How to Manage Polyurethane Waste for Environmental Benefits?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyurethane Waste Management Background and Objectives

Polyurethane, a versatile synthetic polymer, has become ubiquitous in modern society due to its wide range of applications across industries. However, the increasing use of polyurethane has led to a significant environmental challenge: the management of polyurethane waste. This issue has gained prominence in recent years as global awareness of environmental sustainability has grown.

The evolution of polyurethane waste management can be traced back to the mid-20th century when polyurethane production began to scale up. Initially, the focus was primarily on disposal rather than recycling or reuse. As environmental concerns gained traction in the 1970s and 1980s, there was a gradual shift towards exploring more sustainable waste management practices.

In the past two decades, technological advancements and stricter environmental regulations have accelerated the development of innovative solutions for polyurethane waste management. The industry has witnessed a paradigm shift from linear "take-make-dispose" models to more circular approaches that emphasize recycling, recovery, and reuse of polyurethane materials.

The primary objective of modern polyurethane waste management is to minimize environmental impact while maximizing resource efficiency. This involves developing and implementing strategies that reduce the volume of waste sent to landfills, decrease greenhouse gas emissions associated with incineration, and recover valuable materials from end-of-life polyurethane products.

Key technological goals in this field include improving the efficiency and cost-effectiveness of mechanical recycling processes, advancing chemical recycling techniques to break down polyurethane into its constituent components, and developing bio-based alternatives that are more easily biodegradable. Additionally, there is a growing focus on designing polyurethane products with end-of-life considerations in mind, facilitating easier disassembly and recycling.

The future trajectory of polyurethane waste management is likely to be shaped by emerging technologies such as artificial intelligence and machine learning, which can optimize sorting and recycling processes. Furthermore, the integration of polyurethane waste management into broader circular economy initiatives is expected to drive innovation and collaboration across industries.

As we look ahead, the polyurethane industry faces the challenge of balancing the material's valuable properties with the imperative of environmental stewardship. The successful management of polyurethane waste for environmental benefits will require a multifaceted approach, combining technological innovation, policy support, and industry-wide cooperation to create a more sustainable future for this essential material.

The evolution of polyurethane waste management can be traced back to the mid-20th century when polyurethane production began to scale up. Initially, the focus was primarily on disposal rather than recycling or reuse. As environmental concerns gained traction in the 1970s and 1980s, there was a gradual shift towards exploring more sustainable waste management practices.

In the past two decades, technological advancements and stricter environmental regulations have accelerated the development of innovative solutions for polyurethane waste management. The industry has witnessed a paradigm shift from linear "take-make-dispose" models to more circular approaches that emphasize recycling, recovery, and reuse of polyurethane materials.

The primary objective of modern polyurethane waste management is to minimize environmental impact while maximizing resource efficiency. This involves developing and implementing strategies that reduce the volume of waste sent to landfills, decrease greenhouse gas emissions associated with incineration, and recover valuable materials from end-of-life polyurethane products.

Key technological goals in this field include improving the efficiency and cost-effectiveness of mechanical recycling processes, advancing chemical recycling techniques to break down polyurethane into its constituent components, and developing bio-based alternatives that are more easily biodegradable. Additionally, there is a growing focus on designing polyurethane products with end-of-life considerations in mind, facilitating easier disassembly and recycling.

The future trajectory of polyurethane waste management is likely to be shaped by emerging technologies such as artificial intelligence and machine learning, which can optimize sorting and recycling processes. Furthermore, the integration of polyurethane waste management into broader circular economy initiatives is expected to drive innovation and collaboration across industries.

As we look ahead, the polyurethane industry faces the challenge of balancing the material's valuable properties with the imperative of environmental stewardship. The successful management of polyurethane waste for environmental benefits will require a multifaceted approach, combining technological innovation, policy support, and industry-wide cooperation to create a more sustainable future for this essential material.

Market Demand for Sustainable Polyurethane Disposal

The market demand for sustainable polyurethane disposal has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on waste management. Polyurethane, a versatile polymer used in various industries, poses significant challenges in terms of disposal due to its durability and resistance to degradation. This has created a pressing need for innovative and environmentally friendly solutions to manage polyurethane waste effectively.

