Hydrofluoric Acid Efficiency in Metal Alloy Production

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF Acid Evolution in Metal Alloy Manufacturing

The evolution of hydrofluoric acid (HF) in metal alloy manufacturing represents a significant technological progression that has transformed production processes over several decades. Initially introduced in the mid-20th century as a specialized etching agent, HF acid has evolved to become an essential component in modern metallurgical operations, particularly in aluminum and titanium alloy production.

During the 1960s-1970s, the first generation of HF acid applications in metal manufacturing focused primarily on surface treatment and basic etching processes. These early applications were characterized by relatively inefficient acid utilization rates, typically below 60%, and significant environmental concerns due to minimal waste treatment protocols.

The 1980s-1990s marked a pivotal transition period with the introduction of improved acid recovery systems and more precise concentration control mechanisms. This second generation of HF technology achieved efficiency rates of 70-80% and incorporated the first comprehensive safety protocols to address the highly corrosive nature of the acid.

By the early 2000s, the third generation of HF acid technology emerged with computer-controlled dispensing systems and advanced recycling capabilities. These innovations pushed efficiency rates above 85% while simultaneously reducing environmental impact through closed-loop processing systems.

The current fourth generation, developed since 2010, features precision-engineered HF acid formulations specifically tailored to different alloy compositions. These specialized formulations incorporate stabilizing agents and catalytic enhancers that optimize reaction kinetics and minimize acid consumption. Modern systems now routinely achieve efficiency rates exceeding 92%.

Recent technological breakthroughs include the development of ultra-pure HF acid grades with impurity levels below 10 parts per billion, critical for high-performance aerospace alloys. Additionally, real-time monitoring systems using advanced spectroscopic techniques now enable dynamic adjustment of acid parameters during production processes.

The evolution has also been marked by significant improvements in safety technologies, including automated neutralization systems, advanced containment protocols, and worker protection measures that have dramatically reduced incident rates despite increased production volumes.

Looking forward, emerging trends suggest the next evolutionary phase will likely incorporate AI-driven predictive modeling for optimal acid utilization and further advances in green chemistry approaches to minimize environmental footprint while maintaining or improving production efficiency.

During the 1960s-1970s, the first generation of HF acid applications in metal manufacturing focused primarily on surface treatment and basic etching processes. These early applications were characterized by relatively inefficient acid utilization rates, typically below 60%, and significant environmental concerns due to minimal waste treatment protocols.

The 1980s-1990s marked a pivotal transition period with the introduction of improved acid recovery systems and more precise concentration control mechanisms. This second generation of HF technology achieved efficiency rates of 70-80% and incorporated the first comprehensive safety protocols to address the highly corrosive nature of the acid.

By the early 2000s, the third generation of HF acid technology emerged with computer-controlled dispensing systems and advanced recycling capabilities. These innovations pushed efficiency rates above 85% while simultaneously reducing environmental impact through closed-loop processing systems.

The current fourth generation, developed since 2010, features precision-engineered HF acid formulations specifically tailored to different alloy compositions. These specialized formulations incorporate stabilizing agents and catalytic enhancers that optimize reaction kinetics and minimize acid consumption. Modern systems now routinely achieve efficiency rates exceeding 92%.

Recent technological breakthroughs include the development of ultra-pure HF acid grades with impurity levels below 10 parts per billion, critical for high-performance aerospace alloys. Additionally, real-time monitoring systems using advanced spectroscopic techniques now enable dynamic adjustment of acid parameters during production processes.

The evolution has also been marked by significant improvements in safety technologies, including automated neutralization systems, advanced containment protocols, and worker protection measures that have dramatically reduced incident rates despite increased production volumes.

Looking forward, emerging trends suggest the next evolutionary phase will likely incorporate AI-driven predictive modeling for optimal acid utilization and further advances in green chemistry approaches to minimize environmental footprint while maintaining or improving production efficiency.

