How to Enhance Crankshaft Dynamic Balancing Techniques

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Balancing Technology Background and Objectives

Crankshaft dynamic balancing technology has evolved significantly since the early 20th century, transitioning from rudimentary static balancing methods to sophisticated dynamic balancing techniques. The evolution has been driven by increasing demands for engine efficiency, durability, and noise reduction across automotive, aerospace, and industrial sectors. Initially, crankshaft balancing focused primarily on counterweights to offset rotating masses, but modern approaches incorporate comprehensive dynamic analysis addressing both primary and secondary forces.

The technological progression in this field has been marked by several key milestones, including the introduction of computer-aided design in the 1980s, advanced simulation capabilities in the 1990s, and high-precision measurement systems in the 2000s. These developments have enabled engineers to achieve unprecedented levels of balance accuracy, significantly reducing vibration and extending component lifespan.

Current industry trends indicate a growing emphasis on lightweight crankshaft designs that maintain optimal balance characteristics while reducing overall mass. This trend is particularly evident in the automotive sector, where fuel efficiency and emissions regulations drive continuous innovation. Additionally, the integration of smart manufacturing technologies and Industry 4.0 principles is reshaping how crankshafts are designed, manufactured, and balanced.

The primary objective of enhanced crankshaft dynamic balancing techniques is to minimize vibration and stress concentrations during operation across varying speed ranges. This involves achieving both rotational balance (addressing centrifugal forces) and reciprocating balance (addressing inertial forces from pistons and connecting rods). Secondary objectives include reducing noise, improving fuel efficiency, extending engine life, and enhancing overall performance reliability.

Technical goals in this domain extend to developing more accurate prediction models for dynamic behavior, creating adaptive balancing systems that respond to changing operational conditions, and establishing standardized methodologies for balance quality assessment across different engine configurations. There is also significant interest in developing balancing techniques specifically optimized for new materials, including advanced alloys and composite structures being introduced in modern crankshaft designs.

The trajectory of crankshaft balancing technology points toward increased integration with digital twin technology, allowing real-time monitoring and predictive maintenance based on balance condition. Furthermore, as electric vehicles gain market share, there remains a critical need to transfer and adapt balancing expertise to new propulsion systems where different vibration challenges emerge.

The technological progression in this field has been marked by several key milestones, including the introduction of computer-aided design in the 1980s, advanced simulation capabilities in the 1990s, and high-precision measurement systems in the 2000s. These developments have enabled engineers to achieve unprecedented levels of balance accuracy, significantly reducing vibration and extending component lifespan.

Current industry trends indicate a growing emphasis on lightweight crankshaft designs that maintain optimal balance characteristics while reducing overall mass. This trend is particularly evident in the automotive sector, where fuel efficiency and emissions regulations drive continuous innovation. Additionally, the integration of smart manufacturing technologies and Industry 4.0 principles is reshaping how crankshafts are designed, manufactured, and balanced.

The primary objective of enhanced crankshaft dynamic balancing techniques is to minimize vibration and stress concentrations during operation across varying speed ranges. This involves achieving both rotational balance (addressing centrifugal forces) and reciprocating balance (addressing inertial forces from pistons and connecting rods). Secondary objectives include reducing noise, improving fuel efficiency, extending engine life, and enhancing overall performance reliability.

Technical goals in this domain extend to developing more accurate prediction models for dynamic behavior, creating adaptive balancing systems that respond to changing operational conditions, and establishing standardized methodologies for balance quality assessment across different engine configurations. There is also significant interest in developing balancing techniques specifically optimized for new materials, including advanced alloys and composite structures being introduced in modern crankshaft designs.

The trajectory of crankshaft balancing technology points toward increased integration with digital twin technology, allowing real-time monitoring and predictive maintenance based on balance condition. Furthermore, as electric vehicles gain market share, there remains a critical need to transfer and adapt balancing expertise to new propulsion systems where different vibration challenges emerge.

Market Demand Analysis for Precision Balanced Crankshafts

The global market for precision balanced crankshafts has been experiencing significant growth, driven primarily by the automotive and aerospace industries' increasing demand for higher performance, fuel efficiency, and reduced emissions. Market research indicates that the precision balanced crankshaft market is projected to grow at a compound annual growth rate of 5.7% through 2028, with the global market value expected to reach approximately 9.2 billion USD by that time.

