How to Analyze the Environmental Impact of Polyurethane?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyurethane Environmental Impact Analysis: Background and Objectives

Polyurethane, a versatile synthetic polymer, has become ubiquitous in modern society due to its wide range of applications. From insulation and furniture to automotive parts and medical devices, polyurethane's presence in our daily lives is undeniable. However, as environmental concerns gain prominence, it is crucial to analyze the environmental impact of this widely used material.

The evolution of polyurethane technology can be traced back to the 1930s when Otto Bayer and his colleagues at I.G. Farben in Germany first developed polyurethane polymers. Since then, the material has undergone significant advancements, leading to improved properties and expanded applications. The current technological landscape surrounding polyurethane is characterized by ongoing research into more sustainable production methods and enhanced end-of-life management.

As we delve into the environmental impact analysis of polyurethane, it is essential to consider the entire lifecycle of the material, from raw material extraction to disposal or recycling. This comprehensive approach allows for a holistic understanding of polyurethane's environmental footprint and identifies areas for potential improvement.

The primary objective of this analysis is to assess the environmental implications of polyurethane production, use, and disposal. This includes evaluating energy consumption, greenhouse gas emissions, resource depletion, and waste generation associated with polyurethane throughout its lifecycle. Additionally, we aim to identify potential alternatives or modifications that could mitigate the environmental impact of polyurethane without compromising its beneficial properties.

Another crucial aspect of this analysis is to examine the current regulatory landscape surrounding polyurethane production and use. Environmental regulations and policies play a significant role in shaping industry practices and driving innovation towards more sustainable solutions. Understanding these regulatory frameworks is essential for predicting future trends and potential challenges in the polyurethane industry.

Furthermore, this analysis seeks to explore emerging technologies and methodologies that could revolutionize the environmental profile of polyurethane. This includes advancements in bio-based polyurethanes, improved recycling techniques, and novel production processes that reduce energy consumption and emissions.

By conducting a thorough environmental impact analysis of polyurethane, we aim to provide valuable insights for industry stakeholders, policymakers, and researchers. These findings can inform decision-making processes, guide future research and development efforts, and ultimately contribute to the development of more sustainable polyurethane products and practices.

The evolution of polyurethane technology can be traced back to the 1930s when Otto Bayer and his colleagues at I.G. Farben in Germany first developed polyurethane polymers. Since then, the material has undergone significant advancements, leading to improved properties and expanded applications. The current technological landscape surrounding polyurethane is characterized by ongoing research into more sustainable production methods and enhanced end-of-life management.

As we delve into the environmental impact analysis of polyurethane, it is essential to consider the entire lifecycle of the material, from raw material extraction to disposal or recycling. This comprehensive approach allows for a holistic understanding of polyurethane's environmental footprint and identifies areas for potential improvement.

The primary objective of this analysis is to assess the environmental implications of polyurethane production, use, and disposal. This includes evaluating energy consumption, greenhouse gas emissions, resource depletion, and waste generation associated with polyurethane throughout its lifecycle. Additionally, we aim to identify potential alternatives or modifications that could mitigate the environmental impact of polyurethane without compromising its beneficial properties.

Another crucial aspect of this analysis is to examine the current regulatory landscape surrounding polyurethane production and use. Environmental regulations and policies play a significant role in shaping industry practices and driving innovation towards more sustainable solutions. Understanding these regulatory frameworks is essential for predicting future trends and potential challenges in the polyurethane industry.

Furthermore, this analysis seeks to explore emerging technologies and methodologies that could revolutionize the environmental profile of polyurethane. This includes advancements in bio-based polyurethanes, improved recycling techniques, and novel production processes that reduce energy consumption and emissions.

By conducting a thorough environmental impact analysis of polyurethane, we aim to provide valuable insights for industry stakeholders, policymakers, and researchers. These findings can inform decision-making processes, guide future research and development efforts, and ultimately contribute to the development of more sustainable polyurethane products and practices.

Market Demand for Sustainable Polyurethane Products

The market demand for sustainable polyurethane products has been steadily increasing in recent years, driven by growing environmental awareness and stricter regulations. Consumers and industries alike are seeking alternatives to traditional polyurethane materials that offer reduced environmental impact without compromising performance.