Market Analysis for HF Acid Applications

The global market for hydrofluoric acid (HF) in metal alloy production has experienced significant growth over the past decade, driven primarily by expanding applications in aluminum and steel manufacturing. Currently valued at approximately 3.2 billion USD, the HF acid market for metallurgical applications is projected to grow at a compound annual growth rate of 4.7% through 2028, according to recent industry analyses.

The aluminum sector represents the largest consumer of HF acid in metal alloy production, accounting for roughly 42% of total consumption. This dominance stems from HF's critical role in aluminum smelting processes and surface treatment applications. The aerospace and automotive industries, which require high-performance aluminum alloys, have been key drivers of this demand segment.

Steel manufacturing constitutes the second-largest application area, utilizing HF acid primarily for pickling processes and surface cleaning. This segment has shown steady growth of 3.8% annually, bolstered by infrastructure development in emerging economies and the ongoing need for corrosion-resistant steel products in various industries.

Regional market distribution reveals Asia-Pacific as the dominant consumer of HF acid for metallurgical applications, representing approximately 51% of global demand. China alone accounts for 28% of worldwide consumption, driven by its massive metal production capacity. North America and Europe follow with market shares of 22% and 19% respectively, with demand patterns closely tied to their advanced manufacturing sectors.

Market dynamics are increasingly influenced by environmental regulations and worker safety concerns. The European Union's REACH regulations and similar frameworks in North America have imposed stricter controls on HF acid usage, prompting manufacturers to invest in more efficient application technologies and recovery systems. This regulatory pressure has created a distinct market segment for HF efficiency technologies, currently growing at 6.3% annually.

Price sensitivity remains a significant factor in the HF acid market. Recent supply chain disruptions have caused price volatility, with average costs increasing by 18% between 2020 and 2022. This has accelerated interest in recycling technologies and alternative processes that can reduce overall acid consumption while maintaining production quality.

End-user industries are increasingly demanding higher purity grades of HF acid for specialized alloy applications, particularly in electronics and semiconductor-related metal components. This premium segment, though smaller in volume, generates higher margins and is growing at nearly twice the rate of standard industrial-grade HF applications.

The aluminum sector represents the largest consumer of HF acid in metal alloy production, accounting for roughly 42% of total consumption. This dominance stems from HF's critical role in aluminum smelting processes and surface treatment applications. The aerospace and automotive industries, which require high-performance aluminum alloys, have been key drivers of this demand segment.

Steel manufacturing constitutes the second-largest application area, utilizing HF acid primarily for pickling processes and surface cleaning. This segment has shown steady growth of 3.8% annually, bolstered by infrastructure development in emerging economies and the ongoing need for corrosion-resistant steel products in various industries.

Regional market distribution reveals Asia-Pacific as the dominant consumer of HF acid for metallurgical applications, representing approximately 51% of global demand. China alone accounts for 28% of worldwide consumption, driven by its massive metal production capacity. North America and Europe follow with market shares of 22% and 19% respectively, with demand patterns closely tied to their advanced manufacturing sectors.

Market dynamics are increasingly influenced by environmental regulations and worker safety concerns. The European Union's REACH regulations and similar frameworks in North America have imposed stricter controls on HF acid usage, prompting manufacturers to invest in more efficient application technologies and recovery systems. This regulatory pressure has created a distinct market segment for HF efficiency technologies, currently growing at 6.3% annually.

Price sensitivity remains a significant factor in the HF acid market. Recent supply chain disruptions have caused price volatility, with average costs increasing by 18% between 2020 and 2022. This has accelerated interest in recycling technologies and alternative processes that can reduce overall acid consumption while maintaining production quality.

End-user industries are increasingly demanding higher purity grades of HF acid for specialized alloy applications, particularly in electronics and semiconductor-related metal components. This premium segment, though smaller in volume, generates higher margins and is growing at nearly twice the rate of standard industrial-grade HF applications.