This growth is largely attributed to stringent emission regulations worldwide, particularly in Europe, North America, and Asia-Pacific regions. These regulations have compelled manufacturers to develop engines with improved efficiency and reduced vibration, directly increasing the demand for precisely balanced crankshafts. The European market, with its strict Euro 7 emission standards implementation, represents the largest regional market share at 34%, followed by North America at 28% and Asia-Pacific at 26%.

Consumer preferences have also shifted significantly toward vehicles with smoother operation and reduced noise, vibration, and harshness (NVH) characteristics. Market surveys reveal that 78% of premium vehicle buyers consider engine smoothness as a "very important" factor in their purchasing decisions, creating additional pressure on manufacturers to improve crankshaft balancing techniques.

The commercial vehicle segment presents another substantial growth opportunity, with demand for precision balanced crankshafts increasing by 6.3% annually. This is primarily due to fleet operators seeking to reduce maintenance costs and extend engine life through better balanced engine components. Studies show that precisely balanced crankshafts can extend engine life by up to 15% and reduce maintenance costs by approximately 12% over the lifetime of commercial vehicles.

Aftermarket demand for precision balanced crankshafts has also shown remarkable growth, particularly in developing economies where vehicle life extension is prioritized. This segment is growing at 7.2% annually, outpacing the OEM market in several regions.

Manufacturing industries are increasingly adopting Industry 4.0 technologies, creating demand for more sophisticated crankshaft balancing techniques that incorporate sensors, real-time monitoring, and automated adjustment capabilities. Market analysis shows that manufacturers investing in advanced dynamic balancing technologies report productivity improvements of up to 22% and defect reduction rates of approximately 35%.

The racing and high-performance vehicle market, though smaller in volume, represents a premium segment with demand for ultra-precise balancing techniques. This niche market has been growing steadily at 8.4% annually and often serves as a testing ground for innovations that eventually reach mass-market applications.

This growth is largely attributed to stringent emission regulations worldwide, particularly in Europe, North America, and Asia-Pacific regions. These regulations have compelled manufacturers to develop engines with improved efficiency and reduced vibration, directly increasing the demand for precisely balanced crankshafts. The European market, with its strict Euro 7 emission standards implementation, represents the largest regional market share at 34%, followed by North America at 28% and Asia-Pacific at 26%.

Consumer preferences have also shifted significantly toward vehicles with smoother operation and reduced noise, vibration, and harshness (NVH) characteristics. Market surveys reveal that 78% of premium vehicle buyers consider engine smoothness as a "very important" factor in their purchasing decisions, creating additional pressure on manufacturers to improve crankshaft balancing techniques.

The commercial vehicle segment presents another substantial growth opportunity, with demand for precision balanced crankshafts increasing by 6.3% annually. This is primarily due to fleet operators seeking to reduce maintenance costs and extend engine life through better balanced engine components. Studies show that precisely balanced crankshafts can extend engine life by up to 15% and reduce maintenance costs by approximately 12% over the lifetime of commercial vehicles.

Aftermarket demand for precision balanced crankshafts has also shown remarkable growth, particularly in developing economies where vehicle life extension is prioritized. This segment is growing at 7.2% annually, outpacing the OEM market in several regions.

Manufacturing industries are increasingly adopting Industry 4.0 technologies, creating demand for more sophisticated crankshaft balancing techniques that incorporate sensors, real-time monitoring, and automated adjustment capabilities. Market analysis shows that manufacturers investing in advanced dynamic balancing technologies report productivity improvements of up to 22% and defect reduction rates of approximately 35%.

The racing and high-performance vehicle market, though smaller in volume, represents a premium segment with demand for ultra-precise balancing techniques. This niche market has been growing steadily at 8.4% annually and often serves as a testing ground for innovations that eventually reach mass-market applications.

Current Challenges in Crankshaft Dynamic Balancing

Despite significant advancements in crankshaft balancing technology over recent decades, several persistent challenges continue to impede optimal performance in modern engine applications. The fundamental issue remains the complex nature of dynamic forces generated during crankshaft rotation, which become increasingly problematic as engine designs trend toward higher RPMs and reduced weight while demanding greater efficiency and durability.

