How to Optimize Hydrofluoric Acid Utilization in Engineering

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrofluoric Acid Technology Background and Objectives

Hydrofluoric acid (HF) has been a critical chemical compound in various industrial applications since its first commercial production in the late 19th century. Initially utilized primarily in glass etching and metal cleaning, its application scope has significantly expanded over the decades to include semiconductor manufacturing, petroleum refining, and various specialized chemical processes. The evolution of HF technology has been marked by continuous improvements in production methods, handling protocols, and application techniques, driven by both industrial demands and safety considerations.

The technological trajectory of hydrofluoric acid has been shaped by its unique chemical properties - particularly its ability to dissolve silica and form metal fluorides. These characteristics have made it indispensable in certain engineering processes, despite its well-documented hazards. Recent technological developments have focused on enhancing utilization efficiency while minimizing environmental impact and worker exposure risks, reflecting broader industry trends toward sustainability and safety.

Current global HF production exceeds 1.5 million metric tons annually, with demand projected to grow at approximately 3-4% per year, primarily driven by expansion in the semiconductor and petroleum industries. This growth trajectory underscores the importance of optimizing HF utilization across various engineering applications to ensure sustainable resource management and cost-effectiveness.

The primary objectives for hydrofluoric acid technology optimization include reducing consumption rates without compromising process effectiveness, minimizing waste generation through improved recovery and recycling systems, and developing safer handling methodologies that maintain or enhance process efficiency. These objectives align with broader industrial sustainability goals while addressing the specific challenges posed by HF's hazardous nature.

Technological innovation in this field is increasingly focused on developing closed-loop systems that maximize acid recovery, implementing precise dosing technologies that optimize concentration levels for specific applications, and exploring alternative formulations that maintain effectiveness while reducing overall acid requirements. These approaches represent the convergence of chemical engineering advances, digital monitoring technologies, and materials science innovations.

The optimization of hydrofluoric acid utilization also encompasses the development of more selective catalysts and process conditions that enable lower concentration requirements, as well as the integration of real-time monitoring systems that prevent overuse through precise feedback mechanisms. These technological directions reflect the industry's movement toward more resource-efficient and environmentally responsible chemical processes.

The technological trajectory of hydrofluoric acid has been shaped by its unique chemical properties - particularly its ability to dissolve silica and form metal fluorides. These characteristics have made it indispensable in certain engineering processes, despite its well-documented hazards. Recent technological developments have focused on enhancing utilization efficiency while minimizing environmental impact and worker exposure risks, reflecting broader industry trends toward sustainability and safety.

Current global HF production exceeds 1.5 million metric tons annually, with demand projected to grow at approximately 3-4% per year, primarily driven by expansion in the semiconductor and petroleum industries. This growth trajectory underscores the importance of optimizing HF utilization across various engineering applications to ensure sustainable resource management and cost-effectiveness.

The primary objectives for hydrofluoric acid technology optimization include reducing consumption rates without compromising process effectiveness, minimizing waste generation through improved recovery and recycling systems, and developing safer handling methodologies that maintain or enhance process efficiency. These objectives align with broader industrial sustainability goals while addressing the specific challenges posed by HF's hazardous nature.

Technological innovation in this field is increasingly focused on developing closed-loop systems that maximize acid recovery, implementing precise dosing technologies that optimize concentration levels for specific applications, and exploring alternative formulations that maintain effectiveness while reducing overall acid requirements. These approaches represent the convergence of chemical engineering advances, digital monitoring technologies, and materials science innovations.

The optimization of hydrofluoric acid utilization also encompasses the development of more selective catalysts and process conditions that enable lower concentration requirements, as well as the integration of real-time monitoring systems that prevent overuse through precise feedback mechanisms. These technological directions reflect the industry's movement toward more resource-efficient and environmentally responsible chemical processes.

Industrial Market Demand Analysis for HF Acid Applications

The global hydrofluoric acid (HF) market demonstrates robust demand across multiple industrial sectors, with semiconductor manufacturing leading consumption patterns. Current market valuation exceeds $2.3 billion, with projections indicating a compound annual growth rate of 5.7% through 2028, driven primarily by expanding applications in electronics and chemical processing industries.

