How to Advance Polyurethane Recycling Methods?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Recycling Evolution

Polyurethane (PU) recycling has undergone significant evolution since its inception in the 1970s. Initially, the focus was primarily on mechanical recycling methods, which involved grinding and reprocessing PU waste into new products. However, these early techniques were limited in their ability to maintain the material's original properties and were only suitable for certain types of PU waste.

The 1980s and 1990s saw the emergence of chemical recycling methods, particularly glycolysis and hydrolysis. These processes aimed to break down PU into its chemical components, allowing for more versatile recycling options. Glycolysis, which uses glycols to depolymerize PU, became a popular method due to its ability to produce polyols that could be used in new PU formulations. Hydrolysis, on the other hand, used water to break down PU, but faced challenges in terms of energy consumption and waste management.

In the early 2000s, researchers began exploring more advanced chemical recycling techniques, such as acidolysis and aminolysis. These methods offered improved selectivity in breaking down specific PU bonds, potentially leading to higher quality recycled materials. Concurrently, the development of catalysts and process optimizations enhanced the efficiency and economic viability of existing recycling methods.

The late 2000s and early 2010s marked a shift towards more sustainable and environmentally friendly recycling approaches. This period saw increased research into enzymatic degradation of PU, utilizing microorganisms and enzymes to break down the polymer in a more natural and less energy-intensive manner. While promising, these biological methods still faced challenges in scalability and process control.

Recent years have witnessed a surge in innovative recycling technologies. Advanced thermal processes, such as pyrolysis and gasification, have gained attention for their ability to convert PU waste into valuable chemicals and fuels. Additionally, the concept of design for recyclability has emerged, focusing on creating PU products that are inherently easier to recycle from the outset.

The latest frontier in PU recycling involves the integration of artificial intelligence and machine learning. These technologies are being employed to optimize recycling processes, predict material properties, and develop new recycling strategies. Furthermore, the circular economy concept has gained traction, emphasizing closed-loop systems where PU products are designed, used, and recycled with minimal waste and maximum resource efficiency.

Looking ahead, the future of PU recycling is likely to involve a combination of these evolving technologies, with a strong emphasis on sustainability, energy efficiency, and material quality preservation. The integration of smart technologies, coupled with advancements in chemical and biological processes, promises to revolutionize PU recycling, making it more effective, economical, and environmentally friendly.

The 1980s and 1990s saw the emergence of chemical recycling methods, particularly glycolysis and hydrolysis. These processes aimed to break down PU into its chemical components, allowing for more versatile recycling options. Glycolysis, which uses glycols to depolymerize PU, became a popular method due to its ability to produce polyols that could be used in new PU formulations. Hydrolysis, on the other hand, used water to break down PU, but faced challenges in terms of energy consumption and waste management.

In the early 2000s, researchers began exploring more advanced chemical recycling techniques, such as acidolysis and aminolysis. These methods offered improved selectivity in breaking down specific PU bonds, potentially leading to higher quality recycled materials. Concurrently, the development of catalysts and process optimizations enhanced the efficiency and economic viability of existing recycling methods.

The late 2000s and early 2010s marked a shift towards more sustainable and environmentally friendly recycling approaches. This period saw increased research into enzymatic degradation of PU, utilizing microorganisms and enzymes to break down the polymer in a more natural and less energy-intensive manner. While promising, these biological methods still faced challenges in scalability and process control.

Recent years have witnessed a surge in innovative recycling technologies. Advanced thermal processes, such as pyrolysis and gasification, have gained attention for their ability to convert PU waste into valuable chemicals and fuels. Additionally, the concept of design for recyclability has emerged, focusing on creating PU products that are inherently easier to recycle from the outset.

The latest frontier in PU recycling involves the integration of artificial intelligence and machine learning. These technologies are being employed to optimize recycling processes, predict material properties, and develop new recycling strategies. Furthermore, the circular economy concept has gained traction, emphasizing closed-loop systems where PU products are designed, used, and recycled with minimal waste and maximum resource efficiency.