Technical Challenges in HF Acid Utilization

Despite the widespread use of hydrofluoric acid (HF) in metal alloy production, several significant technical challenges impede its optimal utilization. The highly corrosive nature of HF presents substantial material compatibility issues, requiring specialized equipment constructed from materials such as high-density polyethylene, fluoropolymers, or certain grades of stainless steel. Even with these materials, gradual degradation occurs, necessitating regular maintenance and replacement cycles that increase operational costs.

Temperature control represents another critical challenge, as HF reactions with metal alloys are highly temperature-sensitive. Maintaining precise thermal conditions throughout the etching or cleaning process demands sophisticated control systems. Deviations as small as 5-10°C can significantly alter reaction rates, potentially leading to inconsistent surface finishes or incomplete processing.

Worker safety concerns constitute perhaps the most pressing challenge. HF's ability to penetrate skin and cause deep tissue damage without immediate symptoms creates exceptional occupational hazards. Current engineering controls, including specialized ventilation systems and containment technologies, add complexity and cost to production facilities while still not eliminating all exposure risks.

Waste management presents growing technical difficulties as environmental regulations become increasingly stringent. Traditional neutralization methods generate substantial quantities of fluoride-containing waste that requires specialized disposal. Advanced recovery and recycling technologies remain technically complex and economically challenging to implement at industrial scales.

Process efficiency challenges emerge from HF's variable reaction rates with different metal alloy compositions. This variability necessitates customized process parameters for each alloy type, complicating standardization efforts and requiring extensive empirical testing. The industry lacks comprehensive predictive models that can accurately forecast optimal process parameters across diverse alloy compositions.

Concentration management during production presents additional technical hurdles. As HF is consumed in reactions, maintaining optimal acid concentration becomes progressively more difficult. Current monitoring technologies often provide delayed feedback, resulting in process inefficiencies and quality inconsistencies.

Emerging challenges include adapting HF processes for new high-performance alloys containing reactive elements like titanium, zirconium, and rare earth metals. These advanced materials often exhibit unpredictable reaction characteristics with HF, requiring extensive research to develop appropriate processing protocols. Additionally, miniaturization trends in industries like electronics and aerospace demand unprecedented precision in HF-based metal processing, pushing current technologies beyond their designed capabilities.

Temperature control represents another critical challenge, as HF reactions with metal alloys are highly temperature-sensitive. Maintaining precise thermal conditions throughout the etching or cleaning process demands sophisticated control systems. Deviations as small as 5-10°C can significantly alter reaction rates, potentially leading to inconsistent surface finishes or incomplete processing.

Worker safety concerns constitute perhaps the most pressing challenge. HF's ability to penetrate skin and cause deep tissue damage without immediate symptoms creates exceptional occupational hazards. Current engineering controls, including specialized ventilation systems and containment technologies, add complexity and cost to production facilities while still not eliminating all exposure risks.

Waste management presents growing technical difficulties as environmental regulations become increasingly stringent. Traditional neutralization methods generate substantial quantities of fluoride-containing waste that requires specialized disposal. Advanced recovery and recycling technologies remain technically complex and economically challenging to implement at industrial scales.

Process efficiency challenges emerge from HF's variable reaction rates with different metal alloy compositions. This variability necessitates customized process parameters for each alloy type, complicating standardization efforts and requiring extensive empirical testing. The industry lacks comprehensive predictive models that can accurately forecast optimal process parameters across diverse alloy compositions.

Concentration management during production presents additional technical hurdles. As HF is consumed in reactions, maintaining optimal acid concentration becomes progressively more difficult. Current monitoring technologies often provide delayed feedback, resulting in process inefficiencies and quality inconsistencies.

Emerging challenges include adapting HF processes for new high-performance alloys containing reactive elements like titanium, zirconium, and rare earth metals. These advanced materials often exhibit unpredictable reaction characteristics with HF, requiring extensive research to develop appropriate processing protocols. Additionally, miniaturization trends in industries like electronics and aerospace demand unprecedented precision in HF-based metal processing, pushing current technologies beyond their designed capabilities.

