Hydrofluoric Acid Applications in Biofuel Synthesis

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF Acid in Biofuel Evolution and Objectives

Hydrofluoric acid (HF) has emerged as a significant catalyst in biofuel synthesis, marking a transformative shift in renewable energy technology over the past decades. The evolution of HF applications in biofuel production can be traced back to the early 2000s when researchers began exploring alternative catalysts for biomass conversion. Initially limited to laboratory-scale experiments, HF utilization has progressively expanded into industrial applications, demonstrating its versatility across various biofuel production pathways.

The technological trajectory of HF in biofuel synthesis has been characterized by continuous refinement in catalyst formulations, reaction conditions, and process integration. Early applications primarily focused on simple transesterification reactions for biodiesel production, where HF served as an acidic catalyst. Subsequently, more sophisticated applications emerged, including lignocellulosic biomass pretreatment, algal biomass processing, and advanced hydrocarbon biofuel synthesis.

Recent technological advancements have significantly enhanced the efficiency and selectivity of HF-catalyzed processes. Notable developments include the introduction of supported HF catalysts, which reduce acid consumption while maintaining catalytic activity; the development of continuous flow reactors specifically designed for HF-mediated reactions; and the integration of HF catalysis with other conversion technologies in hybrid processing systems.

The primary objective of current HF technology in biofuel synthesis is to overcome the recalcitrance of complex biomass structures, enabling more efficient conversion of diverse feedstocks into high-quality biofuels. Specific technical goals include achieving higher conversion rates, improving product selectivity, reducing energy inputs, and minimizing waste generation. Additionally, there is a growing emphasis on developing safer handling protocols and containment systems to address the inherent hazards associated with HF.

Looking forward, the technological roadmap for HF in biofuel synthesis aims to address several critical challenges. These include enhancing catalyst stability under varying reaction conditions, reducing catalyst leaching, improving recyclability, and developing more environmentally benign formulations. The ultimate objective is to establish HF-based technologies as a cornerstone of next-generation biorefinery operations, capable of processing multiple feedstock types with minimal environmental impact.

The evolution of HF applications in biofuel synthesis aligns with broader trends in renewable energy technology, including the push toward carbon neutrality, circular economy principles, and the valorization of waste streams. As such, the continued development of HF-based processes represents a strategic investment in sustainable energy infrastructure, with potential implications for energy security, rural economic development, and greenhouse gas mitigation efforts.

The technological trajectory of HF in biofuel synthesis has been characterized by continuous refinement in catalyst formulations, reaction conditions, and process integration. Early applications primarily focused on simple transesterification reactions for biodiesel production, where HF served as an acidic catalyst. Subsequently, more sophisticated applications emerged, including lignocellulosic biomass pretreatment, algal biomass processing, and advanced hydrocarbon biofuel synthesis.

Recent technological advancements have significantly enhanced the efficiency and selectivity of HF-catalyzed processes. Notable developments include the introduction of supported HF catalysts, which reduce acid consumption while maintaining catalytic activity; the development of continuous flow reactors specifically designed for HF-mediated reactions; and the integration of HF catalysis with other conversion technologies in hybrid processing systems.

The primary objective of current HF technology in biofuel synthesis is to overcome the recalcitrance of complex biomass structures, enabling more efficient conversion of diverse feedstocks into high-quality biofuels. Specific technical goals include achieving higher conversion rates, improving product selectivity, reducing energy inputs, and minimizing waste generation. Additionally, there is a growing emphasis on developing safer handling protocols and containment systems to address the inherent hazards associated with HF.

Looking forward, the technological roadmap for HF in biofuel synthesis aims to address several critical challenges. These include enhancing catalyst stability under varying reaction conditions, reducing catalyst leaching, improving recyclability, and developing more environmentally benign formulations. The ultimate objective is to establish HF-based technologies as a cornerstone of next-generation biorefinery operations, capable of processing multiple feedstock types with minimal environmental impact.

The evolution of HF applications in biofuel synthesis aligns with broader trends in renewable energy technology, including the push toward carbon neutrality, circular economy principles, and the valorization of waste streams. As such, the continued development of HF-based processes represents a strategic investment in sustainable energy infrastructure, with potential implications for energy security, rural economic development, and greenhouse gas mitigation efforts.

