Hydrofluoric Acid vs Trinitrotoluene: Safe Handling Practices

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF and TNT Properties and Safety Objectives

Hydrofluoric acid (HF) and trinitrotoluene (TNT) represent two distinct hazardous materials with unique chemical properties that necessitate specialized handling protocols. HF is a highly corrosive acid with a molecular formula of HF, appearing as a colorless liquid or gas that readily dissolves in water. Its distinctive property lies in its ability to penetrate tissue rapidly, causing severe burns that may not be immediately apparent, and potentially leading to systemic toxicity through calcium sequestration.

TNT, or 2,4,6-trinitrotoluene (C₇H₅N₃O₆), presents as yellow crystalline solid with significant explosive properties. Unlike many explosives, TNT exhibits remarkable stability under normal conditions, requiring substantial shock, heat, or detonation to initiate explosion. This relative stability has made it a benchmark in explosive technology, with its power often used as a reference point (TNT equivalent) for measuring explosive force.

The evolution of safety practices for both substances reflects increasing understanding of their hazards. HF handling protocols have evolved from basic acid precautions to comprehensive systems addressing both immediate corrosive effects and delayed systemic toxicity. Similarly, TNT safety measures have progressed from rudimentary explosive handling to sophisticated protocols addressing not only explosion risks but also chronic health effects from prolonged exposure.

Current technological trends focus on developing safer alternatives or improved containment systems for both substances. For HF, innovations include less hazardous substitutes for industrial applications and enhanced neutralization technologies. For TNT, research centers on developing insensitive munitions with comparable performance but reduced accidental detonation risk.

The primary safety objective when handling these materials is preventing human exposure while maintaining operational efficiency. For HF, this includes preventing skin contact, inhalation, and environmental release through robust containment systems, specialized PPE, and emergency response protocols including calcium gluconate treatment. For TNT, objectives include preventing unintended detonation through controlled storage conditions, minimizing friction and impact during handling, and reducing exposure to TNT dust which poses both explosive and toxicological hazards.

Secondary objectives include environmental protection, as both substances can cause significant ecological damage if released. This necessitates proper disposal protocols, containment systems for potential spills, and monitoring systems to detect leaks or releases before they become significant hazards.

The technical goals for advancing safety practices include developing real-time monitoring systems for early detection of HF leaks, improving neutralization technologies, creating more effective barrier materials for PPE, and designing safer production processes that minimize human interaction with these hazardous materials.

TNT, or 2,4,6-trinitrotoluene (C₇H₅N₃O₆), presents as yellow crystalline solid with significant explosive properties. Unlike many explosives, TNT exhibits remarkable stability under normal conditions, requiring substantial shock, heat, or detonation to initiate explosion. This relative stability has made it a benchmark in explosive technology, with its power often used as a reference point (TNT equivalent) for measuring explosive force.

The evolution of safety practices for both substances reflects increasing understanding of their hazards. HF handling protocols have evolved from basic acid precautions to comprehensive systems addressing both immediate corrosive effects and delayed systemic toxicity. Similarly, TNT safety measures have progressed from rudimentary explosive handling to sophisticated protocols addressing not only explosion risks but also chronic health effects from prolonged exposure.

Current technological trends focus on developing safer alternatives or improved containment systems for both substances. For HF, innovations include less hazardous substitutes for industrial applications and enhanced neutralization technologies. For TNT, research centers on developing insensitive munitions with comparable performance but reduced accidental detonation risk.

The primary safety objective when handling these materials is preventing human exposure while maintaining operational efficiency. For HF, this includes preventing skin contact, inhalation, and environmental release through robust containment systems, specialized PPE, and emergency response protocols including calcium gluconate treatment. For TNT, objectives include preventing unintended detonation through controlled storage conditions, minimizing friction and impact during handling, and reducing exposure to TNT dust which poses both explosive and toxicological hazards.

Secondary objectives include environmental protection, as both substances can cause significant ecological damage if released. This necessitates proper disposal protocols, containment systems for potential spills, and monitoring systems to detect leaks or releases before they become significant hazards.

The technical goals for advancing safety practices include developing real-time monitoring systems for early detection of HF leaks, improving neutralization technologies, creating more effective barrier materials for PPE, and designing safer production processes that minimize human interaction with these hazardous materials.

