Hydrofluoric Acid Testing Methods for Industrial Safety

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF Acid Testing Background and Objectives

Hydrofluoric acid (HF) represents one of the most hazardous chemicals utilized across multiple industries, including semiconductor manufacturing, glass etching, petroleum refining, and metal processing. Despite its widespread industrial applications, HF poses exceptional risks due to its unique properties - particularly its ability to penetrate tissue rapidly and cause severe systemic toxicity beyond localized burns. The development of reliable testing methods for HF has evolved significantly over the past five decades, driven by increasing safety regulations and industrial demand for risk mitigation.

The historical trajectory of HF testing began with rudimentary colorimetric methods in the 1970s, which offered limited sensitivity and reliability. The 1980s saw the introduction of ion-selective electrode technology, marking a significant advancement in detection capabilities. By the 1990s, ion chromatography emerged as a preferred analytical technique, offering improved precision for quantitative analysis. The early 2000s witnessed the integration of automated monitoring systems, enabling real-time detection in industrial settings.

Current technological trends in HF testing focus on miniaturization, portability, and connectivity. Handheld analyzers with wireless capabilities allow for immediate data transmission to centralized safety systems. Advanced spectroscopic methods, including Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR), have enhanced detection limits to parts-per-billion levels, critical for ensuring workplace safety compliance with increasingly stringent regulations.

The primary objectives of modern HF testing methodologies encompass several dimensions. First, achieving enhanced sensitivity to detect trace amounts of HF before they reach hazardous levels. Second, developing rapid response capabilities to provide real-time monitoring in industrial environments. Third, creating robust systems that maintain accuracy under varying environmental conditions including temperature fluctuations, humidity variations, and presence of interfering chemicals.

Additionally, testing methods must address the challenge of differentiating between gaseous HF and aqueous solutions, as each presents distinct hazards requiring specific mitigation strategies. The ideal testing protocol should also demonstrate field durability, allowing for reliable operation in harsh industrial environments while maintaining calibration integrity over extended periods.

From a regulatory perspective, testing methodologies must align with evolving international standards, including OSHA regulations in the United States, EU REACH requirements, and ISO specifications for analytical procedures. The harmonization of testing protocols across global industrial operations represents a significant challenge and objective for multinational corporations utilizing HF in their processes.

Future testing development aims to incorporate artificial intelligence for predictive analytics, enabling not just detection but forecasting of potential exposure events based on pattern recognition and environmental modeling. This proactive approach represents the next frontier in industrial safety management for hydrofluoric acid handling.

The historical trajectory of HF testing began with rudimentary colorimetric methods in the 1970s, which offered limited sensitivity and reliability. The 1980s saw the introduction of ion-selective electrode technology, marking a significant advancement in detection capabilities. By the 1990s, ion chromatography emerged as a preferred analytical technique, offering improved precision for quantitative analysis. The early 2000s witnessed the integration of automated monitoring systems, enabling real-time detection in industrial settings.

Current technological trends in HF testing focus on miniaturization, portability, and connectivity. Handheld analyzers with wireless capabilities allow for immediate data transmission to centralized safety systems. Advanced spectroscopic methods, including Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR), have enhanced detection limits to parts-per-billion levels, critical for ensuring workplace safety compliance with increasingly stringent regulations.

The primary objectives of modern HF testing methodologies encompass several dimensions. First, achieving enhanced sensitivity to detect trace amounts of HF before they reach hazardous levels. Second, developing rapid response capabilities to provide real-time monitoring in industrial environments. Third, creating robust systems that maintain accuracy under varying environmental conditions including temperature fluctuations, humidity variations, and presence of interfering chemicals.

Additionally, testing methods must address the challenge of differentiating between gaseous HF and aqueous solutions, as each presents distinct hazards requiring specific mitigation strategies. The ideal testing protocol should also demonstrate field durability, allowing for reliable operation in harsh industrial environments while maintaining calibration integrity over extended periods.