Market Analysis for HF-Catalyzed Biofuel Production

The global biofuel market has experienced significant growth over the past decade, driven by increasing environmental concerns and the push for renewable energy sources. The market value reached approximately $141 billion in 2022 and is projected to grow at a CAGR of 8.3% through 2030, potentially reaching $248 billion by the end of the forecast period.

Hydrofluoric acid (HF) catalyzed processes are emerging as a promising segment within this expanding market. Currently, HF-catalyzed biofuel production represents a relatively small portion of the overall biofuel market, estimated at 3-5% of total production capacity. However, this segment is growing at an accelerated rate of 12-15% annually, outpacing the broader biofuel market growth.

Regional analysis reveals varying adoption rates of HF-catalyzed technologies. North America leads with approximately 42% market share, followed by Europe (31%), Asia-Pacific (18%), and the rest of the world (9%). The United States, Germany, and China are the primary markets driving innovation and commercial implementation of these technologies.

The demand for HF-catalyzed biofuel production is particularly strong in the transportation sector, which accounts for 68% of the end-use market. Aviation biofuels represent the fastest-growing segment, with a 17.5% annual growth rate, as airlines seek to reduce their carbon footprint through sustainable aviation fuels (SAF).

Market penetration analysis indicates that HF-catalyzed processes have achieved significant traction in second-generation biofuel production, particularly those utilizing lignocellulosic feedstocks. The technology has demonstrated cost advantages of 15-20% compared to traditional acid catalysts when processing woody biomass and agricultural residues.

Consumer willingness to pay premiums for environmentally friendly fuels continues to strengthen the market outlook. Surveys indicate that 62% of industrial customers and 47% of individual consumers are willing to pay a 5-10% premium for biofuels with lower environmental impact, which includes those produced through more efficient HF-catalyzed processes.

Key market drivers include stringent environmental regulations, particularly in the EU and North America, government incentives for renewable energy adoption, and corporate sustainability commitments. The EU's Renewable Energy Directive II and the US Renewable Fuel Standard provide regulatory frameworks that directly benefit advanced biofuel technologies.

Market barriers include competition from other catalytic processes, safety concerns associated with hydrofluoric acid handling, and capital investment requirements for retrofitting existing facilities. Despite these challenges, the economic benefits of higher conversion efficiency and reduced waste streams position HF-catalyzed processes favorably in the competitive landscape.

Hydrofluoric acid (HF) catalyzed processes are emerging as a promising segment within this expanding market. Currently, HF-catalyzed biofuel production represents a relatively small portion of the overall biofuel market, estimated at 3-5% of total production capacity. However, this segment is growing at an accelerated rate of 12-15% annually, outpacing the broader biofuel market growth.

Regional analysis reveals varying adoption rates of HF-catalyzed technologies. North America leads with approximately 42% market share, followed by Europe (31%), Asia-Pacific (18%), and the rest of the world (9%). The United States, Germany, and China are the primary markets driving innovation and commercial implementation of these technologies.

The demand for HF-catalyzed biofuel production is particularly strong in the transportation sector, which accounts for 68% of the end-use market. Aviation biofuels represent the fastest-growing segment, with a 17.5% annual growth rate, as airlines seek to reduce their carbon footprint through sustainable aviation fuels (SAF).

Market penetration analysis indicates that HF-catalyzed processes have achieved significant traction in second-generation biofuel production, particularly those utilizing lignocellulosic feedstocks. The technology has demonstrated cost advantages of 15-20% compared to traditional acid catalysts when processing woody biomass and agricultural residues.

Consumer willingness to pay premiums for environmentally friendly fuels continues to strengthen the market outlook. Surveys indicate that 62% of industrial customers and 47% of individual consumers are willing to pay a 5-10% premium for biofuels with lower environmental impact, which includes those produced through more efficient HF-catalyzed processes.

Key market drivers include stringent environmental regulations, particularly in the EU and North America, government incentives for renewable energy adoption, and corporate sustainability commitments. The EU's Renewable Energy Directive II and the US Renewable Fuel Standard provide regulatory frameworks that directly benefit advanced biofuel technologies.

Market barriers include competition from other catalytic processes, safety concerns associated with hydrofluoric acid handling, and capital investment requirements for retrofitting existing facilities. Despite these challenges, the economic benefits of higher conversion efficiency and reduced waste streams position HF-catalyzed processes favorably in the competitive landscape.

