How to Measure Tunneling Magnetoresistance (TMR) with High Accuracy

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TMR Measurement Evolution and Objectives

Tunneling Magnetoresistance (TMR) measurement techniques have evolved significantly since the discovery of the TMR effect in 1975 by Jullière. Initially, measurements were conducted at extremely low temperatures with rudimentary equipment, yielding TMR ratios of only a few percent. The field remained relatively dormant until the 1990s when room-temperature TMR was demonstrated, catalyzing renewed interest in this phenomenon for practical applications.

The evolution of TMR measurement techniques has been closely tied to advancements in thin-film deposition technologies and nanofabrication methods. Early measurements relied on simple two-probe techniques that often introduced significant contact resistance errors. As the field progressed, four-probe measurement methods became standard, allowing for more accurate resistance measurements by eliminating lead and contact resistances.

A significant milestone occurred in the early 2000s with the development of MgO-based tunnel barriers, which dramatically increased TMR ratios from approximately 70% to over 600% at room temperature. This breakthrough necessitated more sophisticated measurement approaches to accurately quantify these larger effects and understand the underlying physics.

Modern TMR measurement objectives focus on achieving high precision and reproducibility across various environmental conditions. Current techniques aim to measure TMR ratios with accuracy better than 0.1%, which is essential for quality control in manufacturing processes for magnetic sensors and MRAM devices. Additionally, there is growing emphasis on measuring TMR under dynamic conditions and at high frequencies to support emerging spintronic applications.

Temperature dependence measurements have become increasingly important, as TMR devices must maintain performance across wide operating temperature ranges (-40°C to 125°C for automotive applications). This has driven the development of specialized measurement setups with precise temperature control and stability.

Another critical objective in contemporary TMR measurement is the ability to characterize tunnel junctions with extremely small dimensions (below 20nm), which presents significant challenges in terms of signal-to-noise ratio and measurement stability. Advanced lock-in amplification techniques and noise reduction strategies have been developed to address these challenges.

The field is now moving toward automated, high-throughput measurement systems capable of characterizing thousands of devices per wafer with statistical analysis capabilities. This evolution supports industrial-scale production of TMR-based devices while maintaining stringent quality standards. Future measurement objectives include real-time monitoring during fabrication processes and non-destructive testing methodologies that can be integrated into production lines.

The evolution of TMR measurement techniques has been closely tied to advancements in thin-film deposition technologies and nanofabrication methods. Early measurements relied on simple two-probe techniques that often introduced significant contact resistance errors. As the field progressed, four-probe measurement methods became standard, allowing for more accurate resistance measurements by eliminating lead and contact resistances.

A significant milestone occurred in the early 2000s with the development of MgO-based tunnel barriers, which dramatically increased TMR ratios from approximately 70% to over 600% at room temperature. This breakthrough necessitated more sophisticated measurement approaches to accurately quantify these larger effects and understand the underlying physics.

Modern TMR measurement objectives focus on achieving high precision and reproducibility across various environmental conditions. Current techniques aim to measure TMR ratios with accuracy better than 0.1%, which is essential for quality control in manufacturing processes for magnetic sensors and MRAM devices. Additionally, there is growing emphasis on measuring TMR under dynamic conditions and at high frequencies to support emerging spintronic applications.

Temperature dependence measurements have become increasingly important, as TMR devices must maintain performance across wide operating temperature ranges (-40°C to 125°C for automotive applications). This has driven the development of specialized measurement setups with precise temperature control and stability.

Another critical objective in contemporary TMR measurement is the ability to characterize tunnel junctions with extremely small dimensions (below 20nm), which presents significant challenges in terms of signal-to-noise ratio and measurement stability. Advanced lock-in amplification techniques and noise reduction strategies have been developed to address these challenges.

The field is now moving toward automated, high-throughput measurement systems capable of characterizing thousands of devices per wafer with statistical analysis capabilities. This evolution supports industrial-scale production of TMR-based devices while maintaining stringent quality standards. Future measurement objectives include real-time monitoring during fabrication processes and non-destructive testing methodologies that can be integrated into production lines.

Market Applications and Demand for Precise TMR Measurements

The demand for high-precision TMR measurement technologies has experienced significant growth across multiple industries, driven by the expanding applications of magnetic tunnel junction (MTJ) devices. The global spintronics market, which encompasses TMR technology, was valued at approximately $3.62 billion in 2022 and is projected to reach $21.89 billion by 2030, growing at a CAGR of 25.2% during the forecast period.

Data storage remains the primary market driver for precise TMR measurements. Hard disk drive (HDD) manufacturers require extremely accurate TMR characterization to develop read heads with higher sensitivity, enabling greater storage densities. Similarly, the emerging MRAM (Magnetoresistive Random Access Memory) sector demands precise TMR measurements to ensure reliable performance and quality control during manufacturing processes.

The automotive industry has emerged as a rapidly growing market for TMR sensors, particularly for applications in advanced driver assistance systems (ADAS). These systems require highly accurate position, speed, and angle measurements under varying environmental conditions. The automotive TMR sensor market alone is expected to grow at a CAGR of 18.7% through 2028, creating substantial demand for precise measurement technologies.

