How to Design Compact Polyurethane for Space Constraints?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyurethane Miniaturization Background and Objectives

Polyurethane, a versatile synthetic polymer, has been a cornerstone in various industries since its discovery in the 1930s. Its unique properties, including flexibility, durability, and customizable characteristics, have made it indispensable in applications ranging from automotive to aerospace. However, as technology advances and space becomes an increasingly precious commodity, the need for compact polyurethane solutions has emerged as a critical challenge.

The evolution of polyurethane technology has been driven by the constant demand for improved performance in confined spaces. From early applications in cushioning and insulation, polyurethane has undergone significant transformations to meet the stringent requirements of modern engineering. The miniaturization trend across industries has pushed researchers and engineers to explore innovative ways to reduce the footprint of polyurethane components without compromising their functional properties.

The primary objective of compact polyurethane design is to achieve optimal performance within spatial constraints. This goal encompasses several key aspects, including the reduction of material volume, enhancement of material efficiency, and improvement of overall system integration. By addressing these challenges, researchers aim to unlock new possibilities for polyurethane applications in space-limited environments, such as aerospace, wearable technology, and miniaturized medical devices.

Recent advancements in polymer chemistry and manufacturing techniques have opened up new avenues for polyurethane miniaturization. The development of novel formulations with enhanced mechanical properties allows for thinner and lighter polyurethane components. Additionally, the integration of nanotechnology has enabled the creation of nanocomposite polyurethanes with superior strength-to-weight ratios, further contributing to space-saving designs.

The pursuit of compact polyurethane solutions aligns with broader industry trends towards sustainability and resource efficiency. By optimizing material usage and reducing waste, miniaturization efforts not only address space constraints but also contribute to environmental conservation. This dual benefit has intensified research efforts and attracted significant investment from both public and private sectors.

As we delve deeper into the challenges and opportunities of polyurethane miniaturization, it is crucial to consider the interdisciplinary nature of this endeavor. Success in this field requires collaboration between material scientists, chemical engineers, and application specialists to develop holistic solutions that meet the diverse needs of end-users while adhering to strict spatial limitations.

The evolution of polyurethane technology has been driven by the constant demand for improved performance in confined spaces. From early applications in cushioning and insulation, polyurethane has undergone significant transformations to meet the stringent requirements of modern engineering. The miniaturization trend across industries has pushed researchers and engineers to explore innovative ways to reduce the footprint of polyurethane components without compromising their functional properties.

The primary objective of compact polyurethane design is to achieve optimal performance within spatial constraints. This goal encompasses several key aspects, including the reduction of material volume, enhancement of material efficiency, and improvement of overall system integration. By addressing these challenges, researchers aim to unlock new possibilities for polyurethane applications in space-limited environments, such as aerospace, wearable technology, and miniaturized medical devices.

Recent advancements in polymer chemistry and manufacturing techniques have opened up new avenues for polyurethane miniaturization. The development of novel formulations with enhanced mechanical properties allows for thinner and lighter polyurethane components. Additionally, the integration of nanotechnology has enabled the creation of nanocomposite polyurethanes with superior strength-to-weight ratios, further contributing to space-saving designs.

The pursuit of compact polyurethane solutions aligns with broader industry trends towards sustainability and resource efficiency. By optimizing material usage and reducing waste, miniaturization efforts not only address space constraints but also contribute to environmental conservation. This dual benefit has intensified research efforts and attracted significant investment from both public and private sectors.

As we delve deeper into the challenges and opportunities of polyurethane miniaturization, it is crucial to consider the interdisciplinary nature of this endeavor. Success in this field requires collaboration between material scientists, chemical engineers, and application specialists to develop holistic solutions that meet the diverse needs of end-users while adhering to strict spatial limitations.

Market Demand for Compact Polyurethane Solutions

The market demand for compact polyurethane solutions has been steadily increasing across various industries, driven by the need for space-efficient and lightweight materials. This trend is particularly evident in aerospace, automotive, and consumer electronics sectors, where space constraints are a critical factor in product design and development.

In the aerospace industry, the demand for compact polyurethane solutions has been growing significantly. Aircraft manufacturers are constantly seeking ways to reduce weight and maximize space utilization without compromising safety or performance. Compact polyurethane materials offer an excellent solution for insulation, cushioning, and structural components, contributing to fuel efficiency and overall aircraft design optimization.