From a regulatory perspective, testing methodologies must align with evolving international standards, including OSHA regulations in the United States, EU REACH requirements, and ISO specifications for analytical procedures. The harmonization of testing protocols across global industrial operations represents a significant challenge and objective for multinational corporations utilizing HF in their processes.

Future testing development aims to incorporate artificial intelligence for predictive analytics, enabling not just detection but forecasting of potential exposure events based on pattern recognition and environmental modeling. This proactive approach represents the next frontier in industrial safety management for hydrofluoric acid handling.

Industrial Safety Market Needs Analysis

The global market for hydrofluoric acid (HF) testing methods is experiencing significant growth driven by increasing industrial safety concerns and stringent regulatory requirements. Industries handling HF, including semiconductor manufacturing, chemical processing, glass etching, and petroleum refining, face substantial risks due to the acid's highly corrosive and toxic nature. This has created a robust demand for reliable, accurate, and efficient testing methodologies.

Market research indicates that the industrial safety equipment and testing market related to hazardous chemicals is projected to grow at a compound annual growth rate of 7.2% through 2028, with HF testing solutions representing a critical segment within this market. The semiconductor industry, as the largest consumer of high-purity HF, is particularly driving demand for advanced testing methods that can detect trace amounts of contamination without disrupting production processes.

Regulatory bodies worldwide have strengthened safety standards regarding HF handling, storage, and exposure limits. OSHA in the United States, the European Chemicals Agency, and similar organizations in Asia have implemented more rigorous compliance requirements, creating market pull for comprehensive testing solutions. This regulatory landscape has expanded the market for both preventive testing equipment and emergency response detection systems.

End-users are increasingly demanding real-time monitoring capabilities that can provide immediate alerts when HF concentrations approach dangerous levels. The market shows strong preference for non-invasive testing methods that minimize worker exposure during the testing process itself. Additionally, there is growing interest in portable and wearable detection devices that allow for continuous monitoring in high-risk environments.

Cost considerations remain significant market factors, with many industries seeking balance between testing accuracy and economic feasibility. The total cost of ownership, including equipment maintenance, calibration requirements, and operator training, influences purchasing decisions more than initial acquisition costs alone.

Regional analysis reveals that Asia Pacific represents the fastest-growing market for HF testing solutions, corresponding to the region's expanding semiconductor and electronics manufacturing sectors. North America and Europe maintain substantial market shares driven by stringent safety regulations and the presence of mature chemical processing industries with established safety protocols.

Emerging market opportunities exist in developing integrated safety systems that combine HF testing with broader chemical hazard management platforms. The trend toward digital transformation in industrial settings is creating demand for testing methods with data logging capabilities, remote monitoring features, and integration with facility-wide safety management systems.

Market research indicates that the industrial safety equipment and testing market related to hazardous chemicals is projected to grow at a compound annual growth rate of 7.2% through 2028, with HF testing solutions representing a critical segment within this market. The semiconductor industry, as the largest consumer of high-purity HF, is particularly driving demand for advanced testing methods that can detect trace amounts of contamination without disrupting production processes.

Regulatory bodies worldwide have strengthened safety standards regarding HF handling, storage, and exposure limits. OSHA in the United States, the European Chemicals Agency, and similar organizations in Asia have implemented more rigorous compliance requirements, creating market pull for comprehensive testing solutions. This regulatory landscape has expanded the market for both preventive testing equipment and emergency response detection systems.

End-users are increasingly demanding real-time monitoring capabilities that can provide immediate alerts when HF concentrations approach dangerous levels. The market shows strong preference for non-invasive testing methods that minimize worker exposure during the testing process itself. Additionally, there is growing interest in portable and wearable detection devices that allow for continuous monitoring in high-risk environments.

Cost considerations remain significant market factors, with many industries seeking balance between testing accuracy and economic feasibility. The total cost of ownership, including equipment maintenance, calibration requirements, and operator training, influences purchasing decisions more than initial acquisition costs alone.