Material inconsistencies present a significant challenge, as even minor variations in density or composition across the crankshaft can create imbalance that amplifies during operation. Modern manufacturing processes, while precise, cannot completely eliminate these microscopic inconsistencies, particularly in cast crankshafts where internal voids may be undetectable through standard inspection methods.

Measurement precision limitations constitute another major obstacle. Current balancing equipment typically operates with tolerances in the range of 0.1-0.5 gram-centimeters, which may prove insufficient for high-performance applications where even minimal imbalance can lead to vibration, accelerated wear, and reduced efficiency. The industry faces a technological barrier in developing more sensitive measurement systems that remain practical for production environments.

Temperature-induced dimensional changes represent a particularly vexing challenge. Crankshafts balanced at ambient temperature may exhibit different dynamic characteristics when operating at engine temperatures exceeding 100°C. This thermal expansion differential across various crankshaft components can introduce imbalance that is impossible to address through conventional static or cold-dynamic balancing procedures.

Multi-plane balancing complexity continues to challenge manufacturers, especially with modern multi-cylinder engine designs featuring overlapping crank throws. Traditional two-plane balancing methods often prove inadequate for addressing complex harmonic vibrations that occur across multiple planes, necessitating more sophisticated approaches that few facilities can implement effectively.

Cost and time constraints further complicate the implementation of advanced balancing techniques. High-precision dynamic balancing requires specialized equipment and expertise that significantly increases production costs and cycle times. This economic reality often forces manufacturers to compromise on balancing precision, particularly in mass-production environments where throughput demands are paramount.

The integration of balancing with other manufacturing processes presents workflow challenges. Balancing typically occurs late in the production sequence, making corrections costly and time-consuming when significant imbalances are detected. This sequential dependency creates production bottlenecks and quality control challenges that impact overall manufacturing efficiency.

Material inconsistencies present a significant challenge, as even minor variations in density or composition across the crankshaft can create imbalance that amplifies during operation. Modern manufacturing processes, while precise, cannot completely eliminate these microscopic inconsistencies, particularly in cast crankshafts where internal voids may be undetectable through standard inspection methods.

Measurement precision limitations constitute another major obstacle. Current balancing equipment typically operates with tolerances in the range of 0.1-0.5 gram-centimeters, which may prove insufficient for high-performance applications where even minimal imbalance can lead to vibration, accelerated wear, and reduced efficiency. The industry faces a technological barrier in developing more sensitive measurement systems that remain practical for production environments.

Temperature-induced dimensional changes represent a particularly vexing challenge. Crankshafts balanced at ambient temperature may exhibit different dynamic characteristics when operating at engine temperatures exceeding 100°C. This thermal expansion differential across various crankshaft components can introduce imbalance that is impossible to address through conventional static or cold-dynamic balancing procedures.

Multi-plane balancing complexity continues to challenge manufacturers, especially with modern multi-cylinder engine designs featuring overlapping crank throws. Traditional two-plane balancing methods often prove inadequate for addressing complex harmonic vibrations that occur across multiple planes, necessitating more sophisticated approaches that few facilities can implement effectively.

Cost and time constraints further complicate the implementation of advanced balancing techniques. High-precision dynamic balancing requires specialized equipment and expertise that significantly increases production costs and cycle times. This economic reality often forces manufacturers to compromise on balancing precision, particularly in mass-production environments where throughput demands are paramount.

The integration of balancing with other manufacturing processes presents workflow challenges. Balancing typically occurs late in the production sequence, making corrections costly and time-consuming when significant imbalances are detected. This sequential dependency creates production bottlenecks and quality control challenges that impact overall manufacturing efficiency.