Industrial automation represents another significant market segment. TMR sensors are increasingly deployed in factory automation, robotics, and industrial IoT applications where precise position sensing and contactless measurements are critical. The industrial sensor market is projected to reach $35.4 billion by 2027, with magnetic sensors including TMR technology accounting for approximately 12% of this market.

Healthcare and biomedical applications are creating new demand vectors for high-accuracy TMR measurements. Magnetic biosensors utilizing TMR effects require extremely precise characterization for applications such as point-of-care diagnostics, magnetic particle detection, and lab-on-chip devices. The biomedical sensor market is expected to grow at a CAGR of 16.8% through 2028.

Research institutions and semiconductor manufacturers constitute a specialized but critical market segment. As TMR ratios continue to improve (now exceeding 600% at room temperature in certain materials), the demand for more sophisticated measurement equipment capable of accurately characterizing these high-performance materials has intensified.

Geographically, Asia-Pacific represents the largest market for TMR measurement technologies, driven by the concentration of semiconductor and electronics manufacturing in countries like Japan, South Korea, and China. North America follows closely, with significant demand from research institutions and technology companies developing next-generation magnetic storage and computing solutions.

Data storage remains the primary market driver for precise TMR measurements. Hard disk drive (HDD) manufacturers require extremely accurate TMR characterization to develop read heads with higher sensitivity, enabling greater storage densities. Similarly, the emerging MRAM (Magnetoresistive Random Access Memory) sector demands precise TMR measurements to ensure reliable performance and quality control during manufacturing processes.

The automotive industry has emerged as a rapidly growing market for TMR sensors, particularly for applications in advanced driver assistance systems (ADAS). These systems require highly accurate position, speed, and angle measurements under varying environmental conditions. The automotive TMR sensor market alone is expected to grow at a CAGR of 18.7% through 2028, creating substantial demand for precise measurement technologies.

Industrial automation represents another significant market segment. TMR sensors are increasingly deployed in factory automation, robotics, and industrial IoT applications where precise position sensing and contactless measurements are critical. The industrial sensor market is projected to reach $35.4 billion by 2027, with magnetic sensors including TMR technology accounting for approximately 12% of this market.

Healthcare and biomedical applications are creating new demand vectors for high-accuracy TMR measurements. Magnetic biosensors utilizing TMR effects require extremely precise characterization for applications such as point-of-care diagnostics, magnetic particle detection, and lab-on-chip devices. The biomedical sensor market is expected to grow at a CAGR of 16.8% through 2028.

Research institutions and semiconductor manufacturers constitute a specialized but critical market segment. As TMR ratios continue to improve (now exceeding 600% at room temperature in certain materials), the demand for more sophisticated measurement equipment capable of accurately characterizing these high-performance materials has intensified.

Geographically, Asia-Pacific represents the largest market for TMR measurement technologies, driven by the concentration of semiconductor and electronics manufacturing in countries like Japan, South Korea, and China. North America follows closely, with significant demand from research institutions and technology companies developing next-generation magnetic storage and computing solutions.

Current TMR Measurement Techniques and Limitations

Tunneling Magnetoresistance (TMR) measurement techniques have evolved significantly over the past decades, with several established methodologies now available for researchers and industry professionals. The most widely adopted approach is the four-point probe method, which effectively eliminates contact resistance issues by separating current-carrying and voltage-sensing contacts. This technique allows for precise resistance measurements across magnetic tunnel junctions (MTJs) and has become the gold standard for basic TMR characterization.

For more advanced analysis, lock-in amplifier techniques have gained prominence due to their ability to filter out noise and detect small signal changes. This approach is particularly valuable when measuring high-resistance MTJs or when environmental noise threatens measurement accuracy. The lock-in technique can improve signal-to-noise ratios by orders of magnitude compared to direct DC measurements.

AC impedance spectroscopy represents another sophisticated measurement technique, enabling researchers to analyze frequency-dependent behavior of MTJs. This method provides insights into capacitive and inductive components that may influence TMR readings, especially at higher frequencies relevant to device operation in computing applications.

Despite these advancements, significant limitations persist in current TMR measurement technologies. Temperature instability remains a critical challenge, as even minor thermal fluctuations can substantially alter TMR values. Most commercial systems struggle to maintain temperature stability better than ±0.1°C, which proves insufficient for ultra-high precision measurements where TMR variations can occur at much smaller temperature differentials.

Magnetic field homogeneity presents another substantial limitation. Non-uniform magnetic fields across test samples can lead to incomplete magnetic switching and consequently inaccurate TMR values. Current systems typically achieve field uniformity of approximately 1% across standard sample areas, which becomes problematic for larger arrays or when comparing measurements between different sample positions.

Contact resistance variability continues to plague TMR measurements despite four-point probe implementations. Microscale variations in contact quality can introduce measurement errors, particularly in high-throughput testing environments where contact consistency is difficult to maintain across multiple measurement cycles.

Instrument calibration drift represents a persistent challenge for long-term measurements. Most systems require frequent recalibration, sometimes multiple times daily, to maintain specified accuracy levels. This limitation becomes particularly problematic for experiments requiring extended measurement periods or when comparing data collected over several days.

