How to Improve Polyurethane Adhesive Strength?

JUN 25, 20253 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Adhesive Evolution

Polyurethane (PU) adhesives have undergone significant evolution since their introduction in the 1940s. Initially developed as a byproduct of World War II research, these versatile adhesives quickly found applications in various industries due to their exceptional bonding properties and durability.

The early stages of PU adhesive development focused on improving their basic formulations and understanding the chemistry behind their adhesion mechanisms. Scientists discovered that the reaction between isocyanates and polyols could produce a wide range of adhesive properties, depending on the specific components used and their ratios.

In the 1960s and 1970s, researchers made substantial progress in enhancing the performance of PU adhesives. They introduced new catalysts and additives that improved curing times, bond strength, and resistance to environmental factors such as moisture and temperature fluctuations. This period also saw the development of two-component PU adhesive systems, which offered improved control over curing times and allowed for more specialized applications.

The 1980s and 1990s marked a significant shift towards environmentally friendly formulations. Growing concerns about volatile organic compounds (VOCs) and their impact on human health and the environment led to the development of water-based and solvent-free PU adhesives. These new formulations maintained the excellent bonding properties of traditional PU adhesives while reducing harmful emissions.

In recent decades, the focus has shifted towards improving the overall performance and versatility of PU adhesives. Researchers have explored ways to enhance adhesion strength, particularly on challenging substrates like low surface energy plastics and metals. This has led to the development of hybrid systems, combining PU with other adhesive technologies such as silane-terminated polymers or epoxies.

Nanotechnology has also played a crucial role in the evolution of PU adhesives. The incorporation of nanoparticles, such as carbon nanotubes or graphene, has resulted in significant improvements in mechanical properties, thermal stability, and electrical conductivity of PU adhesives.

Most recently, the industry has been focusing on developing smart and responsive PU adhesives. These advanced formulations can change their properties in response to external stimuli such as temperature, pH, or light. This innovation opens up new possibilities for applications in fields like biomedicine, electronics, and aerospace.

Throughout this evolution, the primary goal has remained consistent: to improve the adhesive strength of PU formulations while addressing specific application requirements and environmental concerns. The journey from basic formulations to today's high-performance, environmentally friendly, and smart PU adhesives demonstrates the continuous innovation in this field, driven by technological advancements and changing market demands.

The early stages of PU adhesive development focused on improving their basic formulations and understanding the chemistry behind their adhesion mechanisms. Scientists discovered that the reaction between isocyanates and polyols could produce a wide range of adhesive properties, depending on the specific components used and their ratios.

In the 1960s and 1970s, researchers made substantial progress in enhancing the performance of PU adhesives. They introduced new catalysts and additives that improved curing times, bond strength, and resistance to environmental factors such as moisture and temperature fluctuations. This period also saw the development of two-component PU adhesive systems, which offered improved control over curing times and allowed for more specialized applications.

The 1980s and 1990s marked a significant shift towards environmentally friendly formulations. Growing concerns about volatile organic compounds (VOCs) and their impact on human health and the environment led to the development of water-based and solvent-free PU adhesives. These new formulations maintained the excellent bonding properties of traditional PU adhesives while reducing harmful emissions.

In recent decades, the focus has shifted towards improving the overall performance and versatility of PU adhesives. Researchers have explored ways to enhance adhesion strength, particularly on challenging substrates like low surface energy plastics and metals. This has led to the development of hybrid systems, combining PU with other adhesive technologies such as silane-terminated polymers or epoxies.

Nanotechnology has also played a crucial role in the evolution of PU adhesives. The incorporation of nanoparticles, such as carbon nanotubes or graphene, has resulted in significant improvements in mechanical properties, thermal stability, and electrical conductivity of PU adhesives.

Most recently, the industry has been focusing on developing smart and responsive PU adhesives. These advanced formulations can change their properties in response to external stimuli such as temperature, pH, or light. This innovation opens up new possibilities for applications in fields like biomedicine, electronics, and aerospace.

Throughout this evolution, the primary goal has remained consistent: to improve the adhesive strength of PU formulations while addressing specific application requirements and environmental concerns. The journey from basic formulations to today's high-performance, environmentally friendly, and smart PU adhesives demonstrates the continuous innovation in this field, driven by technological advancements and changing market demands.

Current Solutions

01 Composition optimization for improved strength

Enhancing polyurethane adhesive strength through careful selection and optimization of components, including isocyanates, polyols, and additives. This approach focuses on balancing the ratio of hard and soft segments, incorporating chain extenders, and selecting appropriate catalysts to achieve desired mechanical properties and bond strength.- Composition optimization for improved strength: Enhancing polyurethane adhesive strength through careful selection and optimization of components, including isocyanates, polyols, and additives. This approach focuses on balancing the ratio of hard and soft segments, incorporating chain extenders, and selecting appropriate catalysts to achieve desired mechanical properties and bond strength.

- Surface treatment techniques: Improving adhesive strength by employing various surface treatment methods on substrates before applying polyurethane adhesive. These techniques include plasma treatment, corona discharge, chemical etching, and application of primers or coupling agents to enhance surface energy and promote better adhesion.