Regional analysis reveals that Asia Pacific represents the fastest-growing market for HF testing solutions, corresponding to the region's expanding semiconductor and electronics manufacturing sectors. North America and Europe maintain substantial market shares driven by stringent safety regulations and the presence of mature chemical processing industries with established safety protocols.

Emerging market opportunities exist in developing integrated safety systems that combine HF testing with broader chemical hazard management platforms. The trend toward digital transformation in industrial settings is creating demand for testing methods with data logging capabilities, remote monitoring features, and integration with facility-wide safety management systems.

Current HF Detection Technologies and Challenges

The detection of hydrofluoric acid (HF) presents significant challenges due to its highly corrosive nature and severe health hazards. Current detection technologies can be broadly categorized into four main approaches: colorimetric methods, electrochemical sensors, spectroscopic techniques, and portable gas detection systems.

Colorimetric detection methods utilize chemical reagents that change color upon exposure to HF. These include zirconium-SPADNS complexes and alizarin-based indicators that shift from red to yellow in the presence of fluoride ions. While these methods offer visual confirmation and relative simplicity, they often lack the sensitivity required for low-concentration detection and may suffer from interference by other ions present in industrial environments.

Electrochemical sensors represent another significant detection approach, utilizing ion-selective electrodes (ISEs) with lanthanum fluoride or other fluoride-sensitive membranes. These sensors measure potential differences created by fluoride ions, offering real-time monitoring capabilities. However, they face challenges including electrode fouling in harsh industrial conditions, limited operational lifespan, and cross-sensitivity to hydroxide ions, particularly at higher pH levels.

Spectroscopic techniques, including ion chromatography and ion-selective spectrophotometry, provide more precise quantitative analysis of HF concentrations. Fourier-transform infrared (FTIR) spectroscopy and tunable diode laser absorption spectroscopy (TDLAS) enable remote sensing capabilities, crucial for monitoring areas too dangerous for direct human access. Despite their accuracy, these systems often require substantial infrastructure, technical expertise, and regular calibration.

Portable gas detection systems utilizing photoionization detectors (PIDs) and metal oxide semiconductor sensors have gained prominence for personal safety applications. These devices offer immediate alerts through visual, auditory, or vibration signals when HF concentrations exceed predetermined thresholds. Their primary limitations include battery life constraints, calibration drift, and potential false positives from cross-reactive compounds.

A significant challenge across all detection methods is the dual-phase nature of HF—it exists as both a gas and in solution—requiring comprehensive monitoring approaches. Additionally, the extreme reactivity of HF with various materials complicates the design of durable, long-lasting detection equipment. Many current technologies struggle with the speed-sensitivity trade-off, where increased detection sensitivity often comes at the cost of response time.

The industrial implementation of these technologies faces further challenges including harsh operating environments, the need for intrinsically safe equipment in explosive atmospheres, and the balance between detection accuracy and cost-effectiveness. Emerging research focuses on developing multi-sensor arrays and machine learning algorithms to improve detection reliability while minimizing false alarms.

Colorimetric detection methods utilize chemical reagents that change color upon exposure to HF. These include zirconium-SPADNS complexes and alizarin-based indicators that shift from red to yellow in the presence of fluoride ions. While these methods offer visual confirmation and relative simplicity, they often lack the sensitivity required for low-concentration detection and may suffer from interference by other ions present in industrial environments.

Electrochemical sensors represent another significant detection approach, utilizing ion-selective electrodes (ISEs) with lanthanum fluoride or other fluoride-sensitive membranes. These sensors measure potential differences created by fluoride ions, offering real-time monitoring capabilities. However, they face challenges including electrode fouling in harsh industrial conditions, limited operational lifespan, and cross-sensitivity to hydroxide ions, particularly at higher pH levels.

