pose significant challenges. While techniques such as active cooling systems or advanced thermal interface materials can effectively mitigate heat issues, they often come with increased production costs and design complexity. Striking a balance between thermal performance and economic viability remains a persistent challenge in PNP transistor circuit design.

The miniaturization trend in electronic devices compounds this issue, as smaller form factors limit the available surface area for heat dissipation. This constraint makes it increasingly difficult to implement traditional cooling solutions effectively. Additionally, the demand for higher power density in modern applications puts further strain on thermal management systems, requiring more sophisticated approaches to heat dissipation.

Another significant challenge is the variability in thermal characteristics among different PNP transistor models and manufacturers. This inconsistency makes it challenging to develop standardized heat management solutions that can be universally applied across various circuit designs. Engineers must often tailor their thermal management strategies to specific transistor types and circuit configurations, adding complexity to the design process.

The integration of PNP transistors in multi-layer printed circuit boards (PCBs) presents additional thermal management difficulties. Heat generated by these components can become trapped between layers, creating localized hot spots that are difficult to address through conventional cooling methods. This issue is particularly pronounced in high-density circuit designs where multiple heat-generating components are in close proximity.

Power efficiency is another critical concern in PNP transistor heat management. As circuits become more complex and energy-conscious, there is a growing need to minimize power losses that contribute to heat generation. Balancing performance requirements with thermal constraints often requires trade-offs that can impact overall system efficiency and functionality.

Environmental factors also play a role in the challenges of PNP transistor heat management. Variations in ambient temperature and humidity can significantly affect the thermal behavior of these devices, necessitating robust thermal management solutions that can adapt to changing operating conditions. This is especially crucial for applications in harsh or unpredictable environments.

Lastly, the cost and complexity of implementing advanced thermal management solutions pose significant challenges. While techniques such as active cooling systems or advanced thermal interface materials can effectively mitigate heat issues, they often come with increased production costs and design complexity. Striking a balance between thermal performance and economic viability remains a persistent challenge in PNP transistor circuit design.

Existing Heat Dissipation Solutions for PNP Transistors

01 Heat sink design for PNP transistor circuits

Effective heat sink designs are crucial for managing heat dissipation in PNP transistor circuits. These designs may include specialized materials, shapes, and structures to maximize heat transfer away from the transistor. Proper heat sink selection and implementation can significantly improve the thermal performance and reliability of PNP transistor-based devices.- Heat sink design for PNP transistor circuits: Efficient heat sink designs are crucial for managing heat dissipation in PNP transistor circuits. These designs may include specialized materials, shapes, and structures to maximize heat transfer away from the transistor, ensuring optimal performance and longevity of the circuit.

- Thermal management in power amplifier circuits: Power amplifier circuits using PNP transistors often require advanced thermal management techniques. This may involve the use of thermal spreaders, active cooling systems, or innovative circuit layouts to distribute heat more effectively and prevent localized hot spots.

- Integration of PNP transistors in high-density circuits: As circuit densities increase, managing heat dissipation for PNP transistors becomes more challenging. Techniques such as 3D integration, advanced packaging solutions, and the use of thermally conductive substrates can help address these challenges in high-density applications.

- Dynamic thermal management for PNP transistor circuits: Implementing dynamic thermal management systems can help optimize heat dissipation in PNP transistor circuits. These systems may include temperature sensors, variable speed cooling fans, and adaptive power management algorithms to adjust circuit operation based on thermal conditions.

- Novel materials for improved heat dissipation: Research into new materials with enhanced thermal properties can significantly improve heat dissipation in PNP transistor circuits. This may include the use of advanced composites, nanomaterials, or phase-change materials integrated into the circuit design or packaging.

