How to Advance Hydrofluoric Acid Containment Strategies

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF Acid Safety Evolution and Objectives

Hydrofluoric acid (HF) has been a critical component in various industrial processes since its first commercial production in the early 20th century. The evolution of HF acid containment strategies has been driven by increasing awareness of its unique hazards, characterized by both corrosive properties and systemic toxicity. Initially, containment focused primarily on basic acid-resistant materials, with limited understanding of HF's ability to penetrate many conventional barriers.

The 1970s marked a significant turning point with major industrial accidents highlighting the inadequacy of existing containment methods. This led to the development of specialized fluoropolymer linings and the implementation of secondary containment systems. By the 1990s, regulatory frameworks such as OSHA's Process Safety Management standards and EPA's Risk Management Plan requirements established more stringent guidelines for HF handling and containment.

Recent technological advancements have introduced smart monitoring systems capable of detecting microscopic leaks before they escalate, alongside the development of advanced composite materials specifically engineered to resist HF permeation. The integration of digital twins and predictive maintenance algorithms has further enhanced containment system reliability by anticipating potential failure points before physical manifestations occur.

The primary objective of modern HF containment strategies is to achieve zero-incident operations through multiple layers of protection. This includes not only physical containment barriers but also process controls that minimize the potential for human error. A secondary objective focuses on minimizing environmental impact through closed-loop systems that capture and neutralize any potential releases.

Long-term objectives in this field include the development of inherently safer alternatives to traditional HF processes, particularly in industries like petroleum refining and semiconductor manufacturing where substitution has proven challenging. Research is increasingly focused on catalytic processes that can achieve similar results with less hazardous materials.

The technological trajectory points toward intelligent containment systems that combine advanced materials science with real-time monitoring and autonomous response capabilities. These systems aim to detect and mitigate potential releases before human intervention becomes necessary, representing a paradigm shift from reactive to proactive safety management.

As global chemical safety standards continue to evolve, particularly in emerging economies, the harmonization of HF containment practices represents another key objective. This includes standardized training protocols, equipment specifications, and emergency response procedures to ensure consistent safety performance across geographical boundaries.

The 1970s marked a significant turning point with major industrial accidents highlighting the inadequacy of existing containment methods. This led to the development of specialized fluoropolymer linings and the implementation of secondary containment systems. By the 1990s, regulatory frameworks such as OSHA's Process Safety Management standards and EPA's Risk Management Plan requirements established more stringent guidelines for HF handling and containment.

Recent technological advancements have introduced smart monitoring systems capable of detecting microscopic leaks before they escalate, alongside the development of advanced composite materials specifically engineered to resist HF permeation. The integration of digital twins and predictive maintenance algorithms has further enhanced containment system reliability by anticipating potential failure points before physical manifestations occur.

The primary objective of modern HF containment strategies is to achieve zero-incident operations through multiple layers of protection. This includes not only physical containment barriers but also process controls that minimize the potential for human error. A secondary objective focuses on minimizing environmental impact through closed-loop systems that capture and neutralize any potential releases.

Long-term objectives in this field include the development of inherently safer alternatives to traditional HF processes, particularly in industries like petroleum refining and semiconductor manufacturing where substitution has proven challenging. Research is increasingly focused on catalytic processes that can achieve similar results with less hazardous materials.

The technological trajectory points toward intelligent containment systems that combine advanced materials science with real-time monitoring and autonomous response capabilities. These systems aim to detect and mitigate potential releases before human intervention becomes necessary, representing a paradigm shift from reactive to proactive safety management.

As global chemical safety standards continue to evolve, particularly in emerging economies, the harmonization of HF containment practices represents another key objective. This includes standardized training protocols, equipment specifications, and emergency response procedures to ensure consistent safety performance across geographical boundaries.

Market Analysis for HF Containment Solutions

The global market for hydrofluoric acid (HF) containment solutions is experiencing significant growth driven by stringent safety regulations and increasing industrial applications of HF. The market size was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory is primarily attributed to expanding semiconductor manufacturing, chemical processing, and petroleum refining industries where HF is extensively utilized.