Market Analysis for Chemical Safety Solutions

The chemical safety solutions market has experienced significant growth in recent years, driven by increasing regulatory requirements and heightened awareness of workplace safety. The global market for chemical safety equipment and solutions was valued at approximately $6.2 billion in 2022 and is projected to reach $9.8 billion by 2028, representing a compound annual growth rate of 7.9%. This growth is particularly evident in industries handling hazardous substances like Hydrofluoric Acid (HF) and Trinitrotoluene (TNT), where proper safety protocols are critical.

Demand for specialized safety solutions for HF handling has seen substantial increase across semiconductor manufacturing, glass etching, and petroleum refining sectors. The semiconductor industry alone accounts for nearly 35% of the global HF safety equipment market, with Asia-Pacific representing the largest regional market share at 42%. This is primarily due to the concentration of semiconductor manufacturing facilities in countries like Taiwan, South Korea, and China.

For TNT and other explosives, the military and mining sectors drive market demand for specialized containment and handling equipment. North America leads this segment with approximately 38% market share, followed by Europe at 29%. The mining industry's expansion in developing regions has created new growth opportunities, with safety solution providers expanding their offerings to address specific explosive material handling requirements.

Regulatory developments have significantly shaped market dynamics. The implementation of stricter safety standards by organizations such as OSHA in the United States and the European Chemicals Agency has compelled industries to invest in advanced safety technologies. Companies are increasingly seeking comprehensive safety solutions rather than individual products, driving the trend toward integrated safety management systems.

The competitive landscape features both specialized safety equipment manufacturers and diversified industrial safety companies. Key market players include 3M Company, Honeywell International, DuPont, Ansell Limited, and MSA Safety, collectively holding approximately 45% market share. Regional players with specialized expertise in either acid or explosive material handling occupy important niches, particularly in emerging markets.

Customer preferences are evolving toward automated safety systems that minimize human exposure to hazardous chemicals. Remote monitoring capabilities, real-time detection systems, and predictive analytics for accident prevention represent high-growth segments within the broader market. The premium segment for advanced HF handling solutions is growing at 12.3% annually, significantly outpacing the overall market.

Emerging economies present substantial growth opportunities, with China and India experiencing annual growth rates of 11.2% and 9.8% respectively in chemical safety solution adoption. However, price sensitivity remains a challenge in these markets, creating opportunities for cost-effective innovation and tiered product offerings.

Demand for specialized safety solutions for HF handling has seen substantial increase across semiconductor manufacturing, glass etching, and petroleum refining sectors. The semiconductor industry alone accounts for nearly 35% of the global HF safety equipment market, with Asia-Pacific representing the largest regional market share at 42%. This is primarily due to the concentration of semiconductor manufacturing facilities in countries like Taiwan, South Korea, and China.

For TNT and other explosives, the military and mining sectors drive market demand for specialized containment and handling equipment. North America leads this segment with approximately 38% market share, followed by Europe at 29%. The mining industry's expansion in developing regions has created new growth opportunities, with safety solution providers expanding their offerings to address specific explosive material handling requirements.

Regulatory developments have significantly shaped market dynamics. The implementation of stricter safety standards by organizations such as OSHA in the United States and the European Chemicals Agency has compelled industries to invest in advanced safety technologies. Companies are increasingly seeking comprehensive safety solutions rather than individual products, driving the trend toward integrated safety management systems.

The competitive landscape features both specialized safety equipment manufacturers and diversified industrial safety companies. Key market players include 3M Company, Honeywell International, DuPont, Ansell Limited, and MSA Safety, collectively holding approximately 45% market share. Regional players with specialized expertise in either acid or explosive material handling occupy important niches, particularly in emerging markets.

Customer preferences are evolving toward automated safety systems that minimize human exposure to hazardous chemicals. Remote monitoring capabilities, real-time detection systems, and predictive analytics for accident prevention represent high-growth segments within the broader market. The premium segment for advanced HF handling solutions is growing at 12.3% annually, significantly outpacing the overall market.

Emerging economies present substantial growth opportunities, with China and India experiencing annual growth rates of 11.2% and 9.8% respectively in chemical safety solution adoption. However, price sensitivity remains a challenge in these markets, creating opportunities for cost-effective innovation and tiered product offerings.

