How to Maximize Benefits of PLA in Product Design?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA in Product Design: Background and Objectives

Polylactic acid (PLA) has emerged as a promising material in product design, offering a sustainable alternative to traditional petroleum-based plastics. The journey of PLA began in the 1930s when it was first synthesized by Wallace Carothers at DuPont. However, it wasn't until the late 20th century that PLA gained significant attention due to growing environmental concerns and the need for biodegradable materials.

The evolution of PLA technology has been driven by advancements in fermentation processes, polymer science, and manufacturing techniques. Initially limited by high production costs and narrow application scope, PLA has undergone substantial improvements in its mechanical properties, thermal stability, and processability over the past few decades. This progress has expanded its potential in various industries, including packaging, textiles, and medical devices.

The primary objective in maximizing the benefits of PLA in product design is to harness its unique properties while addressing its limitations. PLA offers biodegradability, biocompatibility, and the ability to be derived from renewable resources. These characteristics align well with the growing demand for environmentally friendly products and circular economy principles. However, challenges such as brittleness, low heat resistance, and moisture sensitivity need to be overcome to broaden its application spectrum.

Recent technological trends in PLA development focus on enhancing its performance through blending with other materials, developing new copolymers, and optimizing processing conditions. Researchers and industry players are exploring ways to improve PLA's mechanical strength, thermal stability, and barrier properties without compromising its biodegradability. Additionally, efforts are being made to reduce production costs and increase the efficiency of PLA manufacturing processes.

The future trajectory of PLA in product design is closely tied to global sustainability goals and the shift towards a bio-based economy. As regulations on single-use plastics tighten and consumer awareness of environmental issues grows, PLA is poised to play a crucial role in the transition to more sustainable materials. The technology is expected to evolve towards tailored PLA formulations for specific applications, improved end-of-life management strategies, and integration with advanced manufacturing techniques such as 3D printing.

To maximize the benefits of PLA in product design, a multidisciplinary approach is necessary. This involves collaboration between material scientists, product designers, and sustainability experts to develop innovative solutions that leverage PLA's unique properties. The goal is to create products that not only meet performance requirements but also contribute to reducing environmental impact throughout their lifecycle.

The evolution of PLA technology has been driven by advancements in fermentation processes, polymer science, and manufacturing techniques. Initially limited by high production costs and narrow application scope, PLA has undergone substantial improvements in its mechanical properties, thermal stability, and processability over the past few decades. This progress has expanded its potential in various industries, including packaging, textiles, and medical devices.

The primary objective in maximizing the benefits of PLA in product design is to harness its unique properties while addressing its limitations. PLA offers biodegradability, biocompatibility, and the ability to be derived from renewable resources. These characteristics align well with the growing demand for environmentally friendly products and circular economy principles. However, challenges such as brittleness, low heat resistance, and moisture sensitivity need to be overcome to broaden its application spectrum.

Recent technological trends in PLA development focus on enhancing its performance through blending with other materials, developing new copolymers, and optimizing processing conditions. Researchers and industry players are exploring ways to improve PLA's mechanical strength, thermal stability, and barrier properties without compromising its biodegradability. Additionally, efforts are being made to reduce production costs and increase the efficiency of PLA manufacturing processes.

The future trajectory of PLA in product design is closely tied to global sustainability goals and the shift towards a bio-based economy. As regulations on single-use plastics tighten and consumer awareness of environmental issues grows, PLA is poised to play a crucial role in the transition to more sustainable materials. The technology is expected to evolve towards tailored PLA formulations for specific applications, improved end-of-life management strategies, and integration with advanced manufacturing techniques such as 3D printing.

To maximize the benefits of PLA in product design, a multidisciplinary approach is necessary. This involves collaboration between material scientists, product designers, and sustainability experts to develop innovative solutions that leverage PLA's unique properties. The goal is to create products that not only meet performance requirements but also contribute to reducing environmental impact throughout their lifecycle.

Market Analysis for PLA-based Products

The market for PLA-based products has been experiencing significant growth in recent years, driven by increasing environmental awareness and the shift towards sustainable materials. PLA, or polylactic acid, is a biodegradable and renewable thermoplastic derived from plant-based sources such as corn starch or sugarcane. This eco-friendly alternative to traditional petroleum-based plastics has found applications across various industries, including packaging, textiles, and consumer goods.