North America currently dominates the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China, South Korea, and Taiwan, is expected to witness the fastest growth due to rapid industrialization and increasing semiconductor production facilities. The market landscape is characterized by a blend of established players and emerging solution providers, with the top five companies controlling about 40% of the global market share.

Demand analysis reveals three primary market segments for HF containment solutions: prevention systems (42%), detection technologies (33%), and emergency response equipment (25%). The prevention systems segment, including specialized storage tanks, piping systems, and transfer equipment, represents the largest market share due to the critical importance of preventing HF releases at the source.

Customer requirements are evolving toward more integrated and automated containment solutions. End-users increasingly demand real-time monitoring capabilities, remote management features, and systems that can be seamlessly integrated with existing industrial control architectures. There is also growing interest in predictive maintenance technologies that can identify potential containment failures before they occur.

Price sensitivity varies significantly across different market segments. Large chemical and semiconductor manufacturers typically prioritize reliability and comprehensive protection over cost considerations, while smaller industrial operations tend to be more price-sensitive. The average implementation cost for comprehensive HF containment systems ranges from $50,000 for small-scale applications to several million dollars for large industrial facilities.

Market trends indicate a shift toward more sophisticated containment technologies incorporating advanced materials science and digital monitoring capabilities. Solutions featuring IoT connectivity, AI-powered predictive analytics, and remote management capabilities are gaining traction. Additionally, there is increasing demand for modular and scalable containment systems that can be adapted to various facility sizes and configurations.

Regulatory factors significantly influence market dynamics, with OSHA, EPA, and equivalent international bodies continuously updating safety standards for HF handling. These evolving regulations create both challenges and opportunities for solution providers, driving innovation while establishing minimum performance requirements for containment technologies.

North America currently dominates the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China, South Korea, and Taiwan, is expected to witness the fastest growth due to rapid industrialization and increasing semiconductor production facilities. The market landscape is characterized by a blend of established players and emerging solution providers, with the top five companies controlling about 40% of the global market share.

Demand analysis reveals three primary market segments for HF containment solutions: prevention systems (42%), detection technologies (33%), and emergency response equipment (25%). The prevention systems segment, including specialized storage tanks, piping systems, and transfer equipment, represents the largest market share due to the critical importance of preventing HF releases at the source.

Customer requirements are evolving toward more integrated and automated containment solutions. End-users increasingly demand real-time monitoring capabilities, remote management features, and systems that can be seamlessly integrated with existing industrial control architectures. There is also growing interest in predictive maintenance technologies that can identify potential containment failures before they occur.

Price sensitivity varies significantly across different market segments. Large chemical and semiconductor manufacturers typically prioritize reliability and comprehensive protection over cost considerations, while smaller industrial operations tend to be more price-sensitive. The average implementation cost for comprehensive HF containment systems ranges from $50,000 for small-scale applications to several million dollars for large industrial facilities.

Market trends indicate a shift toward more sophisticated containment technologies incorporating advanced materials science and digital monitoring capabilities. Solutions featuring IoT connectivity, AI-powered predictive analytics, and remote management capabilities are gaining traction. Additionally, there is increasing demand for modular and scalable containment systems that can be adapted to various facility sizes and configurations.

Regulatory factors significantly influence market dynamics, with OSHA, EPA, and equivalent international bodies continuously updating safety standards for HF handling. These evolving regulations create both challenges and opportunities for solution providers, driving innovation while establishing minimum performance requirements for containment technologies.

Current HF Containment Technologies and Barriers

Hydrofluoric acid (HF) containment technologies have evolved significantly over the past decades, driven by increasing safety concerns and regulatory requirements. Current containment strategies primarily focus on multiple layers of protection, including specialized storage vessels, transfer systems, and emergency response mechanisms. The most widely adopted primary containment solutions utilize polyethylene, polypropylene, or PTFE-lined vessels, which offer superior chemical resistance to HF's corrosive properties compared to traditional materials.