Current Challenges in Hazardous Materials Handling

The handling of hazardous materials such as Hydrofluoric Acid (HF) and Trinitrotoluene (TNT) presents significant challenges for industries and research facilities worldwide. Despite established protocols, incidents involving these substances continue to occur, highlighting persistent gaps in safety management systems and practices.

One of the primary challenges in handling these materials is the inadequate training of personnel. Many facilities lack comprehensive training programs that address the specific properties and dangers of HF and TNT. HF's ability to penetrate skin without immediate pain sensation and TNT's sensitivity to shock, friction, and heat require specialized knowledge that general hazardous materials training often fails to provide.

Infrastructure limitations pose another significant challenge. Many facilities were not originally designed to handle such hazardous materials, resulting in suboptimal storage conditions, insufficient ventilation systems, and inadequate emergency response equipment. Retrofitting these facilities to meet current safety standards is often costly and technically challenging.

Regulatory compliance represents a complex challenge due to varying standards across different jurisdictions. Organizations operating internationally must navigate a patchwork of regulations, which can lead to confusion and inconsistent safety practices. The lack of harmonized global standards for HF and TNT handling creates significant compliance burdens.

Emergency response capabilities remain insufficient in many organizations. The unique nature of HF burns, which may not be immediately apparent but can cause deep tissue damage, requires specialized medical protocols. Similarly, TNT incidents demand specific firefighting approaches due to explosion risks. Many facilities lack the necessary equipment, antidotes, and trained personnel to respond effectively.

Supply chain security presents growing concerns, particularly for TNT as a potential material for illicit activities. Tracking these materials throughout their lifecycle, from production to disposal, remains challenging despite technological advances in monitoring systems.

Climate considerations add another layer of complexity. Temperature fluctuations can affect the stability of TNT, while extreme weather events may compromise containment systems for both materials. Climate change-induced extreme weather events are forcing organizations to reassess their hazardous material storage protocols.

Waste management of these materials presents ongoing challenges. The disposal of HF-contaminated materials and TNT residues requires specialized processes that are costly and environmentally sensitive. Many facilities struggle with implementing sustainable disposal methods that minimize environmental impact while ensuring safety.

Psychological factors, including complacency among experienced handlers and anxiety among new personnel, contribute to human error in handling procedures. Maintaining consistent vigilance when working with these materials daily represents a significant human factors challenge that technical solutions alone cannot address.

One of the primary challenges in handling these materials is the inadequate training of personnel. Many facilities lack comprehensive training programs that address the specific properties and dangers of HF and TNT. HF's ability to penetrate skin without immediate pain sensation and TNT's sensitivity to shock, friction, and heat require specialized knowledge that general hazardous materials training often fails to provide.

Infrastructure limitations pose another significant challenge. Many facilities were not originally designed to handle such hazardous materials, resulting in suboptimal storage conditions, insufficient ventilation systems, and inadequate emergency response equipment. Retrofitting these facilities to meet current safety standards is often costly and technically challenging.

Regulatory compliance represents a complex challenge due to varying standards across different jurisdictions. Organizations operating internationally must navigate a patchwork of regulations, which can lead to confusion and inconsistent safety practices. The lack of harmonized global standards for HF and TNT handling creates significant compliance burdens.

Emergency response capabilities remain insufficient in many organizations. The unique nature of HF burns, which may not be immediately apparent but can cause deep tissue damage, requires specialized medical protocols. Similarly, TNT incidents demand specific firefighting approaches due to explosion risks. Many facilities lack the necessary equipment, antidotes, and trained personnel to respond effectively.

Supply chain security presents growing concerns, particularly for TNT as a potential material for illicit activities. Tracking these materials throughout their lifecycle, from production to disposal, remains challenging despite technological advances in monitoring systems.

Climate considerations add another layer of complexity. Temperature fluctuations can affect the stability of TNT, while extreme weather events may compromise containment systems for both materials. Climate change-induced extreme weather events are forcing organizations to reassess their hazardous material storage protocols.

Waste management of these materials presents ongoing challenges. The disposal of HF-contaminated materials and TNT residues requires specialized processes that are costly and environmentally sensitive. Many facilities struggle with implementing sustainable disposal methods that minimize environmental impact while ensuring safety.

Psychological factors, including complacency among experienced handlers and anxiety among new personnel, contribute to human error in handling procedures. Maintaining consistent vigilance when working with these materials daily represents a significant human factors challenge that technical solutions alone cannot address.