Looking ahead, the future of PU recycling is likely to involve a combination of these evolving technologies, with a strong emphasis on sustainability, energy efficiency, and material quality preservation. The integration of smart technologies, coupled with advancements in chemical and biological processes, promises to revolutionize PU recycling, making it more effective, economical, and environmentally friendly.

Market Demand Analysis

The global market for polyurethane recycling is experiencing significant growth driven by increasing environmental concerns and regulatory pressures. As landfill space becomes scarce and the environmental impact of plastic waste gains more attention, there is a growing demand for effective recycling solutions for polyurethane materials. The automotive, construction, and furniture industries are the primary sources of polyurethane waste, creating a substantial market opportunity for recycling technologies.

The construction sector, in particular, shows strong potential for recycled polyurethane products. Insulation materials made from recycled polyurethane foam are gaining traction due to their excellent thermal properties and reduced environmental footprint. This trend is further supported by green building initiatives and stricter energy efficiency regulations in many countries.

In the automotive industry, there is an increasing focus on using recycled materials to reduce the overall environmental impact of vehicles. This has led to a rising demand for recycled polyurethane components in car interiors, seating, and other applications. As automakers strive to meet sustainability targets, the market for recycled polyurethane in this sector is expected to grow significantly.

The furniture industry also presents a substantial market for recycled polyurethane, particularly in the form of foam for mattresses and upholstery. Consumers are becoming more environmentally conscious, driving demand for products made from recycled materials. This shift in consumer preferences is encouraging furniture manufacturers to incorporate recycled polyurethane into their products, creating a steady demand for recycling technologies.

Geographically, Europe and North America are currently leading the polyurethane recycling market due to stringent environmental regulations and well-established waste management infrastructure. However, emerging economies in Asia-Pacific and Latin America are expected to show rapid growth in demand for polyurethane recycling solutions as these regions grapple with increasing plastic waste and adopt more sustainable practices.

The market for chemical recycling methods, which can break down polyurethane into its original chemical components, is particularly promising. These advanced recycling techniques offer the potential to create high-quality recycled materials that can be used in a wide range of applications, potentially opening up new market opportunities across various industries.

As governments worldwide implement more stringent waste management policies and circular economy initiatives, the demand for polyurethane recycling is expected to surge. This regulatory landscape is creating a favorable environment for investments in recycling technologies and infrastructure, further driving market growth.

The construction sector, in particular, shows strong potential for recycled polyurethane products. Insulation materials made from recycled polyurethane foam are gaining traction due to their excellent thermal properties and reduced environmental footprint. This trend is further supported by green building initiatives and stricter energy efficiency regulations in many countries.

In the automotive industry, there is an increasing focus on using recycled materials to reduce the overall environmental impact of vehicles. This has led to a rising demand for recycled polyurethane components in car interiors, seating, and other applications. As automakers strive to meet sustainability targets, the market for recycled polyurethane in this sector is expected to grow significantly.

The furniture industry also presents a substantial market for recycled polyurethane, particularly in the form of foam for mattresses and upholstery. Consumers are becoming more environmentally conscious, driving demand for products made from recycled materials. This shift in consumer preferences is encouraging furniture manufacturers to incorporate recycled polyurethane into their products, creating a steady demand for recycling technologies.

Geographically, Europe and North America are currently leading the polyurethane recycling market due to stringent environmental regulations and well-established waste management infrastructure. However, emerging economies in Asia-Pacific and Latin America are expected to show rapid growth in demand for polyurethane recycling solutions as these regions grapple with increasing plastic waste and adopt more sustainable practices.

The market for chemical recycling methods, which can break down polyurethane into its original chemical components, is particularly promising. These advanced recycling techniques offer the potential to create high-quality recycled materials that can be used in a wide range of applications, potentially opening up new market opportunities across various industries.

As governments worldwide implement more stringent waste management policies and circular economy initiatives, the demand for polyurethane recycling is expected to surge. This regulatory landscape is creating a favorable environment for investments in recycling technologies and infrastructure, further driving market growth.

Technical Challenges

Polyurethane recycling faces several significant technical challenges that hinder widespread adoption and efficiency. One of the primary obstacles is the complex chemical structure of polyurethane, which makes it difficult to break down into its original components without degrading the material's properties. The cross-linked nature of polyurethane polymers creates a stable structure that resists conventional recycling methods.