02 Thermal management in integrated circuits with PNP transistors

Integrated circuits incorporating PNP transistors require careful thermal management strategies. This may involve the use of thermal vias, on-chip heat spreaders, or advanced packaging techniques to efficiently dissipate heat generated by the transistors. Proper thermal design at the chip level can prevent hotspots and ensure optimal performance of PNP transistor circuits.Expand Specific Solutions03 Cooling solutions for high-power PNP transistor applications

High-power applications using PNP transistors often require advanced cooling solutions. These may include forced-air cooling, liquid cooling systems, or thermoelectric coolers. The choice of cooling method depends on the specific power requirements and operating conditions of the PNP transistor circuit.Expand Specific Solutions04 Thermal modeling and simulation for PNP transistor circuits

Accurate thermal modeling and simulation techniques are essential for predicting and optimizing heat dissipation in PNP transistor circuits. These methods may involve finite element analysis, computational fluid dynamics, or specialized thermal simulation software. By using these tools, designers can identify potential thermal issues and optimize circuit layouts for improved heat dissipation.Expand Specific Solutions05 Novel materials and structures for enhanced heat dissipation

Research into novel materials and structures aims to improve heat dissipation in PNP transistor circuits. This may include the use of advanced thermal interface materials, nanostructured surfaces, or innovative packaging designs. These developments can lead to more efficient heat transfer and improved thermal management in PNP transistor-based devices.Expand Specific Solutions

Key Players in PNP Transistor Manufacturing

The competition landscape for minimizing heat dissipation in PNP transistor circuits is characterized by a mature market with established players and ongoing innovation. The industry is in a growth phase, driven by increasing demand for energy-efficient electronics across various sectors. Major companies like Texas Instruments, Infineon Technologies, and Renesas Electronics are at the forefront, leveraging their extensive R&D capabilities to develop advanced thermal management solutions. The market size is substantial, with a global reach spanning automotive, consumer electronics, and industrial applications. Technological maturity is high, with continuous improvements in semiconductor materials and circuit design techniques being pursued by both industry leaders and research institutions.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced thermal management techniques for PNP transistor circuits. They utilize a combination of improved package designs and innovative circuit topologies to minimize heat dissipation. One key approach is the implementation of advanced thermal vias and heat spreaders in their IC packages, which efficiently conduct heat away from the transistor junction[1]. Additionally, TI has introduced smart power stage designs that incorporate current sensing and temperature monitoring, allowing for dynamic adjustment of operating conditions to optimize performance while minimizing heat generation[3]. Their latest PNP transistors also feature reduced on-resistance and improved current handling capabilities, further reducing power losses and heat dissipation in high-current applications[5].

Strengths: Comprehensive thermal management solutions, advanced packaging technology, and intelligent power control. Weaknesses: Potentially higher cost due to advanced features, and may require more complex system integration.

Robert Bosch GmbH

Technical Solution: Bosch has developed innovative solutions for minimizing heat dissipation in PNP transistor circuits, particularly for automotive applications. Their approach includes the use of advanced silicon-on-insulator (SOI) technology, which provides better thermal isolation and reduces leakage currents[2]. Bosch has also implemented intelligent power management systems that dynamically adjust the bias conditions of PNP transistors based on real-time temperature and load conditions[4]. Furthermore, they have developed specialized cooling solutions, such as integrated micro-channel liquid cooling for high-power applications, which significantly enhances heat dissipation capabilities in compact designs[6].

Strengths: Expertise in automotive-grade solutions, advanced SOI technology, and integrated cooling systems. Weaknesses: Solutions may be optimized for automotive use, potentially limiting applicability in other sectors.

Innovative Approaches to PNP Transistor Cooling

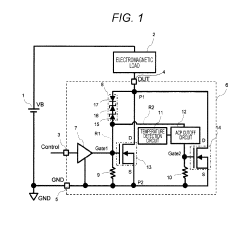

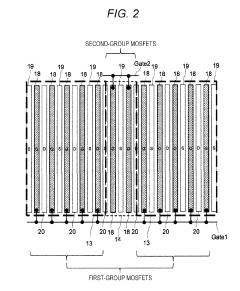

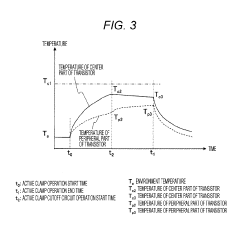

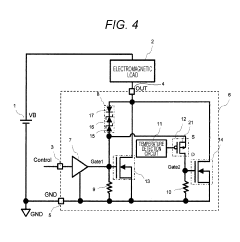

Semiconductor Device

PatentInactiveUS20190260371A1

Innovation

- A semiconductor device configuration with a first and second transistor connected in parallel, an active clamp circuit, and an active clamp cutoff circuit that disconnects the second transistor when its temperature exceeds a threshold, preventing further heat generation and maintaining equal current performance across both transistors.