Semiconductor manufacturing represents the largest demand segment, consuming approximately 60% of global HF production. This dominance stems from HF's critical role in silicon wafer etching, cleaning, and surface preparation processes essential for microchip production. With the semiconductor industry experiencing unprecedented growth due to digitalization trends, HF demand in this sector is expected to increase by 7.2% annually over the next five years.

The chemical processing industry constitutes the second-largest market segment, utilizing HF as a catalyst in alkylation processes for high-octane gasoline production and various fluorochemical manufacturing applications. This sector accounts for roughly 18% of global consumption, with steady growth projections aligned with petroleum refining expansion in emerging economies.

Glass etching and polishing applications represent a significant niche market, particularly in architectural glass, automotive manufacturing, and specialty optics production. This segment comprises approximately 8% of the global HF market, with demand patterns closely following construction and automotive industry cycles.

Regional analysis reveals Asia-Pacific as the dominant consumer, accounting for 65% of global HF demand, with China, South Korea, Taiwan, and Japan leading consumption due to their robust semiconductor and electronics manufacturing bases. North America follows at 18% market share, while Europe represents 12% of global consumption.

Market challenges include increasing regulatory scrutiny regarding HF handling, storage, and disposal due to its highly hazardous nature. Environmental regulations in developed economies are driving demand for reduced-concentration formulations and closed-loop recycling systems that minimize waste and emissions. This regulatory landscape is creating market opportunities for technologies that optimize HF utilization efficiency and recovery processes.

Supply chain vulnerabilities represent another significant market concern, with production concentrated among a limited number of manufacturers. Recent disruptions have highlighted the strategic importance of securing stable HF supply chains, particularly for semiconductor manufacturing, creating premium market segments for reliable suppliers with advanced safety and handling protocols.

Emerging market opportunities include technologies for HF recycling and recovery from waste streams, with potential to reduce fresh acid consumption by up to 40% in some applications. Additionally, development of safer HF alternatives and handling systems is attracting significant investment, particularly in high-risk applications where traditional HF usage poses substantial safety concerns.

Semiconductor manufacturing represents the largest demand segment, consuming approximately 60% of global HF production. This dominance stems from HF's critical role in silicon wafer etching, cleaning, and surface preparation processes essential for microchip production. With the semiconductor industry experiencing unprecedented growth due to digitalization trends, HF demand in this sector is expected to increase by 7.2% annually over the next five years.

The chemical processing industry constitutes the second-largest market segment, utilizing HF as a catalyst in alkylation processes for high-octane gasoline production and various fluorochemical manufacturing applications. This sector accounts for roughly 18% of global consumption, with steady growth projections aligned with petroleum refining expansion in emerging economies.

Glass etching and polishing applications represent a significant niche market, particularly in architectural glass, automotive manufacturing, and specialty optics production. This segment comprises approximately 8% of the global HF market, with demand patterns closely following construction and automotive industry cycles.

Regional analysis reveals Asia-Pacific as the dominant consumer, accounting for 65% of global HF demand, with China, South Korea, Taiwan, and Japan leading consumption due to their robust semiconductor and electronics manufacturing bases. North America follows at 18% market share, while Europe represents 12% of global consumption.

Market challenges include increasing regulatory scrutiny regarding HF handling, storage, and disposal due to its highly hazardous nature. Environmental regulations in developed economies are driving demand for reduced-concentration formulations and closed-loop recycling systems that minimize waste and emissions. This regulatory landscape is creating market opportunities for technologies that optimize HF utilization efficiency and recovery processes.

Supply chain vulnerabilities represent another significant market concern, with production concentrated among a limited number of manufacturers. Recent disruptions have highlighted the strategic importance of securing stable HF supply chains, particularly for semiconductor manufacturing, creating premium market segments for reliable suppliers with advanced safety and handling protocols.

Emerging market opportunities include technologies for HF recycling and recovery from waste streams, with potential to reduce fresh acid consumption by up to 40% in some applications. Additionally, development of safer HF alternatives and handling systems is attracting significant investment, particularly in high-risk applications where traditional HF usage poses substantial safety concerns.