Secondary containment systems typically involve concrete basins with acid-resistant linings, designed to capture and neutralize potential leaks from primary containers. These systems are equipped with leak detection sensors that provide real-time monitoring capabilities, allowing for immediate response to containment breaches. Advanced facilities have implemented automated neutralization systems that deploy calcium or sodium-based neutralizing agents upon leak detection.

Personal protective equipment (PPE) represents another critical layer in current containment strategies, with specialized acid-resistant suits, respiratory protection, and emergency decontamination protocols forming standard practice in facilities handling HF. Industry standards such as NFPA 400 and CGA G-13 provide comprehensive guidelines for these protective measures.

Despite these advancements, significant barriers to optimal HF containment persist. Material limitations remain a primary challenge, as even the most resistant polymers experience degradation over time when exposed to concentrated HF, particularly at elevated temperatures. This necessitates regular inspection and replacement schedules, increasing operational costs and potential exposure risks during maintenance activities.

Engineering challenges also present substantial barriers, particularly in sealing technologies. Gaskets, valves, and connection points remain vulnerable areas in containment systems, with no perfect solution for long-term, maintenance-free operation. The extreme penetrating ability of HF makes these connection points particularly susceptible to microscopic leaks that can develop into significant hazards.

Cost considerations represent another major barrier to implementing state-of-the-art containment technologies. The most effective systems require significant capital investment, creating adoption challenges particularly for smaller operations or facilities in developing regions. This economic barrier has resulted in uneven implementation of best practices globally.

Regulatory inconsistencies across different jurisdictions further complicate containment strategies. While some regions have implemented stringent requirements for HF handling, others maintain minimal standards, creating challenges for multinational organizations attempting to standardize their safety protocols and containment technologies.

Secondary containment systems typically involve concrete basins with acid-resistant linings, designed to capture and neutralize potential leaks from primary containers. These systems are equipped with leak detection sensors that provide real-time monitoring capabilities, allowing for immediate response to containment breaches. Advanced facilities have implemented automated neutralization systems that deploy calcium or sodium-based neutralizing agents upon leak detection.

Personal protective equipment (PPE) represents another critical layer in current containment strategies, with specialized acid-resistant suits, respiratory protection, and emergency decontamination protocols forming standard practice in facilities handling HF. Industry standards such as NFPA 400 and CGA G-13 provide comprehensive guidelines for these protective measures.

Despite these advancements, significant barriers to optimal HF containment persist. Material limitations remain a primary challenge, as even the most resistant polymers experience degradation over time when exposed to concentrated HF, particularly at elevated temperatures. This necessitates regular inspection and replacement schedules, increasing operational costs and potential exposure risks during maintenance activities.

Engineering challenges also present substantial barriers, particularly in sealing technologies. Gaskets, valves, and connection points remain vulnerable areas in containment systems, with no perfect solution for long-term, maintenance-free operation. The extreme penetrating ability of HF makes these connection points particularly susceptible to microscopic leaks that can develop into significant hazards.

Cost considerations represent another major barrier to implementing state-of-the-art containment technologies. The most effective systems require significant capital investment, creating adoption challenges particularly for smaller operations or facilities in developing regions. This economic barrier has resulted in uneven implementation of best practices globally.

Regulatory inconsistencies across different jurisdictions further complicate containment strategies. While some regions have implemented stringent requirements for HF handling, others maintain minimal standards, creating challenges for multinational organizations attempting to standardize their safety protocols and containment technologies.

Contemporary HF Containment Methodologies

01 Specialized containment vessels and materials

Hydrofluoric acid requires specialized containment vessels made from materials resistant to its highly corrosive properties. These materials include fluoropolymers like PTFE (Teflon), certain grades of stainless steel with specific coatings, and high-density polyethylene. The design of these vessels incorporates features such as double-wall construction, specialized seals, and corrosion-resistant linings to prevent leakage and ensure long-term integrity when storing or transporting this dangerous acid.- Specialized containment vessels and materials: Hydrofluoric acid requires specialized containment vessels made from materials resistant to its highly corrosive properties. These include fluoropolymer-lined containers, high-density polyethylene tanks, and specially treated metal alloys that can withstand the acid's aggressive nature. The design of these vessels often incorporates double-wall construction with leak detection systems to provide secondary containment in case of primary containment failure.