Spectroscopic techniques, including ion chromatography and ion-selective spectrophotometry, provide more precise quantitative analysis of HF concentrations. Fourier-transform infrared (FTIR) spectroscopy and tunable diode laser absorption spectroscopy (TDLAS) enable remote sensing capabilities, crucial for monitoring areas too dangerous for direct human access. Despite their accuracy, these systems often require substantial infrastructure, technical expertise, and regular calibration.

Portable gas detection systems utilizing photoionization detectors (PIDs) and metal oxide semiconductor sensors have gained prominence for personal safety applications. These devices offer immediate alerts through visual, auditory, or vibration signals when HF concentrations exceed predetermined thresholds. Their primary limitations include battery life constraints, calibration drift, and potential false positives from cross-reactive compounds.

A significant challenge across all detection methods is the dual-phase nature of HF—it exists as both a gas and in solution—requiring comprehensive monitoring approaches. Additionally, the extreme reactivity of HF with various materials complicates the design of durable, long-lasting detection equipment. Many current technologies struggle with the speed-sensitivity trade-off, where increased detection sensitivity often comes at the cost of response time.

The industrial implementation of these technologies faces further challenges including harsh operating environments, the need for intrinsically safe equipment in explosive atmospheres, and the balance between detection accuracy and cost-effectiveness. Emerging research focuses on developing multi-sensor arrays and machine learning algorithms to improve detection reliability while minimizing false alarms.

Established HF Testing Protocols and Solutions

01 Detection and neutralization methods for hydrofluoric acid

Various methods have been developed for detecting and neutralizing hydrofluoric acid to ensure safety during handling and testing. These methods include colorimetric detection systems that change color upon contact with HF, neutralization techniques using calcium or magnesium compounds, and specialized test kits designed for rapid identification of acid leaks or spills. These detection and neutralization approaches are critical for preventing exposure and mitigating hazards in laboratory and industrial settings.- Detection and neutralization methods for hydrofluoric acid: Various methods have been developed for detecting and neutralizing hydrofluoric acid to ensure safety during handling and testing. These methods include colorimetric detection systems that change color in the presence of hydrofluoric acid, allowing for quick visual identification of leaks or contamination. Additionally, neutralization techniques using calcium or magnesium compounds can be employed to quickly render hydrofluoric acid less harmful in case of spills or exposure, reducing the risk of chemical burns and tissue damage.

- Personal protective equipment and safety protocols: Specialized personal protective equipment (PPE) is essential when working with hydrofluoric acid due to its highly corrosive and toxic nature. This includes chemical-resistant gloves, face shields, acid-resistant clothing, and respiratory protection. Safety protocols involve establishing emergency procedures, proper training for personnel, regular equipment inspections, and implementing engineering controls such as fume hoods and ventilation systems to minimize exposure risks during testing and handling procedures.

- Analytical testing methods for hydrofluoric acid: Various analytical techniques are employed for testing hydrofluoric acid concentration and purity to ensure safe handling. These methods include ion-selective electrode measurements, ion chromatography, titration methods, and spectroscopic techniques. These analytical approaches allow for precise determination of hydrofluoric acid concentration, which is critical for both industrial applications and safety assessments. Proper calibration of testing equipment and standardized procedures are essential for accurate results.

- Containment systems and storage safety: Specialized containment systems are required for the safe storage and handling of hydrofluoric acid during testing procedures. These systems include corrosion-resistant containers made from materials like polyethylene or Teflon, secondary containment structures to prevent spreading in case of leaks, and specialized storage cabinets with proper ventilation. Safety features such as leak detection systems, pressure relief mechanisms, and temperature controls are incorporated to prevent accidents and ensure the integrity of storage vessels.

- Emergency response and first aid procedures: Comprehensive emergency response protocols are essential when working with hydrofluoric acid due to its ability to cause severe burns and systemic toxicity. These include immediate decontamination procedures, application of calcium gluconate gel for skin exposure, eye wash protocols, and respiratory support measures. Testing facilities must have emergency showers, eyewash stations, spill containment kits, and first aid supplies specifically designed for hydrofluoric acid exposure. Regular drills and training ensure personnel can respond quickly and effectively to accidents.