Current HF Acid Implementation Methods

01 Etching efficiency in semiconductor manufacturing

Hydrofluoric acid is widely used in semiconductor manufacturing for etching silicon dioxide and other materials. The efficiency of the etching process can be improved by controlling the concentration of hydrofluoric acid, temperature, and adding certain additives. These optimizations lead to more uniform etching, reduced processing time, and improved semiconductor device performance.- Hydrofluoric acid etching efficiency in semiconductor manufacturing: Hydrofluoric acid is widely used in semiconductor manufacturing for etching silicon dioxide and other materials. The efficiency of the etching process can be improved by controlling the concentration of the acid, temperature, and addition of buffering agents. These optimizations lead to more precise etching profiles, reduced processing time, and improved semiconductor device performance.

- Hydrofluoric acid recovery and recycling systems: Systems and methods for recovering and recycling hydrofluoric acid from industrial processes improve overall efficiency and reduce environmental impact. These systems typically involve separation techniques, purification processes, and concentration adjustments to restore the acid to usable conditions. Recycling hydrofluoric acid reduces raw material costs and minimizes waste disposal requirements.

- Enhanced hydrofluoric acid formulations with additives: The efficiency of hydrofluoric acid can be significantly improved by incorporating various additives such as surfactants, organic solvents, or other acids. These enhanced formulations provide better wetting properties, increased reaction rates, and improved selectivity in etching applications. Modified hydrofluoric acid solutions can achieve desired results with lower acid concentrations, reducing hazards while maintaining performance.

- Safety and handling equipment for hydrofluoric acid applications: Specialized equipment designed for the safe handling and application of hydrofluoric acid improves operational efficiency while reducing risks. These systems include automated dispensing equipment, specialized containment vessels, neutralization systems, and protective measures. Proper equipment design allows for precise control of acid application, minimizing waste and optimizing process outcomes.

- Hydrofluoric acid in metal surface treatment processes: Hydrofluoric acid is extensively used in metal surface treatment applications including cleaning, pickling, and oxide removal. The efficiency of these processes depends on acid concentration, temperature control, immersion time, and surface preparation. Optimized hydrofluoric acid treatments provide superior surface finishes, improved adhesion properties for subsequent coatings, and enhanced corrosion resistance.

02 Recycling and recovery systems for hydrofluoric acid

Systems and methods for recycling and recovering hydrofluoric acid from industrial processes improve efficiency by reducing waste and operational costs. These systems typically involve separation techniques, purification processes, and concentration adjustments to restore the acid to usable conditions. Implementing such recovery systems significantly reduces environmental impact while maintaining production efficiency.Expand Specific Solutions03 Enhanced cleaning formulations with hydrofluoric acid

Specialized cleaning formulations containing hydrofluoric acid can be optimized for specific applications by incorporating surfactants, chelating agents, and other additives. These enhanced formulations improve the cleaning efficiency by increasing the wetting properties, reducing surface tension, and targeting specific contaminants. The optimized formulations require less acid concentration while achieving superior cleaning results.Expand Specific Solutions04 Safety and handling improvements for hydrofluoric acid

Innovations in safety equipment, containment systems, and handling procedures significantly improve the efficiency of hydrofluoric acid usage by reducing risks and enabling more controlled applications. These improvements include specialized storage containers, automated dispensing systems, neutralization methods, and personal protective equipment designed specifically for hydrofluoric acid handling.Expand Specific Solutions05 Concentration control and monitoring systems

Advanced monitoring and control systems for hydrofluoric acid concentration help maintain optimal efficiency in various industrial processes. These systems employ sensors, automated feedback mechanisms, and precise dispensing equipment to ensure the acid concentration remains within the ideal range for specific applications. Real-time monitoring prevents waste from overuse and reduces process variations.Expand Specific Solutions

