How to Overcome Environmental Challenges with Polyurethane?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyurethane Environmental Challenges and Objectives

Polyurethane, a versatile synthetic polymer, has been widely used in various industries for decades. However, its environmental impact has become a growing concern in recent years. The challenges associated with polyurethane's environmental footprint stem from its production process, usage, and end-of-life disposal. These issues include the use of fossil fuel-based raw materials, energy-intensive manufacturing, release of volatile organic compounds (VOCs), and difficulties in recycling and biodegradation.

The primary objective in addressing these environmental challenges is to develop sustainable alternatives and improve the overall lifecycle of polyurethane products. This involves exploring bio-based raw materials, enhancing energy efficiency in production, reducing VOC emissions, and implementing effective recycling and disposal methods. Additionally, there is a focus on creating polyurethane formulations that maintain or improve upon the material's desirable properties while minimizing its environmental impact.

One of the key goals is to reduce the reliance on petroleum-based polyols and isocyanates by incorporating renewable resources. This includes the development of bio-based polyols derived from vegetable oils, such as soybean, castor, and rapeseed oils. These alternatives not only decrease the carbon footprint but also offer potential improvements in certain material properties.

Another critical objective is to optimize the production process to minimize energy consumption and waste generation. This involves implementing more efficient reactor designs, improving heat recovery systems, and exploring alternative catalysts that enable lower reaction temperatures. Furthermore, there is a push towards developing water-based polyurethane systems that reduce or eliminate the need for organic solvents, thereby lowering VOC emissions.

Addressing the end-of-life challenges of polyurethane products is equally important. Research efforts are focused on designing polyurethanes with improved recyclability and biodegradability. This includes the development of chemically recyclable polyurethanes that can be broken down into their original monomers, as well as exploring enzymatic degradation methods for more environmentally friendly disposal.

The overarching aim is to create a circular economy for polyurethane materials, where products are designed for longevity, reuse, and eventual recycling or biodegradation. This holistic approach requires collaboration between material scientists, chemical engineers, and environmental experts to develop innovative solutions that balance performance, cost-effectiveness, and environmental sustainability.

The primary objective in addressing these environmental challenges is to develop sustainable alternatives and improve the overall lifecycle of polyurethane products. This involves exploring bio-based raw materials, enhancing energy efficiency in production, reducing VOC emissions, and implementing effective recycling and disposal methods. Additionally, there is a focus on creating polyurethane formulations that maintain or improve upon the material's desirable properties while minimizing its environmental impact.

One of the key goals is to reduce the reliance on petroleum-based polyols and isocyanates by incorporating renewable resources. This includes the development of bio-based polyols derived from vegetable oils, such as soybean, castor, and rapeseed oils. These alternatives not only decrease the carbon footprint but also offer potential improvements in certain material properties.

Another critical objective is to optimize the production process to minimize energy consumption and waste generation. This involves implementing more efficient reactor designs, improving heat recovery systems, and exploring alternative catalysts that enable lower reaction temperatures. Furthermore, there is a push towards developing water-based polyurethane systems that reduce or eliminate the need for organic solvents, thereby lowering VOC emissions.

Addressing the end-of-life challenges of polyurethane products is equally important. Research efforts are focused on designing polyurethanes with improved recyclability and biodegradability. This includes the development of chemically recyclable polyurethanes that can be broken down into their original monomers, as well as exploring enzymatic degradation methods for more environmentally friendly disposal.

The overarching aim is to create a circular economy for polyurethane materials, where products are designed for longevity, reuse, and eventual recycling or biodegradation. This holistic approach requires collaboration between material scientists, chemical engineers, and environmental experts to develop innovative solutions that balance performance, cost-effectiveness, and environmental sustainability.

Market Demand for Eco-Friendly Polyurethane Solutions

The market demand for eco-friendly polyurethane solutions has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations. Polyurethane, a versatile polymer used in various industries, has traditionally been associated with environmental challenges due to its production process and end-of-life disposal issues. However, there is a significant shift towards more sustainable alternatives that address these concerns while maintaining the material's desirable properties.