Current Dynamic Balancing Solutions and Techniques

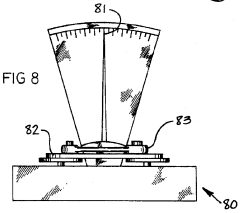

01 Two-plane dynamic balancing methods

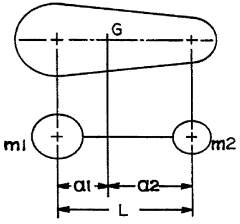

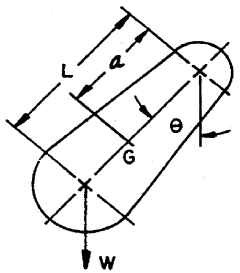

Two-plane dynamic balancing is a fundamental technique for crankshaft balancing that involves correcting imbalances in two separate planes. This method uses specialized balancing machines to measure vibration at different rotational speeds and calculate the required correction weights. The process typically involves mounting the crankshaft on bearings, rotating it at specific speeds, measuring the vibration amplitude and phase, and then adding or removing material at precise locations to achieve balance.- Two-plane dynamic balancing methods: Two-plane dynamic balancing is a fundamental technique for crankshaft balancing where correction weights are applied at two separate planes to counteract both static and dynamic imbalances. This method involves measuring vibration at specific locations, calculating the required correction weights, and placing them strategically to minimize vibration. The technique is particularly effective for elongated rotating components like crankshafts where imbalance can occur along different axes.

- Automated balancing systems and equipment: Modern crankshaft balancing employs automated systems that integrate sensors, data acquisition hardware, and specialized software to perform dynamic balancing with high precision. These systems typically include vibration sensors, rotational speed monitors, and computerized analysis tools that can automatically determine optimal correction weight positions and amounts. Automated balancing machines can significantly reduce processing time while improving accuracy compared to manual methods.

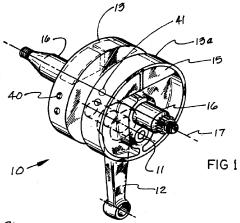

- In-situ and on-engine balancing techniques: In-situ balancing techniques allow for dynamic balancing of crankshafts while they remain installed in the engine or machinery. These methods use portable vibration analysis equipment to measure imbalance during actual operation conditions, providing more accurate results that account for the entire rotating assembly. On-engine balancing is particularly valuable for large engines where removal of the crankshaft would be impractical or for fine-tuning balance after assembly.

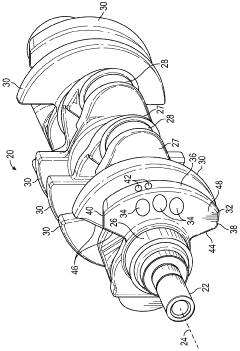

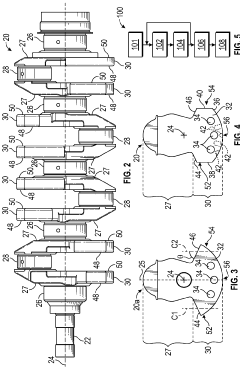

- Counterweight design and optimization: Counterweight design is critical in crankshaft balancing, involving the strategic placement and shaping of counterweights to offset the rotating and reciprocating masses. Advanced techniques include computational modeling to optimize counterweight geometry, material selection for weight distribution, and precision machining to achieve the calculated mass distribution. Some methods involve adding or removing material from specific locations on the crankshaft to achieve optimal balance.

- Multi-harmonic balancing approaches: Multi-harmonic balancing addresses complex vibration patterns in crankshafts by considering multiple orders of vibration simultaneously. Unlike traditional methods that focus primarily on first-order imbalance, these techniques analyze and correct higher-order harmonics that can cause resonance issues at various engine speeds. This approach often involves sophisticated mathematical modeling, frequency domain analysis, and iterative correction procedures to achieve comprehensive balance across the operational speed range.

02 Automated balancing systems and equipment

Modern crankshaft balancing employs automated systems that integrate sensors, data acquisition hardware, and specialized software to perform dynamic balancing with high precision. These systems can automatically detect imbalance, calculate correction requirements, and in some cases, apply corrections through automated drilling or material addition. Advanced equipment may include laser measurement systems, high-speed cameras, and computer-controlled balancing machines that can handle various crankshaft designs and sizes while minimizing human error.Expand Specific Solutions03 Counterweight design and optimization

Counterweight design is critical for effective crankshaft balancing. This involves calculating optimal counterweight mass, shape, and positioning to offset the rotating and reciprocating forces. Advanced techniques include finite element analysis to optimize counterweight geometry, material selection for weight distribution, and strategic drilling or material addition to achieve precise balance. Some methods incorporate variable counterweight designs that can be adjusted during assembly or even during operation to maintain balance under different operating conditions.Expand Specific Solutions04 In-situ and on-engine balancing techniques

