How to Increase Magnetron Pulse Width for Power Density

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Pulse Width Technology Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 1940s, initially developed for radar applications during World War II. The evolution of magnetrons has been characterized by continuous improvements in power output, efficiency, and operational stability. Early magnetrons operated with relatively short pulse widths, limiting their power density capabilities. Over subsequent decades, researchers have progressively enhanced pulse width capabilities, moving from microsecond to millisecond ranges, enabling broader applications across industrial heating, medical equipment, and advanced radar systems.

The technological trajectory of magnetron pulse width expansion has been driven by several key factors, including advancements in materials science, thermal management techniques, and electronic control systems. The introduction of beryllium oxide ceramics in the 1970s and advanced cooling systems in the 1980s represented significant milestones that allowed for longer operational periods without overheating. More recently, digital control systems have enabled precise pulse shaping and timing, further expanding the potential for increased pulse width.

Current industry trends indicate growing demand for higher power density magnetrons across multiple sectors. In industrial processing, longer pulse widths enable more uniform heating and improved energy efficiency. In medical applications, particularly cancer treatment technologies, controlled power density allows for more precise therapeutic outcomes. Defense and aerospace sectors continue to push for enhanced radar capabilities requiring greater power density without sacrificing reliability.

The primary technical objective in magnetron pulse width expansion is to overcome the fundamental thermal and electrical limitations that constrain operational duration. This includes developing solutions for cathode erosion during extended operation, managing anode block heating, preventing mode hopping during longer pulses, and maintaining frequency stability throughout the pulse duration. Secondary objectives include improving overall energy efficiency, reducing cooling requirements, and extending operational lifespan of components.

Looking forward, the technology roadmap aims to achieve pulse widths exceeding 10 milliseconds while maintaining stable operation at high power levels. This represents a significant challenge requiring interdisciplinary approaches combining materials science, thermal engineering, and electronic control systems. Success in this domain would enable next-generation applications in fields ranging from advanced manufacturing to space-based systems, where power density requirements continue to increase.

The strategic importance of this technology development extends beyond immediate applications, potentially enabling new capabilities in emerging fields such as wireless power transmission, advanced propulsion systems, and next-generation communication technologies. As such, magnetron pulse width technology represents a critical enabling technology with broad implications across multiple industrial sectors.

The technological trajectory of magnetron pulse width expansion has been driven by several key factors, including advancements in materials science, thermal management techniques, and electronic control systems. The introduction of beryllium oxide ceramics in the 1970s and advanced cooling systems in the 1980s represented significant milestones that allowed for longer operational periods without overheating. More recently, digital control systems have enabled precise pulse shaping and timing, further expanding the potential for increased pulse width.

Current industry trends indicate growing demand for higher power density magnetrons across multiple sectors. In industrial processing, longer pulse widths enable more uniform heating and improved energy efficiency. In medical applications, particularly cancer treatment technologies, controlled power density allows for more precise therapeutic outcomes. Defense and aerospace sectors continue to push for enhanced radar capabilities requiring greater power density without sacrificing reliability.

The primary technical objective in magnetron pulse width expansion is to overcome the fundamental thermal and electrical limitations that constrain operational duration. This includes developing solutions for cathode erosion during extended operation, managing anode block heating, preventing mode hopping during longer pulses, and maintaining frequency stability throughout the pulse duration. Secondary objectives include improving overall energy efficiency, reducing cooling requirements, and extending operational lifespan of components.

Looking forward, the technology roadmap aims to achieve pulse widths exceeding 10 milliseconds while maintaining stable operation at high power levels. This represents a significant challenge requiring interdisciplinary approaches combining materials science, thermal engineering, and electronic control systems. Success in this domain would enable next-generation applications in fields ranging from advanced manufacturing to space-based systems, where power density requirements continue to increase.

The strategic importance of this technology development extends beyond immediate applications, potentially enabling new capabilities in emerging fields such as wireless power transmission, advanced propulsion systems, and next-generation communication technologies. As such, magnetron pulse width technology represents a critical enabling technology with broad implications across multiple industrial sectors.

Market Demand Analysis for High Power Density Applications

The global market for high power density applications has witnessed substantial growth in recent years, driven primarily by advancements in radar systems, industrial heating, medical equipment, and wireless power transmission technologies. The demand for magnetrons with increased pulse width capabilities stems from the need for higher power density in these critical applications.