Consumer awareness and preferences have played a crucial role in shaping this demand. Environmentally conscious consumers are increasingly seeking products that have a reduced carbon footprint and are made from renewable resources. This trend has pushed manufacturers to invest in research and development of bio-based polyurethanes and recyclable formulations. The automotive industry, for instance, has shown particular interest in lightweight, eco-friendly polyurethane components to improve fuel efficiency and reduce emissions.

The construction sector has also emerged as a key driver for eco-friendly polyurethane solutions. With the rise of green building standards and certifications, there is a growing need for insulation materials that offer superior energy efficiency without compromising environmental sustainability. Polyurethane foam insulation manufacturers are responding by developing products with lower global warming potential and improved recyclability.

In the furniture and bedding industry, the demand for eco-friendly polyurethane foams has surged. Consumers are increasingly looking for mattresses and upholstery made from natural or partially bio-based materials that reduce dependence on petroleum-derived substances. This has led to innovations in soy-based and other plant-derived polyurethane foams that maintain comfort and durability while addressing environmental concerns.

The packaging industry is another sector experiencing a shift towards sustainable polyurethane solutions. With the global focus on reducing plastic waste, there is a growing market for biodegradable and compostable polyurethane packaging materials. These innovations aim to provide the protective properties of traditional polyurethane while ensuring easier end-of-life management.

Market analysts project that the global eco-friendly polyurethane market will continue to expand at a compound annual growth rate of over 5% in the coming years. This growth is supported by ongoing research into new bio-based raw materials, improved recycling technologies, and the development of polyurethane products with reduced environmental impact throughout their lifecycle.

Government regulations and industry standards are also playing a significant role in driving the demand for eco-friendly polyurethane solutions. Many countries have implemented stricter environmental policies, including bans on certain chemicals and requirements for increased recycled content. These regulatory pressures are compelling manufacturers to innovate and adapt their product offerings to meet new sustainability criteria.

Consumer awareness and preferences have played a crucial role in shaping this demand. Environmentally conscious consumers are increasingly seeking products that have a reduced carbon footprint and are made from renewable resources. This trend has pushed manufacturers to invest in research and development of bio-based polyurethanes and recyclable formulations. The automotive industry, for instance, has shown particular interest in lightweight, eco-friendly polyurethane components to improve fuel efficiency and reduce emissions.

The construction sector has also emerged as a key driver for eco-friendly polyurethane solutions. With the rise of green building standards and certifications, there is a growing need for insulation materials that offer superior energy efficiency without compromising environmental sustainability. Polyurethane foam insulation manufacturers are responding by developing products with lower global warming potential and improved recyclability.

In the furniture and bedding industry, the demand for eco-friendly polyurethane foams has surged. Consumers are increasingly looking for mattresses and upholstery made from natural or partially bio-based materials that reduce dependence on petroleum-derived substances. This has led to innovations in soy-based and other plant-derived polyurethane foams that maintain comfort and durability while addressing environmental concerns.

The packaging industry is another sector experiencing a shift towards sustainable polyurethane solutions. With the global focus on reducing plastic waste, there is a growing market for biodegradable and compostable polyurethane packaging materials. These innovations aim to provide the protective properties of traditional polyurethane while ensuring easier end-of-life management.

Market analysts project that the global eco-friendly polyurethane market will continue to expand at a compound annual growth rate of over 5% in the coming years. This growth is supported by ongoing research into new bio-based raw materials, improved recycling technologies, and the development of polyurethane products with reduced environmental impact throughout their lifecycle.

Government regulations and industry standards are also playing a significant role in driving the demand for eco-friendly polyurethane solutions. Many countries have implemented stricter environmental policies, including bans on certain chemicals and requirements for increased recycled content. These regulatory pressures are compelling manufacturers to innovate and adapt their product offerings to meet new sustainability criteria.