In the packaging sector, PLA has gained traction due to its compostable nature and ability to reduce carbon footprint. The food and beverage industry, in particular, has shown a strong interest in PLA-based packaging solutions for items such as disposable cutlery, food containers, and beverage bottles. This trend is expected to continue as more companies commit to sustainability goals and consumers demand environmentally responsible products.

The textile industry has also embraced PLA-based fibers as a sustainable alternative to synthetic materials. PLA fibers are being used in the production of clothing, upholstery, and non-woven fabrics. The growing demand for eco-friendly fashion and home textiles has created a favorable market environment for PLA-based products in this sector.

Consumer goods manufacturers are increasingly incorporating PLA into their product designs, particularly in the production of disposable items and durable goods. Examples include biodegradable trash bags, compostable diapers, and even 3D printing filaments. The versatility of PLA allows for its use in a wide range of applications, from rigid containers to flexible films.

The automotive industry has also shown interest in PLA-based materials for interior components, as automakers seek to reduce the environmental impact of their vehicles. PLA's lightweight properties and potential for reducing fuel consumption make it an attractive option for certain automotive applications.

Despite the positive market outlook, challenges remain for PLA-based products. These include higher production costs compared to conventional plastics, limitations in heat resistance, and the need for proper composting facilities to ensure effective biodegradation. However, ongoing research and development efforts are addressing these issues, potentially expanding the market opportunities for PLA-based products.

As governments worldwide implement stricter regulations on single-use plastics and promote circular economy principles, the demand for PLA-based alternatives is expected to grow. This regulatory push, combined with changing consumer preferences, is likely to drive further innovation and market expansion in the PLA sector.

In the packaging sector, PLA has gained traction due to its compostable nature and ability to reduce carbon footprint. The food and beverage industry, in particular, has shown a strong interest in PLA-based packaging solutions for items such as disposable cutlery, food containers, and beverage bottles. This trend is expected to continue as more companies commit to sustainability goals and consumers demand environmentally responsible products.

The textile industry has also embraced PLA-based fibers as a sustainable alternative to synthetic materials. PLA fibers are being used in the production of clothing, upholstery, and non-woven fabrics. The growing demand for eco-friendly fashion and home textiles has created a favorable market environment for PLA-based products in this sector.

Consumer goods manufacturers are increasingly incorporating PLA into their product designs, particularly in the production of disposable items and durable goods. Examples include biodegradable trash bags, compostable diapers, and even 3D printing filaments. The versatility of PLA allows for its use in a wide range of applications, from rigid containers to flexible films.

The automotive industry has also shown interest in PLA-based materials for interior components, as automakers seek to reduce the environmental impact of their vehicles. PLA's lightweight properties and potential for reducing fuel consumption make it an attractive option for certain automotive applications.

Despite the positive market outlook, challenges remain for PLA-based products. These include higher production costs compared to conventional plastics, limitations in heat resistance, and the need for proper composting facilities to ensure effective biodegradation. However, ongoing research and development efforts are addressing these issues, potentially expanding the market opportunities for PLA-based products.

As governments worldwide implement stricter regulations on single-use plastics and promote circular economy principles, the demand for PLA-based alternatives is expected to grow. This regulatory push, combined with changing consumer preferences, is likely to drive further innovation and market expansion in the PLA sector.

Technical Challenges in PLA Application

Despite the numerous advantages of Polylactic Acid (PLA) in product design, several technical challenges persist in its application. One of the primary obstacles is the material's inherent brittleness, which limits its use in applications requiring high impact resistance or flexibility. This characteristic often necessitates the addition of plasticizers or blending with other polymers, potentially compromising the material's biodegradability or increasing production costs.

Another significant challenge lies in PLA's relatively low heat resistance. With a glass transition temperature of around 60°C, PLA products can deform or lose structural integrity when exposed to elevated temperatures. This limitation restricts its use in applications involving hot liquids or environments with high ambient temperatures, necessitating the development of heat-resistant PLA formulations or alternative cooling strategies in manufacturing processes.

The moisture sensitivity of PLA presents additional complications during processing and storage. Exposure to humidity can lead to hydrolysis, causing degradation of the polymer chains and compromising the material's mechanical properties. This necessitates careful control of environmental conditions during production, storage, and transportation, adding complexity and cost to the supply chain.

PLA's slow crystallization rate poses challenges in injection molding processes, often resulting in extended cycle times and reduced production efficiency. This characteristic can lead to inconsistencies in part quality and dimensional stability, particularly in large or thick-walled components. Addressing this issue requires careful optimization of processing parameters or the use of nucleating agents to enhance crystallization kinetics.