In the radar systems sector, particularly for military and weather monitoring applications, there is a growing requirement for extended range detection and improved resolution. Market research indicates that defense organizations worldwide are investing heavily in radar technology upgrades, with an estimated annual growth rate of 5.7% through 2028. The ability to increase magnetron pulse width directly addresses this market need by enabling higher average power output while maintaining peak power levels.

Industrial heating applications represent another significant market segment driving demand for enhanced magnetron capabilities. The food processing industry, in particular, seeks more efficient heating solutions that can reduce processing time while maintaining product quality. Market analysts report that manufacturers are increasingly adopting microwave heating systems with higher power densities to improve throughput and energy efficiency in production lines.

The medical equipment sector, especially in radiation oncology and medical imaging, requires precise control of power delivery. The market for medical magnetrons is expanding as healthcare facilities upgrade to more advanced treatment systems. Increased pulse width capabilities would allow for more controlled energy delivery in therapeutic applications, addressing a critical need in this sector.

Wireless power transmission technologies, though still emerging, show promising market potential. Research institutions and technology companies are actively exploring high-power wireless charging solutions for electric vehicles and industrial equipment. The ability to efficiently transmit higher power densities through increased magnetron pulse width could accelerate commercial adoption of these technologies.

Consumer electronics manufacturers are also expressing interest in compact, high-efficiency power solutions. As devices become more powerful while decreasing in size, the demand for components that can deliver higher power density in smaller packages continues to grow. This trend is particularly evident in portable computing devices and advanced communication systems.

Market forecasts suggest that regions with strong manufacturing bases, particularly East Asia and North America, will lead in adoption of advanced magnetron technologies. China's significant investments in both industrial automation and defense systems make it a particularly important market for high power density applications.

The economic benefits of increased power density are compelling across all these sectors. End users report that systems with higher power density capabilities can reduce operational costs through improved energy efficiency, decreased maintenance requirements, and enhanced productivity. These tangible benefits are driving willingness to invest in next-generation magnetron technologies.

In the radar systems sector, particularly for military and weather monitoring applications, there is a growing requirement for extended range detection and improved resolution. Market research indicates that defense organizations worldwide are investing heavily in radar technology upgrades, with an estimated annual growth rate of 5.7% through 2028. The ability to increase magnetron pulse width directly addresses this market need by enabling higher average power output while maintaining peak power levels.

Industrial heating applications represent another significant market segment driving demand for enhanced magnetron capabilities. The food processing industry, in particular, seeks more efficient heating solutions that can reduce processing time while maintaining product quality. Market analysts report that manufacturers are increasingly adopting microwave heating systems with higher power densities to improve throughput and energy efficiency in production lines.

The medical equipment sector, especially in radiation oncology and medical imaging, requires precise control of power delivery. The market for medical magnetrons is expanding as healthcare facilities upgrade to more advanced treatment systems. Increased pulse width capabilities would allow for more controlled energy delivery in therapeutic applications, addressing a critical need in this sector.

Wireless power transmission technologies, though still emerging, show promising market potential. Research institutions and technology companies are actively exploring high-power wireless charging solutions for electric vehicles and industrial equipment. The ability to efficiently transmit higher power densities through increased magnetron pulse width could accelerate commercial adoption of these technologies.

Consumer electronics manufacturers are also expressing interest in compact, high-efficiency power solutions. As devices become more powerful while decreasing in size, the demand for components that can deliver higher power density in smaller packages continues to grow. This trend is particularly evident in portable computing devices and advanced communication systems.

Market forecasts suggest that regions with strong manufacturing bases, particularly East Asia and North America, will lead in adoption of advanced magnetron technologies. China's significant investments in both industrial automation and defense systems make it a particularly important market for high power density applications.

The economic benefits of increased power density are compelling across all these sectors. End users report that systems with higher power density capabilities can reduce operational costs through improved energy efficiency, decreased maintenance requirements, and enhanced productivity. These tangible benefits are driving willingness to invest in next-generation magnetron technologies.