Current State and Limitations of Polyurethane Technology

Polyurethane technology has made significant strides in recent years, but it still faces several environmental challenges. The current state of polyurethane production and usage is characterized by a heavy reliance on petroleum-based raw materials, which contributes to greenhouse gas emissions and resource depletion. While efforts have been made to incorporate bio-based materials, the industry still predominantly uses fossil fuel-derived polyols and isocyanates.

One of the primary limitations of current polyurethane technology is its end-of-life management. Most polyurethane products are not biodegradable and can persist in the environment for extended periods. Recycling polyurethane remains challenging due to its thermoset nature, which makes it difficult to break down and reprocess. This has led to significant waste accumulation in landfills and potential environmental contamination.

The production process of polyurethane also poses environmental concerns. The use of volatile organic compounds (VOCs) and other potentially harmful chemicals during manufacturing can lead to air and water pollution if not properly managed. Additionally, some of the catalysts and additives used in polyurethane production may have negative environmental impacts.

Energy consumption in polyurethane production is another area of concern. The synthesis of polyurethane components and the subsequent processing steps often require substantial energy inputs, contributing to the overall carbon footprint of the industry. While efforts have been made to improve energy efficiency, there is still room for significant improvement in this area.

The durability of polyurethane products, while generally considered an advantage, can also be a double-edged sword from an environmental perspective. Long-lasting products reduce the need for frequent replacements, but they also contribute to the accumulation of non-biodegradable materials in the environment when they eventually reach the end of their useful life.

Water-based polyurethane systems have been developed as an alternative to solvent-based systems, reducing VOC emissions. However, these systems often have limitations in terms of performance and application range compared to their solvent-based counterparts. Balancing environmental benefits with product performance remains a challenge for the industry.

The use of flame retardants in polyurethane foams, while necessary for safety in many applications, has raised environmental and health concerns. Some commonly used flame retardants have been found to be persistent organic pollutants, leading to a search for more environmentally friendly alternatives that maintain the required fire safety standards.

One of the primary limitations of current polyurethane technology is its end-of-life management. Most polyurethane products are not biodegradable and can persist in the environment for extended periods. Recycling polyurethane remains challenging due to its thermoset nature, which makes it difficult to break down and reprocess. This has led to significant waste accumulation in landfills and potential environmental contamination.

The production process of polyurethane also poses environmental concerns. The use of volatile organic compounds (VOCs) and other potentially harmful chemicals during manufacturing can lead to air and water pollution if not properly managed. Additionally, some of the catalysts and additives used in polyurethane production may have negative environmental impacts.

Energy consumption in polyurethane production is another area of concern. The synthesis of polyurethane components and the subsequent processing steps often require substantial energy inputs, contributing to the overall carbon footprint of the industry. While efforts have been made to improve energy efficiency, there is still room for significant improvement in this area.

The durability of polyurethane products, while generally considered an advantage, can also be a double-edged sword from an environmental perspective. Long-lasting products reduce the need for frequent replacements, but they also contribute to the accumulation of non-biodegradable materials in the environment when they eventually reach the end of their useful life.

Water-based polyurethane systems have been developed as an alternative to solvent-based systems, reducing VOC emissions. However, these systems often have limitations in terms of performance and application range compared to their solvent-based counterparts. Balancing environmental benefits with product performance remains a challenge for the industry.

The use of flame retardants in polyurethane foams, while necessary for safety in many applications, has raised environmental and health concerns. Some commonly used flame retardants have been found to be persistent organic pollutants, leading to a search for more environmentally friendly alternatives that maintain the required fire safety standards.

Existing Solutions for Eco-Friendly Polyurethane

01 Polyurethane synthesis and composition

This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis may involve different types of isocyanates, polyols, and additives to achieve desired characteristics.- Polyurethane synthesis and composition: This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis often involves the reaction between polyols and isocyanates, with the addition of catalysts and other additives to control the reaction and final properties.

- Polyurethane applications in coatings and films: This point covers the use of polyurethane in various coating and film applications. Polyurethane coatings and films are known for their excellent adhesion, durability, and resistance to chemicals and abrasion. They are used in industries such as automotive, construction, and electronics for protective and decorative purposes.