The global polyurethane market is projected to continue its growth trajectory, with an estimated annual production of over 18 million tons. As production increases, so does the volume of polyurethane waste generated, creating a substantial market opportunity for sustainable disposal methods. Industries such as automotive, construction, and furniture manufacturing are particularly keen on finding eco-friendly alternatives to traditional disposal practices, which often involve landfilling or incineration.

Consumer awareness and demand for sustainable products have also played a crucial role in driving the market for responsible polyurethane waste management. End-users are increasingly seeking products with lower environmental footprints, putting pressure on manufacturers to adopt more sustainable practices throughout the product lifecycle, including disposal.

Government regulations and environmental policies have further catalyzed the demand for sustainable polyurethane disposal solutions. Many countries have implemented stringent waste management regulations, imposing higher costs on traditional disposal methods and incentivizing the development of more sustainable alternatives. This regulatory landscape has created a favorable market environment for innovative waste management technologies and services.

The circular economy concept has gained significant traction in recent years, influencing the polyurethane industry's approach to waste management. There is a growing demand for technologies that can recycle or upcycle polyurethane waste, transforming it into valuable raw materials or new products. This shift towards circularity has opened up new market opportunities for companies specializing in polyurethane recycling and repurposing.

Furthermore, the construction and automotive industries, which are major consumers of polyurethane products, have shown increased interest in sustainable disposal methods. These sectors are actively seeking partners and technologies that can help them meet their sustainability goals and comply with evolving environmental regulations. This trend has created a significant market pull for innovative polyurethane waste management solutions.

In conclusion, the market demand for sustainable polyurethane disposal is robust and growing, driven by environmental concerns, regulatory pressures, and shifting consumer preferences. This demand presents substantial opportunities for companies that can develop and commercialize effective, environmentally friendly solutions for managing polyurethane waste.

The global polyurethane market is projected to continue its growth trajectory, with an estimated annual production of over 18 million tons. As production increases, so does the volume of polyurethane waste generated, creating a substantial market opportunity for sustainable disposal methods. Industries such as automotive, construction, and furniture manufacturing are particularly keen on finding eco-friendly alternatives to traditional disposal practices, which often involve landfilling or incineration.

Consumer awareness and demand for sustainable products have also played a crucial role in driving the market for responsible polyurethane waste management. End-users are increasingly seeking products with lower environmental footprints, putting pressure on manufacturers to adopt more sustainable practices throughout the product lifecycle, including disposal.

Government regulations and environmental policies have further catalyzed the demand for sustainable polyurethane disposal solutions. Many countries have implemented stringent waste management regulations, imposing higher costs on traditional disposal methods and incentivizing the development of more sustainable alternatives. This regulatory landscape has created a favorable market environment for innovative waste management technologies and services.

The circular economy concept has gained significant traction in recent years, influencing the polyurethane industry's approach to waste management. There is a growing demand for technologies that can recycle or upcycle polyurethane waste, transforming it into valuable raw materials or new products. This shift towards circularity has opened up new market opportunities for companies specializing in polyurethane recycling and repurposing.

Furthermore, the construction and automotive industries, which are major consumers of polyurethane products, have shown increased interest in sustainable disposal methods. These sectors are actively seeking partners and technologies that can help them meet their sustainability goals and comply with evolving environmental regulations. This trend has created a significant market pull for innovative polyurethane waste management solutions.

In conclusion, the market demand for sustainable polyurethane disposal is robust and growing, driven by environmental concerns, regulatory pressures, and shifting consumer preferences. This demand presents substantial opportunities for companies that can develop and commercialize effective, environmentally friendly solutions for managing polyurethane waste.

Current Challenges in Polyurethane Waste Handling

The management of polyurethane waste presents significant challenges due to its complex chemical structure and widespread use across various industries. One of the primary issues is the lack of efficient recycling methods for polyurethane materials. Unlike thermoplastics, polyurethanes are thermoset polymers, making them difficult to melt and reshape without degrading their properties. This characteristic severely limits traditional recycling approaches and necessitates the development of innovative techniques.

Another major challenge is the diverse composition of polyurethane waste streams. Polyurethanes are used in a wide range of applications, from furniture and automotive parts to insulation and footwear. Each application may involve different additives, fillers, and chemical formulations, resulting in a heterogeneous waste stream that complicates sorting and processing. This diversity makes it challenging to implement standardized recycling processes across the industry.