Finally, current techniques face significant barriers when measuring ultra-thin tunnel barriers, where quantum effects become pronounced. As the industry moves toward thinner barriers for enhanced performance, conventional measurement approaches struggle to account for quantum mechanical phenomena that influence resistance readings in unpredictable ways.

For more advanced analysis, lock-in amplifier techniques have gained prominence due to their ability to filter out noise and detect small signal changes. This approach is particularly valuable when measuring high-resistance MTJs or when environmental noise threatens measurement accuracy. The lock-in technique can improve signal-to-noise ratios by orders of magnitude compared to direct DC measurements.

AC impedance spectroscopy represents another sophisticated measurement technique, enabling researchers to analyze frequency-dependent behavior of MTJs. This method provides insights into capacitive and inductive components that may influence TMR readings, especially at higher frequencies relevant to device operation in computing applications.

Despite these advancements, significant limitations persist in current TMR measurement technologies. Temperature instability remains a critical challenge, as even minor thermal fluctuations can substantially alter TMR values. Most commercial systems struggle to maintain temperature stability better than ±0.1°C, which proves insufficient for ultra-high precision measurements where TMR variations can occur at much smaller temperature differentials.

Magnetic field homogeneity presents another substantial limitation. Non-uniform magnetic fields across test samples can lead to incomplete magnetic switching and consequently inaccurate TMR values. Current systems typically achieve field uniformity of approximately 1% across standard sample areas, which becomes problematic for larger arrays or when comparing measurements between different sample positions.

Contact resistance variability continues to plague TMR measurements despite four-point probe implementations. Microscale variations in contact quality can introduce measurement errors, particularly in high-throughput testing environments where contact consistency is difficult to maintain across multiple measurement cycles.

Instrument calibration drift represents a persistent challenge for long-term measurements. Most systems require frequent recalibration, sometimes multiple times daily, to maintain specified accuracy levels. This limitation becomes particularly problematic for experiments requiring extended measurement periods or when comparing data collected over several days.

Finally, current techniques face significant barriers when measuring ultra-thin tunnel barriers, where quantum effects become pronounced. As the industry moves toward thinner barriers for enhanced performance, conventional measurement approaches struggle to account for quantum mechanical phenomena that influence resistance readings in unpredictable ways.

State-of-the-Art TMR Measurement Solutions

01 TMR sensor structure optimization for accuracy improvement

Optimizing the structure of TMR sensors can significantly improve their accuracy. This includes designing specific layer configurations, adjusting the thickness of magnetic and non-magnetic layers, and implementing specialized barrier materials. These structural optimizations enhance the tunneling effect and increase the magnetoresistance ratio, resulting in more accurate sensing capabilities and reduced noise interference.- TMR sensor structure optimization for accuracy improvement: Optimizing the structure of TMR sensors can significantly improve their accuracy. This includes designing specific layer configurations, adjusting the thickness of magnetic and non-magnetic layers, and implementing specialized barrier materials. These structural optimizations enhance the tunneling effect, resulting in higher magnetoresistance ratios and improved signal-to-noise ratios, which directly contribute to better measurement accuracy in various applications.

- Signal processing techniques for TMR accuracy enhancement: Advanced signal processing techniques can be employed to enhance the accuracy of TMR sensors. These include implementing specialized amplification circuits, noise filtering algorithms, and digital signal processing methods. By effectively processing the raw signals from TMR elements, these techniques can compensate for inherent sensor limitations, reduce environmental interference, and extract more precise measurements from the tunneling magnetoresistance effect.

- Temperature compensation methods for TMR sensors: Temperature fluctuations can significantly affect the accuracy of TMR sensors. Various compensation methods have been developed to mitigate these effects, including the use of reference sensors, temperature-dependent calibration algorithms, and specialized materials with reduced temperature sensitivity. These approaches help maintain consistent sensor performance across a wide temperature range, ensuring reliable and accurate measurements in varying environmental conditions.

- Calibration systems for high-precision TMR measurements: Sophisticated calibration systems are essential for achieving high-precision TMR measurements. These systems may include automated calibration routines, reference standards, and feedback mechanisms that continuously adjust sensor parameters. By implementing comprehensive calibration protocols, systematic errors can be identified and corrected, leading to significantly improved measurement accuracy and repeatability in TMR-based devices and systems.

- Integration of TMR sensors with advanced readout circuitry: The integration of TMR sensors with specialized readout circuitry plays a crucial role in achieving high accuracy. This includes the development of application-specific integrated circuits (ASICs), advanced amplification stages, and sophisticated analog-to-digital converters optimized for TMR signals. The close coupling between sensor elements and readout electronics minimizes signal degradation, reduces noise introduction, and enables more precise measurement of the tunneling magnetoresistance effect.