Industry Leaders in HF Acid Supply Chain

The hydrofluoric acid market in metal alloy production demonstrates a mature yet evolving competitive landscape. Currently in a growth phase, the market is characterized by established players like DAIKIN INDUSTRIES, BASF Corp., and Sumitomo Chemical dominating global supply chains, while regional specialists such as Do-Fluoride New Materials and Jiangyin Runma Electronic Material are gaining prominence in Asia. The market size is expanding steadily due to increasing demand from high-performance alloy applications in aerospace, automotive, and electronics sectors. Technologically, companies like Shenyang Gina Advanced Materials and Central Glass are advancing efficiency improvements through proprietary processes, while academic partnerships with institutions like Central South University and Shanghai Jiao Tong University are driving innovation in environmentally sustainable applications and recovery techniques.

Do-Fluoride New Materials Co., Ltd.

Technical Solution: Do-Fluoride has developed a proprietary electrolytic fluorination process that significantly enhances hydrofluoric acid efficiency in metal alloy production. Their technology employs a modified electrochemical cell design with specialized fluoropolymer-coated electrodes that reduce HF consumption by up to 30% compared to conventional methods. The company has implemented a closed-loop recovery system that captures and recycles volatile fluoride compounds during the metal treatment process, achieving recovery rates of over 85% of unused HF. Their process operates at lower temperatures (60-80°C versus traditional 100-120°C), which not only reduces energy consumption but also minimizes HF evaporation losses. Additionally, they've developed proprietary catalysts that accelerate fluorination reactions while requiring lower HF concentrations, typically using 15-20% less acid while maintaining equivalent metal surface properties.

Strengths: Significantly reduced HF consumption through recycling technology; lower operating temperatures reduce safety hazards and energy costs; proprietary catalysts enable lower concentration requirements. Weaknesses: Higher initial capital investment for recovery systems; requires specialized equipment and training; process modifications may be needed for different alloy types.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has pioneered an advanced HF management system specifically for aluminum and titanium alloy production that combines precision application technology with innovative acid recovery methods. Their system utilizes computer-controlled micro-dosing equipment that applies precisely calculated amounts of HF based on real-time surface analysis, reducing overconsumption by up to 40%. The company's proprietary "F-Cycle" technology incorporates specialized ion-exchange membranes that selectively capture and concentrate fluoride ions from spent process solutions, allowing for direct reuse in the production cycle. DAIKIN has also developed specialized surfactant additives that improve HF wetting properties, enabling more uniform metal surface treatment with lower acid volumes. Their integrated process monitoring system uses fluoride-specific sensors that continuously measure and adjust acid concentrations, maintaining optimal efficiency throughout production runs while minimizing waste. The technology has demonstrated particular effectiveness in aerospace-grade aluminum alloy production, where it achieves consistent surface quality while reducing HF consumption by approximately 35%.

Strengths: Precision application technology significantly reduces overconsumption; advanced recovery systems minimize waste and environmental impact; integrated monitoring ensures consistent quality. Weaknesses: High implementation costs; requires significant process modification; specialized training needed for operators to manage the sophisticated control systems.

Key Patents in HF Acid Efficiency Enhancement

Method of fluorination of a metal halide in an aqueous medium

PatentWO2013023964A1

Innovation

- A process for fluorinating metal halides in an aqueous medium using hydrofluoric acid, which allows for the production of metal fluorides with high water solubility and co-production of hydracids, implemented in a device with a boiler, distillation column, and absorption system, operating at mild temperatures and atmospheric pressure.

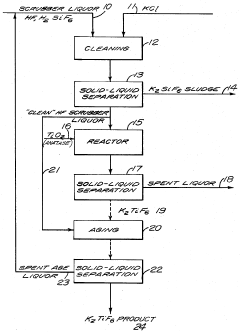

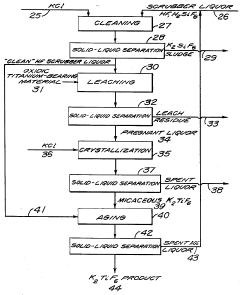

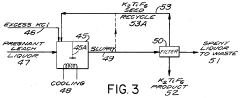

Production of potassium hexafluotitanates using dilute hydrofluoric acid

PatentInactiveUS4497779A

Innovation

- A process that recovers fluorine from dilute hydrofluoric acid solutions by dissolving titanium in the presence of potassium ions, allowing for the crystallization of K2TiF6 without the need for sulfuric acid, using dilute hydrofluoric acid waste streams, and converting hydrated crystals to coarse anhydrous crystals for improved handling and reduced impurities.