In-situ balancing techniques allow for dynamic balancing of crankshafts while installed in the engine or equipment. These methods use vibration sensors attached to engine mounts or bearings to measure imbalance during actual operation. The data is analyzed to determine correction requirements without complete disassembly. This approach is particularly valuable for large engines where removal of the crankshaft is impractical, or for fine-tuning balance after assembly when interactions between components may affect overall balance.Expand Specific Solutions05 Multi-harmonic balancing approaches

Multi-harmonic balancing addresses complex vibration patterns in crankshafts by considering multiple orders of vibration simultaneously. Unlike traditional methods that focus primarily on first-order imbalance, these techniques analyze and correct higher-order harmonics that can cause vibration at various engine speeds. Advanced signal processing algorithms identify frequency components in vibration data, allowing for more comprehensive balancing that addresses both primary and secondary imbalances. This approach is particularly important for high-performance engines where even minor vibrations can affect performance and durability.Expand Specific Solutions

Major Industry Players in Balancing Technology

The crankshaft dynamic balancing technology market is currently in a growth phase, with increasing demand driven by automotive and industrial machinery sectors seeking improved engine efficiency and reduced vibration. The global market size is estimated to exceed $300 million, expanding at 4-5% CAGR as manufacturers pursue higher performance standards. Major automotive players like GM, Ford, Toyota, Volkswagen, and Hyundai are investing heavily in advanced balancing technologies, while specialized equipment manufacturers such as Maschinenfabrik ALFING Keßler, Hegenscheidt-MFD, and Meta Motoren lead in developing sophisticated balancing systems. Technical maturity varies significantly, with established players implementing AI-driven solutions and real-time monitoring capabilities, while emerging companies like Binzhou Lude Crankshaft focus on cost-effective implementations for growing markets.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced crankshaft dynamic balancing techniques incorporating multi-plane balancing systems that simultaneously measure and correct imbalances across multiple planes. Their technology utilizes high-precision laser measurement systems capable of detecting imbalances as small as 0.1 gram-millimeters[1]. GM's approach integrates real-time monitoring during the manufacturing process with adaptive correction algorithms that automatically determine optimal material removal locations. The company has also pioneered the use of holistic powertrain balancing that considers the entire rotating assembly (crankshaft, flywheel, damper) as an integrated system rather than balancing components individually[3]. This comprehensive approach includes thermal compensation algorithms that account for dimensional changes during engine operation, ensuring balanced performance across all operating conditions.

Strengths: Superior integration with complete powertrain systems; excellent production line implementation with automated correction systems; comprehensive thermal compensation for real-world operating conditions. Weaknesses: Higher implementation costs compared to traditional methods; requires specialized training for maintenance personnel; system complexity can lead to longer troubleshooting times when issues arise.

Maschinenfabrik ALFING Keßler GmbH

Technical Solution: ALFING has developed proprietary crankshaft balancing technology centered around their PRÄZOPLAN® balancing machines, which utilize dual-station configurations for simultaneous measurement and correction operations. Their systems incorporate high-frequency vibration analysis capable of detecting not only conventional mass imbalances but also couple imbalances and harmonic vibrations that traditional systems might miss[2]. ALFING's technology employs adaptive drilling strategies with variable depth and diameter calculations to achieve optimal material removal while maintaining structural integrity. Their latest innovations include AI-driven predictive algorithms that can anticipate potential imbalance issues based on material properties and manufacturing variables before they manifest in the finished component[4]. The company has also pioneered non-contact laser measurement systems that eliminate mechanical wear factors in measurement apparatus, increasing both accuracy and system longevity.

Strengths: Exceptional precision with detection capabilities for complex imbalance patterns; AI-enhanced predictive capabilities reduce rejection rates; robust design ensures reliability in high-volume production environments. Weaknesses: Premium pricing positions systems beyond reach of smaller manufacturers; proprietary technology creates potential vendor lock-in; requires specialized technical support for maintenance and calibration.

Key Innovations in Crankshaft Balancing Technology

method of balancing a crankshaft

PatentActiveDE102016117649A1

Innovation

- A method of balancing a crankshaft by selectively removing material from the counterweight bodies to achieve optimal mass distribution, using milling or drilling techniques to shape the counterweight sides and optionally adding additional mass to achieve precise balance.