- Safety systems and monitoring technologies: Advanced monitoring and detection systems are essential for hydrofluoric acid containment. These include continuous monitoring devices that can detect minute leaks, automated emergency response systems, pressure and temperature sensors, and real-time data analysis tools. These technologies enable early detection of potential containment breaches, allowing for rapid response to prevent or minimize exposure and environmental contamination.

- Neutralization and emergency response strategies: Effective hydrofluoric acid containment includes neutralization methods and emergency response protocols. This involves the strategic placement of neutralizing agents like calcium carbonate or specialized HF neutralizers near storage areas, emergency shower and eyewash stations, and detailed spill response procedures. Advanced containment systems may incorporate automated neutralization systems that activate upon detection of a leak.

- Facility design and engineering controls: Purpose-built facilities for hydrofluoric acid handling incorporate engineering controls such as ventilation systems with scrubbers to capture acid vapors, sloped floors leading to collection sumps, segregated drainage systems, and physical barriers to prevent accidental releases. These facilities are designed with containment dikes, berms, or trenches around storage areas to contain potential spills and prevent widespread contamination.

- Transport and handling containment solutions: Specialized transport and handling systems for hydrofluoric acid include purpose-designed tankers with reinforced acid-resistant linings, secure valve systems with multiple redundancies, and custom transfer equipment that minimizes the risk of exposure during loading and unloading operations. These systems often incorporate dry-disconnect couplings, closed-loop transfer systems, and specialized packaging designed to withstand impacts and prevent leakage during transportation.

02 Secondary containment systems

Secondary containment systems are critical for hydrofluoric acid handling to prevent environmental contamination and protect personnel in case of primary containment failure. These systems typically include containment basins, berms, sumps, and collection areas designed to capture and contain any leaks or spills. Advanced secondary containment designs incorporate neutralization capabilities, leak detection sensors, and drainage systems that direct spilled acid to treatment facilities, ensuring that any escaped acid is promptly contained and neutralized.Expand Specific Solutions03 Monitoring and detection systems

Sophisticated monitoring and detection systems are essential components of hydrofluoric acid containment strategies. These systems employ various sensors and analytical techniques to detect leaks, monitor vapor concentrations, and assess containment integrity. Advanced monitoring solutions include continuous real-time sensors, automated alarm systems, and integrated monitoring networks that can detect even minute concentrations of hydrofluoric acid. These systems often incorporate redundant detection methods and are designed to trigger automatic containment protocols when leaks are detected.Expand Specific Solutions04 Neutralization and emergency response technologies

Neutralization technologies and emergency response systems are integrated into hydrofluoric acid containment strategies to mitigate the effects of potential releases. These include automated calcium-based neutralization systems, emergency scrubbers, and specialized absorption materials designed to rapidly neutralize hydrofluoric acid. Emergency response technologies also encompass specialized ventilation systems, isolation protocols, and rapid deployment containment barriers that can be activated in the event of a containment breach to minimize exposure and environmental impact.Expand Specific Solutions05 Engineered safety systems and protocols

Comprehensive engineered safety systems and protocols form a critical component of hydrofluoric acid containment strategies. These include specialized valve systems, pressure relief mechanisms, and automated shutdown procedures designed to prevent catastrophic failures. Advanced containment facilities incorporate redundant safety features, fail-safe mechanisms, and integrated control systems that can automatically respond to abnormal conditions. These engineered systems are complemented by rigorous operational protocols, maintenance procedures, and regular integrity testing to ensure the ongoing effectiveness of containment measures.Expand Specific Solutions