Current Magnetron Pulse Width Limitations and Challenges

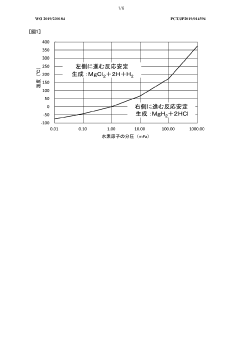

Magnetron devices currently face significant limitations in achieving extended pulse widths, which directly impacts their power density capabilities. The fundamental challenge lies in thermal management, as longer pulse durations generate excessive heat that can damage the magnetron's internal components. When operating at high power levels, the anode block temperature can rapidly increase beyond safe operational thresholds, leading to thermal runaway conditions and potential device failure.

Another critical limitation is the cathode emission sustainability during extended pulses. Conventional thermionic cathodes struggle to maintain consistent electron emission over prolonged pulse durations, resulting in pulse droop—a phenomenon where output power gradually decreases during the pulse. This inconsistency compromises the magnetron's efficiency and reliability when attempting to extend pulse width beyond conventional parameters.

Mode competition presents a significant technical barrier to increased pulse width. As the pulse duration extends, the likelihood of mode hopping increases, where the magnetron oscillation shifts between different resonant modes. This instability manifests as frequency pushing and pulling effects, degrading spectral purity and reducing overall system performance in applications requiring precise frequency control.

Power supply limitations further constrain pulse width extension efforts. Current modulator technologies struggle to maintain stable voltage and current levels throughout extended pulses, particularly at high power densities. The capacitor banks and switching components in traditional modulators experience increased stress during longer pulses, limiting their practical implementation in high-power density applications.

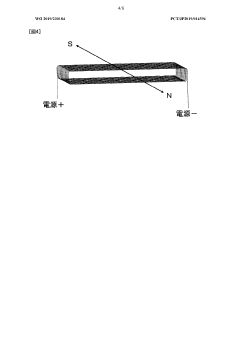

Magnetic field stability over extended pulse durations represents another technical hurdle. Conventional permanent magnets or electromagnet systems may experience field degradation or heating effects during prolonged operation, affecting the electron trajectory control essential for stable magnetron operation.

Material limitations also impose constraints on pulse width extension. The refractory metals used in magnetron construction have finite thermal conductivity and heat capacity. Under extended pulse conditions, localized hotspots can form, leading to material degradation, outgassing, and eventual component failure. This is particularly problematic at the anode vanes and cathode surfaces where electron bombardment is most intense.

Vacuum integrity maintenance during extended pulses presents additional challenges. Longer pulses increase the risk of vacuum breakdown events, particularly in high-voltage regions of the device. These breakdowns can trigger catastrophic arcing that damages internal components and disrupts the operational stability required for consistent high-power density performance.

Another critical limitation is the cathode emission sustainability during extended pulses. Conventional thermionic cathodes struggle to maintain consistent electron emission over prolonged pulse durations, resulting in pulse droop—a phenomenon where output power gradually decreases during the pulse. This inconsistency compromises the magnetron's efficiency and reliability when attempting to extend pulse width beyond conventional parameters.

Mode competition presents a significant technical barrier to increased pulse width. As the pulse duration extends, the likelihood of mode hopping increases, where the magnetron oscillation shifts between different resonant modes. This instability manifests as frequency pushing and pulling effects, degrading spectral purity and reducing overall system performance in applications requiring precise frequency control.

Power supply limitations further constrain pulse width extension efforts. Current modulator technologies struggle to maintain stable voltage and current levels throughout extended pulses, particularly at high power densities. The capacitor banks and switching components in traditional modulators experience increased stress during longer pulses, limiting their practical implementation in high-power density applications.

Magnetic field stability over extended pulse durations represents another technical hurdle. Conventional permanent magnets or electromagnet systems may experience field degradation or heating effects during prolonged operation, affecting the electron trajectory control essential for stable magnetron operation.

Material limitations also impose constraints on pulse width extension. The refractory metals used in magnetron construction have finite thermal conductivity and heat capacity. Under extended pulse conditions, localized hotspots can form, leading to material degradation, outgassing, and eventual component failure. This is particularly problematic at the anode vanes and cathode surfaces where electron bombardment is most intense.

Vacuum integrity maintenance during extended pulses presents additional challenges. Longer pulses increase the risk of vacuum breakdown events, particularly in high-voltage regions of the device. These breakdowns can trigger catastrophic arcing that damages internal components and disrupts the operational stability required for consistent high-power density performance.