Current Status and Barriers in HF Biofuel Applications

The global landscape of hydrofluoric acid (HF) applications in biofuel synthesis presents a complex picture of technological advancement alongside significant implementation challenges. Currently, HF serves multiple functions in biofuel production processes, primarily as a catalyst in alkylation reactions for high-octane biofuel components and as a pretreatment agent for lignocellulosic biomass conversion. Laboratory-scale research has demonstrated HF's effectiveness in breaking down recalcitrant plant cell walls, thereby enhancing sugar release for subsequent fermentation processes.

Despite these promising applications, industrial-scale implementation remains limited due to several critical barriers. The corrosive nature of HF presents substantial materials compatibility challenges, necessitating specialized equipment constructed from costly fluoropolymers or monel alloys. This requirement significantly increases capital expenditure for biofuel facilities considering HF-based processes, creating economic hurdles particularly for smaller producers and developing markets.

Safety concerns constitute another major impediment to widespread adoption. HF's high toxicity and ability to penetrate skin and cause deep tissue damage demand rigorous safety protocols, specialized training, and sophisticated containment systems. These requirements add operational complexity and cost layers that many biofuel producers find prohibitive, especially when alternative catalysts with lower hazard profiles are available.

Regulatory constraints further complicate the landscape. Many jurisdictions have implemented increasingly stringent regulations governing HF handling, storage, and disposal. Compliance with these regulations requires substantial documentation, monitoring systems, and waste management protocols that create administrative burdens for biofuel producers. Regional variations in regulatory frameworks also impede standardization of HF-based biofuel technologies across international markets.

Environmental considerations represent another significant barrier. While HF can enhance process efficiency, concerns about potential environmental contamination from accidental releases or improper disposal have prompted resistance from both regulatory bodies and local communities. The carbon footprint associated with HF production and transportation also undermines some of the sustainability benefits that biofuels aim to deliver.

Technical challenges persist in optimizing HF concentration, reaction conditions, and recovery systems for different biomass feedstocks. The heterogeneous nature of biomass resources means that HF-based processes require significant customization, limiting economies of scale and technology transfer between different biofuel production contexts. Recovery and recycling of HF from reaction mixtures remains technically challenging and energy-intensive, affecting both economic viability and environmental performance.

The geographical distribution of HF technology development shows concentration in advanced economies with established chemical industries, particularly the United States, Germany, and Japan. This creates knowledge and implementation gaps in emerging economies where biofuel production potential is often highest due to biomass availability and favorable growing conditions.

Despite these promising applications, industrial-scale implementation remains limited due to several critical barriers. The corrosive nature of HF presents substantial materials compatibility challenges, necessitating specialized equipment constructed from costly fluoropolymers or monel alloys. This requirement significantly increases capital expenditure for biofuel facilities considering HF-based processes, creating economic hurdles particularly for smaller producers and developing markets.

Safety concerns constitute another major impediment to widespread adoption. HF's high toxicity and ability to penetrate skin and cause deep tissue damage demand rigorous safety protocols, specialized training, and sophisticated containment systems. These requirements add operational complexity and cost layers that many biofuel producers find prohibitive, especially when alternative catalysts with lower hazard profiles are available.

Regulatory constraints further complicate the landscape. Many jurisdictions have implemented increasingly stringent regulations governing HF handling, storage, and disposal. Compliance with these regulations requires substantial documentation, monitoring systems, and waste management protocols that create administrative burdens for biofuel producers. Regional variations in regulatory frameworks also impede standardization of HF-based biofuel technologies across international markets.

Environmental considerations represent another significant barrier. While HF can enhance process efficiency, concerns about potential environmental contamination from accidental releases or improper disposal have prompted resistance from both regulatory bodies and local communities. The carbon footprint associated with HF production and transportation also undermines some of the sustainability benefits that biofuels aim to deliver.

Technical challenges persist in optimizing HF concentration, reaction conditions, and recovery systems for different biomass feedstocks. The heterogeneous nature of biomass resources means that HF-based processes require significant customization, limiting economies of scale and technology transfer between different biofuel production contexts. Recovery and recycling of HF from reaction mixtures remains technically challenging and energy-intensive, affecting both economic viability and environmental performance.

The geographical distribution of HF technology development shows concentration in advanced economies with established chemical industries, particularly the United States, Germany, and Japan. This creates knowledge and implementation gaps in emerging economies where biofuel production potential is often highest due to biomass availability and favorable growing conditions.