The environmental persistence of polyurethane waste is also a significant concern. When disposed of in landfills, polyurethanes can take hundreds of years to decompose, contributing to long-term environmental pollution. Moreover, the incineration of polyurethane waste, while sometimes used as a disposal method, can release toxic gases and contribute to air pollution if not properly controlled.

Economic factors pose additional challenges to effective polyurethane waste management. The costs associated with collecting, sorting, and processing polyurethane waste often outweigh the value of recovered materials, making recycling initiatives financially unsustainable without external support or regulatory incentives. This economic barrier has hindered the development and implementation of large-scale recycling infrastructure for polyurethane waste.

Furthermore, the lack of comprehensive regulations and standardized practices for polyurethane waste management across different regions and countries creates inconsistencies in handling procedures. This regulatory gap makes it difficult to establish unified approaches to waste collection, processing, and recycling on a global scale.

The technical limitations in current recycling technologies also present significant hurdles. While some methods, such as mechanical recycling and chemical recycling, show promise, they often struggle with maintaining the quality and performance of recycled polyurethane materials. This quality degradation limits the applications of recycled polyurethanes, often relegating them to lower-value products.

Addressing these challenges requires a multifaceted approach involving technological innovation, regulatory support, and industry collaboration. Developing more efficient and cost-effective recycling technologies, implementing extended producer responsibility programs, and creating markets for recycled polyurethane products are crucial steps toward improving the environmental sustainability of polyurethane waste management.

Another major challenge is the diverse composition of polyurethane waste streams. Polyurethanes are used in a wide range of applications, from furniture and automotive parts to insulation and footwear. Each application may involve different additives, fillers, and chemical formulations, resulting in a heterogeneous waste stream that complicates sorting and processing. This diversity makes it challenging to implement standardized recycling processes across the industry.

The environmental persistence of polyurethane waste is also a significant concern. When disposed of in landfills, polyurethanes can take hundreds of years to decompose, contributing to long-term environmental pollution. Moreover, the incineration of polyurethane waste, while sometimes used as a disposal method, can release toxic gases and contribute to air pollution if not properly controlled.

Economic factors pose additional challenges to effective polyurethane waste management. The costs associated with collecting, sorting, and processing polyurethane waste often outweigh the value of recovered materials, making recycling initiatives financially unsustainable without external support or regulatory incentives. This economic barrier has hindered the development and implementation of large-scale recycling infrastructure for polyurethane waste.

Furthermore, the lack of comprehensive regulations and standardized practices for polyurethane waste management across different regions and countries creates inconsistencies in handling procedures. This regulatory gap makes it difficult to establish unified approaches to waste collection, processing, and recycling on a global scale.

The technical limitations in current recycling technologies also present significant hurdles. While some methods, such as mechanical recycling and chemical recycling, show promise, they often struggle with maintaining the quality and performance of recycled polyurethane materials. This quality degradation limits the applications of recycled polyurethanes, often relegating them to lower-value products.

Addressing these challenges requires a multifaceted approach involving technological innovation, regulatory support, and industry collaboration. Developing more efficient and cost-effective recycling technologies, implementing extended producer responsibility programs, and creating markets for recycled polyurethane products are crucial steps toward improving the environmental sustainability of polyurethane waste management.

Existing Polyurethane Waste Treatment Solutions

01 Recycling and reuse of polyurethane waste

Polyurethane waste can be recycled and reused in various applications, reducing the amount of waste sent to landfills. This process involves collecting, sorting, and processing polyurethane waste to create new products or materials. Recycling polyurethane waste helps conserve resources, reduce energy consumption, and minimize environmental impact.- Recycling and reuse of polyurethane waste: Polyurethane waste can be recycled and reused in various applications, reducing the amount of waste sent to landfills. This process involves collecting, sorting, and processing polyurethane waste to create new products or materials. Recycling polyurethane waste helps conserve resources, reduce energy consumption, and minimize environmental impact.

- Energy recovery from polyurethane waste: Polyurethane waste can be used as an alternative fuel source in energy recovery processes. This method involves burning the waste in controlled environments to generate heat or electricity. Energy recovery from polyurethane waste reduces the reliance on fossil fuels and helps in waste management, contributing to overall environmental benefits.