The diversity of polyurethane formulations further complicates recycling efforts. Different products may contain varying additives, fillers, and chemical compositions, making it challenging to develop a universal recycling process. This heterogeneity often results in inconsistent quality of recycled materials, limiting their potential applications.

Another major challenge is the separation of polyurethane from other materials in composite products. Many consumer goods, such as furniture and automotive parts, contain polyurethane combined with other materials like metals, fabrics, or other plastics. Efficiently separating these components without contamination is a significant technical hurdle.

The energy-intensive nature of current recycling processes poses both economic and environmental challenges. Chemical recycling methods, while effective in breaking down polyurethane, often require high temperatures and pressures, leading to substantial energy consumption and potentially offsetting the environmental benefits of recycling.

Contamination of polyurethane waste streams with other materials or chemicals can significantly impact the recycling process. Impurities can interfere with chemical reactions, reduce the quality of recycled products, or even render the recycling process ineffective. Developing robust purification techniques is crucial for improving recycling outcomes.

The degradation of polyurethane during its lifecycle presents another challenge. Exposure to environmental factors like UV radiation, heat, and moisture can alter the material's chemical structure, making it more difficult to recycle effectively. This degradation can lead to a loss of valuable properties in the recycled material.

Scaling up laboratory-proven recycling techniques to industrial levels remains a significant technical challenge. Many promising methods demonstrate effectiveness on a small scale but face obstacles in maintaining efficiency and cost-effectiveness when scaled to commercial volumes.

Lastly, the lack of standardized testing and quality control methods for recycled polyurethane materials hinders their acceptance in various industries. Developing reliable techniques to assess the properties and performance of recycled polyurethane is essential for expanding its use in high-value applications.

The diversity of polyurethane formulations further complicates recycling efforts. Different products may contain varying additives, fillers, and chemical compositions, making it challenging to develop a universal recycling process. This heterogeneity often results in inconsistent quality of recycled materials, limiting their potential applications.

Another major challenge is the separation of polyurethane from other materials in composite products. Many consumer goods, such as furniture and automotive parts, contain polyurethane combined with other materials like metals, fabrics, or other plastics. Efficiently separating these components without contamination is a significant technical hurdle.

The energy-intensive nature of current recycling processes poses both economic and environmental challenges. Chemical recycling methods, while effective in breaking down polyurethane, often require high temperatures and pressures, leading to substantial energy consumption and potentially offsetting the environmental benefits of recycling.

Contamination of polyurethane waste streams with other materials or chemicals can significantly impact the recycling process. Impurities can interfere with chemical reactions, reduce the quality of recycled products, or even render the recycling process ineffective. Developing robust purification techniques is crucial for improving recycling outcomes.

The degradation of polyurethane during its lifecycle presents another challenge. Exposure to environmental factors like UV radiation, heat, and moisture can alter the material's chemical structure, making it more difficult to recycle effectively. This degradation can lead to a loss of valuable properties in the recycled material.

Scaling up laboratory-proven recycling techniques to industrial levels remains a significant technical challenge. Many promising methods demonstrate effectiveness on a small scale but face obstacles in maintaining efficiency and cost-effectiveness when scaled to commercial volumes.

Lastly, the lack of standardized testing and quality control methods for recycled polyurethane materials hinders their acceptance in various industries. Developing reliable techniques to assess the properties and performance of recycled polyurethane is essential for expanding its use in high-value applications.

Current PU Recycling

01 Chemical recycling of polyurethane

This method involves breaking down polyurethane into its chemical components through processes such as glycolysis, hydrolysis, or aminolysis. The resulting products can be used to create new polyurethane or other materials. This approach allows for the recovery of valuable raw materials and reduces waste.- Chemical recycling of polyurethane: This method involves breaking down polyurethane into its chemical components through processes such as glycolysis, hydrolysis, or aminolysis. The resulting products can be used to create new polyurethane or other materials. This approach allows for the recovery of valuable raw materials and reduces waste.