Established HF Catalytic Processes for Biofuel Synthesis

01 Etching and cleaning applications in semiconductor manufacturing

Hydrofluoric acid is widely used in semiconductor manufacturing processes for etching silicon dioxide and cleaning silicon wafers. It effectively removes oxide layers, contaminants, and residues from semiconductor surfaces. Various formulations and concentrations of hydrofluoric acid are employed depending on the specific requirements of the etching or cleaning process, often in combination with other chemicals to enhance performance and control the etching rate.- Etching and cleaning applications in semiconductor manufacturing: Hydrofluoric acid is widely used in semiconductor manufacturing processes for etching silicon dioxide and cleaning silicon wafers. It effectively removes oxide layers, contaminants, and residues from semiconductor surfaces. Various formulations and concentrations of hydrofluoric acid are employed depending on the specific requirements of the etching or cleaning process, often in combination with other chemicals to enhance performance and control etch rates.

- Production and purification methods of hydrofluoric acid: Various methods for producing and purifying hydrofluoric acid have been developed. These include processes for manufacturing high-purity hydrofluoric acid from fluoride-containing raw materials, techniques for removing impurities, and systems for handling and storing the acid safely. Purification methods often involve distillation, filtration, or chemical treatments to achieve the desired quality for industrial applications.

- Waste treatment and recovery systems: Environmental concerns have led to the development of methods for treating hydrofluoric acid waste and recovering valuable components. These systems aim to neutralize the acid, remove fluoride ions from wastewater, and in some cases recover and recycle the acid for reuse. Treatment processes may involve precipitation, ion exchange, adsorption, or chemical neutralization to minimize environmental impact and comply with regulations.

- Safety measures and handling protocols: Due to the highly corrosive and toxic nature of hydrofluoric acid, specialized safety measures and handling protocols have been developed. These include protective equipment designs, emergency response procedures, detection systems for leaks or spills, and specialized containers or delivery systems that minimize exposure risks. Safety innovations focus on preventing contact with skin and eyes, avoiding inhalation of vapors, and providing rapid response in case of accidents.

- Specialized formulations for specific industrial applications: Hydrofluoric acid is formulated in various ways for specific industrial applications beyond semiconductor manufacturing. These include glass etching compositions, metal surface treatments, oil well stimulation fluids, and cleaning solutions for various industries. The formulations often combine hydrofluoric acid with other chemicals to achieve desired properties such as controlled reactivity, improved safety, enhanced effectiveness, or compatibility with specific materials.

02 Production and purification methods of hydrofluoric acid

Various methods are employed for the production and purification of hydrofluoric acid. These include processes involving the reaction of calcium fluoride with sulfuric acid, purification techniques to remove impurities, and specialized distillation methods. Advanced manufacturing processes focus on producing high-purity hydrofluoric acid for specialized applications in electronics and other industries where trace contaminants can be problematic.Expand Specific Solutions03 Safety measures and handling protocols

Due to its highly corrosive and toxic nature, specialized safety measures and handling protocols are essential when working with hydrofluoric acid. These include the use of specific personal protective equipment, specialized containment systems, neutralization procedures, and emergency response protocols. Safety innovations include improved storage containers, detection systems for leaks, and specialized first aid treatments for exposure incidents.Expand Specific Solutions04 Waste treatment and environmental protection

Methods for treating hydrofluoric acid waste to minimize environmental impact include neutralization processes, recovery and recycling techniques, and conversion to less hazardous compounds. Environmental protection measures involve specialized containment systems, monitoring protocols, and treatment facilities designed to handle hydrofluoric acid waste safely and in compliance with environmental regulations.Expand Specific Solutions05 Industrial applications beyond semiconductors

Hydrofluoric acid has numerous applications outside of semiconductor manufacturing, including glass etching and frosting, metal surface treatment, oil refining catalysts, and fluorochemical production. It is used in various concentrations and formulations depending on the specific application requirements. In metal treatment, it is particularly valuable for removing oxide layers and preparing surfaces for subsequent processing or coating.Expand Specific Solutions

Industry Leaders in HF-Based Biofuel Technology

The hydrofluoric acid applications in biofuel synthesis market is currently in an emerging growth phase, characterized by increasing research activities and commercial implementations. The global market size is estimated to be expanding at a CAGR of 5-7%, driven by renewable energy mandates and sustainability initiatives. From a technological maturity perspective, the field shows varying degrees of development across applications. Industry leaders like Honeywell International Technologies and UOP LLC have established mature catalytic processes, while companies such as REG Synthetic Fuels and Dow Global Technologies are advancing innovative approaches for efficient biofuel production. Shell and Arkema France are investing in proprietary technologies to enhance conversion efficiency, while research institutions like the Agency for Science, Technology & Research are developing next-generation processes that could significantly reduce production costs and environmental impact.