02 Personal protective equipment and safety protocols

Safety protocols and personal protective equipment (PPE) are essential when working with hydrofluoric acid. This includes specialized acid-resistant gloves, face shields, chemical splash goggles, and full-body protection. Safety protocols involve proper training, emergency response procedures, decontamination methods, and first aid measures specific to HF exposure. Implementing comprehensive safety protocols and ensuring proper use of PPE significantly reduces the risk of injury when testing with or handling hydrofluoric acid.Expand Specific Solutions03 Monitoring systems and exposure controls

Advanced monitoring systems and exposure controls have been developed to ensure safety during hydrofluoric acid testing. These include continuous air monitoring devices that detect HF vapors, automated alarm systems that alert personnel to dangerous concentration levels, ventilation systems designed to remove acid fumes, and containment technologies that prevent accidental releases. These monitoring and control measures provide real-time safety information and help maintain exposure levels below permissible limits.Expand Specific Solutions04 Safe handling and storage techniques

Safe handling and storage techniques for hydrofluoric acid include specialized containers made from compatible materials like polyethylene or Teflon, secondary containment systems to prevent spills from spreading, proper labeling and hazard communication, and dedicated storage areas with controlled access. Testing methods incorporate procedures for safely transferring, diluting, and disposing of hydrofluoric acid. These techniques minimize the risk of accidental exposure and ensure the integrity of testing procedures.Expand Specific Solutions05 Alternative testing methods to reduce HF exposure

Research has focused on developing alternative testing methods that reduce or eliminate the need for direct handling of hydrofluoric acid. These include enclosed automated testing systems, remote sampling techniques, substitute reagents with lower hazard profiles, and analytical methods that require smaller quantities of acid. By implementing these alternative approaches, laboratories and industrial facilities can maintain testing capabilities while significantly improving safety conditions for workers and reducing environmental risks.Expand Specific Solutions

Leading Companies in HF Detection Industry

The hydrofluoric acid testing methods market is in a growth phase, driven by increasing industrial safety regulations and awareness. The global market size is expanding steadily, particularly in semiconductor manufacturing, chemical processing, and oil refining industries. Technologically, the field shows moderate maturity with ongoing innovations in detection sensitivity and real-time monitoring capabilities. Key players include Siemens AG offering comprehensive industrial safety solutions, Ecolab USA developing specialized chemical testing protocols, and Stella Chemifa Corp. focusing on high-purity chemical analysis methods. Research institutions like Commissariat à l'énergie atomique contribute advanced detection technologies, while specialized companies such as Do-Fluoride New Materials and KIOXIA Corp. are developing industry-specific testing applications for their respective sectors.

Siemens AG

Technical Solution: Siemens has developed an integrated approach to hydrofluoric acid testing for industrial safety applications, centered around their SIPROCESS GA700 gas analyzer platform. This system utilizes tunable diode laser absorption spectroscopy (TDLAS) technology to detect HF vapor with exceptional sensitivity and specificity, capable of measuring concentrations from sub-ppm to percentage levels in real-time. Their solution incorporates distributed sensor networks throughout industrial facilities, connected via industrial ethernet to centralized monitoring stations. Siemens' approach includes specialized sampling systems designed to withstand the corrosive nature of HF while maintaining sample integrity. Their technology integrates with facility automation systems, enabling automatic process shutdown when dangerous HF levels are detected. Siemens has also developed specialized algorithms that can differentiate between HF and potential interferents in complex industrial atmospheres, minimizing false alarms. The system includes comprehensive data logging and analysis capabilities, allowing for trend analysis and predictive maintenance of safety systems. Their testing methodology incorporates automated self-diagnostic routines that continuously verify system performance and calibration status.