The automotive sector has also shown a strong interest in compact polyurethane solutions. As vehicles become more complex with the integration of advanced technologies, manufacturers are challenged to fit more components into limited spaces. Compact polyurethane materials are being increasingly used in interior components, seating systems, and noise reduction applications, allowing for sleeker designs and improved passenger comfort without sacrificing functionality.

Consumer electronics is another key market driving the demand for compact polyurethane solutions. With the trend towards smaller, thinner, and more feature-packed devices, manufacturers are seeking materials that can provide protection, insulation, and structural support within tight space constraints. Compact polyurethane foams and elastomers are being utilized in smartphones, laptops, and wearable devices to enhance durability and performance while maintaining slim profiles.

The construction industry has also recognized the benefits of compact polyurethane solutions, particularly in urban environments where space is at a premium. These materials are being used in prefabricated building components, insulation systems, and modular construction, allowing for more efficient use of limited space while maintaining thermal efficiency and structural integrity.

Market analysts project that the global demand for compact polyurethane solutions will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is attributed to ongoing technological advancements, increasing urbanization, and the push for more sustainable and energy-efficient products across industries.

As environmental concerns gain prominence, there is also a growing demand for eco-friendly compact polyurethane solutions. Manufacturers are investing in research and development to create bio-based and recyclable polyurethane materials that maintain the desired compact properties while reducing environmental impact. This shift towards sustainability is expected to open up new market opportunities and drive further innovation in the compact polyurethane sector.

In the aerospace industry, the demand for compact polyurethane solutions has been growing significantly. Aircraft manufacturers are constantly seeking ways to reduce weight and maximize space utilization without compromising safety or performance. Compact polyurethane materials offer an excellent solution for insulation, cushioning, and structural components, contributing to fuel efficiency and overall aircraft design optimization.

The automotive sector has also shown a strong interest in compact polyurethane solutions. As vehicles become more complex with the integration of advanced technologies, manufacturers are challenged to fit more components into limited spaces. Compact polyurethane materials are being increasingly used in interior components, seating systems, and noise reduction applications, allowing for sleeker designs and improved passenger comfort without sacrificing functionality.

Consumer electronics is another key market driving the demand for compact polyurethane solutions. With the trend towards smaller, thinner, and more feature-packed devices, manufacturers are seeking materials that can provide protection, insulation, and structural support within tight space constraints. Compact polyurethane foams and elastomers are being utilized in smartphones, laptops, and wearable devices to enhance durability and performance while maintaining slim profiles.

The construction industry has also recognized the benefits of compact polyurethane solutions, particularly in urban environments where space is at a premium. These materials are being used in prefabricated building components, insulation systems, and modular construction, allowing for more efficient use of limited space while maintaining thermal efficiency and structural integrity.

Market analysts project that the global demand for compact polyurethane solutions will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is attributed to ongoing technological advancements, increasing urbanization, and the push for more sustainable and energy-efficient products across industries.

As environmental concerns gain prominence, there is also a growing demand for eco-friendly compact polyurethane solutions. Manufacturers are investing in research and development to create bio-based and recyclable polyurethane materials that maintain the desired compact properties while reducing environmental impact. This shift towards sustainability is expected to open up new market opportunities and drive further innovation in the compact polyurethane sector.

Current Challenges in Polyurethane Miniaturization

The miniaturization of polyurethane materials presents several significant challenges in the context of space-constrained applications. One of the primary obstacles is maintaining the desired mechanical properties while reducing the overall volume of the material. As polyurethane components are scaled down, there is a risk of compromising their strength, flexibility, and durability, which are crucial for many applications.

Another challenge lies in the formulation process. Achieving consistent and uniform properties in smaller polyurethane components requires precise control over the mixing and curing processes. The reduced scale amplifies the impact of any variations in raw material ratios, mixing times, or curing conditions, potentially leading to inconsistencies in the final product.

The interface between polyurethane and other materials becomes increasingly critical as dimensions decrease. Ensuring proper adhesion and compatibility with substrates or adjacent components in compact designs can be particularly challenging, as the surface area-to-volume ratio increases significantly in miniaturized structures.