- Biodegradable polyurethane formulations: Development of biodegradable polyurethane formulations helps reduce the environmental impact of polyurethane waste. These formulations are designed to break down naturally in the environment, reducing long-term pollution and waste accumulation. Biodegradable polyurethanes can be used in various applications while minimizing their ecological footprint.

- Polyurethane waste in construction materials: Incorporating polyurethane waste into construction materials offers environmental benefits by reducing the need for virgin resources and diverting waste from landfills. Polyurethane waste can be used as a filler or additive in concrete, asphalt, and other building materials, improving their properties while promoting sustainable construction practices.

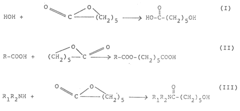

- Chemical recycling of polyurethane waste: Chemical recycling processes can break down polyurethane waste into its original chemical components or other valuable chemicals. This method allows for the recovery of raw materials that can be used to produce new polyurethane products or other materials. Chemical recycling offers a more sustainable approach to managing polyurethane waste compared to traditional disposal methods.

02 Energy recovery from polyurethane waste

Polyurethane waste can be used as an alternative fuel source in energy recovery processes. This method involves burning the waste in controlled conditions to generate heat or electricity. Energy recovery from polyurethane waste reduces reliance on fossil fuels and helps manage waste more efficiently, contributing to a reduction in greenhouse gas emissions.Expand Specific Solutions03 Chemical recycling of polyurethane waste

Chemical recycling processes can break down polyurethane waste into its original chemical components or other valuable chemicals. These recovered materials can then be used to produce new polyurethane products or other materials. This approach helps close the loop in the polyurethane lifecycle, reducing the need for virgin raw materials and minimizing waste.Expand Specific Solutions04 Biodegradable polyurethane alternatives

Development of biodegradable polyurethane alternatives can help reduce the environmental impact of polyurethane waste. These materials are designed to break down naturally in the environment, reducing long-term pollution and waste accumulation. Biodegradable polyurethanes can be used in various applications while offering improved end-of-life management.Expand Specific Solutions05 Waste reduction through improved manufacturing processes

Implementing more efficient manufacturing processes can help reduce polyurethane waste generation at the source. This includes optimizing material usage, improving production techniques, and implementing quality control measures to minimize defects and waste. By reducing waste during production, the overall environmental impact of polyurethane products can be decreased.Expand Specific Solutions

Key Players in Polyurethane Waste Management Industry

The management of polyurethane waste for environmental benefits is an evolving field in the mature polyurethane industry. The market for sustainable polyurethane waste management is growing, driven by increasing environmental concerns and regulatory pressures. While the technology is still developing, several key players are making significant strides. Companies like Covestro, BASF, and Bayer AG are at the forefront, leveraging their extensive experience in polyurethane production to develop innovative recycling solutions. Emerging players such as Zhejiang Huafon New Materials and Shandong Dongte Environmental Technology are also contributing to the advancement of recycling technologies. The industry is transitioning from traditional disposal methods to more sustainable practices, with a focus on chemical recycling and upcycling processes to maximize environmental benefits and resource efficiency.

Bayer AG

Technical Solution: Bayer, through its material science division (now part of Covestro), has developed a process called "dream reaction" for recycling polyurethane. This method involves using a special catalyst to break down polyurethane into its original components - polyol and isocyanate. These raw materials can then be used to create new polyurethane products. The process is particularly effective for flexible foams and can be applied to a wide range of polyurethane waste sources, including automotive parts and furniture.

Strengths: High-quality output suitable for various applications, applicable to diverse waste sources. Weaknesses: May require precise control of reaction conditions, potentially limiting scalability.

BASF Corp.

Technical Solution: BASF has developed a chemical recycling process for polyurethane waste called ChemCycling. This innovative technology breaks down polyurethane foam into its basic chemical components, which can then be used to produce new polyurethane products. The process involves pyrolysis, where the waste material is heated in the absence of oxygen, converting it into pyrolysis oil. This oil is then further refined and used as a feedstock for new polyurethane production, effectively closing the loop in the material's lifecycle.

Strengths: Enables true circular economy for polyurethane, reduces reliance on fossil resources, and minimizes waste. Weaknesses: Energy-intensive process, may require high initial investment, and depends on efficient waste collection systems.