The limited availability of high-molecular-weight PLA grades suitable for certain applications, such as film extrusion or fiber spinning, presents another technical hurdle. Developing PLA formulations with enhanced melt strength and processability remains an active area of research, as these properties are crucial for expanding the material's applicability in various product design scenarios.

Furthermore, achieving consistent color and appearance in PLA products can be challenging due to the material's sensitivity to processing conditions and additives. This issue is particularly relevant in consumer goods applications where aesthetic consistency is crucial. Overcoming this challenge requires careful formulation of colorants and stabilizers compatible with PLA's unique chemical structure.

Lastly, the end-of-life management of PLA products presents both opportunities and challenges. While PLA is biodegradable under specific conditions, ensuring proper disposal and composting infrastructure remains a significant hurdle in many regions. Additionally, the potential contamination of PLA waste streams with conventional plastics can complicate recycling efforts, necessitating the development of efficient sorting and recycling technologies tailored to bioplastics.

Another significant challenge lies in PLA's relatively low heat resistance. With a glass transition temperature of around 60°C, PLA products can deform or lose structural integrity when exposed to elevated temperatures. This limitation restricts its use in applications involving hot liquids or environments with high ambient temperatures, necessitating the development of heat-resistant PLA formulations or alternative cooling strategies in manufacturing processes.

The moisture sensitivity of PLA presents additional complications during processing and storage. Exposure to humidity can lead to hydrolysis, causing degradation of the polymer chains and compromising the material's mechanical properties. This necessitates careful control of environmental conditions during production, storage, and transportation, adding complexity and cost to the supply chain.

PLA's slow crystallization rate poses challenges in injection molding processes, often resulting in extended cycle times and reduced production efficiency. This characteristic can lead to inconsistencies in part quality and dimensional stability, particularly in large or thick-walled components. Addressing this issue requires careful optimization of processing parameters or the use of nucleating agents to enhance crystallization kinetics.

The limited availability of high-molecular-weight PLA grades suitable for certain applications, such as film extrusion or fiber spinning, presents another technical hurdle. Developing PLA formulations with enhanced melt strength and processability remains an active area of research, as these properties are crucial for expanding the material's applicability in various product design scenarios.

Furthermore, achieving consistent color and appearance in PLA products can be challenging due to the material's sensitivity to processing conditions and additives. This issue is particularly relevant in consumer goods applications where aesthetic consistency is crucial. Overcoming this challenge requires careful formulation of colorants and stabilizers compatible with PLA's unique chemical structure.

Lastly, the end-of-life management of PLA products presents both opportunities and challenges. While PLA is biodegradable under specific conditions, ensuring proper disposal and composting infrastructure remains a significant hurdle in many regions. Additionally, the potential contamination of PLA waste streams with conventional plastics can complicate recycling efforts, necessitating the development of efficient sorting and recycling technologies tailored to bioplastics.

Current PLA Design Solutions

01 Biodegradability and environmental friendliness

PLA is a biodegradable polymer derived from renewable resources, making it an environmentally friendly alternative to traditional plastics. It can decompose naturally in the environment, reducing plastic waste and pollution. This property makes PLA suitable for various applications where eco-friendliness is a priority.- Biodegradability and environmental friendliness: PLA is a biodegradable polymer derived from renewable resources, making it an environmentally friendly alternative to traditional plastics. It can decompose naturally in the environment, reducing plastic waste and pollution. This property makes PLA suitable for various applications, particularly in packaging and disposable products.

- Biocompatibility and medical applications: PLA exhibits excellent biocompatibility, making it suitable for various medical applications. It can be used in tissue engineering, drug delivery systems, and biomedical implants. The material's ability to be absorbed by the body over time makes it particularly useful for temporary medical devices and scaffolds in regenerative medicine.

- Versatility in manufacturing processes: PLA can be processed using various manufacturing techniques, including injection molding, extrusion, and 3D printing. This versatility allows for the production of a wide range of products with different shapes and properties. PLA's compatibility with existing manufacturing equipment makes it an attractive option for industries transitioning to more sustainable materials.

- Improved mechanical properties through blending and composites: PLA can be blended with other materials or reinforced with fibers to enhance its mechanical properties. These modifications can improve strength, toughness, and heat resistance, expanding the range of applications for PLA-based materials. Composite materials using PLA as a matrix can combine the benefits of biodegradability with enhanced performance characteristics.