Heat management is another concern in compact polyurethane designs. Smaller components may have limited capacity for heat dissipation, which can affect the material's performance and longevity, especially in applications involving thermal cycling or exposure to extreme temperatures.

The manufacturing process itself poses challenges when producing miniaturized polyurethane components. Traditional molding and casting techniques may not be suitable for creating intricate, small-scale structures with high precision. This necessitates the development of new manufacturing methods or the adaptation of existing ones to accommodate the demands of miniaturization.

Furthermore, the characterization and quality control of miniaturized polyurethane components present unique difficulties. Standard testing methods may not be applicable or may require significant modification to accurately assess the properties and performance of these compact structures.

Lastly, the environmental impact and recyclability of miniaturized polyurethane components must be considered. As products become smaller and more complex, separating and recycling different materials at the end of their lifecycle becomes increasingly challenging, potentially conflicting with sustainability goals and regulations.

Addressing these challenges requires a multidisciplinary approach, combining expertise in polymer chemistry, materials science, manufacturing processes, and application-specific engineering. Innovations in formulation, processing techniques, and testing methodologies are essential to overcome these obstacles and unlock the full potential of compact polyurethane designs in space-constrained applications.

Another challenge lies in the formulation process. Achieving consistent and uniform properties in smaller polyurethane components requires precise control over the mixing and curing processes. The reduced scale amplifies the impact of any variations in raw material ratios, mixing times, or curing conditions, potentially leading to inconsistencies in the final product.

The interface between polyurethane and other materials becomes increasingly critical as dimensions decrease. Ensuring proper adhesion and compatibility with substrates or adjacent components in compact designs can be particularly challenging, as the surface area-to-volume ratio increases significantly in miniaturized structures.

Heat management is another concern in compact polyurethane designs. Smaller components may have limited capacity for heat dissipation, which can affect the material's performance and longevity, especially in applications involving thermal cycling or exposure to extreme temperatures.

The manufacturing process itself poses challenges when producing miniaturized polyurethane components. Traditional molding and casting techniques may not be suitable for creating intricate, small-scale structures with high precision. This necessitates the development of new manufacturing methods or the adaptation of existing ones to accommodate the demands of miniaturization.

Furthermore, the characterization and quality control of miniaturized polyurethane components present unique difficulties. Standard testing methods may not be applicable or may require significant modification to accurately assess the properties and performance of these compact structures.

Lastly, the environmental impact and recyclability of miniaturized polyurethane components must be considered. As products become smaller and more complex, separating and recycling different materials at the end of their lifecycle becomes increasingly challenging, potentially conflicting with sustainability goals and regulations.

Addressing these challenges requires a multidisciplinary approach, combining expertise in polymer chemistry, materials science, manufacturing processes, and application-specific engineering. Innovations in formulation, processing techniques, and testing methodologies are essential to overcome these obstacles and unlock the full potential of compact polyurethane designs in space-constrained applications.

Existing Compact Polyurethane Design Approaches

01 Polyurethane foam compactness improvement

Various methods are employed to enhance the compactness of polyurethane foams, including optimizing the formulation, controlling the reaction conditions, and incorporating specific additives. These techniques aim to produce denser, more uniform foam structures with improved mechanical properties and reduced void spaces.- Polyurethane foam compactness improvement: Various methods are employed to enhance the compactness of polyurethane foam, including optimizing the formulation, controlling the reaction conditions, and using specific additives. These techniques aim to increase the density and structural integrity of the foam, resulting in improved mechanical properties and performance.

- Compactness measurement and analysis techniques: Advanced imaging and analysis techniques are utilized to measure and evaluate the compactness of polyurethane materials. These methods include digital image processing, microscopy, and computational algorithms to assess the internal structure, pore distribution, and overall density of the polyurethane samples.

- Polyurethane compactness in coating applications: The compactness of polyurethane coatings is crucial for their performance in various industries. Researchers focus on developing compact polyurethane coatings with enhanced durability, chemical resistance, and adhesion properties. This involves optimizing the polymer structure and crosslinking density to achieve a tighter, more compact molecular arrangement.