Innovative Approaches to Polyurethane Recycling

Process for recycling plastics

PatentInactiveEP0736564A2

Innovation

- A recycling process that involves swelling polyurethane waste in suitable agents, comminuting it to form a free-flowing gel, and then dissolving or chemically reacting it with polyols and other additives to produce new polyurethane products without generating additional toxic by-products, allowing for the incorporation of other plastics and adjusting the hydroxyl group content for optimal processing.

Process for recycling of polyurethane from solvent-containing waste pastes from the production of polyurethanes

PatentInactiveEP0510301A1

Innovation

- A method involving the addition of methyl ethyl ketone to achieve a 30% dry weight, mixing with acyl polyethylene glycol ester as an emulsifier, followed by steam distillation to separate and recover solvent and polyurethane, producing a reusable polyurethane granulate through filtration and drying.

Environmental Regulations on Polyurethane Waste

Environmental regulations on polyurethane waste have become increasingly stringent in recent years, reflecting growing concerns about the environmental impact of this widely used material. These regulations vary across different regions and countries, but generally aim to minimize the environmental footprint of polyurethane throughout its lifecycle, from production to disposal.

In the European Union, the Waste Framework Directive (2008/98/EC) sets the overarching legal framework for waste management, including polyurethane waste. This directive emphasizes the waste hierarchy, prioritizing prevention, reuse, and recycling over disposal. The EU has also implemented specific regulations targeting end-of-life vehicles and waste electrical and electronic equipment (WEEE), both of which often contain polyurethane components.

The United States Environmental Protection Agency (EPA) regulates polyurethane waste under the Resource Conservation and Recovery Act (RCRA). This act classifies certain polyurethane wastes as hazardous, particularly those containing isocyanates or other toxic substances. Facilities generating or handling such wastes must comply with strict storage, transportation, and disposal requirements.

In China, the Law on the Prevention and Control of Environmental Pollution by Solid Waste governs the management of polyurethane waste. Recent amendments to this law have introduced more stringent requirements for waste producers, including mandatory recycling quotas and extended producer responsibility schemes.

Many countries have implemented landfill bans or restrictions on polyurethane waste, encouraging alternative disposal methods such as recycling or energy recovery. For instance, Japan's Home Appliance Recycling Law mandates the recycling of polyurethane foam from refrigerators and air conditioners.

Regulations are also evolving to address emerging concerns, such as microplastics pollution from polyurethane degradation. The EU's proposed Microplastics Restriction under REACH aims to limit the intentional use of microplastics, including those derived from polyurethane, in various products.

As environmental awareness grows, regulations are likely to become more stringent, potentially including mandatory recycling targets, extended producer responsibility schemes, and stricter controls on the use of certain additives in polyurethane production. Companies operating in the polyurethane industry must stay informed about these evolving regulations to ensure compliance and minimize environmental impacts.

In the European Union, the Waste Framework Directive (2008/98/EC) sets the overarching legal framework for waste management, including polyurethane waste. This directive emphasizes the waste hierarchy, prioritizing prevention, reuse, and recycling over disposal. The EU has also implemented specific regulations targeting end-of-life vehicles and waste electrical and electronic equipment (WEEE), both of which often contain polyurethane components.

The United States Environmental Protection Agency (EPA) regulates polyurethane waste under the Resource Conservation and Recovery Act (RCRA). This act classifies certain polyurethane wastes as hazardous, particularly those containing isocyanates or other toxic substances. Facilities generating or handling such wastes must comply with strict storage, transportation, and disposal requirements.

In China, the Law on the Prevention and Control of Environmental Pollution by Solid Waste governs the management of polyurethane waste. Recent amendments to this law have introduced more stringent requirements for waste producers, including mandatory recycling quotas and extended producer responsibility schemes.

Many countries have implemented landfill bans or restrictions on polyurethane waste, encouraging alternative disposal methods such as recycling or energy recovery. For instance, Japan's Home Appliance Recycling Law mandates the recycling of polyurethane foam from refrigerators and air conditioners.

Regulations are also evolving to address emerging concerns, such as microplastics pollution from polyurethane degradation. The EU's proposed Microplastics Restriction under REACH aims to limit the intentional use of microplastics, including those derived from polyurethane, in various products.