Current Utilization Challenges and Technical Limitations

Hydrofluoric acid (HF) utilization in engineering faces significant challenges due to its highly corrosive nature and extreme toxicity. Current industrial applications, particularly in semiconductor manufacturing, metal surface treatment, and glass etching, struggle with inefficient consumption patterns where up to 40% of HF may be wasted during processing. This inefficiency stems from outdated delivery systems that lack precision control mechanisms, resulting in excess application and subsequent disposal of unconsumed acid.

Material compatibility presents another major limitation, as HF rapidly deteriorates conventional containment materials. Even specialized fluoropolymer linings and high-nickel alloys experience accelerated degradation under industrial conditions, necessitating frequent replacement and creating production downtime. The average lifespan of HF-handling equipment remains approximately 30% shorter than equipment used for other industrial acids, significantly increasing operational costs.

Worker safety concerns severely restrict optimization efforts, as stringent safety protocols often prioritize risk reduction over process efficiency. Current personal protective equipment (PPE) requirements and handling procedures, while necessary, create workflow bottlenecks that impede implementation of more efficient utilization techniques. The technical challenge lies in developing systems that simultaneously enhance safety and improve acid utilization rates.

Recycling and recovery technologies for HF remain underdeveloped compared to other industrial chemicals. Current recovery methods achieve only 50-65% recapture rates in most applications, with the remainder requiring neutralization and disposal. Distillation and membrane separation techniques show promise but face scaling limitations and high energy consumption challenges that render them economically unviable for many industrial applications.

Monitoring and control systems represent another technical limitation. Real-time concentration sensors for HF solutions often lack the precision required for optimal dosing, with error margins of ±5-8% being common in industrial settings. This imprecision leads to conservative overdosing practices to ensure process effectiveness, directly contributing to waste generation.

Regulatory constraints further complicate optimization efforts. Increasingly stringent environmental regulations regarding HF emissions and waste disposal create compliance challenges that sometimes conflict with efficiency improvements. The technical community has yet to develop comprehensive solutions that simultaneously address regulatory requirements and utilization efficiency.

Lastly, knowledge gaps in reaction kinetics at varying concentrations and temperatures limit the development of predictive models for optimizing HF consumption. Without accurate modeling capabilities, engineers must rely on conservative estimates and empirical testing, which inherently leads to suboptimal utilization patterns and increased consumption rates across industrial applications.

Material compatibility presents another major limitation, as HF rapidly deteriorates conventional containment materials. Even specialized fluoropolymer linings and high-nickel alloys experience accelerated degradation under industrial conditions, necessitating frequent replacement and creating production downtime. The average lifespan of HF-handling equipment remains approximately 30% shorter than equipment used for other industrial acids, significantly increasing operational costs.

Worker safety concerns severely restrict optimization efforts, as stringent safety protocols often prioritize risk reduction over process efficiency. Current personal protective equipment (PPE) requirements and handling procedures, while necessary, create workflow bottlenecks that impede implementation of more efficient utilization techniques. The technical challenge lies in developing systems that simultaneously enhance safety and improve acid utilization rates.

Recycling and recovery technologies for HF remain underdeveloped compared to other industrial chemicals. Current recovery methods achieve only 50-65% recapture rates in most applications, with the remainder requiring neutralization and disposal. Distillation and membrane separation techniques show promise but face scaling limitations and high energy consumption challenges that render them economically unviable for many industrial applications.

Monitoring and control systems represent another technical limitation. Real-time concentration sensors for HF solutions often lack the precision required for optimal dosing, with error margins of ±5-8% being common in industrial settings. This imprecision leads to conservative overdosing practices to ensure process effectiveness, directly contributing to waste generation.

Regulatory constraints further complicate optimization efforts. Increasingly stringent environmental regulations regarding HF emissions and waste disposal create compliance challenges that sometimes conflict with efficiency improvements. The technical community has yet to develop comprehensive solutions that simultaneously address regulatory requirements and utilization efficiency.