- Nanocomposite reinforcement for polyurethane compactness: Incorporation of nanoparticles and nanostructures into polyurethane matrices is explored to enhance compactness. These nanocomposites can significantly improve the mechanical properties, thermal stability, and overall compactness of polyurethane materials, leading to enhanced performance in various applications.

- Compactness optimization in polyurethane adhesives: Research focuses on improving the compactness of polyurethane adhesives to enhance their bonding strength and durability. This involves tailoring the chemical composition, curing conditions, and application methods to achieve a more compact and uniform adhesive layer, resulting in superior adhesion performance across different substrates.

02 Compactness measurement and analysis techniques

Advanced imaging and analysis methods are utilized to assess and quantify the compactness of polyurethane materials. These techniques may include microscopy, tomography, and digital image processing, allowing for precise evaluation of material density, pore distribution, and overall structural integrity.Expand Specific Solutions03 Polyurethane compactness in coating applications

Strategies for improving the compactness of polyurethane coatings focus on enhancing film formation, reducing porosity, and increasing adhesion to substrates. This may involve modifying the polyurethane chemistry, optimizing application methods, or incorporating specific additives to achieve a more compact and durable coating layer.Expand Specific Solutions04 Nanocomposite reinforcement for polyurethane compactness

Incorporation of nanoparticles or nanofibers into polyurethane matrices is explored to enhance material compactness. These nanocomposites can significantly improve the mechanical properties, thermal stability, and overall density of the polyurethane, resulting in more compact and high-performance materials.Expand Specific Solutions05 Compactness optimization in polyurethane processing

Various processing techniques and parameters are investigated to optimize the compactness of polyurethane products during manufacturing. This includes adjusting mixing ratios, curing conditions, and molding processes to achieve the desired level of compactness in the final product while maintaining other essential properties.Expand Specific Solutions

Key Players in Compact Polyurethane Development

The compact polyurethane design for space constraints market is in a growth phase, driven by increasing demand in aerospace, automotive, and electronics industries. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is moderately mature but rapidly evolving. Companies like BASF Corp., Covestro Deutschland AG, and Wanhua Chemical Group Co., Ltd. are at the forefront, developing advanced formulations and manufacturing processes. Dow Global Technologies LLC and Evonik Operations GmbH are also making significant strides in miniaturization and performance enhancement. Academic institutions such as Chongqing University and the University of South Florida are contributing to fundamental research, pushing the boundaries of compact polyurethane applications in space-constrained environments.

BASF Corp.

Technical Solution: BASF has developed a compact polyurethane solution for space-constrained applications. Their approach involves using microcellular polyurethane systems with optimized cell structure and density. This allows for the creation of lightweight yet strong materials that can be molded into complex shapes. The company has also introduced nano-reinforced polyurethane formulations that enhance mechanical properties without significantly increasing volume. Additionally, BASF employs reactive injection molding techniques to produce thin-walled, high-performance polyurethane parts suitable for tight spaces.

Strengths: Advanced material science capabilities, wide range of customizable formulations, and global manufacturing presence. Weaknesses: Higher cost compared to traditional materials, potential environmental concerns with some formulations.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a series of compact polyurethane solutions for space-constrained applications. Their approach focuses on high-performance MDI (methylene diphenyl diisocyanate) and innovative polyol systems. They have created ultra-low density foam formulations that maintain structural integrity in minimal space. Wanhua also employs advanced catalyst systems to control reaction kinetics, allowing for precise control of cell structure and overall material properties. Their compact polyurethane systems feature improved flow characteristics, enabling the filling of complex molds and tight spaces without compromising performance.

Strengths: Strong R&D capabilities in isocyanates and polyols, vertically integrated production, and cost-effective solutions. Weaknesses: Relatively newer player in some global markets, potential regulatory challenges in certain regions.

Innovative Polyurethane Compaction Technologies

Compact polyurethane

PatentWO2020127814A1

Innovation

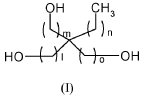

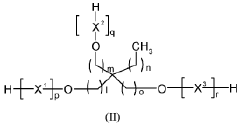

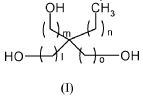

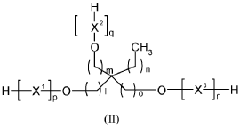

- A compact polyurethane with a density greater than 850 g/l is produced by reacting a polyisocyanate composition with a polyol composition containing a polyether polyol obtained from a polyol starter with a functionality of 3 to 6, using a boron-based fluorine-containing Lewis acid catalyst, resulting in a high proportion of primary hydroxyl groups and reduced secondary hydroxyl groups, which enhances reactivity and hydrophobicity.