In the automotive sector, there is a significant push for lightweight, eco-friendly materials to improve fuel efficiency and reduce emissions. Sustainable polyurethane foams and coatings are gaining traction for use in vehicle interiors, seating, and insulation. Major automakers are setting ambitious targets for incorporating recycled and bio-based materials, creating a substantial market for sustainable polyurethane alternatives.

The construction industry represents another key market for sustainable polyurethane products. Energy-efficient building materials are in high demand, with sustainable polyurethane insulation playing a crucial role in reducing energy consumption and carbon footprints. Green building certifications like LEED are driving adoption of environmentally friendly materials, including those made from recycled or bio-based polyurethanes.

In the furniture and bedding sector, consumer preferences are shifting towards products with lower environmental impact. Manufacturers are responding by developing mattresses, cushions, and upholstery using sustainable polyurethane foams. These products often command premium prices, indicating consumers' willingness to pay for eco-friendly options.

The packaging industry is also experiencing increased demand for sustainable materials. Polyurethane-based biodegradable packaging solutions are gaining market share as companies seek to reduce plastic waste and meet sustainability goals. This trend is particularly strong in the food and beverage sector, where concerns about plastic pollution are driving innovation in packaging materials.

Textile and footwear manufacturers are exploring sustainable polyurethane alternatives for synthetic leathers and performance fabrics. The fashion industry's growing focus on sustainability is creating opportunities for bio-based and recycled polyurethane materials that offer similar properties to traditional synthetics with a lower environmental footprint.

Market research indicates that the global sustainable polyurethane market is expected to grow significantly in the coming years. Factors contributing to this growth include increasing environmental regulations, corporate sustainability initiatives, and changing consumer preferences. However, challenges remain in terms of cost competitiveness and performance parity with traditional polyurethanes.

To meet this growing demand, chemical companies and material scientists are investing heavily in research and development of sustainable polyurethane technologies. This includes exploring bio-based feedstocks, improving recycling processes, and developing novel polyurethane formulations with reduced environmental impact. The market is likely to see continued innovation and expansion as sustainability becomes an increasingly critical factor in material selection across industries.

In the automotive sector, there is a significant push for lightweight, eco-friendly materials to improve fuel efficiency and reduce emissions. Sustainable polyurethane foams and coatings are gaining traction for use in vehicle interiors, seating, and insulation. Major automakers are setting ambitious targets for incorporating recycled and bio-based materials, creating a substantial market for sustainable polyurethane alternatives.

The construction industry represents another key market for sustainable polyurethane products. Energy-efficient building materials are in high demand, with sustainable polyurethane insulation playing a crucial role in reducing energy consumption and carbon footprints. Green building certifications like LEED are driving adoption of environmentally friendly materials, including those made from recycled or bio-based polyurethanes.

In the furniture and bedding sector, consumer preferences are shifting towards products with lower environmental impact. Manufacturers are responding by developing mattresses, cushions, and upholstery using sustainable polyurethane foams. These products often command premium prices, indicating consumers' willingness to pay for eco-friendly options.

The packaging industry is also experiencing increased demand for sustainable materials. Polyurethane-based biodegradable packaging solutions are gaining market share as companies seek to reduce plastic waste and meet sustainability goals. This trend is particularly strong in the food and beverage sector, where concerns about plastic pollution are driving innovation in packaging materials.

Textile and footwear manufacturers are exploring sustainable polyurethane alternatives for synthetic leathers and performance fabrics. The fashion industry's growing focus on sustainability is creating opportunities for bio-based and recycled polyurethane materials that offer similar properties to traditional synthetics with a lower environmental footprint.

Market research indicates that the global sustainable polyurethane market is expected to grow significantly in the coming years. Factors contributing to this growth include increasing environmental regulations, corporate sustainability initiatives, and changing consumer preferences. However, challenges remain in terms of cost competitiveness and performance parity with traditional polyurethanes.

To meet this growing demand, chemical companies and material scientists are investing heavily in research and development of sustainable polyurethane technologies. This includes exploring bio-based feedstocks, improving recycling processes, and developing novel polyurethane formulations with reduced environmental impact. The market is likely to see continued innovation and expansion as sustainability becomes an increasingly critical factor in material selection across industries.