Leading Organizations in HF Management Industry

The hydrofluoric acid containment market is currently in a growth phase, driven by increasing safety regulations and industrial applications across semiconductor manufacturing, petrochemicals, and energy sectors. The global market size is estimated to exceed $1.5 billion, with projected annual growth of 5-7%. Leading players demonstrate varying levels of technological maturity: established chemical giants like DuPont, Air Liquide, and Arkema offer comprehensive containment solutions with advanced materials; specialized companies such as Daiseki and Kunshan Mingkuan focus on treatment and recycling technologies; while Asian manufacturers including Do-Fluoride New Materials and Fujian Tianfu are rapidly advancing with cost-effective innovations. Research institutions like Beijing University of Chemical Technology and Tohoku University are driving next-generation containment technologies through collaborative industry partnerships.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an integrated HF containment and monitoring system that combines physical containment with advanced digital monitoring technologies. Their solution incorporates specialized corrosion-resistant alloys (such as Monel and Hastelloy) for primary containment vessels and piping, coupled with secondary containment structures featuring proprietary polymer linings. The system is distinguished by its Honeywell Experion® Process Knowledge System integration, which provides real-time monitoring of multiple parameters including temperature, pressure, pH levels, and trace HF detection in surrounding air. Their technology employs distributed fiber optic sensing for leak detection, capable of pinpointing breach locations with meter-level accuracy along extensive piping networks. Honeywell's containment strategy also includes automated emergency response systems that can initiate neutralization procedures and ventilation controls upon detection of containment failures, significantly reducing response time during critical incidents.

Strengths: Comprehensive integration of physical containment with digital monitoring provides multiple layers of protection; real-time data analytics enable predictive maintenance; automated response systems reduce human error risks during emergencies. Weaknesses: Complex system architecture requires specialized maintenance personnel; high initial capital investment; potential cybersecurity vulnerabilities in the digital monitoring components.

Arkema France SA

Technical Solution: Arkema has pioneered an innovative HF containment strategy based on their Kynar® PVDF (polyvinylidene fluoride) technology. Their system utilizes specialized grades of PVDF specifically engineered to resist the permeation and degradation effects of concentrated hydrofluoric acid. The containment solution incorporates multi-layer structures with an inner layer of high-purity PVDF that maintains chemical integrity even at elevated temperatures up to 150°C, while external layers provide mechanical strength and environmental protection. Arkema's technology includes proprietary welding and joining techniques that eliminate potential leak points in traditional connection methods. Their containment systems feature integrated conductive layers that enable electrical leak detection through impedance monitoring, capable of detecting microscopic breaches before visible leakage occurs. Additionally, Arkema has developed specialized PVDF-based composite materials that incorporate graphene nanoplatelets, significantly enhancing mechanical properties while maintaining chemical resistance, allowing for thinner wall constructions that improve heat transfer in reaction vessels while maintaining containment integrity.

Strengths: Exceptional chemical compatibility with HF across wide temperature ranges; non-metallic construction eliminates corrosion concerns; electrical leak detection provides early warning capabilities; lighter weight compared to metal alternatives. Weaknesses: Lower mechanical strength compared to metal containment systems necessitates careful design considerations; higher material costs compared to conventional plastics; specialized installation techniques required for optimal performance.

Critical Patents in HF Containment Systems

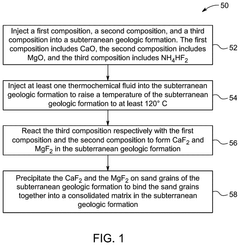

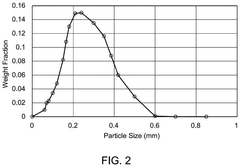

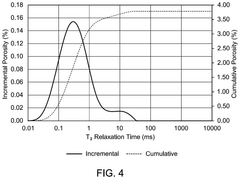

Method for consolidating target region in a geologic formation

PatentActiveUS20250059432A1

Innovation

- A method involving the injection of CaO, MgO, and NH4HF2 compositions into subterranean formations, followed by the introduction of thermochemical fluids to raise the temperature and induce the precipitation of calcium and magnesium fluorides, which bind sand grains into a consolidated matrix.