Compressible layer of polyurethane and method for its production

PatentInactiveEP1215051A3

Innovation

- A compressible polyurethane layer with expanded and/or non-expanded thermoplastic hollow spheres is applied to rotationally symmetrical bodies, allowing for easy, cost-effective, and reproducible production, which can be adjusted for desired compressibility and surface roughness.

Space-Efficient Polyurethane Material Properties

Polyurethane materials possess unique properties that make them ideal for space-constrained applications. Their versatility in formulation allows for the creation of compact, high-performance materials that can meet specific space requirements without compromising functionality.

One of the key properties of space-efficient polyurethane is its high strength-to-weight ratio. This characteristic enables the development of lightweight yet durable materials that can withstand various stresses and strains in confined spaces. By carefully selecting the chemical components and adjusting the molecular structure, it is possible to achieve optimal mechanical properties while minimizing material volume.

Density control is another crucial aspect of designing compact polyurethane. Through precise manipulation of the foaming process, manufacturers can create materials with tailored densities, ranging from low-density flexible foams to high-density rigid structures. This flexibility allows for the optimization of space utilization while maintaining the desired performance characteristics.

The ability to customize the hardness and flexibility of polyurethane is particularly valuable in space-constrained applications. By adjusting the ratio of hard and soft segments in the polymer structure, it is possible to create materials that can conform to irregular shapes or provide specific cushioning properties within limited dimensions.

Thermal insulation is an additional property that can be engineered into space-efficient polyurethane materials. By incorporating closed-cell structures or specific additives, polyurethane can offer excellent thermal resistance in a compact form, making it suitable for applications where both space savings and temperature control are critical.

Chemical resistance is another important attribute of polyurethane that can be tailored for space-constrained environments. By selecting appropriate isocyanates and polyols, it is possible to develop materials that resist degradation from various chemicals, oils, and solvents, ensuring longevity and reliability in challenging conditions.

The dimensional stability of polyurethane is crucial for maintaining its compact form over time. Advanced formulations can minimize shrinkage and expansion due to temperature fluctuations or environmental factors, ensuring that the material retains its space-efficient properties throughout its lifecycle.

Lastly, the processing versatility of polyurethane allows for the creation of complex shapes and structures that can maximize space utilization. Techniques such as reaction injection molding (RIM) and spray application enable the production of intricate geometries and seamless integration with other components, further enhancing the material's suitability for space-constrained designs.

One of the key properties of space-efficient polyurethane is its high strength-to-weight ratio. This characteristic enables the development of lightweight yet durable materials that can withstand various stresses and strains in confined spaces. By carefully selecting the chemical components and adjusting the molecular structure, it is possible to achieve optimal mechanical properties while minimizing material volume.

Density control is another crucial aspect of designing compact polyurethane. Through precise manipulation of the foaming process, manufacturers can create materials with tailored densities, ranging from low-density flexible foams to high-density rigid structures. This flexibility allows for the optimization of space utilization while maintaining the desired performance characteristics.

The ability to customize the hardness and flexibility of polyurethane is particularly valuable in space-constrained applications. By adjusting the ratio of hard and soft segments in the polymer structure, it is possible to create materials that can conform to irregular shapes or provide specific cushioning properties within limited dimensions.

Thermal insulation is an additional property that can be engineered into space-efficient polyurethane materials. By incorporating closed-cell structures or specific additives, polyurethane can offer excellent thermal resistance in a compact form, making it suitable for applications where both space savings and temperature control are critical.

Chemical resistance is another important attribute of polyurethane that can be tailored for space-constrained environments. By selecting appropriate isocyanates and polyols, it is possible to develop materials that resist degradation from various chemicals, oils, and solvents, ensuring longevity and reliability in challenging conditions.