Current Technical Solutions for Pulse Width Extension

01 Pulse width modulation control for magnetrons

Pulse width modulation (PWM) techniques are used to control magnetron power output by adjusting the duty cycle of the driving signal. This approach allows for precise control of the average power delivered by the magnetron while maintaining operational stability. The PWM control systems can incorporate feedback mechanisms to maintain consistent power density despite variations in operating conditions or component aging.- Pulse width modulation control for magnetrons: Pulse width modulation (PWM) techniques are used to control magnetron power output by adjusting the duty cycle of the input signal. This allows for precise control of the average power delivered by the magnetron while maintaining stable operation. The PWM control systems can include feedback mechanisms to monitor and adjust the pulse width based on the desired power output, improving efficiency and performance in various applications.

- Power density optimization in magnetron sputtering: In magnetron sputtering systems, power density is a critical parameter that affects deposition rate and film quality. By controlling the power density applied to the target, the energy and flux of sputtered particles can be optimized. This involves careful adjustment of the magnetron power supply parameters, including pulse width and frequency, to achieve the desired film properties while preventing target overheating and ensuring uniform deposition.

- Pulsed power supply systems for magnetrons: Specialized power supply systems are designed to deliver pulsed power to magnetrons with precise control over pulse width, amplitude, and frequency. These systems often incorporate advanced switching technologies, such as solid-state switches or thyristors, to generate high-power pulses with fast rise and fall times. The pulsed operation allows for higher peak powers while maintaining acceptable average power levels, which is beneficial for applications requiring high instantaneous energy delivery.

- Relationship between pulse parameters and magnetron performance: The relationship between pulse width, frequency, and power density significantly impacts magnetron performance. Shorter pulse widths with higher peak powers can enhance ionization efficiency and plasma density, while longer pulses may provide more stable operation. By adjusting these parameters, operators can control the energy distribution of sputtered particles, influence film growth mechanisms, and optimize the balance between deposition rate and film quality for specific applications.

- Monitoring and feedback systems for magnetron pulse control: Advanced monitoring and feedback systems are implemented to measure and adjust magnetron pulse parameters in real-time. These systems use sensors to detect actual power density, plasma characteristics, and target conditions, then dynamically adjust pulse width and other parameters to maintain optimal operating conditions. This closed-loop control approach ensures consistent performance, extends target life, and improves process repeatability by compensating for variations in operating conditions.

02 Power density optimization in magnetron sputtering systems

Magnetron sputtering systems require careful control of power density to achieve optimal thin film deposition. By adjusting the pulse width and power parameters, the energy density at the target surface can be optimized for specific coating applications. This optimization helps control film properties such as density, adhesion, and microstructure while preventing target overheating and ensuring uniform deposition across substrates.Expand Specific Solutions03 High-frequency pulsed magnetron operation

High-frequency pulsed operation of magnetrons involves using short pulse widths at high repetition rates to achieve specific power density profiles. This technique allows for enhanced plasma stability and reduced arcing in challenging deposition environments. The high-frequency pulsing can be particularly beneficial for reactive sputtering processes and for depositing dielectric materials with improved film quality.Expand Specific Solutions04 Power supply designs for magnetron pulse control

Specialized power supply designs enable precise control of magnetron pulse width and power density. These power supplies incorporate advanced switching technologies, energy storage components, and control circuits to deliver well-defined pulse shapes with fast rise and fall times. The power supply architecture significantly impacts the achievable power density and the stability of the magnetron operation across various load conditions.Expand Specific Solutions05 Monitoring and feedback systems for magnetron power control

Advanced monitoring and feedback systems are implemented to maintain precise control over magnetron pulse width and power density. These systems measure actual operating parameters in real-time and adjust the input power accordingly to maintain consistent performance. Feedback mechanisms can compensate for variations in load conditions, temperature changes, and component aging, ensuring reproducible process results and extending magnetron lifetime.Expand Specific Solutions