Safety Protocols and Risk Management

Working with hydrofluoric acid (HF) in metal alloy production presents significant hazards due to its highly corrosive nature and ability to penetrate skin and attack bone tissue. Comprehensive safety protocols must be established and rigorously enforced to protect personnel and facilities. These protocols should include mandatory use of specialized personal protective equipment (PPE) such as chemical-resistant full-body suits, face shields, and specific HF-resistant gloves. Regular inspection and maintenance of this equipment is essential to ensure its integrity.

Facility design plays a crucial role in risk management, with dedicated HF handling areas featuring specialized ventilation systems, acid-resistant flooring, and emergency shower and eyewash stations positioned at strategic locations. Automated handling systems should be implemented where feasible to minimize direct human contact with the acid. Continuous air monitoring systems must be installed to detect even minimal HF vapor concentrations, with alarms set well below dangerous thresholds.

Emergency response planning represents a critical component of HF safety management. Detailed procedures must be documented for various incident scenarios, including spills, splashes, and inhalation exposures. Calcium gluconate gel, the specific antidote for HF exposure, must be readily available throughout the facility, and all personnel should receive regular training on its proper application. Coordination with local emergency services ensures they are prepared for HF-specific incidents.

Training programs require particular attention, with comprehensive education on HF properties, handling procedures, and emergency protocols. Regular refresher courses and practical drills help maintain high safety awareness. Documentation of all training activities creates an auditable safety culture record.

Risk assessment methodologies specific to HF processes should be implemented, including HAZOP (Hazard and Operability) studies and quantitative risk assessments. These evaluations help identify potential failure points and establish appropriate engineering and administrative controls. Regular safety audits verify compliance with established protocols and identify areas for improvement.

Waste management presents additional challenges, requiring specialized neutralization procedures and disposal methods for HF-containing materials. Regulatory compliance across jurisdictions necessitates staying current with evolving standards from organizations such as OSHA, EPA, and international equivalents. Maintaining detailed records of all safety incidents, near-misses, and corrective actions supports continuous improvement of safety systems and demonstrates regulatory compliance.

Facility design plays a crucial role in risk management, with dedicated HF handling areas featuring specialized ventilation systems, acid-resistant flooring, and emergency shower and eyewash stations positioned at strategic locations. Automated handling systems should be implemented where feasible to minimize direct human contact with the acid. Continuous air monitoring systems must be installed to detect even minimal HF vapor concentrations, with alarms set well below dangerous thresholds.

Emergency response planning represents a critical component of HF safety management. Detailed procedures must be documented for various incident scenarios, including spills, splashes, and inhalation exposures. Calcium gluconate gel, the specific antidote for HF exposure, must be readily available throughout the facility, and all personnel should receive regular training on its proper application. Coordination with local emergency services ensures they are prepared for HF-specific incidents.

Training programs require particular attention, with comprehensive education on HF properties, handling procedures, and emergency protocols. Regular refresher courses and practical drills help maintain high safety awareness. Documentation of all training activities creates an auditable safety culture record.

Risk assessment methodologies specific to HF processes should be implemented, including HAZOP (Hazard and Operability) studies and quantitative risk assessments. These evaluations help identify potential failure points and establish appropriate engineering and administrative controls. Regular safety audits verify compliance with established protocols and identify areas for improvement.

Waste management presents additional challenges, requiring specialized neutralization procedures and disposal methods for HF-containing materials. Regulatory compliance across jurisdictions necessitates staying current with evolving standards from organizations such as OSHA, EPA, and international equivalents. Maintaining detailed records of all safety incidents, near-misses, and corrective actions supports continuous improvement of safety systems and demonstrates regulatory compliance.