UOP LLC

Technical Solution: UOP LLC, a Honeywell company, has developed advanced catalytic processes utilizing hydrofluoric acid (HF) as a catalyst in biofuel synthesis. Their technology focuses on the alkylation of olefins with isobutane to produce high-octane components for biofuel blending. The process employs a proprietary solid catalyst system that incorporates HF in a bound form, reducing the hazards associated with conventional liquid HF while maintaining catalytic efficiency. This innovation allows for the conversion of biomass-derived feedstocks into drop-in biofuels compatible with existing infrastructure. UOP's approach includes a regeneration system that extends catalyst life and minimizes waste, while their integrated process design optimizes energy consumption across the production chain. The technology has demonstrated yields exceeding 95% in commercial-scale operations, with significant reductions in greenhouse gas emissions compared to conventional petroleum fuels.

Strengths: Proprietary solid catalyst system reduces HF handling risks while maintaining high catalytic activity; integrated process design minimizes energy consumption; compatible with existing fuel infrastructure. Weaknesses: Higher initial capital investment compared to conventional processes; requires specialized handling protocols despite safety improvements; catalyst regeneration adds operational complexity.

Furanix Technologies BV

Technical Solution: Furanix Technologies has developed a groundbreaking process utilizing dilute hydrofluoric acid as a catalyst for the conversion of biomass-derived carbohydrates to 5-hydroxymethylfurfural (HMF) and 2,5-furandicarboxylic acid (FDCA), key platform chemicals for biofuel synthesis. Their proprietary YXY® Technology employs HF in a biphasic reactor system that achieves selective dehydration of C6 sugars with yields exceeding 80%, significantly higher than conventional mineral acid catalysts. The process operates at moderate temperatures (80-120°C) and pressures, reducing energy requirements while maintaining high selectivity. Furanix has engineered a closed-loop system that recovers and reuses over 98% of the HF catalyst, addressing environmental and economic concerns. Their technology enables the production of furanic biofuels with energy densities comparable to petroleum-derived fuels. The company has successfully scaled this technology to demonstration level, processing several tons of biomass daily with consistent product quality and minimal waste generation.

Strengths: Achieves exceptionally high yields of furanic platform chemicals; biphasic reactor design enhances selectivity and product separation; efficient catalyst recovery system minimizes environmental impact. Weaknesses: Process sensitivity to feedstock composition requires careful upstream preparation; specialized materials needed for HF-containing environments increase capital costs; safety protocols for HF handling add operational complexity.

Key Technical Innovations in HF-Mediated Biofuel Reactions

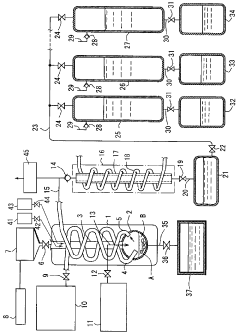

Hydrofluoric acid production apparatus and hydrofluoric acid production method

PatentWO2007004516A1

Innovation

- A hydrofluoric acid generator using a ceramic adsorbent mainly composed of activated alumina and silicon dioxide, where fluorine ions are adsorbed, and then reacted with a strong alkali or acid, with crystalline silicon dioxide added to generate hexafluorosilicate gas, which is cooled and hydrolyzed to produce hydrofluoric acid, while phosphoric acid is used to prevent aluminum elution and maintain adsorbent stability.

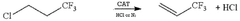

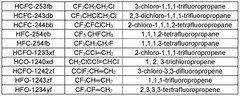

Method for producing 1,1,1-trifluoropropene from the dehydrochlorination of 3-chloro-1,1,1-trifluoropropane

PatentWO2024205836A1

Innovation

- A dehydrochlorination process using an activated carbon catalyst with hydrogen chloride (HCI) as a co-feed in the vapor phase, increasing the conversion rate of 3-chloro-1,1,1-trifluoropropane to 1,1,1-trifluoropropene.