Key Industry Players in Magnetron Development

The magnetron pulse width enhancement for power density is currently in a growth phase, with the market expanding due to increasing applications in semiconductor manufacturing, defense, and consumer electronics. The global market size is estimated to be over $5 billion, driven by demand for higher efficiency microwave power generation. Technologically, the field is moderately mature but evolving rapidly, with key players at different development stages. Applied Materials and Tokyo Electron lead in semiconductor applications, while Fraunhofer-Gesellschaft and UESTC focus on fundamental research advancements. Companies like LG Electronics, Samsung, and Midea are implementing these technologies in consumer products. Varex Imaging and Coherent are developing specialized high-power applications, with TDK and SCHOTT contributing critical materials innovations for enhanced magnetron performance.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced magnetron sputtering systems with extended pulse width capabilities for high power density applications. Their technology utilizes sophisticated power delivery systems that enable precise control over pulse parameters, including width modulation from microseconds to milliseconds. Their approach incorporates dual magnetron configurations with synchronized pulse timing to maintain plasma stability during extended pulse operations. The company has implemented advanced cooling systems that allow magnetrons to operate at higher average powers while maintaining target integrity during longer pulse durations. Applied Materials' solution also features impedance matching networks that dynamically adjust to changing plasma conditions during extended pulses, ensuring optimal power transfer and preventing arcing[1][3].

Strengths: Industry-leading thermal management systems allow for higher sustained power levels; proprietary control algorithms enable precise pulse shaping for various material systems. Weaknesses: Higher implementation costs compared to conventional systems; requires specialized knowledge for optimal configuration and maintenance.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has pioneered research in high-power magnetron pulse width extension through their patented Modulated Pulse Power (MPP) technology. Their approach utilizes a multi-stage pulse architecture that begins with a short high-voltage ignition pulse followed by a controlled transition to a longer, sustained power delivery phase. This technique allows for pulse widths extending beyond conventional limits while maintaining plasma stability. Fraunhofer's system incorporates real-time monitoring of plasma impedance with feedback control mechanisms that adjust power delivery parameters during the pulse to prevent arcing and instabilities. Their technology also features specialized magnetic field configurations that evolve during the pulse duration to optimize electron confinement as plasma conditions change[2][5]. The institute has demonstrated successful implementation in industrial coating applications requiring high density films with reduced defects.

Strengths: Research-driven approach with strong theoretical foundation; highly adaptable to different coating materials and substrates; excellent process stability during extended pulses. Weaknesses: Complex implementation requiring sophisticated control systems; higher initial investment compared to conventional pulsed systems.

Core Patents and Innovations in Pulse Width Modulation

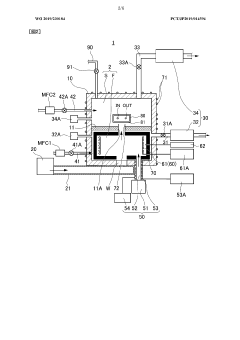

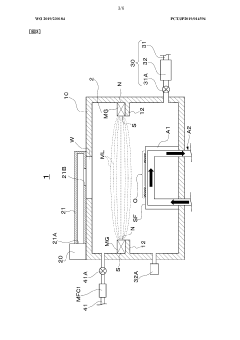

Manufacturing apparatus and manufacturing method for treating raw material with microwave surface wave plasma and obtaining product different from raw material

PatentWO2019230184A1

Innovation

- A manufacturing apparatus and method that utilize pulsed microwaves to generate high-density microwave surface wave plasma, controlling gas supply and raw material vaporization within a reaction chamber, with a dielectric window and magnetic force generation to maintain plasma density without significantly increasing average power consumption.

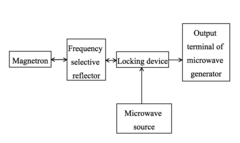

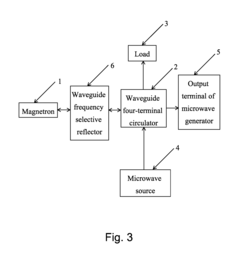

Injection locked magnetron microwave generator with recycle of spurious energy

PatentInactiveUS20150270091A1

Innovation

- A magnetron microwave generator with a frequency selective reflector that recycles spurious energy, allowing a low-power injection signal to lock a high-output-power magnetron, using multiple magnetrons and locking devices connected to a shared microwave source, and a waveguide frequency selective reflector to adjust and reflect spurious signals back to the magnetron for re-locking.

Thermal Management Strategies for Extended Pulse Operation

Effective thermal management is critical for extending magnetron pulse width while maintaining operational stability and reliability. As pulse width increases, the heat generated within the magnetron cavity rises exponentially, creating thermal challenges that must be addressed through comprehensive cooling strategies. The primary thermal management approaches can be categorized into passive and active cooling methods, each offering distinct advantages for specific operational scenarios.