Current Environmental Challenges in Polyurethane Production

The production of polyurethane poses significant environmental challenges that require urgent attention. One of the primary concerns is the use of isocyanates, which are highly reactive chemicals essential in polyurethane manufacturing. These compounds can have severe health impacts on workers and nearby communities if not properly managed, potentially causing respiratory issues and skin irritation.

Another major challenge is the emission of volatile organic compounds (VOCs) during the production process. These emissions contribute to air pollution and can lead to the formation of ground-level ozone, a key component of smog. The release of VOCs not only affects local air quality but also has broader implications for climate change and ecosystem health.

The energy-intensive nature of polyurethane production is a significant contributor to greenhouse gas emissions. The high temperatures and pressures required in the manufacturing process result in substantial carbon dioxide emissions, exacerbating global warming concerns. Additionally, the production of raw materials used in polyurethane, such as polyols derived from fossil fuels, further increases the carbon footprint of the industry.

Water pollution is another critical environmental issue associated with polyurethane production. The discharge of untreated or inadequately treated wastewater containing chemical residues and byproducts can contaminate local water sources, harming aquatic ecosystems and potentially affecting human health through the water supply chain.

The disposal and end-of-life management of polyurethane products present ongoing challenges. Many polyurethane products are not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to the accumulation of these materials in landfills or natural habitats, contributing to long-term environmental degradation.

Furthermore, the recycling of polyurethane products is complex and often economically challenging. The cross-linked structure of many polyurethane materials makes them difficult to break down and reprocess, leading to a high proportion of these products ending up in waste streams rather than being recycled.

Lastly, the depletion of non-renewable resources used in polyurethane production, particularly petroleum-based raw materials, raises concerns about long-term sustainability. The reliance on finite resources not only contributes to environmental degradation through extraction processes but also poses challenges for the future availability and cost of raw materials for the industry.

Another major challenge is the emission of volatile organic compounds (VOCs) during the production process. These emissions contribute to air pollution and can lead to the formation of ground-level ozone, a key component of smog. The release of VOCs not only affects local air quality but also has broader implications for climate change and ecosystem health.

The energy-intensive nature of polyurethane production is a significant contributor to greenhouse gas emissions. The high temperatures and pressures required in the manufacturing process result in substantial carbon dioxide emissions, exacerbating global warming concerns. Additionally, the production of raw materials used in polyurethane, such as polyols derived from fossil fuels, further increases the carbon footprint of the industry.

Water pollution is another critical environmental issue associated with polyurethane production. The discharge of untreated or inadequately treated wastewater containing chemical residues and byproducts can contaminate local water sources, harming aquatic ecosystems and potentially affecting human health through the water supply chain.

The disposal and end-of-life management of polyurethane products present ongoing challenges. Many polyurethane products are not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to the accumulation of these materials in landfills or natural habitats, contributing to long-term environmental degradation.

Furthermore, the recycling of polyurethane products is complex and often economically challenging. The cross-linked structure of many polyurethane materials makes them difficult to break down and reprocess, leading to a high proportion of these products ending up in waste streams rather than being recycled.

Lastly, the depletion of non-renewable resources used in polyurethane production, particularly petroleum-based raw materials, raises concerns about long-term sustainability. The reliance on finite resources not only contributes to environmental degradation through extraction processes but also poses challenges for the future availability and cost of raw materials for the industry.

Existing Methodologies for Polyurethane Environmental Impact Analysis

01 Biodegradable polyurethane formulations

Development of biodegradable polyurethane formulations to reduce environmental impact. These formulations incorporate natural or bio-based materials that can break down more easily in the environment, reducing long-term pollution and waste accumulation.- Biodegradable polyurethane formulations: Development of biodegradable polyurethane formulations to reduce environmental impact. These formulations incorporate natural or bio-based materials that can break down more easily in the environment, reducing long-term pollution and waste accumulation.

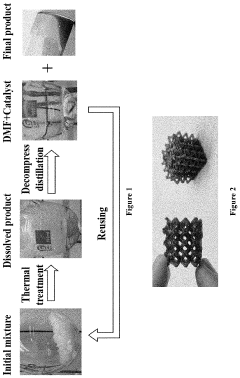

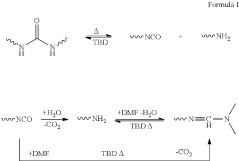

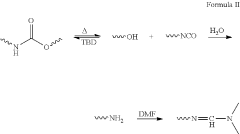

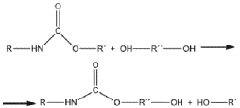

- Recycling and reuse of polyurethane materials: Implementation of recycling and reuse processes for polyurethane materials to minimize waste and conserve resources. This includes developing methods for breaking down used polyurethane products and reprocessing them into new materials or applications.