Environmental Impact Assessment

Hydrofluoric acid (HF) releases pose significant environmental threats due to the chemical's high reactivity and toxicity. When containment strategies fail, HF can contaminate soil, groundwater, and surface water systems, creating long-lasting ecological damage. Studies indicate that even low concentrations of HF can dramatically alter soil pH, affecting nutrient availability and microbial communities essential for ecosystem health.

Atmospheric releases present another critical concern, as HF can form acidic precipitation that damages vegetation and aquatic ecosystems far from the original release site. Research from the Environmental Protection Agency documents cases where HF emissions have caused defoliation of trees and reduced biodiversity in affected areas. The compound's water solubility facilitates its rapid integration into hydrological systems, potentially affecting drinking water sources and aquatic habitats.

Current environmental monitoring systems for HF often prove inadequate, particularly in detecting low-level chronic releases that may occur around industrial facilities. Advanced containment strategies must incorporate comprehensive environmental monitoring networks capable of real-time detection and early warning capabilities to minimize ecological impact during containment failures.

The bioaccumulation potential of fluoride compounds resulting from HF releases presents long-term ecological concerns. Studies in regions with historical HF contamination show fluoride accumulation in plant tissues and subsequent biomagnification through food chains, affecting wildlife populations. Particularly vulnerable are aquatic ecosystems, where fish and amphibian populations show developmental abnormalities in areas with elevated fluoride levels.

Remediation of HF-contaminated environments presents significant challenges due to the compound's mobility and persistence. Traditional neutralization techniques using calcium compounds can themselves alter soil structure and ecosystem function. More advanced containment strategies must consider not only immediate neutralization but also long-term environmental restoration approaches.

Climate considerations also affect HF containment environmental impacts. Higher temperatures increase volatilization rates, while changing precipitation patterns can affect the dispersion and concentration of HF in environmental media. Future containment systems must account for these climate variables to effectively mitigate environmental damage under changing conditions.

Economic valuation of environmental damages from HF releases indicates costs extending far beyond immediate cleanup expenses. Ecosystem service losses, including reduced agricultural productivity, compromised water resources, and diminished recreational value of natural areas, represent significant externalities that justify investment in advanced containment technologies from both environmental and economic perspectives.

Atmospheric releases present another critical concern, as HF can form acidic precipitation that damages vegetation and aquatic ecosystems far from the original release site. Research from the Environmental Protection Agency documents cases where HF emissions have caused defoliation of trees and reduced biodiversity in affected areas. The compound's water solubility facilitates its rapid integration into hydrological systems, potentially affecting drinking water sources and aquatic habitats.

Current environmental monitoring systems for HF often prove inadequate, particularly in detecting low-level chronic releases that may occur around industrial facilities. Advanced containment strategies must incorporate comprehensive environmental monitoring networks capable of real-time detection and early warning capabilities to minimize ecological impact during containment failures.

The bioaccumulation potential of fluoride compounds resulting from HF releases presents long-term ecological concerns. Studies in regions with historical HF contamination show fluoride accumulation in plant tissues and subsequent biomagnification through food chains, affecting wildlife populations. Particularly vulnerable are aquatic ecosystems, where fish and amphibian populations show developmental abnormalities in areas with elevated fluoride levels.

Remediation of HF-contaminated environments presents significant challenges due to the compound's mobility and persistence. Traditional neutralization techniques using calcium compounds can themselves alter soil structure and ecosystem function. More advanced containment strategies must consider not only immediate neutralization but also long-term environmental restoration approaches.

Climate considerations also affect HF containment environmental impacts. Higher temperatures increase volatilization rates, while changing precipitation patterns can affect the dispersion and concentration of HF in environmental media. Future containment systems must account for these climate variables to effectively mitigate environmental damage under changing conditions.