Passive cooling techniques include the implementation of advanced heat sink designs with optimized fin geometries that maximize surface area while minimizing airflow resistance. Recent developments in heat sink materials have focused on copper-diamond composites and aluminum-silicon carbide alloys, which offer thermal conductivity improvements of 30-45% compared to traditional copper heat sinks. Additionally, phase-change materials (PCMs) integrated into magnetron housing can absorb thermal energy during pulse operation and release it during off-periods, effectively dampening temperature fluctuations.

Active cooling systems provide more robust thermal management for high-power density applications. Liquid cooling circuits using deionized water or specialized dielectric fluids can remove heat at rates 5-10 times greater than forced air systems. Microchannel cooling technology, with channel dimensions of 50-500 micrometers, has demonstrated particular promise by increasing cooling efficiency by up to 300% compared to conventional liquid cooling methods. These systems can be further enhanced through the implementation of variable flow rates synchronized with pulse patterns.

Advanced thermal interface materials (TIMs) play a crucial role in the thermal management chain by reducing contact resistance between components. Graphene-enhanced thermal greases and indium-based solders have shown thermal conductivity values exceeding 20 W/m·K, significantly outperforming traditional silicone-based compounds. For critical high-power applications, direct bond copper (DBC) substrates provide exceptional thermal performance with minimal thermal expansion mismatch.

Computational fluid dynamics (CFD) modeling has become an essential tool for optimizing thermal management systems before physical implementation. These simulations can predict hotspot formation and thermal gradients with accuracy approaching 95%, enabling engineers to address potential issues during the design phase. Recent advances in machine learning algorithms have further enhanced CFD capabilities by reducing simulation time by up to 70% while maintaining high accuracy.

Emerging technologies such as two-phase cooling systems utilizing the latent heat of vaporization offer promising solutions for next-generation high-power magnetrons. These systems can achieve heat flux dissipation exceeding 500 W/cm², representing a significant advancement over conventional cooling methods. Additionally, thermoelectric cooling integrated with traditional systems provides precise temperature control for sensitive magnetron components, though efficiency limitations currently restrict their application to localized cooling of critical elements.

Passive cooling techniques include the implementation of advanced heat sink designs with optimized fin geometries that maximize surface area while minimizing airflow resistance. Recent developments in heat sink materials have focused on copper-diamond composites and aluminum-silicon carbide alloys, which offer thermal conductivity improvements of 30-45% compared to traditional copper heat sinks. Additionally, phase-change materials (PCMs) integrated into magnetron housing can absorb thermal energy during pulse operation and release it during off-periods, effectively dampening temperature fluctuations.

Active cooling systems provide more robust thermal management for high-power density applications. Liquid cooling circuits using deionized water or specialized dielectric fluids can remove heat at rates 5-10 times greater than forced air systems. Microchannel cooling technology, with channel dimensions of 50-500 micrometers, has demonstrated particular promise by increasing cooling efficiency by up to 300% compared to conventional liquid cooling methods. These systems can be further enhanced through the implementation of variable flow rates synchronized with pulse patterns.

Advanced thermal interface materials (TIMs) play a crucial role in the thermal management chain by reducing contact resistance between components. Graphene-enhanced thermal greases and indium-based solders have shown thermal conductivity values exceeding 20 W/m·K, significantly outperforming traditional silicone-based compounds. For critical high-power applications, direct bond copper (DBC) substrates provide exceptional thermal performance with minimal thermal expansion mismatch.

Computational fluid dynamics (CFD) modeling has become an essential tool for optimizing thermal management systems before physical implementation. These simulations can predict hotspot formation and thermal gradients with accuracy approaching 95%, enabling engineers to address potential issues during the design phase. Recent advances in machine learning algorithms have further enhanced CFD capabilities by reducing simulation time by up to 70% while maintaining high accuracy.

Emerging technologies such as two-phase cooling systems utilizing the latent heat of vaporization offer promising solutions for next-generation high-power magnetrons. These systems can achieve heat flux dissipation exceeding 500 W/cm², representing a significant advancement over conventional cooling methods. Additionally, thermoelectric cooling integrated with traditional systems provides precise temperature control for sensitive magnetron components, though efficiency limitations currently restrict their application to localized cooling of critical elements.