Strengths: Siemens offers exceptional integration capabilities with existing industrial control systems, providing seamless incorporation into safety protocols. Their solutions deliver high reliability in harsh industrial environments with minimal maintenance requirements. Weaknesses: The systems represent significant capital investment and may require specialized configuration for specific industrial applications, potentially limiting accessibility for smaller operations.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed comprehensive hydrofluoric acid (HF) testing methodologies focused on industrial safety applications. Their approach combines real-time monitoring systems with specialized chemical indicators that change color upon HF exposure, allowing for immediate visual detection of leaks. Ecolab's testing protocol includes proprietary HF-specific ion-selective electrodes that can detect concentrations as low as 0.1 ppm in various industrial environments. Their integrated safety system incorporates continuous monitoring stations strategically positioned throughout facilities, connected to centralized alarm systems. The company has also pioneered automated sampling techniques that minimize human exposure during testing procedures, utilizing robotics for sample collection in high-risk areas. Ecolab's methodology includes specialized spectrophotometric analysis techniques calibrated specifically for HF detection across different industrial matrices, ensuring accurate readings even in the presence of interfering compounds.

Strengths: Ecolab's solutions offer exceptional sensitivity and specificity for HF detection in complex industrial environments. Their integrated approach combining detection, monitoring, and emergency response systems provides comprehensive safety coverage. Weaknesses: The systems require regular calibration and maintenance by specialized technicians, and the initial implementation costs can be significant for smaller facilities.

Critical Patents and Research in HF Detection

Method for detection of fluoride or hydrogen fluoride and detection kit

PatentInactiveUS20080248593A1

Innovation

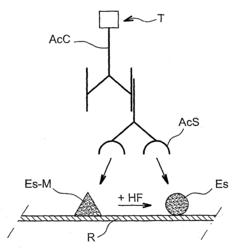

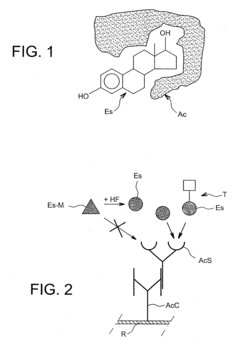

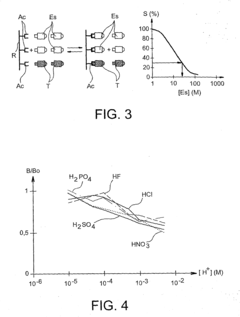

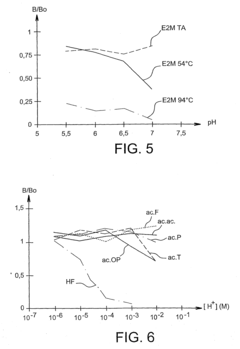

- A method involving a silylated organic compound that undergoes desilylation in the presence of HF, allowing for separate detection of the silylated and desilylated forms, using reagents like BTSFA and MTBSTFA, and employing immunological tests for enhanced sensitivity and specificity.

Apparatus and method for determining hydrofluoric acid in aqueous solutions

PatentInactiveEP0293663A3

Innovation

- A portable device with a silicon electrode and platinum counter-electrode arrangement that utilizes anodic oxidation of silicon oxide to detect hydrofluoric acid, indicated by a light-emitting diode, allowing for qualitative assessment and precise measurement using calibration solutions, and further quantification with an ammeter.

Regulatory Compliance for HF Handling

Regulatory compliance for hydrofluoric acid (HF) handling is governed by a complex framework of international, national, and local regulations due to the extreme hazards associated with this chemical. The Occupational Safety and Health Administration (OSHA) in the United States establishes permissible exposure limits (PELs) for HF at 3 ppm as an 8-hour time-weighted average, with specific requirements for monitoring, medical surveillance, and emergency response protocols. These standards are codified under 29 CFR 1910.1000 and complemented by the OSHA Process Safety Management standard (29 CFR 1910.119) for facilities handling large quantities.