Lastly, knowledge gaps in reaction kinetics at varying concentrations and temperatures limit the development of predictive models for optimizing HF consumption. Without accurate modeling capabilities, engineers must rely on conservative estimates and empirical testing, which inherently leads to suboptimal utilization patterns and increased consumption rates across industrial applications.

Current HF Optimization Methodologies and Solutions

01 Semiconductor manufacturing applications

Hydrofluoric acid is widely used in semiconductor manufacturing processes, particularly for etching silicon dioxide and cleaning silicon wafers. It is essential for removing oxide layers, surface contaminants, and native oxides during chip fabrication. The acid is often used in diluted forms or in combination with other chemicals to achieve precise etching rates and surface properties required for high-performance semiconductor devices.- Semiconductor manufacturing applications: Hydrofluoric acid is widely used in semiconductor manufacturing processes, particularly for etching silicon dioxide and cleaning silicon wafers. It is essential for removing oxide layers, surface contaminants, and native oxides during chip fabrication. The acid is often used in diluted forms or in combination with other chemicals to achieve precise etching rates and surface properties required for high-performance semiconductor devices.

- Glass etching and processing: Hydrofluoric acid is uniquely effective for etching and processing glass surfaces. It reacts with silicon dioxide in glass to form silicon tetrafluoride gas and water. This property makes it valuable for frosting glass, creating decorative patterns, adjusting optical properties, and manufacturing specialized glass products. The controlled application of hydrofluoric acid allows for precise modification of glass surface characteristics for various industrial and commercial applications.

- Metal surface treatment and cleaning: Hydrofluoric acid is employed for metal surface treatment, particularly for cleaning and pickling stainless steel, aluminum, and titanium alloys. It effectively removes oxide layers, scale, and contaminants from metal surfaces prior to further processing such as plating, coating, or welding. The acid is often used in combination with nitric acid or other chemicals to enhance its effectiveness while minimizing base metal attack, resulting in clean, oxide-free surfaces with improved properties.

- Fluorochemical production: Hydrofluoric acid serves as a key raw material in the production of various fluorochemicals, including refrigerants, fluoropolymers, and pharmaceutical intermediates. It is used to introduce fluorine atoms into organic compounds through reactions such as fluorination and hydrofluorination. The acid enables the synthesis of compounds with unique properties such as chemical stability, heat resistance, and non-stick characteristics, which are valuable across multiple industries including automotive, electronics, and healthcare.

- Waste treatment and recycling systems: Specialized systems have been developed for the treatment, neutralization, and recycling of hydrofluoric acid waste. These systems employ various technologies including chemical precipitation, ion exchange, membrane filtration, and thermal decomposition to safely process spent hydrofluoric acid from industrial processes. The recovery and recycling of hydrofluoric acid not only reduces environmental impact but also provides economic benefits through resource conservation and reduced waste disposal costs.

02 Glass etching and processing

Hydrofluoric acid is uniquely effective for etching and processing glass surfaces. It reacts with silicon dioxide in glass to form silicon tetrafluoride and water. This property makes it valuable for frosting glass, creating decorative patterns, and manufacturing specialized glass products. The acid is also used for cleaning glass surfaces and removing stubborn deposits that other acids cannot dissolve.Expand Specific Solutions03 Metal surface treatment and cleaning

Hydrofluoric acid is employed for metal surface treatment, particularly for aluminum, titanium, and stainless steel. It effectively removes oxide layers, scale, and contaminants from metal surfaces, preparing them for subsequent processes like coating, plating, or welding. The acid is often used in pickling solutions for stainless steel and in combination with nitric acid for titanium processing to achieve specific surface properties.Expand Specific Solutions04 Fluorochemical production

Hydrofluoric acid serves as a key raw material in the production of various fluorochemicals, including refrigerants, fluoropolymers, and pharmaceutical intermediates. It is used to introduce fluorine atoms into organic compounds, creating products with unique properties such as chemical resistance, thermal stability, and low surface energy. The manufacturing processes often involve specialized equipment due to the corrosive nature of hydrofluoric acid.Expand Specific Solutions05 Waste treatment and recycling systems