- Mechanical recycling of polyurethane: Mechanical recycling involves grinding or shredding polyurethane waste into smaller particles, which can then be used as fillers in new products or reprocessed into new polyurethane materials. This method is particularly useful for recycling foam and elastomer products.

- Thermochemical recycling of polyurethane: This method uses heat and pressure to break down polyurethane into smaller molecules, which can be used as fuel or chemical feedstock. Processes such as pyrolysis and gasification fall under this category, offering an alternative to landfilling or incineration.

- Biological recycling of polyurethane: This emerging method utilizes microorganisms or enzymes to break down polyurethane into simpler compounds. While still in development, this approach offers a potentially eco-friendly solution for polyurethane recycling, especially for difficult-to-recycle polyurethane foams.

- Advanced sorting and separation techniques: These methods focus on improving the efficiency of polyurethane recycling by developing advanced sorting and separation techniques. This includes the use of spectroscopic methods, artificial intelligence, and robotics to identify and separate different types of polyurethane waste, enabling more targeted recycling processes.

02 Mechanical recycling of polyurethane

Mechanical recycling involves grinding or shredding polyurethane waste into smaller particles, which can then be used as fillers in new products or reprocessed into new polyurethane materials. This method is particularly useful for recycling foam and elastomer products.Expand Specific Solutions03 Thermochemical recycling of polyurethane

This method uses heat and pressure to break down polyurethane into smaller molecules, which can be used as fuel or chemical feedstock. Processes such as pyrolysis and gasification fall under this category, offering an alternative approach to recycling polyurethane waste.Expand Specific Solutions04 Biological recycling of polyurethane

Biological recycling methods utilize microorganisms or enzymes to break down polyurethane into simpler compounds. This eco-friendly approach is still in development but shows promise for future large-scale applications in polyurethane recycling.Expand Specific Solutions05 Solvent-based recycling of polyurethane

This method involves dissolving polyurethane in specific solvents to separate it into its components. The recovered materials can then be purified and reused in new polyurethane production. This approach is particularly useful for recycling composite materials containing polyurethane.Expand Specific Solutions

Key Industry Players

The polyurethane recycling industry is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding, with a projected CAGR of 7.5% from 2021 to 2028. Technologically, the field is advancing but still maturing. Companies like BASF, Covestro, and Evonik are leading innovation, developing chemical recycling methods and bio-based alternatives. Emerging players such as Ioniqa Technologies and PuREC are introducing novel recycling technologies. Universities and research institutions, including Zhejiang University and the National Institute of Chemistry Slovenia, are contributing to fundamental research. The competitive landscape is diverse, with collaborations between industry leaders and startups driving progress in polyurethane recycling methods.

Covestro Deutschland AG

Technical Solution: Covestro has developed a novel chemical recycling process for polyurethane (PU) foam mattresses. This innovative method breaks down the PU foam into its original chemical components, polyols and isocyanates, which can then be used to produce new high-quality PU materials. The process involves a smart reactor system that can handle various PU foam compositions and efficiently separate the resulting components. Covestro's technology also includes a purification step to ensure the recycled raw materials meet the quality standards for new PU production.

Strengths: Closed-loop recycling, high-quality output, versatility in handling different PU foams. Weaknesses: Energy-intensive process, potential for hazardous by-products, limited to specific PU types.

BASF Corp.

Technical Solution: BASF has introduced a groundbreaking enzymatic recycling process for polyurethanes. This bio-based approach uses specially engineered enzymes to break down PU into its monomeric building blocks. The process operates under mild conditions, reducing energy consumption and environmental impact. BASF's technology can handle a wide range of PU waste, including flexible foams, rigid foams, and elastomers. The resulting recycled raw materials are purified and can be used to create new PU products with properties comparable to those made from virgin materials.

Strengths: Eco-friendly process, low energy requirements, broad applicability to various PU types. Weaknesses: Potentially higher costs due to enzyme production, longer processing times compared to chemical methods.