- Potential in packaging and consumer goods: PLA's properties make it an excellent choice for packaging applications and consumer goods. It can be used to create food packaging, disposable cutlery, and other single-use items that are more environmentally friendly than traditional plastics. PLA's clarity and printability also make it suitable for labels and other packaging components that require visual appeal.

02 Biocompatibility and medical applications

PLA exhibits excellent biocompatibility, making it suitable for various medical applications. It can be used in tissue engineering, drug delivery systems, and biodegradable implants. The material's ability to be safely absorbed by the body over time makes it valuable in the medical field for temporary support structures and controlled release of medications.Expand Specific Solutions03 Versatility in manufacturing and processing

PLA can be processed using various manufacturing techniques, including 3D printing, injection molding, and extrusion. This versatility allows for the production of a wide range of products, from packaging materials to consumer goods. The material's adaptability to different processing methods enhances its applicability across multiple industries.Expand Specific Solutions04 Improved mechanical properties through blending and composites

PLA's mechanical properties can be enhanced by blending it with other materials or creating composites. This allows for the development of materials with improved strength, flexibility, and durability while maintaining biodegradability. Such improvements expand the potential applications of PLA in various industries, including automotive and construction.Expand Specific Solutions05 Potential in sustainable packaging solutions

PLA offers significant benefits in the packaging industry as a sustainable alternative to conventional plastics. It can be used to create food packaging, disposable cutlery, and other single-use items that are biodegradable and compostable. This property helps reduce the environmental impact of packaging waste and aligns with growing consumer demand for eco-friendly products.Expand Specific Solutions

Key Players in PLA Industry

The market for maximizing PLA benefits in product design is in a growth phase, driven by increasing demand for sustainable materials. The global PLA market is projected to reach $5.2 billion by 2026, with a CAGR of 19.5%. Technologically, PLA applications are advancing rapidly, with companies like 3M Innovative Properties Co., International Business Machines Corp., and TotalEnergies OneTech SAS leading innovation. Academic institutions such as Sichuan University and Tongji University are contributing to fundamental research. The industry is seeing a convergence of material science, product design, and sustainability, with players like Stora Enso Oyj and Danone SA exploring novel applications in packaging and consumer goods.

3M Innovative Properties Co.

Technical Solution: 3M has developed a proprietary PLA-based technology called "Envision" for sustainable packaging solutions. This technology involves blending PLA with other bio-based materials to enhance its performance characteristics. The resulting material offers improved barrier properties, heat resistance, and durability compared to standard PLA. 3M's approach also includes the development of specialized coatings and additives to further enhance the material's properties for specific applications in food packaging, consumer goods, and industrial products.

Strengths: Enhanced material properties, versatility in applications, and strong brand reputation in materials science. Weaknesses: Potentially higher production costs and the need for specialized processing equipment.

International Business Machines Corp.

Technical Solution: IBM has developed an AI-driven approach to optimize PLA product design. Their system utilizes machine learning algorithms to analyze vast datasets of material properties, manufacturing parameters, and product performance metrics. This allows for rapid iteration and optimization of PLA-based product designs, considering factors such as strength-to-weight ratio, thermal stability, and biodegradability. IBM's technology also incorporates simulation tools to predict product performance under various environmental conditions, enabling designers to make informed decisions about material composition and structural design to maximize the benefits of PLA in specific applications.

Strengths: Advanced AI and data analytics capabilities, potential for significant time and cost savings in product development. Weaknesses: Reliance on large datasets and potential limitations in real-world validation of AI-generated designs.

Innovative PLA Applications

Injection molding sole material, sole containing same and preparation method and application thereof

PatentInactiveUS20230058137A1

Innovation

- A chain extension modified PLA injection molding sole material is developed, incorporating epoxidized soybean oil, SBS, SEBS, heavy calcium, naphthenic oil, and wear-resistant agents, enhancing thermal stability, toughness, and biodegradability, and utilizing a dynamic crosslinking process with TMPTA and zinc oxide to improve molecular weight and properties.