Established Safety Handling Procedures

01 Protective equipment and containment systems for hydrofluoric acid

Specialized protective equipment and containment systems are essential for safely handling hydrofluoric acid. These include chemical-resistant gloves, face shields, acid-resistant aprons, and respiratory protection. Containment systems such as specialized storage tanks with acid-resistant linings, secondary containment areas, and closed handling systems help prevent exposure and contain potential spills. Emergency equipment including eyewash stations and safety showers should be readily accessible in areas where hydrofluoric acid is handled.- Protective equipment and containment systems for handling hydrofluoric acid: Specialized protective equipment and containment systems are essential for safely handling hydrofluoric acid. This includes acid-resistant gloves, face shields, chemical-resistant clothing, and respiratory protection. Containment systems such as specialized storage tanks, secondary containment areas, and closed handling systems help prevent exposure and contain potential spills. Emergency eyewash stations and safety showers should be readily accessible in areas where hydrofluoric acid is handled.

- Safe storage and transportation protocols for trinitrotoluene: Trinitrotoluene requires specific storage and transportation protocols to prevent accidents. It should be stored in cool, dry areas away from heat sources, direct sunlight, and incompatible materials. Specialized containers designed to withstand shock and prevent static electricity buildup are necessary. Transportation must follow strict regulations including proper labeling, documentation, and use of explosion-proof vehicles. Storage facilities should have adequate ventilation, temperature control, and fire suppression systems.

- Detection and monitoring systems for chemical safety: Advanced detection and monitoring systems are crucial for early identification of leaks, spills, or dangerous concentration levels of hydrofluoric acid and trinitrotoluene. These include gas detectors, vapor monitors, and automated alarm systems that can alert personnel to potential hazards. Continuous monitoring technologies with real-time data collection help maintain safe working environments. Regular calibration and maintenance of these systems ensure their reliability in emergency situations.

- Neutralization and decontamination procedures: Specific neutralization and decontamination procedures are essential for addressing spills or exposures to hydrofluoric acid and trinitrotoluene. For hydrofluoric acid, calcium-based neutralizing agents are effective in binding fluoride ions. Trinitrotoluene requires specialized decontamination solutions to render it safe. Proper waste disposal methods must be followed after neutralization. Emergency response teams should be trained in these procedures, and appropriate neutralizing agents should be readily available in areas where these chemicals are handled.

- Training and emergency response protocols: Comprehensive training programs and emergency response protocols are vital for personnel working with hydrofluoric acid and trinitrotoluene. Training should cover proper handling techniques, recognition of hazards, use of protective equipment, and emergency procedures. Regular drills and simulations help prepare workers for potential incidents. Emergency response plans should include evacuation procedures, medical treatment protocols for exposures, and coordination with local emergency services. Documentation and regular updating of these protocols ensure preparedness for chemical incidents.

02 Neutralization and decontamination procedures for hazardous chemicals

Proper neutralization and decontamination procedures are critical when handling hydrofluoric acid and trinitrotoluene. For hydrofluoric acid, calcium-based neutralizing agents like calcium gluconate are effective for both spill management and treatment of exposure. For trinitrotoluene, specialized decontamination solutions that break down the explosive compound without triggering detonation are required. Contaminated equipment and surfaces must undergo thorough decontamination following established protocols to prevent secondary exposure or environmental contamination.Expand Specific Solutions03 Explosion prevention and safety measures for trinitrotoluene

Handling trinitrotoluene requires strict explosion prevention protocols including temperature control, elimination of ignition sources, and proper grounding to prevent static electricity buildup. Safety measures include using non-sparking tools, maintaining controlled environments with regulated humidity and temperature, and implementing buffer zones around handling areas. Personnel should be trained in explosive material handling procedures and emergency response protocols. Regular inspection of storage facilities and handling equipment is necessary to identify potential hazards before they lead to accidents.Expand Specific Solutions04 Transportation and storage requirements for hazardous chemicals

Transportation and storage of hydrofluoric acid and trinitrotoluene require specialized containers and facilities designed to prevent leaks, spills, or unintended reactions. For hydrofluoric acid, polyethylene or fluoropolymer-lined containers are used, while trinitrotoluene requires explosion-proof containers with shock absorption capabilities. Storage facilities must maintain appropriate temperature and humidity controls, provide adequate ventilation, and include monitoring systems for detecting leaks or pressure buildup. Segregation from incompatible materials is essential to prevent dangerous chemical reactions.Expand Specific Solutions05 Emergency response and first aid protocols