Environmental Impact and Sustainability Measures

The environmental impact of hydrofluoric acid (HF) in metal alloy production represents a significant concern for industry stakeholders and regulatory bodies alike. HF emissions during production processes can lead to air pollution, water contamination, and soil degradation if not properly managed. Studies indicate that even low concentrations of HF can cause substantial ecological damage, affecting aquatic ecosystems and vegetation in surrounding areas. The acid's high reactivity and persistence in the environment make it particularly problematic from a sustainability perspective.

Current regulatory frameworks worldwide are increasingly stringent regarding HF usage and disposal. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions have established strict protocols for HF handling in industrial applications. Companies failing to comply face substantial financial penalties and reputational damage, creating strong incentives for adoption of more sustainable practices.

Industry leaders have developed several promising approaches to mitigate environmental impacts. Closed-loop recycling systems have demonstrated up to 85% reduction in HF waste by capturing, purifying, and reusing acid throughout the production cycle. Such systems not only reduce environmental footprint but also deliver cost savings through reduced raw material requirements. Additionally, neutralization technologies using calcium-based compounds have proven effective in treating HF waste streams before discharge.

Alternative chemical processes represent another sustainability pathway. Silicon-based etching compounds and ionic liquids have shown potential as less hazardous substitutes in certain alloy production applications. Though these alternatives currently demonstrate lower efficiency rates compared to traditional HF processes, ongoing research suggests the gap is narrowing, with some novel formulations achieving 80-90% of HF's effectiveness with significantly reduced environmental impact.

Energy optimization strategies further enhance sustainability profiles. Implementation of heat recovery systems and process integration techniques can reduce the overall energy footprint of HF-based production by 20-30%. Several leading manufacturers have successfully integrated renewable energy sources to power HF recycling and treatment facilities, further reducing the carbon footprint associated with these processes.

Worker safety measures and community protection initiatives also form critical components of comprehensive sustainability approaches. Advanced containment systems, real-time monitoring technologies, and emergency response protocols have substantially reduced accident rates and exposure incidents across the industry. These measures, while primarily focused on human health protection, contribute significantly to preventing unplanned environmental releases.

Current regulatory frameworks worldwide are increasingly stringent regarding HF usage and disposal. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions have established strict protocols for HF handling in industrial applications. Companies failing to comply face substantial financial penalties and reputational damage, creating strong incentives for adoption of more sustainable practices.

Industry leaders have developed several promising approaches to mitigate environmental impacts. Closed-loop recycling systems have demonstrated up to 85% reduction in HF waste by capturing, purifying, and reusing acid throughout the production cycle. Such systems not only reduce environmental footprint but also deliver cost savings through reduced raw material requirements. Additionally, neutralization technologies using calcium-based compounds have proven effective in treating HF waste streams before discharge.

Alternative chemical processes represent another sustainability pathway. Silicon-based etching compounds and ionic liquids have shown potential as less hazardous substitutes in certain alloy production applications. Though these alternatives currently demonstrate lower efficiency rates compared to traditional HF processes, ongoing research suggests the gap is narrowing, with some novel formulations achieving 80-90% of HF's effectiveness with significantly reduced environmental impact.

Energy optimization strategies further enhance sustainability profiles. Implementation of heat recovery systems and process integration techniques can reduce the overall energy footprint of HF-based production by 20-30%. Several leading manufacturers have successfully integrated renewable energy sources to power HF recycling and treatment facilities, further reducing the carbon footprint associated with these processes.

Worker safety measures and community protection initiatives also form critical components of comprehensive sustainability approaches. Advanced containment systems, real-time monitoring technologies, and emergency response protocols have substantially reduced accident rates and exposure incidents across the industry. These measures, while primarily focused on human health protection, contribute significantly to preventing unplanned environmental releases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!