Innovative PU Recycling

New method for recycling of polyurethane

PatentWO2023078802A1

Innovation

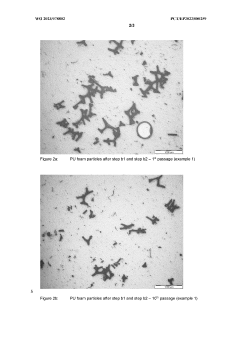

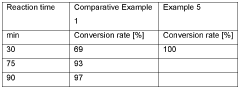

- A process involving the preparation of a polyurethane dispersion with a particle size of 0.1 to 12 mm and a polyurethane content of 4 to 20% by weight, followed by solvolysis, allows for precise dosing, efficient feeding, and rapid conversion, overcoming the limitations of prior art by increasing the external surface area of the polyurethane powder and facilitating mixing and heat transfer.

Degradable polyurethanes and composites thereof

PatentInactiveUS20180162987A1

Innovation

- Development of degradable isocyanate-based polyurethane polymers and composites that can be broken down into reusable components using acid-sensitive cross-linking points, allowing for separation and recycling of reinforcing materials and polymer matrices under mild conditions.

Environmental Impact

Polyurethane recycling methods have significant environmental implications, both in terms of potential benefits and challenges. The increasing global production and consumption of polyurethane products have led to a growing concern about their environmental impact, particularly due to their non-biodegradable nature and the accumulation of waste in landfills and oceans.

Effective recycling methods for polyurethane can substantially reduce the environmental footprint of these materials. By diverting polyurethane waste from landfills and incinerators, recycling helps conserve natural resources and reduce greenhouse gas emissions associated with the production of virgin materials. Additionally, recycling can mitigate the release of harmful chemicals and microplastics into ecosystems, which pose threats to wildlife and human health.

However, the current state of polyurethane recycling presents several environmental challenges. Many existing recycling processes require high energy inputs, potentially offsetting some of the environmental benefits. Chemical recycling methods, while effective in breaking down polyurethane into its constituent components, often involve the use of solvents and catalysts that may have their own environmental impacts if not properly managed.

The development of more advanced polyurethane recycling methods holds promise for improving environmental outcomes. Emerging technologies, such as enzymatic degradation and supercritical fluid processes, offer the potential for more energy-efficient and environmentally friendly recycling solutions. These methods could reduce the reliance on harmful chemicals and minimize waste generation during the recycling process.

Furthermore, the advancement of polyurethane recycling methods could contribute to the circular economy model, where materials are continuously reused and recycled. This approach would not only reduce the demand for fossil fuel-based raw materials but also decrease the overall carbon footprint of polyurethane production and disposal.

It is crucial to consider the life cycle assessment of different recycling methods to fully understand their environmental impact. This includes evaluating factors such as energy consumption, water usage, emissions, and the potential for creating valuable secondary products. By optimizing these factors, advanced recycling methods can maximize environmental benefits while minimizing negative impacts.

In conclusion, the environmental impact of advancing polyurethane recycling methods is multifaceted. While challenges exist, the potential for significant positive outcomes in terms of resource conservation, waste reduction, and pollution prevention underscores the importance of continued research and development in this field. As technologies improve and become more widely adopted, the environmental benefits of polyurethane recycling are likely to increase, contributing to a more sustainable and circular approach to materials management.

Effective recycling methods for polyurethane can substantially reduce the environmental footprint of these materials. By diverting polyurethane waste from landfills and incinerators, recycling helps conserve natural resources and reduce greenhouse gas emissions associated with the production of virgin materials. Additionally, recycling can mitigate the release of harmful chemicals and microplastics into ecosystems, which pose threats to wildlife and human health.

However, the current state of polyurethane recycling presents several environmental challenges. Many existing recycling processes require high energy inputs, potentially offsetting some of the environmental benefits. Chemical recycling methods, while effective in breaking down polyurethane into its constituent components, often involve the use of solvents and catalysts that may have their own environmental impacts if not properly managed.

The development of more advanced polyurethane recycling methods holds promise for improving environmental outcomes. Emerging technologies, such as enzymatic degradation and supercritical fluid processes, offer the potential for more energy-efficient and environmentally friendly recycling solutions. These methods could reduce the reliance on harmful chemicals and minimize waste generation during the recycling process.

Furthermore, the advancement of polyurethane recycling methods could contribute to the circular economy model, where materials are continuously reused and recycled. This approach would not only reduce the demand for fossil fuel-based raw materials but also decrease the overall carbon footprint of polyurethane production and disposal.