As environmental awareness grows, regulations are likely to become more stringent, potentially including mandatory recycling targets, extended producer responsibility schemes, and stricter controls on the use of certain additives in polyurethane production. Companies operating in the polyurethane industry must stay informed about these evolving regulations to ensure compliance and minimize environmental impacts.

Economic Viability of Polyurethane Recycling Methods

The economic viability of polyurethane recycling methods is a critical factor in determining the feasibility and sustainability of managing polyurethane waste for environmental benefits. Various recycling techniques have been developed, each with its own cost implications and potential revenue streams.

Mechanical recycling, one of the most straightforward methods, involves grinding polyurethane waste into powder or small particles for use in new products. This method is relatively low-cost and can be economically viable for large-scale operations. However, the market value of recycled polyurethane powder may be limited, affecting the overall profitability.

Chemical recycling, particularly glycolysis, offers a more advanced approach to polyurethane recycling. This process breaks down the polymer into its chemical components, which can then be used to produce new polyurethane products. While the initial investment for chemical recycling facilities is higher, the resulting products often have greater market value, potentially offsetting the increased costs.

Energy recovery through incineration is another option for managing polyurethane waste. This method can generate electricity or heat, providing an economic benefit. However, the environmental impact and regulatory constraints associated with incineration may limit its widespread adoption and economic viability in some regions.

The economic feasibility of polyurethane recycling is also influenced by factors such as collection and transportation costs, energy prices, and the availability of virgin raw materials. As petroleum prices fluctuate, the cost-competitiveness of recycled polyurethane materials may change, affecting the overall economic viability of recycling operations.

Government policies and regulations play a significant role in shaping the economic landscape for polyurethane recycling. Incentives, such as tax breaks or subsidies for recycling operations, can improve the financial attractiveness of these methods. Conversely, stricter regulations on waste disposal may increase the cost of alternative disposal methods, making recycling more economically competitive.

Market demand for recycled polyurethane products is another crucial factor. As sustainability becomes increasingly important to consumers and businesses, the demand for products containing recycled materials may grow, potentially increasing the value of recycled polyurethane and improving the economic viability of recycling methods.

In conclusion, the economic viability of polyurethane recycling methods varies depending on the specific technique employed, market conditions, regulatory environment, and technological advancements. As the industry continues to innovate and scale up recycling operations, the economic feasibility of these methods is likely to improve, contributing to more sustainable management of polyurethane waste.

Mechanical recycling, one of the most straightforward methods, involves grinding polyurethane waste into powder or small particles for use in new products. This method is relatively low-cost and can be economically viable for large-scale operations. However, the market value of recycled polyurethane powder may be limited, affecting the overall profitability.

Chemical recycling, particularly glycolysis, offers a more advanced approach to polyurethane recycling. This process breaks down the polymer into its chemical components, which can then be used to produce new polyurethane products. While the initial investment for chemical recycling facilities is higher, the resulting products often have greater market value, potentially offsetting the increased costs.

Energy recovery through incineration is another option for managing polyurethane waste. This method can generate electricity or heat, providing an economic benefit. However, the environmental impact and regulatory constraints associated with incineration may limit its widespread adoption and economic viability in some regions.

The economic feasibility of polyurethane recycling is also influenced by factors such as collection and transportation costs, energy prices, and the availability of virgin raw materials. As petroleum prices fluctuate, the cost-competitiveness of recycled polyurethane materials may change, affecting the overall economic viability of recycling operations.

Government policies and regulations play a significant role in shaping the economic landscape for polyurethane recycling. Incentives, such as tax breaks or subsidies for recycling operations, can improve the financial attractiveness of these methods. Conversely, stricter regulations on waste disposal may increase the cost of alternative disposal methods, making recycling more economically competitive.

Market demand for recycled polyurethane products is another crucial factor. As sustainability becomes increasingly important to consumers and businesses, the demand for products containing recycled materials may grow, potentially increasing the value of recycled polyurethane and improving the economic viability of recycling methods.

In conclusion, the economic viability of polyurethane recycling methods varies depending on the specific technique employed, market conditions, regulatory environment, and technological advancements. As the industry continues to innovate and scale up recycling operations, the economic feasibility of these methods is likely to improve, contributing to more sustainable management of polyurethane waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!