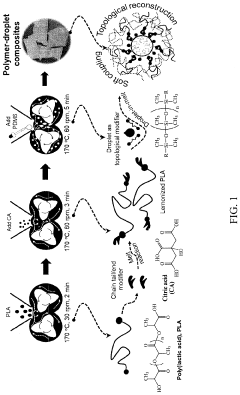

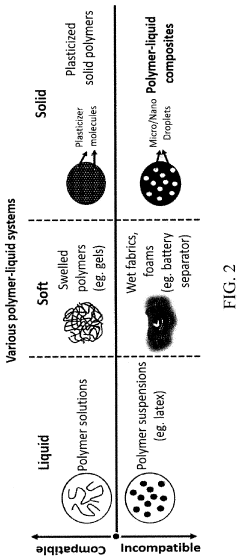

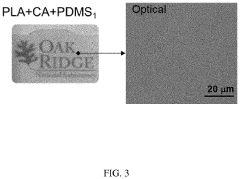

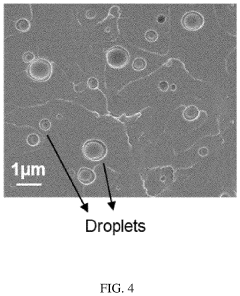

Toughened polyester composites containing polyester matrix and droplets of high boiling liquid therein

PatentActiveUS20200354566A1

Innovation

- The development of topological supertough polymer-droplet composites (PDCs) by incorporating droplets of high boiling point liquids into a polyester matrix, along with a modifier like polycarboxylic, polyol, or polyamine compounds, to create a hierarchical topological super-toughening mechanism, significantly improving toughness and strain rate energy absorption.

Environmental Impact of PLA

The environmental impact of PLA (Polylactic Acid) is a crucial consideration when maximizing its benefits in product design. PLA, derived from renewable resources such as corn starch or sugarcane, offers significant advantages over traditional petroleum-based plastics in terms of sustainability and reduced carbon footprint.

One of the primary environmental benefits of PLA is its biodegradability. Under proper composting conditions, PLA can break down into water, carbon dioxide, and organic matter within a few months to a year. This characteristic significantly reduces the long-term environmental impact associated with plastic waste accumulation in landfills and oceans.

PLA production also consumes less energy compared to conventional plastics, resulting in lower greenhouse gas emissions. Studies have shown that PLA manufacturing can reduce carbon dioxide emissions by up to 80% compared to petroleum-based plastics. This reduction in energy consumption and emissions contributes to mitigating climate change and improving overall environmental sustainability.

Furthermore, PLA's renewable sourcing helps conserve finite fossil fuel resources. By utilizing plant-based materials, PLA production reduces dependence on petroleum, promoting a more sustainable and circular economy. This shift towards bio-based materials aligns with global efforts to reduce reliance on non-renewable resources and minimize environmental degradation associated with fossil fuel extraction.

However, it is essential to consider the potential environmental trade-offs associated with PLA production. The cultivation of crops for PLA feedstock may lead to increased land use, water consumption, and the use of fertilizers and pesticides. These factors can impact biodiversity and contribute to soil degradation if not managed sustainably.

To maximize the environmental benefits of PLA in product design, it is crucial to implement a holistic approach. This includes optimizing the entire lifecycle of PLA products, from raw material sourcing to end-of-life management. Designers should focus on creating products that are not only made from PLA but also designed for easy disassembly, recycling, or composting.

Additionally, improving PLA's durability and performance characteristics can extend product lifespans, reducing the need for frequent replacements and minimizing overall resource consumption. Innovations in PLA formulations and processing techniques can enhance its resistance to heat, moisture, and mechanical stress, making it suitable for a wider range of applications while maintaining its environmental advantages.

One of the primary environmental benefits of PLA is its biodegradability. Under proper composting conditions, PLA can break down into water, carbon dioxide, and organic matter within a few months to a year. This characteristic significantly reduces the long-term environmental impact associated with plastic waste accumulation in landfills and oceans.

PLA production also consumes less energy compared to conventional plastics, resulting in lower greenhouse gas emissions. Studies have shown that PLA manufacturing can reduce carbon dioxide emissions by up to 80% compared to petroleum-based plastics. This reduction in energy consumption and emissions contributes to mitigating climate change and improving overall environmental sustainability.

Furthermore, PLA's renewable sourcing helps conserve finite fossil fuel resources. By utilizing plant-based materials, PLA production reduces dependence on petroleum, promoting a more sustainable and circular economy. This shift towards bio-based materials aligns with global efforts to reduce reliance on non-renewable resources and minimize environmental degradation associated with fossil fuel extraction.

However, it is essential to consider the potential environmental trade-offs associated with PLA production. The cultivation of crops for PLA feedstock may lead to increased land use, water consumption, and the use of fertilizers and pesticides. These factors can impact biodiversity and contribute to soil degradation if not managed sustainably.