02 Signal processing techniques for TMR accuracy enhancement

Advanced signal processing techniques can be employed to enhance the accuracy of TMR sensors. These include implementing specialized amplification circuits, noise filtering algorithms, and signal conditioning methods. By processing the raw signals from TMR sensors, unwanted noise can be eliminated and the true magnetoresistance signal can be isolated, leading to more precise measurements and improved overall accuracy.Expand Specific Solutions03 Temperature compensation methods for TMR sensors

Temperature fluctuations can significantly affect the accuracy of TMR sensors. Various compensation methods have been developed to mitigate these effects, including the use of reference sensors, temperature-dependent calibration algorithms, and specialized materials with reduced temperature sensitivity. These approaches help maintain consistent performance across a wide temperature range, ensuring reliable and accurate measurements in varying environmental conditions.Expand Specific Solutions04 Calibration techniques for high-precision TMR measurements

Calibration techniques play a crucial role in achieving high-precision TMR measurements. These include factory calibration procedures, in-field calibration methods, and self-calibration algorithms. By establishing accurate reference points and compensating for systematic errors, these calibration approaches ensure that TMR sensors provide consistent and reliable measurements over their operational lifetime, even as components age or environmental conditions change.Expand Specific Solutions05 Integration of TMR sensors with advanced readout electronics

The integration of TMR sensors with advanced readout electronics significantly improves measurement accuracy. This includes the development of specialized integrated circuits, high-resolution analog-to-digital converters, and optimized sensor interfaces. By closely coupling the sensor element with sophisticated electronics designed specifically for TMR signal characteristics, system-level performance is enhanced, resulting in more accurate magnetic field measurements and improved overall sensing capabilities.Expand Specific Solutions

Leading Research Institutions and Companies in TMR Technology

The Tunneling Magnetoresistance (TMR) measurement landscape is currently in a growth phase, with the market expanding due to increasing applications in data storage, sensors, and MRAM technologies. The global TMR sensor market is projected to reach significant scale as IoT and automotive applications drive demand. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specializations. Everspin Technologies leads in MRAM applications, while TDK and Alps Alpine excel in sensor implementations. Research institutions like Tsinghua University and IMEC contribute fundamental advancements, while semiconductor manufacturers including GlobalFoundries, NXP, and STMicroelectronics integrate TMR into broader product ecosystems. Western Digital and IBM focus on storage applications, creating a competitive ecosystem balancing specialized expertise with manufacturing scale.

Everspin Technologies, Inc.

Technical Solution: Everspin Technologies has developed a comprehensive TMR measurement system that combines specialized test fixtures with proprietary signal processing algorithms. Their approach utilizes a four-point probe measurement technique that eliminates contact resistance effects, crucial for accurate TMR ratio determination. The system incorporates temperature-controlled environments (4K to 400K) to characterize TMR behavior across operating conditions. Everspin's methodology includes both DC and AC measurement capabilities, with lock-in amplifier integration for enhanced signal-to-noise ratio in low-resistance devices. Their advanced calibration protocols account for thermal drift and equipment variations, ensuring measurement repeatability within 0.5%. For production environments, they've implemented automated wafer-level testing systems capable of high-throughput TMR measurements with statistical process control integration.

Strengths: Industry-leading measurement accuracy (±0.2% for TMR ratios) and exceptional repeatability. Their integrated production testing capabilities enable high-volume manufacturing quality control. Weaknesses: Proprietary system requires significant capital investment and specialized training. The measurement setup has limited flexibility for novel device geometries outside standard MRAM configurations.

TDK Corp.

Technical Solution: TDK has pioneered an ultra-precise TMR measurement platform specifically designed for next-generation high-density recording heads and sensors. Their system employs a dual-channel differential measurement approach that effectively cancels common-mode noise, critical for detecting the small resistance changes in advanced TMR devices. TDK's methodology incorporates specialized magnetic field generation systems capable of producing precisely controlled fields up to 2T with uniformity better than 0.1% across the sample area. Their measurement electronics feature custom-designed low-noise amplifiers with noise floors below 1nV/√Hz, enabling detection of resistance changes below 0.01%. For temperature-dependent studies, TDK utilizes a proprietary thermal management system that maintains sample temperature stability within ±0.05K while allowing measurements from cryogenic to elevated temperatures. The entire measurement process is controlled by TDK's advanced automation software that implements real-time data analysis and correction algorithms.

Strengths: Exceptional signal-to-noise ratio enabling measurement of extremely small TMR effects in advanced materials. Their integrated field generation system provides precise control over magnetic conditions during measurement. Weaknesses: The system is optimized primarily for recording head applications and may require significant modifications for other TMR device types. High operational complexity requires specialized expertise to achieve optimal results.

Critical Patents and Literature on High-Accuracy TMR Measurement

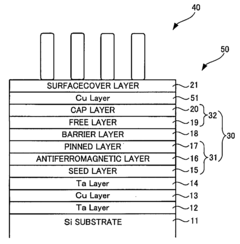

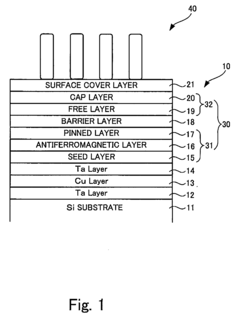

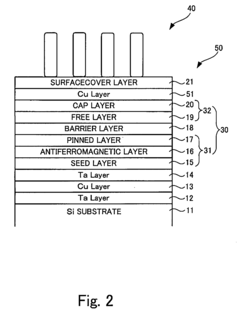

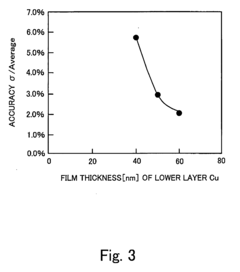

Thin film resistance measurement method and tunnel magnetoresistive element fabrication method

PatentInactiveUS20080174322A1

Innovation

- A thin film resistance measurement method involving a sample preparation step with low resistance layers above and below the thin film, including a surface cover layer to prevent oxidation, and a resistance measurement step using probes applied to the surface, allowing for precise measurement and adjustment of film formation conditions to achieve high accuracy in resistance values.