- Energy-efficient production methods: Adoption of energy-efficient production methods for polyurethane manufacturing to reduce carbon footprint. This involves optimizing processes, using renewable energy sources, and implementing advanced technologies to minimize energy consumption during production.

- Low-VOC and eco-friendly polyurethane alternatives: Development of low-VOC (Volatile Organic Compound) and eco-friendly alternatives to traditional polyurethane formulations. These alternatives aim to reduce harmful emissions and improve indoor air quality, particularly in applications such as coatings and adhesives.

- Life cycle assessment and environmental impact monitoring: Implementation of life cycle assessment tools and environmental impact monitoring systems for polyurethane products. These tools help manufacturers and consumers understand the full environmental impact of polyurethane materials from production to disposal, enabling more informed decisions and improvements in sustainability.

02 Recycling and upcycling of polyurethane waste

Implementation of recycling and upcycling processes for polyurethane waste to minimize environmental impact. This includes developing methods to break down and reuse polyurethane materials, reducing the amount of waste sent to landfills and conserving resources.Expand Specific Solutions03 Energy-efficient production methods

Adoption of energy-efficient production methods for polyurethane manufacturing to reduce carbon footprint. This involves optimizing processes, using renewable energy sources, and implementing technologies that minimize energy consumption during production.Expand Specific Solutions04 Water-based polyurethane systems

Development of water-based polyurethane systems to reduce the use of volatile organic compounds (VOCs) and harmful solvents. These systems have lower environmental impact during application and curing, improving air quality and reducing health risks.Expand Specific Solutions05 Life cycle assessment and environmental impact monitoring

Implementation of life cycle assessment tools and environmental impact monitoring systems for polyurethane products. These tools help manufacturers and consumers understand the full environmental impact of polyurethane materials from production to disposal, enabling more informed decisions and improvements in sustainability.Expand Specific Solutions

Key Players in Polyurethane Industry and Environmental Research

The environmental impact analysis of polyurethane is a complex field in a mature industry, with a growing market driven by sustainability concerns. The global polyurethane market is expected to reach $79 billion by 2025, indicating significant economic importance. Companies like Covestro Deutschland AG, SK Chemicals Co. Ltd., and Braskem SA are leading innovation in eco-friendly polyurethane technologies. Research institutions such as Nankai University and Zhejiang University are contributing to advancements in biodegradable polyurethanes. The technology's maturity varies, with some areas like bio-based polyols showing rapid progress, while others, such as end-of-life recycling, still present challenges. Overall, the industry is transitioning towards more sustainable practices, with a focus on reducing environmental impact throughout the product lifecycle.

Covestro Deutschland AG

Technical Solution: Covestro has developed a comprehensive Life Cycle Assessment (LCA) approach for analyzing the environmental impact of polyurethane. Their method involves assessing the entire lifecycle of polyurethane products, from raw material extraction to end-of-life disposal. They use advanced software tools to model the environmental impacts across various categories, including carbon footprint, water consumption, and resource depletion. Covestro also focuses on developing bio-based and CO2-based polyurethanes to reduce the overall environmental impact.

Strengths: Comprehensive lifecycle approach, advanced modeling tools, focus on sustainable alternatives. Weaknesses: Complexity in data collection across the supply chain, potential for regional variations in environmental impact.

Econic Technologies Ltd.

Technical Solution: Econic Technologies has pioneered a catalyst technology that enables the use of CO2 as a raw material in polyurethane production. Their approach focuses on reducing the carbon footprint of polyurethane by incorporating waste CO2 into the polymer structure. This technology allows for up to 50% of the conventional oil-based raw materials to be replaced with CO2. Econic's analysis of environmental impact centers on the reduction of greenhouse gas emissions and the utilization of waste CO2, providing a circular economy solution for polyurethane production.