To maximize the environmental benefits of PLA in product design, it is crucial to implement a holistic approach. This includes optimizing the entire lifecycle of PLA products, from raw material sourcing to end-of-life management. Designers should focus on creating products that are not only made from PLA but also designed for easy disassembly, recycling, or composting.

Additionally, improving PLA's durability and performance characteristics can extend product lifespans, reducing the need for frequent replacements and minimizing overall resource consumption. Innovations in PLA formulations and processing techniques can enhance its resistance to heat, moisture, and mechanical stress, making it suitable for a wider range of applications while maintaining its environmental advantages.

PLA Regulatory Framework

The regulatory framework for Polylactic Acid (PLA) plays a crucial role in maximizing its benefits in product design. As a biodegradable and renewable material, PLA is subject to various regulations and standards that govern its production, use, and disposal.

In the United States, the Food and Drug Administration (FDA) regulates PLA for food contact applications. The FDA has approved PLA for use in food packaging and other food-contact materials, provided it meets specific safety and performance criteria. This approval has opened up numerous opportunities for PLA in the food industry, allowing designers to create eco-friendly packaging solutions that comply with regulatory requirements.

The European Union has established comprehensive regulations for bioplastics, including PLA, through the European Committee for Standardization (CEN). These standards cover aspects such as biodegradability, compostability, and recycling. The EN 13432 standard, in particular, sets criteria for packaging recoverable through composting and biodegradation, which PLA can meet under certain conditions.

In the realm of medical applications, PLA must adhere to stringent regulatory requirements. The material has gained approval from regulatory bodies such as the FDA and the European Medicines Agency (EMA) for use in various medical devices and drug delivery systems. This regulatory acceptance has enabled product designers to leverage PLA's biocompatibility and biodegradability in innovative medical solutions.

Environmental regulations also significantly impact PLA's use in product design. Many countries have implemented policies to reduce plastic waste and promote the use of biodegradable materials. For instance, France has banned single-use plastic products, creating opportunities for PLA-based alternatives. Similarly, Japan has established the "Green Purchasing Law," which encourages the use of environmentally friendly materials like PLA in government procurement.

The regulatory landscape for PLA is continually evolving, with new standards and certifications emerging to address specific applications and end-of-life scenarios. For example, the development of standards for marine biodegradability is ongoing, which could expand PLA's potential use in marine environments.

Product designers must stay informed about these regulatory developments to maximize the benefits of PLA. Compliance with relevant standards not only ensures legal and environmental responsibility but also opens up new market opportunities. By aligning product designs with regulatory requirements, designers can create innovative, sustainable solutions that meet both consumer demands and regulatory expectations.

In the United States, the Food and Drug Administration (FDA) regulates PLA for food contact applications. The FDA has approved PLA for use in food packaging and other food-contact materials, provided it meets specific safety and performance criteria. This approval has opened up numerous opportunities for PLA in the food industry, allowing designers to create eco-friendly packaging solutions that comply with regulatory requirements.

The European Union has established comprehensive regulations for bioplastics, including PLA, through the European Committee for Standardization (CEN). These standards cover aspects such as biodegradability, compostability, and recycling. The EN 13432 standard, in particular, sets criteria for packaging recoverable through composting and biodegradation, which PLA can meet under certain conditions.

In the realm of medical applications, PLA must adhere to stringent regulatory requirements. The material has gained approval from regulatory bodies such as the FDA and the European Medicines Agency (EMA) for use in various medical devices and drug delivery systems. This regulatory acceptance has enabled product designers to leverage PLA's biocompatibility and biodegradability in innovative medical solutions.

Environmental regulations also significantly impact PLA's use in product design. Many countries have implemented policies to reduce plastic waste and promote the use of biodegradable materials. For instance, France has banned single-use plastic products, creating opportunities for PLA-based alternatives. Similarly, Japan has established the "Green Purchasing Law," which encourages the use of environmentally friendly materials like PLA in government procurement.

The regulatory landscape for PLA is continually evolving, with new standards and certifications emerging to address specific applications and end-of-life scenarios. For example, the development of standards for marine biodegradability is ongoing, which could expand PLA's potential use in marine environments.

Product designers must stay informed about these regulatory developments to maximize the benefits of PLA. Compliance with relevant standards not only ensures legal and environmental responsibility but also opens up new market opportunities. By aligning product designs with regulatory requirements, designers can create innovative, sustainable solutions that meet both consumer demands and regulatory expectations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!