Comprehensive emergency response and first aid protocols are vital when working with hydrofluoric acid and trinitrotoluene. For hydrofluoric acid exposure, immediate flushing with water followed by application of calcium gluconate gel is critical to prevent tissue damage and systemic toxicity. For trinitrotoluene incidents, evacuation procedures, containment strategies, and specialized medical treatment for TNT poisoning must be established. Emergency response teams should be trained in chemical-specific hazards, proper use of neutralizing agents, and coordination with medical personnel for effective treatment of exposures.Expand Specific Solutions

Leading Organizations in Chemical Safety Standards

The hydrofluoric acid and trinitrotoluene handling safety market is in a mature growth phase, with an estimated global market size of $3-5 billion annually. The technical landscape is characterized by established safety protocols and specialized equipment, with ongoing innovation focused on risk mitigation. Leading players include Honeywell International Technologies and Daikin Industries, who have developed advanced containment systems, while Sinochem Lantian and Shandong Exceris Chemical focus on chemical stabilization technologies. Academic institutions like Tsinghua University collaborate with industrial partners on next-generation safety solutions. The market is seeing increased regulatory scrutiny driving demand for sophisticated handling technologies from companies like AGC and Arkema France, who are investing in automated systems to minimize human exposure during chemical processing operations.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed comprehensive safety management systems for handling hydrofluoric acid (HF) that integrate advanced containment technologies with real-time monitoring solutions. Their approach includes specialized double-walled containment vessels with leak detection systems that provide immediate alerts if primary containment is compromised. For HF handling, Honeywell employs proprietary fluoropolymer linings in storage and transport equipment that resist HF's corrosive properties. Their safety protocol incorporates automated neutralization systems using calcium-based compounds that can rapidly respond to spills. For trinitrotoluene (TNT), Honeywell has engineered remote handling systems that minimize direct human contact, utilizing robotic arms and mechanical transfer mechanisms operated from blast-protected control rooms. Their TNT facilities feature specialized water deluge systems that can rapidly saturate areas to prevent detonation during emergencies.

Strengths: Industry-leading integration of automation and safety systems reduces human exposure risk; comprehensive emergency response protocols exceed regulatory requirements. Weaknesses: Higher implementation costs compared to standard safety systems; requires specialized training and maintenance programs that smaller operations may find resource-intensive.

Société Nationale des Poudres et Explosifs SA

Technical Solution: SNPE has pioneered advanced handling technologies for trinitrotoluene (TNT) based on decades of experience in explosives manufacturing. Their safety approach centers on a proprietary "minimal presence" methodology that limits the quantity of TNT in any single processing area to reduce potential incident severity. SNPE's handling system employs remote-controlled equipment with pneumatic transfer mechanisms that eliminate friction and static electricity risks. Their facilities feature specialized blast walls with pressure-relief panels designed to direct explosion forces away from personnel and critical infrastructure. For temperature control during TNT processing, SNPE utilizes a closed-loop water cooling system that maintains optimal temperatures below 90°C to prevent decomposition reactions. Their safety protocols include continuous monitoring of TNT's chemical stability through automated sampling and analysis systems that can detect early signs of decomposition. For hydrofluoric acid, SNPE has developed specialized fluoropolymer containment systems with redundant barriers and neutralization capabilities.

Strengths: Unparalleled expertise in explosives handling with proven safety record in high-risk environments; comprehensive training programs that have become industry standards. Weaknesses: Systems designed primarily for large-scale industrial operations may be difficult to scale down for smaller applications; high capital investment requirements for full implementation.