Method and apparatus for testing tunnel magnetoresistive effect element, manufacturing method of tunnel magnetoresistive effect element and tunnel magnetoresistive effect element

PatentActiveUS7417442B2

Innovation

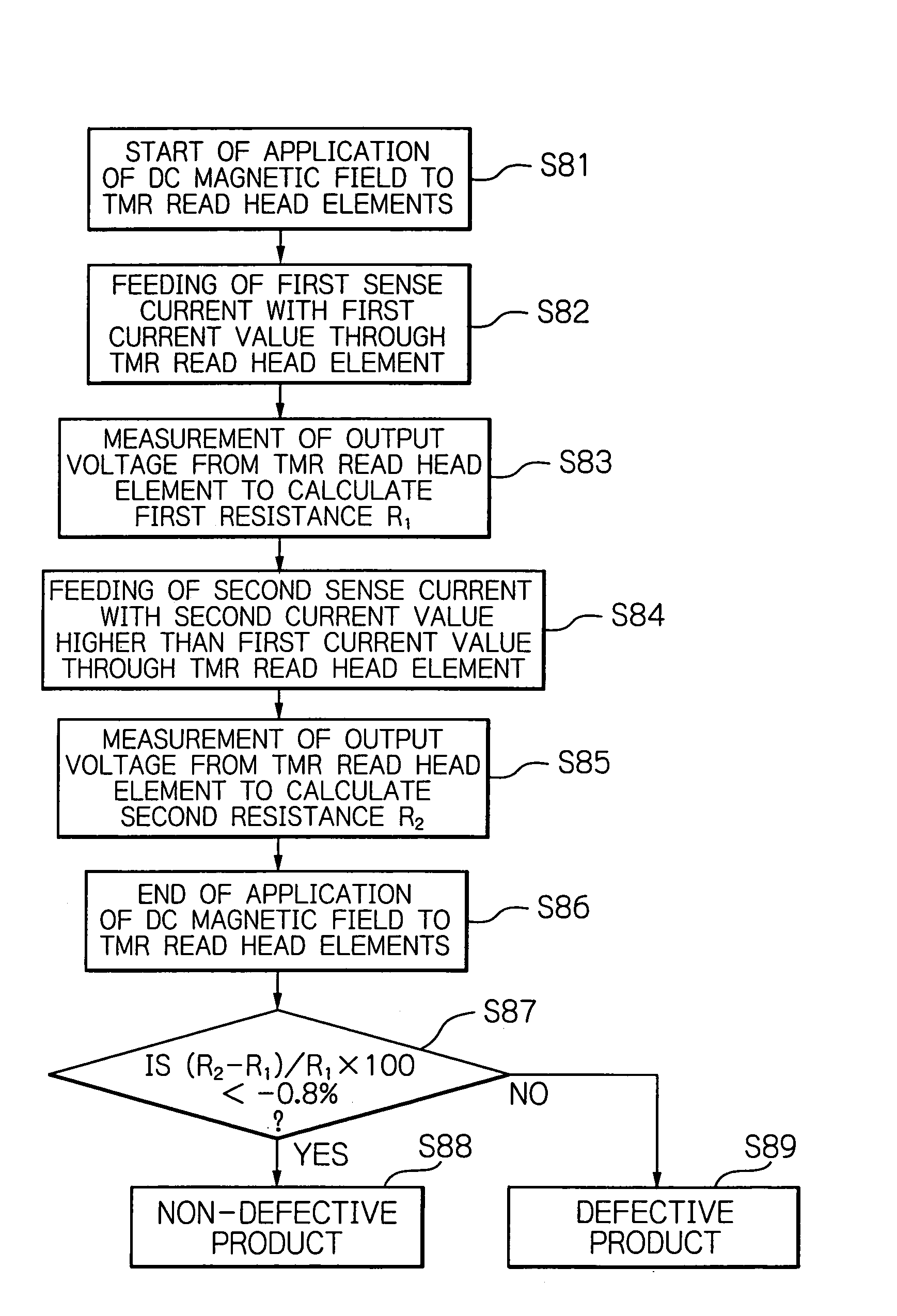

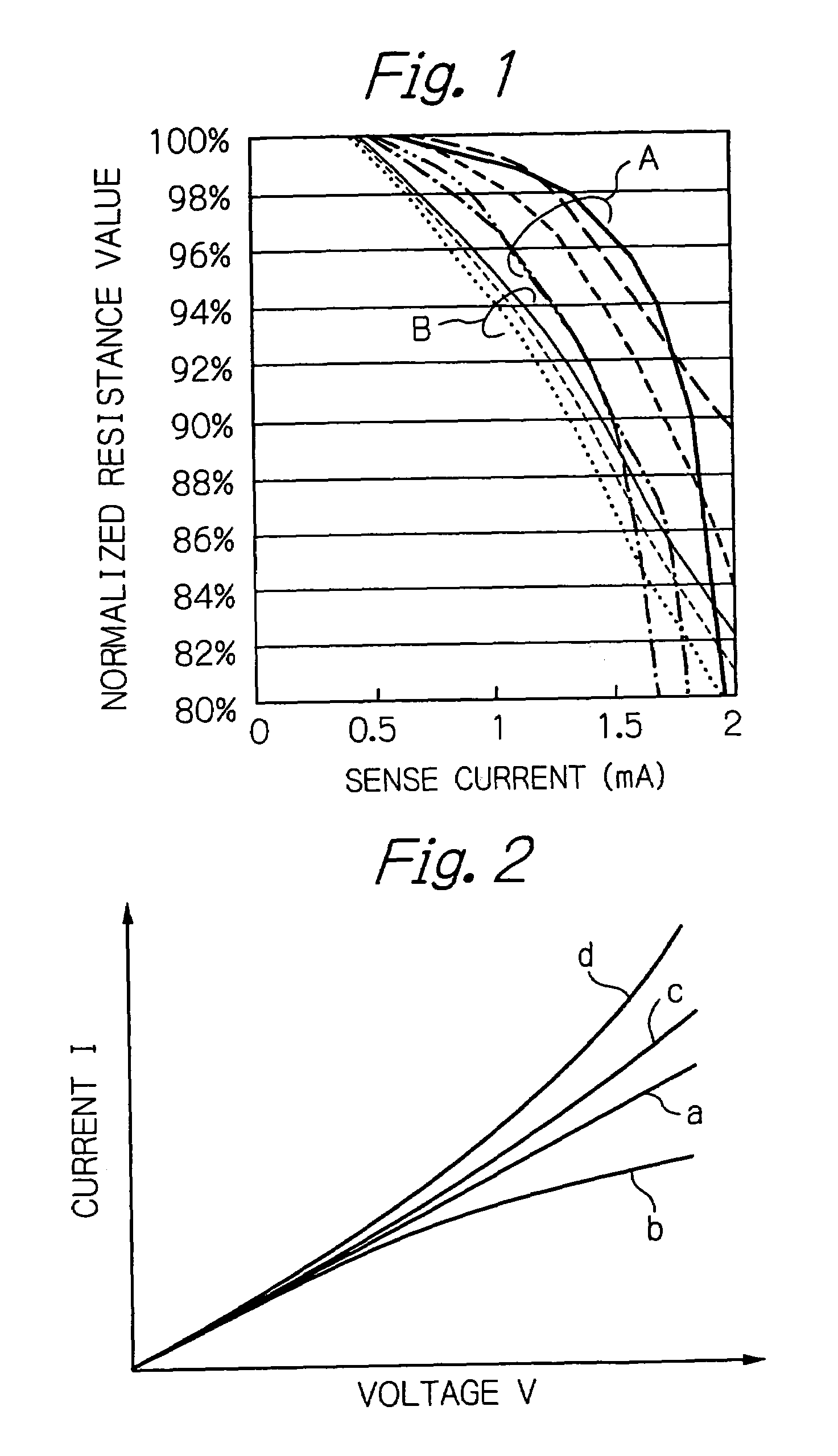

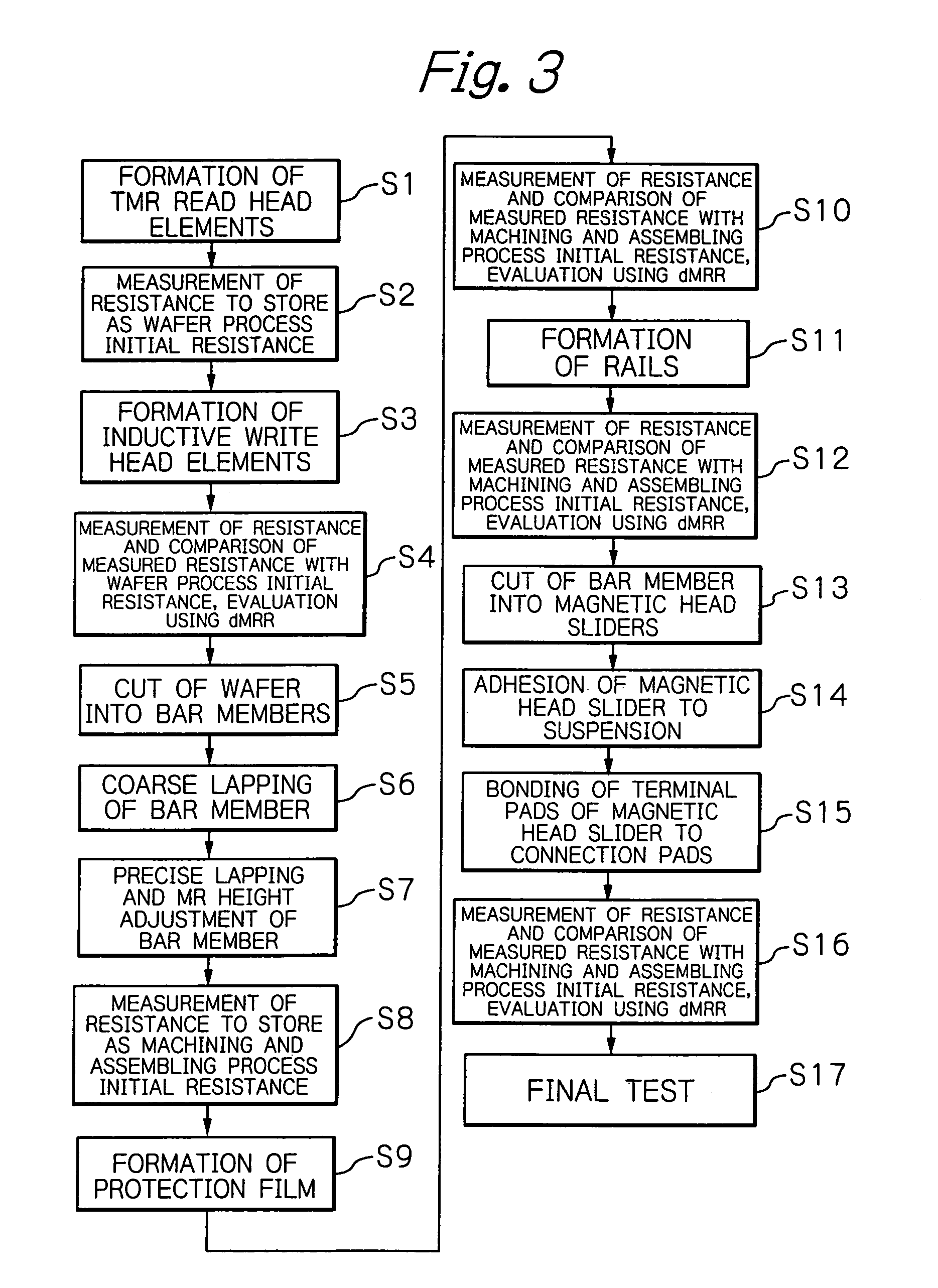

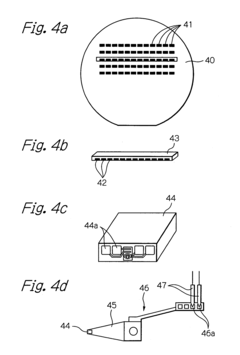

- A method involving the measurement of resistances using multiple sense currents with different current values, calculating the ratio of change in resistance, and evaluating the TMR elements based on this ratio to quickly and easily determine their reliability without causing damage, allowing for 100% inspection of manufactured TMR elements.

Calibration Standards and Reference Materials for TMR Measurements

Accurate measurement of Tunneling Magnetoresistance (TMR) requires well-established calibration standards and reference materials to ensure reliability and reproducibility across different laboratories and measurement systems. Currently, the field faces challenges due to the lack of universally accepted standards specifically designed for TMR measurements.

The National Institute of Standards and Technology (NIST) has developed several reference materials for magnetic measurements that can be adapted for TMR calibration. These include standard reference materials (SRMs) with certified magnetic properties that provide traceability to SI units. For instance, NIST SRM 2853 consists of thin film magnetic multilayers with well-characterized magnetoresistance properties that can serve as calibration references for TMR measurements.

International standards organizations, including IEEE Magnetics Society and the International Electrotechnical Commission (IEC), have been working toward establishing standardized protocols for TMR measurements. The IEEE Standard 1559-2009 provides guidelines for magnetic thin film measurements that can be partially applied to TMR systems, though specific TMR standards are still under development.

Commercial reference samples from companies like Quantum Design and Lake Shore Cryotronics offer another avenue for calibration. These samples typically consist of well-characterized magnetic tunnel junctions with known TMR ratios across different temperature ranges and magnetic field strengths. While useful for relative calibration, these commercial standards often lack the rigorous certification of national metrology institutes.

Round-robin testing programs have emerged as a valuable approach to establish de facto standards in the TMR community. These collaborative efforts involve multiple laboratories measuring identical samples and comparing results to establish consensus values. The European Metrology Research Programme has coordinated several such initiatives specifically for spintronic measurements, including TMR.

For ultra-high precision measurements, on-chip calibration standards are increasingly being integrated into TMR measurement systems. These standards consist of reference tunnel junctions fabricated alongside the test structures using identical processes, allowing for in-situ calibration that accounts for sample-specific variations and environmental factors.

The development of computational reference models also provides a complementary approach to physical standards. These models, based on first-principles calculations and micromagnetic simulations, predict theoretical TMR values for specific material combinations and junction geometries, offering a theoretical benchmark against which experimental measurements can be compared.

The National Institute of Standards and Technology (NIST) has developed several reference materials for magnetic measurements that can be adapted for TMR calibration. These include standard reference materials (SRMs) with certified magnetic properties that provide traceability to SI units. For instance, NIST SRM 2853 consists of thin film magnetic multilayers with well-characterized magnetoresistance properties that can serve as calibration references for TMR measurements.