Specialized systems have been developed for the treatment, neutralization, and recycling of hydrofluoric acid waste. These systems aim to minimize environmental impact and recover valuable components from spent acid solutions. Technologies include precipitation methods, membrane filtration, ion exchange, and chemical neutralization processes. Advanced monitoring and safety features are incorporated to handle the hazardous nature of hydrofluoric acid during treatment operations.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The hydrofluoric acid utilization optimization market is currently in a growth phase, with increasing demand driven by semiconductor manufacturing, chemical processing, and clean energy applications. The global market size is estimated to exceed $2 billion, expanding at approximately 5-7% CAGR. Leading players demonstrate varying levels of technical maturity: Do-Fluoride New Materials and Stella Chemifa have established strong positions in high-purity HF production; Honeywell and Arkema focus on advanced handling systems; while Ecolab and Dorf Ketal specialize in efficiency-enhancing solutions. Companies like Jiangyin Runma and DuPont are advancing recovery and recycling technologies. Academic institutions including Tongji University and Shandong University are collaborating with industry leaders to develop next-generation sustainable utilization methods, indicating a market transitioning toward more environmentally responsible practices.

Do-Fluoride New Materials Co., Ltd.

Technical Solution: Do-Fluoride has developed a closed-loop hydrofluoric acid recovery system specifically designed for semiconductor manufacturing processes. Their technology employs a multi-stage distillation process combined with selective membrane filtration to recover up to 95% of HF from waste streams. The system incorporates real-time monitoring sensors that analyze acid concentration and impurity levels, automatically adjusting recovery parameters to maintain optimal efficiency. Additionally, they've implemented a proprietary neutralization technique that reduces the volume of fluoride-containing waste by converting it into commercially valuable calcium fluoride, which can be reused in their own production processes. Their latest innovation includes a vapor condensation technology that captures HF emissions during processing, significantly reducing environmental impact and worker exposure risks.

Strengths: High recovery rate (95%) significantly reduces raw material costs and waste disposal expenses. The closed-loop system minimizes environmental impact and improves workplace safety. Weaknesses: The system requires significant initial capital investment and specialized maintenance expertise. The recovery process consumes substantial energy, potentially offsetting some cost benefits.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered an advanced HF management system called "SmartFlow" that integrates digital monitoring with precise dosing technology. Their approach utilizes IoT-enabled sensors throughout the HF handling process to provide real-time data on concentration, flow rates, and system integrity. The SmartFlow system incorporates predictive analytics to optimize HF usage based on historical performance data and current process requirements, reducing consumption by up to 30% compared to conventional methods. Honeywell's technology includes a proprietary scrubber design that captures and neutralizes HF vapors with over 99.5% efficiency, significantly reducing emissions. Their system also features automated safety protocols that can detect leaks or abnormalities and initiate containment procedures within milliseconds, dramatically improving worker safety. The technology has been successfully implemented across semiconductor manufacturing, oil refining, and chemical processing industries.

Strengths: The integrated digital monitoring system provides unprecedented control over HF usage, significantly reducing waste and improving safety. The predictive analytics capability allows for continuous optimization of processes. Weaknesses: The complex system requires specialized training for operators and maintenance personnel. High initial implementation costs may be prohibitive for smaller operations.

Critical Patents and Technical Innovations in HF Management

Continuous process to produce hexafluoroisopropanol

PatentInactiveEP2398754A2

Innovation

- A continuous process involving the contact of hexafluoroacetone with hydrogen in a mixing device, followed by hydrogenation using an immobilized catalyst in a packed bed reactor, with a portion of the product stream recycled to maintain steady-state operation and control temperature rises.

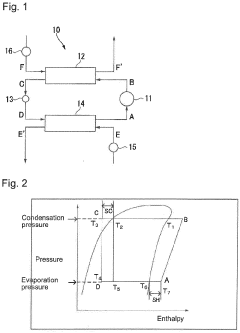

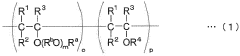

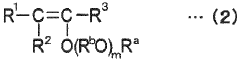

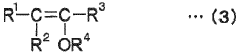

Composition for heat cycle system, and heat cycle system

PatentActiveEP3812446A1

Innovation

- A composition for a heat cycle system incorporating an unsaturated fluorinated hydrocarbon compound with specific refrigerant oils, such as polyol ester or polyvinyl ether refrigerant oils, to enhance lubricity and maintain low global warming potential and high cycle performance.