Critical Safety Technologies and Innovations

Monoazo-based dye for acid detection

PatentActiveUS20160327529A1

Innovation

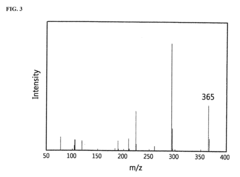

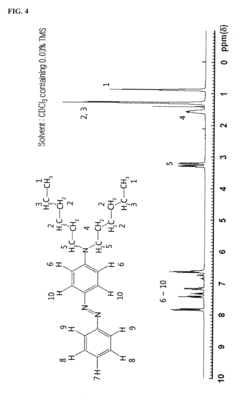

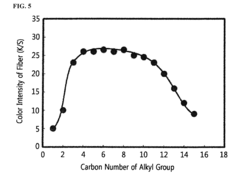

- A monoazo-based dye, represented by Formula 1, which changes color upon exposure to acid and retains high color fastness even after dyeing into fibers, synthesized through a diazotization-coupling reaction, using N,N-diC3-12 alkylaniline azobenzene structure, allowing for rapid and reversible color change in response to acidic gases.

Process for purifying trinitro-2,4,6 toluene

PatentInactiveEP0025733A2

Innovation

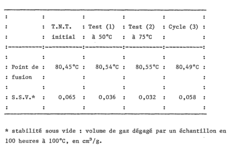

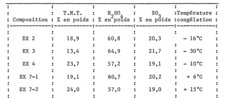

- A composition comprising 7-30% by weight of 2,4,6-trinitrotoluene, 50-80% by weight of sulfuric acid, and 10-28% by weight of sulfuric anhydride, which forms a stable solution when mixed with sulfuric oleum, reducing sensitivity and allowing safe storage and transport by dissolving TNT, thereby avoiding explosive properties.

Regulatory Framework for Hazardous Chemicals

The regulatory landscape governing hazardous chemicals like Hydrofluoric Acid (HF) and Trinitrotoluene (TNT) is complex and multi-layered, spanning international conventions, federal regulations, and local ordinances. These frameworks establish the foundation for safe handling practices and risk management protocols essential for preventing catastrophic incidents.

At the international level, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides standardized criteria for hazard classification and communication. Both HF and TNT fall under stringent GHS categories, with HF classified as an acute toxic substance and corrosive material, while TNT is categorized as an explosive and potential carcinogen. The United Nations Recommendations on the Transport of Dangerous Goods further regulates international movement of these substances.

In the United States, the Occupational Safety and Health Administration (OSHA) establishes permissible exposure limits (PELs) for HF at 3 ppm as an 8-hour time-weighted average, while TNT has a PEL of 0.5 mg/m³. OSHA's Process Safety Management (PSM) standard applies to both chemicals when threshold quantities are exceeded, requiring comprehensive safety programs including process hazard analysis and emergency response planning.

The Environmental Protection Agency (EPA) regulates these substances under multiple statutes. The Resource Conservation and Recovery Act (RCRA) classifies spent HF and TNT residues as hazardous wastes requiring specialized disposal protocols. The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) establishes reportable quantities for releases—10 pounds for HF and 10 pounds for TNT.

European regulations under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and the Seveso III Directive impose additional requirements for facilities handling these substances within EU member states, including safety reports and major accident prevention policies.

Industry-specific standards complement these regulatory frameworks. The American Chemistry Council's Responsible Care program and the Institute of Makers of Explosives' Safety Library provide voluntary guidelines that often exceed minimum regulatory requirements for handling HF and TNT respectively.

Recent regulatory trends indicate movement toward more stringent controls, particularly for HF due to several high-profile incidents at petroleum refineries. The Chemical Facility Anti-Terrorism Standards (CFATS) now classify both chemicals as chemicals of interest, requiring facilities to implement security measures proportionate to the risk they pose.

At the international level, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides standardized criteria for hazard classification and communication. Both HF and TNT fall under stringent GHS categories, with HF classified as an acute toxic substance and corrosive material, while TNT is categorized as an explosive and potential carcinogen. The United Nations Recommendations on the Transport of Dangerous Goods further regulates international movement of these substances.

In the United States, the Occupational Safety and Health Administration (OSHA) establishes permissible exposure limits (PELs) for HF at 3 ppm as an 8-hour time-weighted average, while TNT has a PEL of 0.5 mg/m³. OSHA's Process Safety Management (PSM) standard applies to both chemicals when threshold quantities are exceeded, requiring comprehensive safety programs including process hazard analysis and emergency response planning.

The Environmental Protection Agency (EPA) regulates these substances under multiple statutes. The Resource Conservation and Recovery Act (RCRA) classifies spent HF and TNT residues as hazardous wastes requiring specialized disposal protocols. The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) establishes reportable quantities for releases—10 pounds for HF and 10 pounds for TNT.