It is crucial to consider the life cycle assessment of different recycling methods to fully understand their environmental impact. This includes evaluating factors such as energy consumption, water usage, emissions, and the potential for creating valuable secondary products. By optimizing these factors, advanced recycling methods can maximize environmental benefits while minimizing negative impacts.

In conclusion, the environmental impact of advancing polyurethane recycling methods is multifaceted. While challenges exist, the potential for significant positive outcomes in terms of resource conservation, waste reduction, and pollution prevention underscores the importance of continued research and development in this field. As technologies improve and become more widely adopted, the environmental benefits of polyurethane recycling are likely to increase, contributing to a more sustainable and circular approach to materials management.

Circular Economy

The concept of a circular economy is central to advancing polyurethane recycling methods. This approach aims to minimize waste and maximize resource efficiency by keeping materials in use for as long as possible. In the context of polyurethane recycling, circular economy principles drive the development of innovative recycling technologies and processes that can effectively recover and reuse polyurethane materials.

One key aspect of circular economy in polyurethane recycling is the design for recyclability. This involves creating polyurethane products with end-of-life considerations in mind, making them easier to disassemble and recycle. By incorporating recyclable materials and designing products for easy separation of components, manufacturers can significantly improve the recyclability of polyurethane products.

Another important element is the development of closed-loop recycling systems. These systems aim to recover polyurethane materials from end-of-life products and reintroduce them into the production cycle as raw materials. This approach not only reduces waste but also decreases the demand for virgin materials, leading to a more sustainable production process.

The circular economy model also emphasizes the importance of collaboration across the value chain. This includes partnerships between manufacturers, recyclers, and waste management companies to create efficient collection and recycling networks. Such collaborations can lead to the development of standardized recycling processes and the establishment of a robust infrastructure for polyurethane recycling.

Furthermore, the circular economy approach encourages the exploration of alternative business models, such as product-as-a-service or leasing models. These models can incentivize manufacturers to design more durable and recyclable products, as they retain ownership and responsibility for the product throughout its lifecycle.

Advancing polyurethane recycling methods within a circular economy framework also involves addressing challenges such as contamination and material degradation. This requires ongoing research and development of advanced sorting and purification technologies to ensure the quality of recycled polyurethane materials meets industry standards.

In conclusion, the circular economy concept provides a comprehensive framework for advancing polyurethane recycling methods. By focusing on design for recyclability, closed-loop systems, collaboration, and innovative business models, the polyurethane industry can move towards a more sustainable and resource-efficient future.

One key aspect of circular economy in polyurethane recycling is the design for recyclability. This involves creating polyurethane products with end-of-life considerations in mind, making them easier to disassemble and recycle. By incorporating recyclable materials and designing products for easy separation of components, manufacturers can significantly improve the recyclability of polyurethane products.

Another important element is the development of closed-loop recycling systems. These systems aim to recover polyurethane materials from end-of-life products and reintroduce them into the production cycle as raw materials. This approach not only reduces waste but also decreases the demand for virgin materials, leading to a more sustainable production process.

The circular economy model also emphasizes the importance of collaboration across the value chain. This includes partnerships between manufacturers, recyclers, and waste management companies to create efficient collection and recycling networks. Such collaborations can lead to the development of standardized recycling processes and the establishment of a robust infrastructure for polyurethane recycling.

Furthermore, the circular economy approach encourages the exploration of alternative business models, such as product-as-a-service or leasing models. These models can incentivize manufacturers to design more durable and recyclable products, as they retain ownership and responsibility for the product throughout its lifecycle.

Advancing polyurethane recycling methods within a circular economy framework also involves addressing challenges such as contamination and material degradation. This requires ongoing research and development of advanced sorting and purification technologies to ensure the quality of recycled polyurethane materials meets industry standards.

In conclusion, the circular economy concept provides a comprehensive framework for advancing polyurethane recycling methods. By focusing on design for recyclability, closed-loop systems, collaboration, and innovative business models, the polyurethane industry can move towards a more sustainable and resource-efficient future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!