The Environmental Protection Agency (EPA) regulates HF under multiple statutes, including the Clean Air Act, where it is listed as a hazardous air pollutant, and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), which mandates reporting of releases exceeding reportable quantities. The EPA's Risk Management Program (40 CFR Part 68) further requires facilities with significant HF quantities to develop and implement risk management plans.

In the European Union, HF handling falls under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labeling and Packaging (CLP) regulation. These frameworks establish strict documentation requirements, safety data sheet standards, and hazard communication protocols. The Seveso III Directive additionally imposes major accident prevention policies and safety management systems for facilities handling dangerous substances like HF.

Industry-specific standards provide detailed guidance for HF handling in various sectors. The American Petroleum Institute (API) has developed RP 751 specifically for safe operation of hydrofluoric acid alkylation units in petroleum refineries. Similarly, SEMI S2 guidelines address HF safety in semiconductor manufacturing, while the National Association of Corrosion Engineers (NACE) provides standards for materials selection and testing in HF environments.

Testing methods for regulatory compliance include workplace air monitoring using NIOSH Method 7902 or OSHA Method ID-110, which employ ion-specific electrode analysis after collection on treated filters. Surface wipe sampling techniques, outlined in ASTM D7659, are essential for detecting contamination on equipment and work surfaces. For medical surveillance, biological monitoring of workers' urine for fluoride levels provides a critical indicator of exposure, with testing protocols specified in ACGIH's Biological Exposure Indices.

Compliance documentation requirements are extensive, including detailed process safety information, written standard operating procedures, training records, and incident investigation reports. Regular compliance audits must verify implementation of these elements, with findings documented and corrective actions tracked to completion. Many jurisdictions also mandate periodic submission of compliance reports to regulatory authorities, particularly for facilities operating under special permits or variances.

The Environmental Protection Agency (EPA) regulates HF under multiple statutes, including the Clean Air Act, where it is listed as a hazardous air pollutant, and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), which mandates reporting of releases exceeding reportable quantities. The EPA's Risk Management Program (40 CFR Part 68) further requires facilities with significant HF quantities to develop and implement risk management plans.

In the European Union, HF handling falls under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labeling and Packaging (CLP) regulation. These frameworks establish strict documentation requirements, safety data sheet standards, and hazard communication protocols. The Seveso III Directive additionally imposes major accident prevention policies and safety management systems for facilities handling dangerous substances like HF.

Industry-specific standards provide detailed guidance for HF handling in various sectors. The American Petroleum Institute (API) has developed RP 751 specifically for safe operation of hydrofluoric acid alkylation units in petroleum refineries. Similarly, SEMI S2 guidelines address HF safety in semiconductor manufacturing, while the National Association of Corrosion Engineers (NACE) provides standards for materials selection and testing in HF environments.

Testing methods for regulatory compliance include workplace air monitoring using NIOSH Method 7902 or OSHA Method ID-110, which employ ion-specific electrode analysis after collection on treated filters. Surface wipe sampling techniques, outlined in ASTM D7659, are essential for detecting contamination on equipment and work surfaces. For medical surveillance, biological monitoring of workers' urine for fluoride levels provides a critical indicator of exposure, with testing protocols specified in ACGIH's Biological Exposure Indices.

Compliance documentation requirements are extensive, including detailed process safety information, written standard operating procedures, training records, and incident investigation reports. Regular compliance audits must verify implementation of these elements, with findings documented and corrective actions tracked to completion. Many jurisdictions also mandate periodic submission of compliance reports to regulatory authorities, particularly for facilities operating under special permits or variances.

Environmental Impact Assessment of HF Testing

The environmental impact of hydrofluoric acid (HF) testing methods represents a critical consideration for industrial safety protocols. Current HF testing methodologies generate various waste streams that require careful management to prevent ecological damage. These include liquid waste containing diluted HF solutions, contaminated testing materials, and potentially hazardous air emissions during certain analytical procedures.