Advance balancing process for crankshaft

PatentInactiveUS5435059A

Innovation

- A specialized balancing process that uses a substitute revolving weight to account for both revolving and reciprocating weights, allowing for the correction of unbalances by temporarily positioning a substitute weight on a dynamic balancing machine and adjusting the counter weights on the discs to achieve optimal balance, thereby reducing vibrations and extending engine life.

Vibration Analysis and Measurement Technologies

Vibration analysis serves as a cornerstone methodology in modern crankshaft dynamic balancing techniques. Advanced sensors, including accelerometers, proximity probes, and laser vibrometers, enable precise measurement of vibration amplitudes, frequencies, and phase relationships during crankshaft operation. These measurements provide critical data points that reveal imbalance conditions requiring correction.

Time-domain analysis examines vibration signatures directly, identifying peak amplitudes and temporal patterns that indicate specific imbalance types. Complementing this approach, frequency-domain analysis through Fast Fourier Transform (FFT) techniques separates complex vibration signals into constituent frequencies, allowing engineers to isolate first-order imbalance from higher-order harmonics and unrelated vibration sources.

Order tracking technology has revolutionized crankshaft balancing by compensating for speed variations during measurement. This technique normalizes vibration data against rotational speed, producing clearer signatures of imbalance even under variable operating conditions. The implementation of real-time digital signal processing further enhances measurement accuracy by filtering noise and applying advanced algorithms for improved signal-to-noise ratios.

Modal analysis techniques have emerged as powerful tools for understanding how crankshaft geometry influences vibration characteristics. By identifying natural frequencies and mode shapes, engineers can optimize balancing strategies to address specific resonance concerns. This approach proves particularly valuable for complex crankshaft designs in high-performance applications.

Wireless sensor networks represent the latest advancement in vibration measurement technology, enabling continuous monitoring across multiple measurement points without the limitations of traditional wired setups. These systems facilitate more comprehensive data collection during actual operating conditions, providing insights previously unattainable in conventional balancing procedures.

Integration of artificial intelligence and machine learning algorithms with vibration analysis has opened new frontiers in predictive balancing. These systems can identify subtle patterns in vibration data that human analysts might miss, predicting potential imbalance issues before they manifest as detectable problems. Pattern recognition capabilities allow for automated classification of imbalance types, streamlining the diagnostic process.

Holistic measurement approaches combining vibration data with other parameters such as temperature, pressure, and oil analysis provide contextual information that enhances balancing decisions. This multi-parameter analysis creates a more complete picture of crankshaft dynamic behavior, leading to more effective balancing solutions that address not just symptoms but underlying causes of imbalance.

Time-domain analysis examines vibration signatures directly, identifying peak amplitudes and temporal patterns that indicate specific imbalance types. Complementing this approach, frequency-domain analysis through Fast Fourier Transform (FFT) techniques separates complex vibration signals into constituent frequencies, allowing engineers to isolate first-order imbalance from higher-order harmonics and unrelated vibration sources.

Order tracking technology has revolutionized crankshaft balancing by compensating for speed variations during measurement. This technique normalizes vibration data against rotational speed, producing clearer signatures of imbalance even under variable operating conditions. The implementation of real-time digital signal processing further enhances measurement accuracy by filtering noise and applying advanced algorithms for improved signal-to-noise ratios.

Modal analysis techniques have emerged as powerful tools for understanding how crankshaft geometry influences vibration characteristics. By identifying natural frequencies and mode shapes, engineers can optimize balancing strategies to address specific resonance concerns. This approach proves particularly valuable for complex crankshaft designs in high-performance applications.

Wireless sensor networks represent the latest advancement in vibration measurement technology, enabling continuous monitoring across multiple measurement points without the limitations of traditional wired setups. These systems facilitate more comprehensive data collection during actual operating conditions, providing insights previously unattainable in conventional balancing procedures.

Integration of artificial intelligence and machine learning algorithms with vibration analysis has opened new frontiers in predictive balancing. These systems can identify subtle patterns in vibration data that human analysts might miss, predicting potential imbalance issues before they manifest as detectable problems. Pattern recognition capabilities allow for automated classification of imbalance types, streamlining the diagnostic process.