Safety Protocols and Risk Mitigation Strategies

Hydrofluoric acid (HF) presents significant hazards in engineering applications due to its highly corrosive nature and ability to cause severe tissue damage upon contact. Implementing comprehensive safety protocols is paramount for any facility utilizing this chemical. Primary safety measures must include specialized personal protective equipment (PPE) such as chemical-resistant suits, gloves, face shields, and respiratory protection designed specifically for HF exposure. Regular inspection and maintenance of this equipment should be conducted to ensure integrity and effectiveness.

Engineering controls represent the first line of defense in HF risk management. These include closed handling systems, proper ventilation with local exhaust, continuous air monitoring systems, and automated processes that minimize direct human interaction with the acid. Facilities should implement secondary containment systems, including acid-resistant barriers, spill containment berms, and neutralization stations strategically positioned throughout work areas.

Emergency response planning must be exceptionally thorough when working with HF. This includes installation of emergency showers and eyewash stations within 10 seconds of travel time from any potential exposure point. Calcium gluconate gel, the specific antidote for HF exposure, must be readily available in multiple locations. Staff should undergo specialized training in HF-specific first aid procedures, with regular drills to maintain response readiness.

Administrative controls form another critical layer of protection. These include detailed standard operating procedures (SOPs) for all HF-related tasks, permit-to-work systems for high-risk activities, regular safety audits, and comprehensive documentation of all safety incidents. Job rotation strategies can help minimize individual exposure times, while buddy systems ensure no worker handles HF alone.

Risk assessment methodologies specific to HF applications should be implemented, including Hazard and Operability Studies (HAZOP) and Failure Mode and Effects Analysis (FMEA). These systematic approaches help identify potential failure points and develop targeted mitigation strategies. Quantitative risk assessment tools can further help prioritize safety investments based on probability and consequence analysis.

Waste management protocols must address the unique challenges of HF disposal. This includes neutralization procedures using appropriate bases, segregation from incompatible materials, and compliance with environmental regulations. Monitoring systems should track HF concentrations in waste streams, with treatment processes verified through regular testing.

Finally, continuous improvement of safety systems requires establishing key performance indicators for HF safety, conducting regular safety reviews, and maintaining open communication channels for workers to report concerns. Industry collaboration through sharing best practices and near-miss incidents can further enhance organizational learning and safety culture development.

Engineering controls represent the first line of defense in HF risk management. These include closed handling systems, proper ventilation with local exhaust, continuous air monitoring systems, and automated processes that minimize direct human interaction with the acid. Facilities should implement secondary containment systems, including acid-resistant barriers, spill containment berms, and neutralization stations strategically positioned throughout work areas.

Emergency response planning must be exceptionally thorough when working with HF. This includes installation of emergency showers and eyewash stations within 10 seconds of travel time from any potential exposure point. Calcium gluconate gel, the specific antidote for HF exposure, must be readily available in multiple locations. Staff should undergo specialized training in HF-specific first aid procedures, with regular drills to maintain response readiness.

Administrative controls form another critical layer of protection. These include detailed standard operating procedures (SOPs) for all HF-related tasks, permit-to-work systems for high-risk activities, regular safety audits, and comprehensive documentation of all safety incidents. Job rotation strategies can help minimize individual exposure times, while buddy systems ensure no worker handles HF alone.

Risk assessment methodologies specific to HF applications should be implemented, including Hazard and Operability Studies (HAZOP) and Failure Mode and Effects Analysis (FMEA). These systematic approaches help identify potential failure points and develop targeted mitigation strategies. Quantitative risk assessment tools can further help prioritize safety investments based on probability and consequence analysis.

Waste management protocols must address the unique challenges of HF disposal. This includes neutralization procedures using appropriate bases, segregation from incompatible materials, and compliance with environmental regulations. Monitoring systems should track HF concentrations in waste streams, with treatment processes verified through regular testing.