Water resource contamination poses the most significant environmental risk associated with HF testing. Even at low concentrations, fluoride ions can persist in aquatic ecosystems, potentially affecting freshwater organisms and disrupting ecological balance. Studies indicate that concentrations as low as 0.5 mg/L can impact sensitive aquatic species, highlighting the importance of proper wastewater treatment from testing facilities.

Atmospheric emissions from HF testing, though typically minimal in well-designed laboratory settings, require monitoring and control measures. Volatile HF can contribute to air quality degradation and potentially cause acid precipitation in surrounding areas if released in significant quantities. Modern testing facilities increasingly implement scrubber systems and fume hoods with specialized filtration to mitigate these risks.

Soil contamination represents another environmental concern, particularly in industrial settings where regular HF testing occurs. Fluoride accumulation in soil can alter pH levels and affect plant growth, potentially creating long-term ecological impacts in areas surrounding testing facilities. Comprehensive soil monitoring programs have become standard practice at facilities conducting regular HF analysis.

The lifecycle assessment of HF testing materials reveals additional environmental considerations. Single-use testing kits, while convenient and safer for personnel, generate substantial solid waste. Reusable testing equipment reduces waste generation but requires chemical cleaning processes that produce secondary waste streams requiring treatment.

Recent advancements in green chemistry approaches to HF testing show promising environmental benefits. Ion-selective electrode methods and spectrophotometric techniques have been optimized to reduce reagent consumption and waste generation. These environmentally preferable methods maintain detection accuracy while minimizing the ecological footprint of testing operations.

Regulatory frameworks increasingly emphasize the environmental aspects of HF testing. The EPA's Resource Conservation and Recovery Act classifies certain HF testing wastes as hazardous, mandating specific disposal protocols. International standards such as ISO 14001 provide frameworks for environmental management systems that address the full lifecycle impacts of industrial testing procedures, including those involving hydrofluoric acid.

Water resource contamination poses the most significant environmental risk associated with HF testing. Even at low concentrations, fluoride ions can persist in aquatic ecosystems, potentially affecting freshwater organisms and disrupting ecological balance. Studies indicate that concentrations as low as 0.5 mg/L can impact sensitive aquatic species, highlighting the importance of proper wastewater treatment from testing facilities.

Atmospheric emissions from HF testing, though typically minimal in well-designed laboratory settings, require monitoring and control measures. Volatile HF can contribute to air quality degradation and potentially cause acid precipitation in surrounding areas if released in significant quantities. Modern testing facilities increasingly implement scrubber systems and fume hoods with specialized filtration to mitigate these risks.

Soil contamination represents another environmental concern, particularly in industrial settings where regular HF testing occurs. Fluoride accumulation in soil can alter pH levels and affect plant growth, potentially creating long-term ecological impacts in areas surrounding testing facilities. Comprehensive soil monitoring programs have become standard practice at facilities conducting regular HF analysis.

The lifecycle assessment of HF testing materials reveals additional environmental considerations. Single-use testing kits, while convenient and safer for personnel, generate substantial solid waste. Reusable testing equipment reduces waste generation but requires chemical cleaning processes that produce secondary waste streams requiring treatment.

Recent advancements in green chemistry approaches to HF testing show promising environmental benefits. Ion-selective electrode methods and spectrophotometric techniques have been optimized to reduce reagent consumption and waste generation. These environmentally preferable methods maintain detection accuracy while minimizing the ecological footprint of testing operations.

Regulatory frameworks increasingly emphasize the environmental aspects of HF testing. The EPA's Resource Conservation and Recovery Act classifies certain HF testing wastes as hazardous, mandating specific disposal protocols. International standards such as ISO 14001 provide frameworks for environmental management systems that address the full lifecycle impacts of industrial testing procedures, including those involving hydrofluoric acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!