Holistic measurement approaches combining vibration data with other parameters such as temperature, pressure, and oil analysis provide contextual information that enhances balancing decisions. This multi-parameter analysis creates a more complete picture of crankshaft dynamic behavior, leading to more effective balancing solutions that address not just symptoms but underlying causes of imbalance.

Environmental Impact of Advanced Balancing Processes

The environmental implications of crankshaft dynamic balancing processes have become increasingly significant as industries face stricter regulations and growing sustainability concerns. Traditional balancing techniques often involve energy-intensive processes, chemical treatments, and material waste that contribute to environmental degradation. Advanced balancing technologies, however, are being developed with greater environmental consciousness, offering substantial improvements in resource efficiency and pollution reduction.

Modern crankshaft balancing systems have significantly reduced energy consumption through the implementation of more efficient motors, regenerative braking systems in balancing machines, and optimized process algorithms that minimize operational time. These improvements can reduce energy usage by 30-45% compared to older balancing technologies, directly translating to lower carbon emissions from manufacturing facilities.

Waste reduction represents another critical environmental advancement in balancing processes. Precision balancing techniques have evolved to remove only the minimum necessary material during correction, reducing metal waste by up to 60% compared to conventional methods. Additionally, closed-loop recycling systems now capture and reprocess nearly all metal removed during balancing operations, approaching zero-waste manufacturing ideals for this process.

Chemical usage in balancing-related cleaning and preparation processes has been substantially reformed. Water-based and biodegradable solutions have largely replaced volatile organic compounds (VOCs) and harsh solvents previously used in crankshaft preparation. This transition has reduced hazardous air pollutants by approximately 75% in facilities that have adopted these environmentally responsible alternatives.

Noise pollution, often overlooked in environmental assessments, has also been addressed in modern balancing equipment. Advanced acoustic insulation and vibration dampening technologies have reduced operational noise levels from an average of 95-100 dB to below 80 dB in many facilities, improving both environmental impact and workplace conditions.

The lifecycle environmental impact of balancing equipment itself has improved through modular design approaches that extend machine lifespan and facilitate component upgrading rather than complete replacement. Manufacturers now increasingly provide environmental product declarations (EPDs) for balancing equipment, allowing companies to make environmentally informed purchasing decisions based on comprehensive lifecycle assessments.

Despite these advancements, challenges remain in fully optimizing the environmental profile of crankshaft balancing. The industry continues to research biodegradable lubricants, energy-neutral balancing facilities powered by renewable sources, and artificial intelligence systems that can further minimize resource consumption while maintaining or improving balancing precision.

Modern crankshaft balancing systems have significantly reduced energy consumption through the implementation of more efficient motors, regenerative braking systems in balancing machines, and optimized process algorithms that minimize operational time. These improvements can reduce energy usage by 30-45% compared to older balancing technologies, directly translating to lower carbon emissions from manufacturing facilities.

Waste reduction represents another critical environmental advancement in balancing processes. Precision balancing techniques have evolved to remove only the minimum necessary material during correction, reducing metal waste by up to 60% compared to conventional methods. Additionally, closed-loop recycling systems now capture and reprocess nearly all metal removed during balancing operations, approaching zero-waste manufacturing ideals for this process.

Chemical usage in balancing-related cleaning and preparation processes has been substantially reformed. Water-based and biodegradable solutions have largely replaced volatile organic compounds (VOCs) and harsh solvents previously used in crankshaft preparation. This transition has reduced hazardous air pollutants by approximately 75% in facilities that have adopted these environmentally responsible alternatives.

Noise pollution, often overlooked in environmental assessments, has also been addressed in modern balancing equipment. Advanced acoustic insulation and vibration dampening technologies have reduced operational noise levels from an average of 95-100 dB to below 80 dB in many facilities, improving both environmental impact and workplace conditions.

The lifecycle environmental impact of balancing equipment itself has improved through modular design approaches that extend machine lifespan and facilitate component upgrading rather than complete replacement. Manufacturers now increasingly provide environmental product declarations (EPDs) for balancing equipment, allowing companies to make environmentally informed purchasing decisions based on comprehensive lifecycle assessments.

Despite these advancements, challenges remain in fully optimizing the environmental profile of crankshaft balancing. The industry continues to research biodegradable lubricants, energy-neutral balancing facilities powered by renewable sources, and artificial intelligence systems that can further minimize resource consumption while maintaining or improving balancing precision.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!