Finally, continuous improvement of safety systems requires establishing key performance indicators for HF safety, conducting regular safety reviews, and maintaining open communication channels for workers to report concerns. Industry collaboration through sharing best practices and near-miss incidents can further enhance organizational learning and safety culture development.

Environmental Impact and Sustainable Alternatives

Hydrofluoric acid (HF) utilization in engineering processes presents significant environmental challenges due to its highly toxic and corrosive nature. When released into the environment, HF can contaminate soil and water systems, causing severe ecological damage and potential harm to aquatic organisms. The acid's high water solubility enables rapid dispersion in aquatic environments, leading to pH alterations that disrupt ecosystem balance and biodiversity.

Air emissions from industrial processes using HF pose additional concerns, as airborne HF can contribute to acid rain formation and cause vegetation damage in surrounding areas. Worker exposure risks compound these environmental issues, necessitating comprehensive safety protocols that often require substantial resource allocation.

Current regulatory frameworks worldwide are increasingly stringent regarding HF handling and disposal. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions mandate strict controls on HF emissions and waste management. Companies must navigate complex compliance requirements, including detailed documentation of HF lifecycle management and implementation of advanced treatment technologies before discharge.

Sustainable alternatives to traditional HF applications are emerging across various engineering sectors. In semiconductor manufacturing, aqueous solutions containing ammonium fluoride have demonstrated effectiveness as less hazardous substitutes. The metal finishing industry has made progress with organic acid-based formulations that achieve comparable surface preparation results without HF's environmental footprint.

Closed-loop recycling systems represent another promising approach, enabling the capture and reuse of HF from process streams. Advanced membrane filtration technologies and ion exchange systems can recover up to 90% of HF from waste streams, significantly reducing fresh acid requirements and environmental discharge volumes.

Green chemistry principles are driving innovation in process redesign, with catalytic approaches enabling lower concentration HF usage while maintaining performance efficacy. Computational modeling and process simulation tools are optimizing reaction conditions to minimize HF quantities required for specific applications.

Economic analyses indicate that while initial implementation costs for sustainable alternatives may exceed conventional HF processes, long-term operational savings from reduced waste management requirements, lower regulatory compliance costs, and decreased liability exposure often yield positive return on investment within 3-5 years. Additionally, companies adopting sustainable HF alternatives frequently report enhanced corporate reputation and improved stakeholder relations, providing intangible but valuable business benefits.

Air emissions from industrial processes using HF pose additional concerns, as airborne HF can contribute to acid rain formation and cause vegetation damage in surrounding areas. Worker exposure risks compound these environmental issues, necessitating comprehensive safety protocols that often require substantial resource allocation.

Current regulatory frameworks worldwide are increasingly stringent regarding HF handling and disposal. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions mandate strict controls on HF emissions and waste management. Companies must navigate complex compliance requirements, including detailed documentation of HF lifecycle management and implementation of advanced treatment technologies before discharge.

Sustainable alternatives to traditional HF applications are emerging across various engineering sectors. In semiconductor manufacturing, aqueous solutions containing ammonium fluoride have demonstrated effectiveness as less hazardous substitutes. The metal finishing industry has made progress with organic acid-based formulations that achieve comparable surface preparation results without HF's environmental footprint.

Closed-loop recycling systems represent another promising approach, enabling the capture and reuse of HF from process streams. Advanced membrane filtration technologies and ion exchange systems can recover up to 90% of HF from waste streams, significantly reducing fresh acid requirements and environmental discharge volumes.

Green chemistry principles are driving innovation in process redesign, with catalytic approaches enabling lower concentration HF usage while maintaining performance efficacy. Computational modeling and process simulation tools are optimizing reaction conditions to minimize HF quantities required for specific applications.

Economic analyses indicate that while initial implementation costs for sustainable alternatives may exceed conventional HF processes, long-term operational savings from reduced waste management requirements, lower regulatory compliance costs, and decreased liability exposure often yield positive return on investment within 3-5 years. Additionally, companies adopting sustainable HF alternatives frequently report enhanced corporate reputation and improved stakeholder relations, providing intangible but valuable business benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!