Safety Protocols and Handling Standards for HF in Biofuel Production

The implementation of stringent safety protocols for hydrofluoric acid (HF) handling in biofuel production environments is paramount due to its extreme corrosivity and toxicity. Industry standards mandate comprehensive risk assessments before incorporating HF into any biofuel synthesis process, with particular emphasis on facility design specifications that include specialized ventilation systems, acid-resistant materials, and dedicated containment areas.

Personal protective equipment requirements for HF handling exceed standard laboratory protocols, necessitating chemical-resistant full-body suits, face shields, specialized gloves with specific chemical resistance ratings, and respiratory protection with appropriate acid gas cartridges. Emergency response equipment must be strategically positioned throughout facilities, including calcium gluconate gel stations, emergency showers, and eyewash stations specifically designed for HF exposure.

Standard operating procedures must detail precise handling methodologies, including transfer techniques that minimize exposure risk, dilution protocols that account for HF's exothermic reaction with water, and waste neutralization procedures. These SOPs require regular validation through simulated emergency scenarios and must be updated to reflect evolving best practices in the industry.

Monitoring systems represent a critical safety component, with requirements for continuous air quality monitoring, regular equipment integrity checks, and automated alarm systems that detect even minimal HF vapor concentrations. The implementation of digital monitoring platforms has significantly enhanced safety management by providing real-time data analytics and predictive maintenance capabilities.

Training programs for personnel working with HF in biofuel applications must exceed basic hazardous material handling certifications, incorporating specialized modules on HF's unique properties, exposure symptoms, and emergency response protocols. Certification renewal requirements typically mandate quarterly refresher training and annual comprehensive reassessment.

Regulatory compliance frameworks vary globally but generally align with standards established by organizations such as OSHA, EPA, and equivalent international bodies. Documentation requirements include detailed exposure control plans, incident response procedures, and comprehensive training records that demonstrate ongoing compliance with evolving regulatory standards.

Industry best practices increasingly emphasize the implementation of inherently safer design principles that minimize HF quantities through process intensification techniques, explore less hazardous alternatives where technically feasible, and incorporate advanced containment technologies that significantly reduce exposure risks during routine operations and maintenance activities.

Personal protective equipment requirements for HF handling exceed standard laboratory protocols, necessitating chemical-resistant full-body suits, face shields, specialized gloves with specific chemical resistance ratings, and respiratory protection with appropriate acid gas cartridges. Emergency response equipment must be strategically positioned throughout facilities, including calcium gluconate gel stations, emergency showers, and eyewash stations specifically designed for HF exposure.

Standard operating procedures must detail precise handling methodologies, including transfer techniques that minimize exposure risk, dilution protocols that account for HF's exothermic reaction with water, and waste neutralization procedures. These SOPs require regular validation through simulated emergency scenarios and must be updated to reflect evolving best practices in the industry.

Monitoring systems represent a critical safety component, with requirements for continuous air quality monitoring, regular equipment integrity checks, and automated alarm systems that detect even minimal HF vapor concentrations. The implementation of digital monitoring platforms has significantly enhanced safety management by providing real-time data analytics and predictive maintenance capabilities.

Training programs for personnel working with HF in biofuel applications must exceed basic hazardous material handling certifications, incorporating specialized modules on HF's unique properties, exposure symptoms, and emergency response protocols. Certification renewal requirements typically mandate quarterly refresher training and annual comprehensive reassessment.

Regulatory compliance frameworks vary globally but generally align with standards established by organizations such as OSHA, EPA, and equivalent international bodies. Documentation requirements include detailed exposure control plans, incident response procedures, and comprehensive training records that demonstrate ongoing compliance with evolving regulatory standards.

Industry best practices increasingly emphasize the implementation of inherently safer design principles that minimize HF quantities through process intensification techniques, explore less hazardous alternatives where technically feasible, and incorporate advanced containment technologies that significantly reduce exposure risks during routine operations and maintenance activities.

Environmental Impact Assessment of HF-Based Biofuel Technologies

The integration of hydrofluoric acid (HF) in biofuel synthesis processes necessitates a comprehensive environmental impact assessment to ensure sustainable implementation. Current HF-based technologies for biofuel production demonstrate varying degrees of environmental footprint across their lifecycle stages, from raw material extraction to end-product utilization.