- Nanoparticle reinforcement: Incorporating nanoparticles such as carbon nanotubes, graphene, or silica nanoparticles into polyurethane adhesive formulations to enhance mechanical properties and bond strength. These nanofillers can improve load transfer, increase crosslinking density, and provide additional reinforcement to the adhesive matrix.

- Moisture-curing polyurethane adhesives: Developing moisture-curing polyurethane adhesive formulations that react with ambient humidity to form strong, durable bonds. These adhesives often contain isocyanate-terminated prepolymers and additives that promote rapid curing and enhanced adhesion to various substrates, particularly in high-humidity environments.

- Two-component polyurethane adhesive systems: Designing two-component polyurethane adhesive systems that offer improved control over curing time, pot life, and final mechanical properties. These systems typically consist of a polyol component and an isocyanate component that are mixed just before application, allowing for customization of adhesive properties based on specific application requirements.

02 Surface treatment techniques

Improving adhesive strength by applying various surface treatment methods to the substrates before bonding. These techniques may include plasma treatment, corona discharge, chemical etching, or application of primers to increase surface energy and promote better adhesion between the polyurethane adhesive and the substrate.Expand Specific Solutions03 Nanoparticle reinforcement

Incorporating nanoparticles such as carbon nanotubes, graphene, or silica nanoparticles into polyurethane adhesive formulations to enhance mechanical properties and bond strength. These nanofillers can improve load transfer, increase crosslinking density, and provide additional reinforcement to the adhesive matrix.Expand Specific Solutions04 Moisture-curing systems

Developing moisture-curing polyurethane adhesive systems that react with ambient humidity to form strong, durable bonds. These adhesives typically contain isocyanate-terminated prepolymers that crosslink upon exposure to moisture, resulting in improved adhesive strength and resistance to environmental factors.Expand Specific Solutions05 Heat-activated bonding

Utilizing heat-activated polyurethane adhesives that achieve optimal strength through thermal curing processes. These adhesives may incorporate thermally-triggered catalysts or employ two-component systems that react at elevated temperatures, resulting in enhanced crosslinking and improved mechanical properties of the cured adhesive.Expand Specific Solutions

Key Industry Players

The polyurethane adhesive strength improvement market is in a mature growth stage, with a global market size exceeding $10 billion. Technological advancements are driven by key players like Henkel, BASF, and Sika, who are focusing on enhancing adhesive performance through innovative formulations and application techniques. The technology's maturity is evident in the diverse range of solutions offered by companies such as Bayer, Wanhua Chemical, and Covestro. These firms are investing heavily in R&D to develop high-performance, environmentally friendly adhesives. The competitive landscape is characterized by a mix of established chemical giants and specialized adhesive manufacturers, with emerging players from Asia, particularly China, gaining market share through cost-effective solutions and rapid innovation cycles.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a two-component polyurethane adhesive system that combines high initial strength with excellent final adhesion. This system utilizes a unique blend of isocyanates and polyols, optimized for rapid curing and strong bond formation. The adhesive incorporates nano-sized fillers to enhance its mechanical properties and improve its resistance to environmental factors. Additionally, Henkel has implemented a surface treatment technology that enhances the adhesive's ability to bond with various substrates, including low surface energy materials.

Strengths: Rapid curing, high initial strength, excellent final adhesion, and versatility across different substrates. Weaknesses: May require specialized application equipment and careful mixing of components.

BASF Corp.

Technical Solution: BASF has introduced an innovative polyurethane adhesive formulation that focuses on improving bond strength through molecular engineering. Their approach involves the use of specially designed chain extenders and cross-linking agents that create a more densely interconnected polymer network. This results in enhanced mechanical properties and improved adhesion. BASF has also incorporated reactive nanoparticles into the adhesive matrix, which form additional covalent bonds with the substrate, further increasing the overall bond strength. The company has developed a proprietary curing catalyst system that ensures optimal reaction kinetics, leading to consistent and reliable bond formation across various environmental conditions.

Strengths: Superior bond strength, improved durability, and consistent performance across different environments. Weaknesses: Potentially higher cost due to specialized components and more complex formulation.

Innovative Formulations

Polyurethane adhesive

PatentPendingJP2023038422A

Innovation

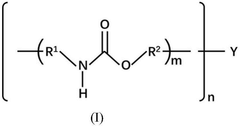

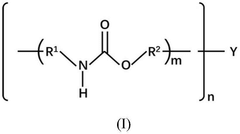

- A polyurethane adhesive formulation containing a polyurethane polyol synthesized from a polyol compound and a polyisocyanate compound, with the addition of an ether ester compound represented by formula (1), ensuring a polyether polyol compound content of 46 to 100 parts by mass, and optional additives for enhanced properties.

Polyurethane toughening agent and adhesive composition prepared therefrom

PatentWO2025077798A1

Innovation

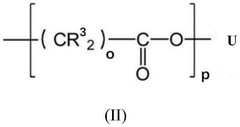

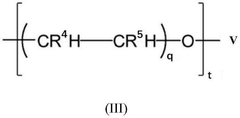

- A polyurethane (PU) toughening agent with a specific polymer structure, formed by reacting a polyol with a polyisocyanate compound, followed by a multi-functional compound to create a dendritic structure, which is then terminated with a phenolic compound, is used to enhance the mechanical properties and adjust the peel strength of adhesives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!