Method and circuit for controlling radiant heat of transistor using metal-insulator transition device

PatentActiveEP2220546A2

Innovation

- A circuit utilizing a metal-insulator transition (MIT) device that abruptly transitions at a critical temperature to control heat generation by reducing or shutting off current to the transistor, preventing overheating and allowing for semi-permanent use without replacement.

Thermal Management Materials and Technologies

Thermal management materials and technologies play a crucial role in minimizing heat dissipation in PNP transistor circuits. Advanced materials with high thermal conductivity and low electrical resistance are essential for efficient heat dissipation. Ceramic substrates, such as aluminum nitride and beryllium oxide, offer excellent thermal properties and are widely used in high-power applications.

Metal-matrix composites, combining metals with ceramic particles, provide enhanced thermal conductivity while maintaining mechanical strength. These materials are particularly useful in applications requiring both heat dissipation and structural integrity. Graphene and carbon nanotubes have emerged as promising materials for thermal management due to their exceptional thermal conductivity and lightweight nature.

Heat spreaders and heat sinks are fundamental components in thermal management systems. Copper and aluminum remain popular choices for heat sinks due to their high thermal conductivity and cost-effectiveness. However, advanced heat sink designs incorporating microchannels and phase-change materials have shown significant improvements in heat dissipation efficiency.

Thermal interface materials (TIMs) are critical for reducing thermal resistance between components and heat sinks. Next-generation TIMs include graphene-based compounds and liquid metal alloys, offering superior thermal conductivity compared to traditional thermal greases.

Active cooling technologies, such as thermoelectric coolers and miniature liquid cooling systems, provide precise temperature control in sensitive electronic applications. These technologies are particularly useful in managing localized hot spots in PNP transistor circuits.

Thermal simulation and modeling tools have become indispensable in optimizing thermal management strategies. Computational fluid dynamics (CFD) software enables engineers to predict heat flow and optimize component placement for maximum thermal efficiency.

Emerging technologies in thermal management include 3D-printed heat sinks with complex geometries, allowing for customized cooling solutions. Additionally, research into phononic crystals and thermal metamaterials shows promise for directing and controlling heat flow at the nanoscale.

The integration of artificial intelligence and machine learning algorithms in thermal management systems is enabling real-time optimization of cooling strategies based on dynamic operating conditions. This adaptive approach enhances overall system efficiency and reliability in PNP transistor circuits.

Metal-matrix composites, combining metals with ceramic particles, provide enhanced thermal conductivity while maintaining mechanical strength. These materials are particularly useful in applications requiring both heat dissipation and structural integrity. Graphene and carbon nanotubes have emerged as promising materials for thermal management due to their exceptional thermal conductivity and lightweight nature.

Heat spreaders and heat sinks are fundamental components in thermal management systems. Copper and aluminum remain popular choices for heat sinks due to their high thermal conductivity and cost-effectiveness. However, advanced heat sink designs incorporating microchannels and phase-change materials have shown significant improvements in heat dissipation efficiency.

Thermal interface materials (TIMs) are critical for reducing thermal resistance between components and heat sinks. Next-generation TIMs include graphene-based compounds and liquid metal alloys, offering superior thermal conductivity compared to traditional thermal greases.

Active cooling technologies, such as thermoelectric coolers and miniature liquid cooling systems, provide precise temperature control in sensitive electronic applications. These technologies are particularly useful in managing localized hot spots in PNP transistor circuits.