Strengths: Innovative CO2 utilization, significant reduction in oil-based raw materials, circular economy approach. Weaknesses: Limited to specific types of polyurethane applications, may require modifications to existing production processes.

Innovative Approaches in Polyurethane Lifecycle Assessment

Method for recycling and reusing polyurethane foam

PatentActiveUS20230002585A1

Innovation

- A method involving the use of solvents and catalysts to convert polyurethane foam into functionalized oligomers, which are then chemically modified to introduce photosensitive groups, forming high-value added photocurable resins suitable for coatings and 3D printing, with adjustable properties and efficient recycling processes.

Method for the recycling of polyurethane material waste for producing chemical feedstock for the production of isocyanates and polyurethanes

PatentWO2020239716A1

Innovation

- A process involving pyrolysis of polyurethane waste to produce carbon dioxide, carbon monoxide, and hydrogen, followed by electrolysis to convert carbon dioxide into carbon monoxide, which is then used to produce isocyanates, and further processed into polyurethane materials, utilizing renewable energy and closed-loop recycling to reduce fossil fuel dependency.

Regulatory Framework for Polyurethane Environmental Standards

The regulatory framework for polyurethane environmental standards is a complex and evolving landscape that plays a crucial role in analyzing and mitigating the environmental impact of polyurethane. This framework encompasses a wide range of regulations, guidelines, and standards set by various national and international bodies to ensure the responsible production, use, and disposal of polyurethane products.

At the global level, the United Nations Environment Programme (UNEP) has established guidelines for the sustainable management of chemicals, which include provisions relevant to polyurethane production and use. These guidelines aim to reduce the environmental and health risks associated with chemical substances throughout their lifecycle.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of the regulatory framework for polyurethane. REACH requires manufacturers and importers to register chemical substances, including those used in polyurethane production, and provide information on their properties, hazards, and safe use.

The United States Environmental Protection Agency (EPA) has implemented several regulations under the Toxic Substances Control Act (TSCA) that impact polyurethane production and use. These include reporting requirements for new chemical substances and significant new uses of existing chemicals, as well as restrictions on certain chemicals used in polyurethane manufacturing.

Many countries have also established specific standards for volatile organic compound (VOC) emissions from polyurethane products, particularly in indoor environments. These standards aim to reduce air pollution and protect human health by limiting the release of harmful chemicals during the use phase of polyurethane products.

The end-of-life management of polyurethane products is another critical aspect addressed by regulatory frameworks. The EU's Waste Framework Directive and similar regulations in other regions set guidelines for the recycling, recovery, and disposal of polyurethane waste, promoting circular economy principles and minimizing environmental impact.

Industry-specific standards, such as those developed by the International Organization for Standardization (ISO), provide guidelines for testing methods, quality control, and environmental performance of polyurethane products. These standards help ensure consistency in assessing the environmental impact of polyurethane across different applications and industries.

As environmental concerns continue to grow, regulatory frameworks are evolving to address emerging issues related to polyurethane. This includes increased focus on microplastics, biodegradability, and the use of bio-based raw materials in polyurethane production. Future regulations are likely to emphasize life cycle assessments and promote the development of more sustainable polyurethane formulations and manufacturing processes.

At the global level, the United Nations Environment Programme (UNEP) has established guidelines for the sustainable management of chemicals, which include provisions relevant to polyurethane production and use. These guidelines aim to reduce the environmental and health risks associated with chemical substances throughout their lifecycle.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is a cornerstone of the regulatory framework for polyurethane. REACH requires manufacturers and importers to register chemical substances, including those used in polyurethane production, and provide information on their properties, hazards, and safe use.

The United States Environmental Protection Agency (EPA) has implemented several regulations under the Toxic Substances Control Act (TSCA) that impact polyurethane production and use. These include reporting requirements for new chemical substances and significant new uses of existing chemicals, as well as restrictions on certain chemicals used in polyurethane manufacturing.

Many countries have also established specific standards for volatile organic compound (VOC) emissions from polyurethane products, particularly in indoor environments. These standards aim to reduce air pollution and protect human health by limiting the release of harmful chemicals during the use phase of polyurethane products.

The end-of-life management of polyurethane products is another critical aspect addressed by regulatory frameworks. The EU's Waste Framework Directive and similar regulations in other regions set guidelines for the recycling, recovery, and disposal of polyurethane waste, promoting circular economy principles and minimizing environmental impact.