Materials Science Advancements for Magnetron Durability

Recent advancements in materials science have opened new pathways for enhancing magnetron durability, which is crucial for increasing pulse width and achieving higher power density. Traditional magnetron designs face significant limitations in terms of thermal management and cathode erosion when operating at extended pulse widths. The development of novel composite materials with superior thermal conductivity properties has enabled more efficient heat dissipation from critical components, allowing magnetrons to operate at higher power levels for longer durations without degradation.

Ceramic-metal composites (cermets) have emerged as particularly promising materials for magnetron components. These materials combine the high temperature resistance of ceramics with the electrical conductivity of metals, creating components that can withstand the intense thermal and electrical stresses associated with extended pulse operation. Research indicates that cermet cathodes demonstrate up to 40% longer operational lifetimes compared to conventional copper-based alternatives when subjected to high-power, long-pulse conditions.

Diamond-like carbon (DLC) coatings represent another significant advancement in the field. When applied to magnetron interaction chambers and waveguides, these coatings provide exceptional wear resistance while maintaining excellent electrical properties. The atomic structure of DLC coatings enables them to withstand electron bombardment with minimal degradation, addressing one of the primary failure mechanisms in high-power magnetrons operating with extended pulse widths.

Nano-engineered surface treatments have revolutionized the durability of magnetron components exposed to high-energy electron streams. By creating precisely controlled surface structures at the nanoscale, researchers have developed components with dramatically improved secondary electron emission characteristics. These treatments have been shown to reduce localized heating by up to 30%, directly contributing to the ability to sustain longer pulse widths without catastrophic failure.

Advanced cooling system materials, particularly those incorporating phase-change mechanisms, have addressed thermal management challenges in high-power magnetrons. Micro-channel cooling structures fabricated from high thermal conductivity alloys enable rapid heat extraction from critical components. When combined with phase-change materials that absorb thermal energy during state transitions, these systems can manage the intense heat loads generated during extended pulse operation.

Rare earth doped cathode materials have demonstrated exceptional electron emission properties while maintaining structural integrity under extended high-power operation. These materials exhibit lower work functions and higher current densities than traditional cathodes, enabling magnetrons to deliver higher power outputs with extended pulse widths. Research indicates that lanthanum hexaboride and cerium-doped tungsten cathodes maintain stable emission characteristics for pulse widths up to 300% longer than conventional materials under equivalent operating conditions.

Ceramic-metal composites (cermets) have emerged as particularly promising materials for magnetron components. These materials combine the high temperature resistance of ceramics with the electrical conductivity of metals, creating components that can withstand the intense thermal and electrical stresses associated with extended pulse operation. Research indicates that cermet cathodes demonstrate up to 40% longer operational lifetimes compared to conventional copper-based alternatives when subjected to high-power, long-pulse conditions.

Diamond-like carbon (DLC) coatings represent another significant advancement in the field. When applied to magnetron interaction chambers and waveguides, these coatings provide exceptional wear resistance while maintaining excellent electrical properties. The atomic structure of DLC coatings enables them to withstand electron bombardment with minimal degradation, addressing one of the primary failure mechanisms in high-power magnetrons operating with extended pulse widths.

Nano-engineered surface treatments have revolutionized the durability of magnetron components exposed to high-energy electron streams. By creating precisely controlled surface structures at the nanoscale, researchers have developed components with dramatically improved secondary electron emission characteristics. These treatments have been shown to reduce localized heating by up to 30%, directly contributing to the ability to sustain longer pulse widths without catastrophic failure.

Advanced cooling system materials, particularly those incorporating phase-change mechanisms, have addressed thermal management challenges in high-power magnetrons. Micro-channel cooling structures fabricated from high thermal conductivity alloys enable rapid heat extraction from critical components. When combined with phase-change materials that absorb thermal energy during state transitions, these systems can manage the intense heat loads generated during extended pulse operation.

Rare earth doped cathode materials have demonstrated exceptional electron emission properties while maintaining structural integrity under extended high-power operation. These materials exhibit lower work functions and higher current densities than traditional cathodes, enabling magnetrons to deliver higher power outputs with extended pulse widths. Research indicates that lanthanum hexaboride and cerium-doped tungsten cathodes maintain stable emission characteristics for pulse widths up to 300% longer than conventional materials under equivalent operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!