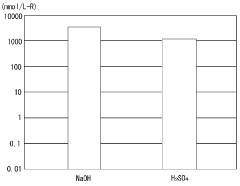

Primary concerns center on potential atmospheric emissions during HF handling and processing. Studies indicate that even low-concentration HF releases can contribute to localized air quality degradation and potential acid rain formation in production-intensive regions. Monitoring data from existing facilities suggests emission rates ranging from 0.3-1.2 kg HF per ton of biofuel produced, depending on process optimization and containment technologies employed.

Water ecosystem impacts present another significant consideration, as HF-contaminated wastewater from biofuel refineries requires specialized treatment protocols. Research indicates that conventional wastewater treatment facilities achieve only 85-92% HF removal efficiency, necessitating additional tertiary treatment processes to meet increasingly stringent environmental regulations. Groundwater vulnerability assessments in regions with high biofuel production capacity highlight potential contamination risks from improper waste management practices.

Carbon footprint analyses of HF-catalyzed biofuel synthesis reveal mixed results when compared to conventional petroleum refining. While the biofuel end-product offers 15-30% reduced greenhouse gas emissions during combustion, the energy-intensive nature of HF production and handling partially offsets these benefits. Life cycle assessments indicate that advanced HF recovery and recycling systems can improve the overall environmental performance by reducing virgin HF requirements by up to 75%.

Land use implications of HF-based biofuel technologies extend beyond the immediate production facility footprint. The agricultural feedstock requirements create potential competition with food crops, though second-generation processes utilizing agricultural waste and non-food biomass mitigate this concern. Buffer zone requirements around HF-utilizing facilities further impact land availability in densely populated regions.

Emerging technologies for HF substitution and process intensification show promise for reducing environmental impacts. Ionic liquid catalysts and solid acid catalysts demonstrate comparable conversion efficiencies with significantly reduced toxicity profiles. Additionally, closed-loop processing systems with advanced monitoring capabilities have demonstrated 40-60% reductions in environmental releases during pilot-scale implementations.

Regulatory frameworks governing HF use in biofuel production vary considerably across jurisdictions, creating challenges for standardized environmental impact assessment methodologies. Leading markets have established specific emissions thresholds and monitoring requirements, while developing regions often lack specialized regulatory oversight for these emerging technologies.

Primary concerns center on potential atmospheric emissions during HF handling and processing. Studies indicate that even low-concentration HF releases can contribute to localized air quality degradation and potential acid rain formation in production-intensive regions. Monitoring data from existing facilities suggests emission rates ranging from 0.3-1.2 kg HF per ton of biofuel produced, depending on process optimization and containment technologies employed.

Water ecosystem impacts present another significant consideration, as HF-contaminated wastewater from biofuel refineries requires specialized treatment protocols. Research indicates that conventional wastewater treatment facilities achieve only 85-92% HF removal efficiency, necessitating additional tertiary treatment processes to meet increasingly stringent environmental regulations. Groundwater vulnerability assessments in regions with high biofuel production capacity highlight potential contamination risks from improper waste management practices.

Carbon footprint analyses of HF-catalyzed biofuel synthesis reveal mixed results when compared to conventional petroleum refining. While the biofuel end-product offers 15-30% reduced greenhouse gas emissions during combustion, the energy-intensive nature of HF production and handling partially offsets these benefits. Life cycle assessments indicate that advanced HF recovery and recycling systems can improve the overall environmental performance by reducing virgin HF requirements by up to 75%.

Land use implications of HF-based biofuel technologies extend beyond the immediate production facility footprint. The agricultural feedstock requirements create potential competition with food crops, though second-generation processes utilizing agricultural waste and non-food biomass mitigate this concern. Buffer zone requirements around HF-utilizing facilities further impact land availability in densely populated regions.

Emerging technologies for HF substitution and process intensification show promise for reducing environmental impacts. Ionic liquid catalysts and solid acid catalysts demonstrate comparable conversion efficiencies with significantly reduced toxicity profiles. Additionally, closed-loop processing systems with advanced monitoring capabilities have demonstrated 40-60% reductions in environmental releases during pilot-scale implementations.

Regulatory frameworks governing HF use in biofuel production vary considerably across jurisdictions, creating challenges for standardized environmental impact assessment methodologies. Leading markets have established specific emissions thresholds and monitoring requirements, while developing regions often lack specialized regulatory oversight for these emerging technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!