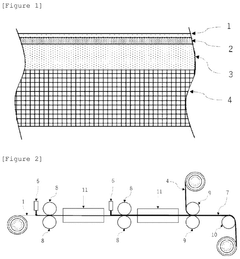

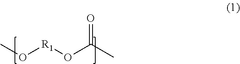

- Polyurethane foam technology: This category encompasses the development and production of polyurethane foams. It includes various types of foams such as flexible, rigid, and spray foams, each with specific applications. The technology involves controlling the foam structure, density, and properties through the use of different raw materials, catalysts, and blowing agents.

- Polyurethane in textile and fiber applications: This point focuses on the use of polyurethane in textile and fiber applications. Polyurethane fibers and coatings are used to enhance the properties of fabrics, such as elasticity, water resistance, and durability. Applications include sportswear, technical textiles, and artificial leather production.

- Environmentally friendly polyurethane technologies: This category covers the development of more sustainable and environmentally friendly polyurethane technologies. It includes the use of bio-based raw materials, recycling methods for polyurethane waste, and the development of polyurethanes with reduced environmental impact. These technologies aim to address concerns about the environmental footprint of traditional polyurethane production and disposal.

02 Polyurethane applications in coatings and films

This point covers the use of polyurethane in various coating and film applications. It includes formulations for protective coatings, adhesive films, and surface treatments. The polyurethane-based coatings and films may offer properties such as weather resistance, chemical resistance, and improved adhesion to different substrates.Expand Specific Solutions03 Polyurethane foam technology

This category encompasses innovations in polyurethane foam production and properties. It includes methods for creating various types of foams, such as flexible, rigid, or viscoelastic foams. The technology may involve different blowing agents, catalysts, and additives to control foam structure, density, and performance characteristics.Expand Specific Solutions04 Polyurethane in textile and fiber applications

This point focuses on the use of polyurethane in textile and fiber-related applications. It includes methods for incorporating polyurethane into fabrics, creating polyurethane fibers, and developing polyurethane-based finishes for textiles. These applications may enhance properties such as elasticity, moisture management, and durability of textile products.Expand Specific Solutions05 Environmentally friendly polyurethane technologies

This category covers innovations in developing more sustainable and environmentally friendly polyurethane materials and processes. It includes bio-based polyurethanes, recyclable or biodegradable formulations, and production methods with reduced environmental impact. These technologies aim to address concerns about the environmental footprint of traditional polyurethane products.Expand Specific Solutions

Key Players in Sustainable Polyurethane Industry

The polyurethane industry is in a mature growth phase, with a global market size expected to reach $79.2 billion by 2025. The technology for overcoming environmental challenges with polyurethane is rapidly evolving, driven by increasing environmental regulations and consumer demand for sustainable products. Major players like BASF Corp., Covestro Deutschland AG, and Bayer AG are at the forefront of developing eco-friendly polyurethane solutions. These companies, along with others such as DuPont de Nemours, Inc. and 3M Innovative Properties Co., are investing heavily in research and development to create bio-based polyurethanes, improve recycling processes, and reduce the environmental impact of production. The technological maturity varies across different applications, with some areas like bio-based polyols showing significant progress, while others, such as fully biodegradable polyurethanes, are still in early development stages.

BASF Corp.

Technical Solution: BASF has developed a range of innovative polyurethane solutions to address environmental challenges. Their Elastocool technology uses CO2 as a raw material in polyurethane production, reducing the carbon footprint. They've also created bio-based polyols derived from renewable resources like castor oil. BASF's Elastopan material combines recycled polyurethane with virgin material, promoting circular economy principles. Their water-based polyurethane dispersions offer low VOC emissions for coatings and adhesives applications.

Strengths: Strong R&D capabilities, diverse product portfolio, and commitment to sustainability. Weaknesses: High production costs for some eco-friendly solutions, potential regulatory challenges in different markets.