European regulations under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and the Seveso III Directive impose additional requirements for facilities handling these substances within EU member states, including safety reports and major accident prevention policies.

Industry-specific standards complement these regulatory frameworks. The American Chemistry Council's Responsible Care program and the Institute of Makers of Explosives' Safety Library provide voluntary guidelines that often exceed minimum regulatory requirements for handling HF and TNT respectively.

Recent regulatory trends indicate movement toward more stringent controls, particularly for HF due to several high-profile incidents at petroleum refineries. The Chemical Facility Anti-Terrorism Standards (CFATS) now classify both chemicals as chemicals of interest, requiring facilities to implement security measures proportionate to the risk they pose.

Emergency Response and Incident Mitigation Strategies

Emergency response protocols for Hydrofluoric Acid (HF) and Trinitrotoluene (TNT) incidents require fundamentally different approaches due to their distinct hazard profiles. For HF incidents, immediate response must focus on neutralization using calcium gluconate or calcium carbonate solutions, while maintaining strict respiratory protection for first responders. Water fog or fine spray systems should be deployed to suppress vapor formation, with specialized acid-resistant protective equipment mandatory for all personnel within the containment zone.

TNT incidents, conversely, demand evacuation protocols with significantly larger perimeter controls due to explosion risks. Fire suppression efforts must be conducted from maximum distance using remote-controlled equipment whenever possible, with cooling of adjacent areas to prevent sympathetic detonation of unexploded material. Unlike HF, water application to TNT fires requires careful consideration as it may spread contamination without effectively suppressing the hazard.

Communication systems represent a critical component in both scenarios, with redundant notification channels and pre-established emergency response networks essential. Modern incident management increasingly incorporates real-time monitoring through IoT sensors that can detect HF vapor concentrations or thermal anomalies indicating TNT instability, enabling faster response activation and more precise hazard assessment.

Decontamination procedures differ substantially between the two substances. HF contamination requires immediate calcium-based neutralization followed by extended medical monitoring due to potential delayed systemic effects, while TNT contamination focuses on physical removal of particulates and prevention of static electricity during cleanup operations. Both scenarios benefit from mobile decontamination units with specialized waste containment systems.

Post-incident analysis methodologies have evolved significantly, with comprehensive digital documentation now standard practice. This includes drone-based aerial assessment of affected areas, thermal imaging to identify residual hot spots, and chemical sampling with portable spectrometry. These technologies enable more effective containment verification and inform future mitigation strategies.

Training programs for emergency responders increasingly utilize virtual reality simulations specific to each substance, allowing personnel to practice response protocols without exposure risk. These simulations incorporate realistic chemical behavior models based on computational fluid dynamics and reaction kinetics, significantly improving response effectiveness during actual incidents.

TNT incidents, conversely, demand evacuation protocols with significantly larger perimeter controls due to explosion risks. Fire suppression efforts must be conducted from maximum distance using remote-controlled equipment whenever possible, with cooling of adjacent areas to prevent sympathetic detonation of unexploded material. Unlike HF, water application to TNT fires requires careful consideration as it may spread contamination without effectively suppressing the hazard.

Communication systems represent a critical component in both scenarios, with redundant notification channels and pre-established emergency response networks essential. Modern incident management increasingly incorporates real-time monitoring through IoT sensors that can detect HF vapor concentrations or thermal anomalies indicating TNT instability, enabling faster response activation and more precise hazard assessment.

Decontamination procedures differ substantially between the two substances. HF contamination requires immediate calcium-based neutralization followed by extended medical monitoring due to potential delayed systemic effects, while TNT contamination focuses on physical removal of particulates and prevention of static electricity during cleanup operations. Both scenarios benefit from mobile decontamination units with specialized waste containment systems.

Post-incident analysis methodologies have evolved significantly, with comprehensive digital documentation now standard practice. This includes drone-based aerial assessment of affected areas, thermal imaging to identify residual hot spots, and chemical sampling with portable spectrometry. These technologies enable more effective containment verification and inform future mitigation strategies.

Training programs for emergency responders increasingly utilize virtual reality simulations specific to each substance, allowing personnel to practice response protocols without exposure risk. These simulations incorporate realistic chemical behavior models based on computational fluid dynamics and reaction kinetics, significantly improving response effectiveness during actual incidents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!