International standards organizations, including IEEE Magnetics Society and the International Electrotechnical Commission (IEC), have been working toward establishing standardized protocols for TMR measurements. The IEEE Standard 1559-2009 provides guidelines for magnetic thin film measurements that can be partially applied to TMR systems, though specific TMR standards are still under development.

Commercial reference samples from companies like Quantum Design and Lake Shore Cryotronics offer another avenue for calibration. These samples typically consist of well-characterized magnetic tunnel junctions with known TMR ratios across different temperature ranges and magnetic field strengths. While useful for relative calibration, these commercial standards often lack the rigorous certification of national metrology institutes.

Round-robin testing programs have emerged as a valuable approach to establish de facto standards in the TMR community. These collaborative efforts involve multiple laboratories measuring identical samples and comparing results to establish consensus values. The European Metrology Research Programme has coordinated several such initiatives specifically for spintronic measurements, including TMR.

For ultra-high precision measurements, on-chip calibration standards are increasingly being integrated into TMR measurement systems. These standards consist of reference tunnel junctions fabricated alongside the test structures using identical processes, allowing for in-situ calibration that accounts for sample-specific variations and environmental factors.

The development of computational reference models also provides a complementary approach to physical standards. These models, based on first-principles calculations and micromagnetic simulations, predict theoretical TMR values for specific material combinations and junction geometries, offering a theoretical benchmark against which experimental measurements can be compared.

Error Analysis and Uncertainty Quantification in TMR Measurements

Accurate measurement of Tunneling Magnetoresistance (TMR) requires comprehensive understanding of potential error sources and their quantification. Systematic errors in TMR measurements often originate from instrument calibration issues, temperature fluctuations, and contact resistance variations. These systematic uncertainties can significantly impact the reliability of TMR ratio calculations, particularly when measuring high TMR values exceeding 200%.

Statistical uncertainties present another challenge, arising from noise in the measurement system, sample inhomogeneities, and random fluctuations in the magnetic field. Advanced statistical methods such as bootstrapping and Monte Carlo simulations have emerged as valuable tools for quantifying these uncertainties. These approaches enable researchers to establish confidence intervals for TMR measurements, providing a more robust framework for reporting results.

Environmental factors introduce additional complexities in uncertainty quantification. Temperature stability represents a critical parameter, as TMR values typically exhibit temperature dependence that must be accounted for in precision measurements. Similarly, electromagnetic interference can introduce noise that masks the true TMR signal, necessitating appropriate shielding and filtering techniques. Quantifying these environmental contributions to measurement uncertainty requires controlled experimental conditions and reference standards.

Sample-specific variations further complicate TMR measurements. Interface quality between the magnetic layers and the tunnel barrier significantly influences TMR magnitude, while structural defects can create localized variations across the sample. These spatial inhomogeneities necessitate multiple measurements at different sample locations to establish representative TMR values with appropriate uncertainty bounds.

Measurement protocol standardization has emerged as a crucial approach to reducing uncertainties. Round-robin testing between laboratories has revealed significant variations in TMR results for identical samples, highlighting the need for standardized procedures. Recent efforts by international metrology institutes have focused on establishing reference materials and measurement protocols that enable traceability and comparability of TMR measurements across different research groups and industrial settings.

Advanced uncertainty propagation techniques have been developed specifically for TMR measurements. These mathematical frameworks account for correlations between different measurement parameters and their combined effect on the final TMR value. Software tools implementing these techniques now enable researchers to perform comprehensive uncertainty analysis, identifying the dominant error sources and guiding efforts to improve measurement accuracy.

Statistical uncertainties present another challenge, arising from noise in the measurement system, sample inhomogeneities, and random fluctuations in the magnetic field. Advanced statistical methods such as bootstrapping and Monte Carlo simulations have emerged as valuable tools for quantifying these uncertainties. These approaches enable researchers to establish confidence intervals for TMR measurements, providing a more robust framework for reporting results.

Environmental factors introduce additional complexities in uncertainty quantification. Temperature stability represents a critical parameter, as TMR values typically exhibit temperature dependence that must be accounted for in precision measurements. Similarly, electromagnetic interference can introduce noise that masks the true TMR signal, necessitating appropriate shielding and filtering techniques. Quantifying these environmental contributions to measurement uncertainty requires controlled experimental conditions and reference standards.

Sample-specific variations further complicate TMR measurements. Interface quality between the magnetic layers and the tunnel barrier significantly influences TMR magnitude, while structural defects can create localized variations across the sample. These spatial inhomogeneities necessitate multiple measurements at different sample locations to establish representative TMR values with appropriate uncertainty bounds.

Measurement protocol standardization has emerged as a crucial approach to reducing uncertainties. Round-robin testing between laboratories has revealed significant variations in TMR results for identical samples, highlighting the need for standardized procedures. Recent efforts by international metrology institutes have focused on establishing reference materials and measurement protocols that enable traceability and comparability of TMR measurements across different research groups and industrial settings.

Advanced uncertainty propagation techniques have been developed specifically for TMR measurements. These mathematical frameworks account for correlations between different measurement parameters and their combined effect on the final TMR value. Software tools implementing these techniques now enable researchers to perform comprehensive uncertainty analysis, identifying the dominant error sources and guiding efforts to improve measurement accuracy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!