Thermal simulation and modeling tools have become indispensable in optimizing thermal management strategies. Computational fluid dynamics (CFD) software enables engineers to predict heat flow and optimize component placement for maximum thermal efficiency.

Emerging technologies in thermal management include 3D-printed heat sinks with complex geometries, allowing for customized cooling solutions. Additionally, research into phononic crystals and thermal metamaterials shows promise for directing and controlling heat flow at the nanoscale.

The integration of artificial intelligence and machine learning algorithms in thermal management systems is enabling real-time optimization of cooling strategies based on dynamic operating conditions. This adaptive approach enhances overall system efficiency and reliability in PNP transistor circuits.

Environmental Impact of PNP Transistor Heat Reduction

The environmental impact of reducing heat dissipation in PNP transistor circuits extends beyond immediate energy efficiency gains. As transistors become more efficient in managing heat, the overall power consumption of electronic devices decreases, leading to reduced energy demand and associated greenhouse gas emissions. This improvement in energy efficiency contributes to the broader goal of sustainable electronics and aligns with global efforts to combat climate change.

Minimizing heat dissipation in PNP transistors also has implications for the lifecycle of electronic products. With better thermal management, components are less likely to fail due to heat-related stress, potentially extending the lifespan of devices. This longevity can result in a decrease in electronic waste generation, addressing a significant environmental concern in the technology sector.

The manufacturing process for more thermally efficient PNP transistors may require advanced materials and techniques. While these processes might initially have a higher environmental footprint, the long-term benefits of improved efficiency and durability can offset the initial impact. Manufacturers may need to invest in cleaner production methods and materials to align with the environmental benefits of the end product.

Reduced heat dissipation also means less energy is wasted as heat, which can have a cumulative effect on the urban heat island phenomenon. As electronic devices become more prevalent in urban environments, their collective heat output contributes to increased ambient temperatures. By minimizing this heat output, PNP transistor improvements can play a role in mitigating local temperature increases in densely populated areas.

The development of more efficient PNP transistors may also drive innovation in cooling technologies. As the focus shifts from managing excess heat to preventing its generation, there could be a reduced need for energy-intensive cooling systems in electronic devices and data centers. This shift could lead to the development of more passive cooling solutions, further reducing the environmental impact of electronic systems.

In the context of the circular economy, improved PNP transistor efficiency could facilitate better recyclability of electronic components. With less thermal stress and degradation, the materials used in these transistors may retain their quality for longer, making them more suitable for recycling and reuse in future applications. This aspect contributes to the conservation of resources and reduction of raw material extraction.

Minimizing heat dissipation in PNP transistors also has implications for the lifecycle of electronic products. With better thermal management, components are less likely to fail due to heat-related stress, potentially extending the lifespan of devices. This longevity can result in a decrease in electronic waste generation, addressing a significant environmental concern in the technology sector.

The manufacturing process for more thermally efficient PNP transistors may require advanced materials and techniques. While these processes might initially have a higher environmental footprint, the long-term benefits of improved efficiency and durability can offset the initial impact. Manufacturers may need to invest in cleaner production methods and materials to align with the environmental benefits of the end product.

Reduced heat dissipation also means less energy is wasted as heat, which can have a cumulative effect on the urban heat island phenomenon. As electronic devices become more prevalent in urban environments, their collective heat output contributes to increased ambient temperatures. By minimizing this heat output, PNP transistor improvements can play a role in mitigating local temperature increases in densely populated areas.

The development of more efficient PNP transistors may also drive innovation in cooling technologies. As the focus shifts from managing excess heat to preventing its generation, there could be a reduced need for energy-intensive cooling systems in electronic devices and data centers. This shift could lead to the development of more passive cooling solutions, further reducing the environmental impact of electronic systems.

In the context of the circular economy, improved PNP transistor efficiency could facilitate better recyclability of electronic components. With less thermal stress and degradation, the materials used in these transistors may retain their quality for longer, making them more suitable for recycling and reuse in future applications. This aspect contributes to the conservation of resources and reduction of raw material extraction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!