Industry-specific standards, such as those developed by the International Organization for Standardization (ISO), provide guidelines for testing methods, quality control, and environmental performance of polyurethane products. These standards help ensure consistency in assessing the environmental impact of polyurethane across different applications and industries.

As environmental concerns continue to grow, regulatory frameworks are evolving to address emerging issues related to polyurethane. This includes increased focus on microplastics, biodegradability, and the use of bio-based raw materials in polyurethane production. Future regulations are likely to emphasize life cycle assessments and promote the development of more sustainable polyurethane formulations and manufacturing processes.

Circular Economy Strategies for Polyurethane Waste Management

Circular economy strategies for polyurethane waste management are becoming increasingly crucial as the environmental impact of this versatile material gains attention. These strategies aim to minimize waste, maximize resource efficiency, and reduce the overall environmental footprint of polyurethane throughout its lifecycle.

One key approach is the development of advanced recycling technologies. Mechanical recycling methods can be employed to grind and reprocess polyurethane foam into new products, such as carpet underlay or sports surfaces. Chemical recycling techniques, including glycolysis and hydrolysis, break down polyurethane into its chemical components, which can then be used to produce new polyurethane or other materials.

Another important strategy is the design for recyclability. Manufacturers are increasingly focusing on creating polyurethane products that are easier to disassemble and recycle at the end of their life. This includes using single-polymer designs, avoiding contamination with other materials, and incorporating additives that facilitate recycling processes.

The implementation of take-back programs and reverse logistics systems is also gaining traction. These initiatives encourage consumers and businesses to return used polyurethane products to manufacturers or specialized recycling facilities, ensuring proper handling and recycling of the material.

Biodegradable polyurethane formulations represent an innovative approach to waste management. By incorporating bio-based components or designing polyurethanes that can break down under specific environmental conditions, researchers are working to reduce the long-term environmental impact of polyurethane waste.

Upcycling strategies are emerging as creative solutions for polyurethane waste. This involves transforming waste materials into higher-value products, such as using recycled polyurethane in the production of high-performance insulation materials or as fillers in composite materials.

Collaboration across the value chain is essential for implementing effective circular economy strategies. This includes partnerships between raw material suppliers, manufacturers, recyclers, and end-users to create closed-loop systems and ensure the efficient recovery and reuse of polyurethane materials.

Lastly, policy and regulatory frameworks play a crucial role in driving circular economy practices. Extended producer responsibility schemes, landfill bans for recyclable materials, and incentives for using recycled content are examples of measures that can promote more sustainable polyurethane waste management practices.

One key approach is the development of advanced recycling technologies. Mechanical recycling methods can be employed to grind and reprocess polyurethane foam into new products, such as carpet underlay or sports surfaces. Chemical recycling techniques, including glycolysis and hydrolysis, break down polyurethane into its chemical components, which can then be used to produce new polyurethane or other materials.

Another important strategy is the design for recyclability. Manufacturers are increasingly focusing on creating polyurethane products that are easier to disassemble and recycle at the end of their life. This includes using single-polymer designs, avoiding contamination with other materials, and incorporating additives that facilitate recycling processes.

The implementation of take-back programs and reverse logistics systems is also gaining traction. These initiatives encourage consumers and businesses to return used polyurethane products to manufacturers or specialized recycling facilities, ensuring proper handling and recycling of the material.

Biodegradable polyurethane formulations represent an innovative approach to waste management. By incorporating bio-based components or designing polyurethanes that can break down under specific environmental conditions, researchers are working to reduce the long-term environmental impact of polyurethane waste.

Upcycling strategies are emerging as creative solutions for polyurethane waste. This involves transforming waste materials into higher-value products, such as using recycled polyurethane in the production of high-performance insulation materials or as fillers in composite materials.

Collaboration across the value chain is essential for implementing effective circular economy strategies. This includes partnerships between raw material suppliers, manufacturers, recyclers, and end-users to create closed-loop systems and ensure the efficient recovery and reuse of polyurethane materials.

Lastly, policy and regulatory frameworks play a crucial role in driving circular economy practices. Extended producer responsibility schemes, landfill bans for recyclable materials, and incentives for using recycled content are examples of measures that can promote more sustainable polyurethane waste management practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!