Economic valuation of environmental damages from HF releases indicates costs extending far beyond immediate cleanup expenses. Ecosystem service losses, including reduced agricultural productivity, compromised water resources, and diminished recreational value of natural areas, represent significant externalities that justify investment in advanced containment technologies from both environmental and economic perspectives.

Regulatory Compliance Framework

The regulatory landscape for hydrofluoric acid (HF) containment has evolved significantly over the past decades, reflecting growing awareness of its extreme hazards. At the federal level in the United States, the Occupational Safety and Health Administration (OSHA) has established comprehensive standards under 29 CFR 1910.1200 for hazard communication and 29 CFR 1910.119 for process safety management, specifically addressing HF as a highly hazardous chemical. These regulations mandate rigorous risk assessment protocols, detailed documentation of safety procedures, and regular compliance audits.

The Environmental Protection Agency (EPA) further regulates HF under the Risk Management Program (40 CFR Part 68) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), requiring facilities to develop and implement risk management plans and report releases exceeding reportable quantities. Additionally, the Department of Transportation (DOT) regulates the transport of HF under 49 CFR, classifying it as a Class 8 Corrosive Material with specific packaging, labeling, and shipping requirements.

International frameworks have also been established, with the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and CLP (Classification, Labeling and Packaging) regulations imposing stringent requirements for HF handling. The United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides standardized hazard communication elements that have been widely adopted globally.

Industry-specific standards complement these regulatory frameworks. The American Chemistry Council's Hydrofluoric Acid Industry Practices Standards and the American Petroleum Institute's Recommended Practice 751 (Safe Operation of Hydrofluoric Acid Alkylation Units) provide detailed guidance for specific sectors. These standards often exceed minimum regulatory requirements, establishing best practices for containment system design, maintenance protocols, and emergency response procedures.

Recent regulatory trends indicate a move toward more performance-based approaches rather than prescriptive requirements. This shift allows organizations to develop innovative containment strategies tailored to their specific operational contexts while still meeting safety objectives. Regulatory bodies are increasingly emphasizing the importance of safety culture and management systems in addition to technical controls.

Compliance challenges remain significant, particularly for multinational organizations navigating varying regulatory requirements across jurisdictions. The cost of compliance has risen substantially, with investments in advanced containment technologies, monitoring systems, and personnel training representing significant operational expenditures. However, these investments typically yield positive returns through reduced incident rates, lower insurance premiums, and enhanced corporate reputation.

The Environmental Protection Agency (EPA) further regulates HF under the Risk Management Program (40 CFR Part 68) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), requiring facilities to develop and implement risk management plans and report releases exceeding reportable quantities. Additionally, the Department of Transportation (DOT) regulates the transport of HF under 49 CFR, classifying it as a Class 8 Corrosive Material with specific packaging, labeling, and shipping requirements.

International frameworks have also been established, with the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and CLP (Classification, Labeling and Packaging) regulations imposing stringent requirements for HF handling. The United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides standardized hazard communication elements that have been widely adopted globally.

Industry-specific standards complement these regulatory frameworks. The American Chemistry Council's Hydrofluoric Acid Industry Practices Standards and the American Petroleum Institute's Recommended Practice 751 (Safe Operation of Hydrofluoric Acid Alkylation Units) provide detailed guidance for specific sectors. These standards often exceed minimum regulatory requirements, establishing best practices for containment system design, maintenance protocols, and emergency response procedures.

Recent regulatory trends indicate a move toward more performance-based approaches rather than prescriptive requirements. This shift allows organizations to develop innovative containment strategies tailored to their specific operational contexts while still meeting safety objectives. Regulatory bodies are increasingly emphasizing the importance of safety culture and management systems in addition to technical controls.

Compliance challenges remain significant, particularly for multinational organizations navigating varying regulatory requirements across jurisdictions. The cost of compliance has risen substantially, with investments in advanced containment technologies, monitoring systems, and personnel training representing significant operational expenditures. However, these investments typically yield positive returns through reduced incident rates, lower insurance premiums, and enhanced corporate reputation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!