The dimensional stability of polyurethane is crucial for maintaining its compact form over time. Advanced formulations can minimize shrinkage and expansion due to temperature fluctuations or environmental factors, ensuring that the material retains its space-efficient properties throughout its lifecycle.

Lastly, the processing versatility of polyurethane allows for the creation of complex shapes and structures that can maximize space utilization. Techniques such as reaction injection molding (RIM) and spray application enable the production of intricate geometries and seamless integration with other components, further enhancing the material's suitability for space-constrained designs.

Environmental Impact of Compact Polyurethane Production

The production of compact polyurethane for space-constrained applications raises significant environmental concerns that must be addressed. The manufacturing process involves the use of various chemicals, including isocyanates and polyols, which can have detrimental effects on the environment if not properly managed. Emissions from production facilities may contribute to air pollution, particularly through the release of volatile organic compounds (VOCs) and particulate matter.

Water pollution is another potential issue, as the production process may generate wastewater containing chemical residues. Proper treatment and disposal of this wastewater are crucial to prevent contamination of local water sources. Additionally, the energy-intensive nature of polyurethane production contributes to greenhouse gas emissions, further impacting climate change.

The use of petroleum-based raw materials in traditional polyurethane production raises sustainability concerns. As the demand for compact polyurethane increases, the strain on non-renewable resources becomes more pronounced. This has led to research into bio-based alternatives and recycling technologies to reduce the environmental footprint of production.

Waste management is a critical aspect of compact polyurethane production. Off-cuts, trimmings, and defective products can contribute to landfill waste if not properly recycled or repurposed. Developing efficient recycling methods for polyurethane waste is essential for minimizing environmental impact and promoting a circular economy approach.

The compact nature of the polyurethane products designed for space constraints may offer some environmental benefits. Smaller products generally require less raw material, potentially reducing resource consumption and waste generation. However, the increased complexity of manufacturing compact designs may offset some of these gains through increased energy use or specialized processing requirements.

Lifecycle assessment (LCA) studies are crucial for understanding the full environmental impact of compact polyurethane production. These assessments consider all stages from raw material extraction to end-of-life disposal, providing a comprehensive view of the product's environmental footprint. Results from LCA studies can guide manufacturers in identifying areas for improvement and implementing more sustainable practices.

Regulatory compliance plays a significant role in mitigating the environmental impact of compact polyurethane production. Manufacturers must adhere to local, national, and international environmental regulations, which may include restrictions on chemical use, emissions limits, and waste management protocols. Staying ahead of evolving environmental regulations is essential for long-term sustainability in the industry.

Water pollution is another potential issue, as the production process may generate wastewater containing chemical residues. Proper treatment and disposal of this wastewater are crucial to prevent contamination of local water sources. Additionally, the energy-intensive nature of polyurethane production contributes to greenhouse gas emissions, further impacting climate change.

The use of petroleum-based raw materials in traditional polyurethane production raises sustainability concerns. As the demand for compact polyurethane increases, the strain on non-renewable resources becomes more pronounced. This has led to research into bio-based alternatives and recycling technologies to reduce the environmental footprint of production.

Waste management is a critical aspect of compact polyurethane production. Off-cuts, trimmings, and defective products can contribute to landfill waste if not properly recycled or repurposed. Developing efficient recycling methods for polyurethane waste is essential for minimizing environmental impact and promoting a circular economy approach.

The compact nature of the polyurethane products designed for space constraints may offer some environmental benefits. Smaller products generally require less raw material, potentially reducing resource consumption and waste generation. However, the increased complexity of manufacturing compact designs may offset some of these gains through increased energy use or specialized processing requirements.

Lifecycle assessment (LCA) studies are crucial for understanding the full environmental impact of compact polyurethane production. These assessments consider all stages from raw material extraction to end-of-life disposal, providing a comprehensive view of the product's environmental footprint. Results from LCA studies can guide manufacturers in identifying areas for improvement and implementing more sustainable practices.

Regulatory compliance plays a significant role in mitigating the environmental impact of compact polyurethane production. Manufacturers must adhere to local, national, and international environmental regulations, which may include restrictions on chemical use, emissions limits, and waste management protocols. Staying ahead of evolving environmental regulations is essential for long-term sustainability in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!