Covestro Deutschland AG

Technical Solution: Covestro has developed several technologies to address environmental challenges with polyurethane. Their cardyon technology uses CO2 as a raw material to produce polyols, reducing reliance on fossil fuels. They've also created partially bio-based polyurethanes using plant-based raw materials. Covestro's INSQIN technology enables waterborne polyurethane coatings for textiles, reducing solvent use. Their Impranil eco line offers bio-based waterborne polyurethane dispersions for various applications, promoting sustainability in the coating industry.

Strengths: Innovative CO2 utilization technology, strong focus on bio-based materials, and diverse sustainable product range. Weaknesses: Higher costs associated with some eco-friendly solutions, potential scalability challenges for newer technologies.

Core Innovations in Green Polyurethane Chemistry

Antibacterial mildewproof polyurethane composite material containing natural plant and a preparation method thereof

PatentInactiveUS20190367702A1

Innovation

- A polyurethane composite material incorporating plant oil polyether polyols, modified MDI, and a composite plant extract from garlic, Chinese pulsatilla root, and sage, with specific ratios and processing methods to create an antibacterial and mildewproof material that is environmentally friendly and degradable.

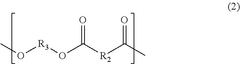

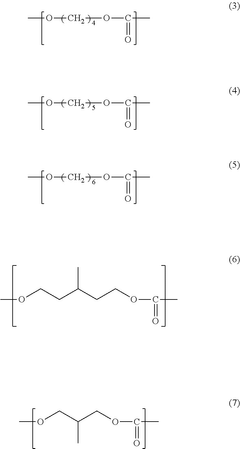

Polyester polycarbonate polyol

PatentPendingUS20250034332A1

Innovation

- A polyester polycarbonate polyol with specific repeating units and a hydroxyl value of 35 to 85 mgKOH/g, which is used to produce a polyurethane with excellent balance of physical properties including flexibility, chemical resistance, hydrolysis resistance, low-temperature characteristics, heat resistance, wear resistance, adhesiveness, and appearance, while minimizing the use of organic solvents.

Life Cycle Assessment of Polyurethane Products

Life Cycle Assessment (LCA) of polyurethane products is a crucial tool for evaluating and mitigating the environmental impacts associated with these versatile materials. The assessment typically covers the entire lifecycle of polyurethane products, from raw material extraction to end-of-life disposal or recycling.

The production phase of polyurethane involves the synthesis of isocyanates and polyols, which are energy-intensive processes. LCA studies have shown that this stage contributes significantly to the overall environmental footprint. However, the long service life and excellent insulation properties of polyurethane products often offset these initial impacts, particularly in applications such as building insulation where energy savings are realized over time.

During the use phase, polyurethane products generally exhibit favorable environmental performance due to their durability and efficiency. For instance, polyurethane foams used in automotive seating reduce vehicle weight, leading to improved fuel efficiency and lower emissions over the vehicle's lifespan.

End-of-life management presents both challenges and opportunities for polyurethane products. While landfilling remains common, innovative recycling technologies are emerging. Mechanical recycling can recover materials for use in new products, while chemical recycling breaks down polyurethane into its chemical components for reuse in production.

Recent advancements in bio-based polyurethanes offer promising alternatives to traditional petroleum-based formulations. These materials, derived from renewable resources such as vegetable oils or agricultural waste, can significantly reduce the carbon footprint of polyurethane products. LCA studies comparing bio-based and conventional polyurethanes have demonstrated potential environmental benefits, particularly in terms of reduced greenhouse gas emissions and fossil resource depletion.

Water-based polyurethane systems represent another eco-friendly innovation, addressing concerns about volatile organic compound (VOC) emissions. These systems eliminate the need for solvent-based formulations, improving air quality during application and reducing the overall environmental impact of the product lifecycle.

To overcome environmental challenges, the polyurethane industry is increasingly focusing on circular economy principles. This involves designing products for easier disassembly and recycling, as well as developing more efficient recycling processes. Closed-loop systems, where post-consumer polyurethane waste is reintegrated into new production cycles, are being explored to minimize resource consumption and waste generation.

LCA studies play a vital role in guiding these sustainability efforts by identifying hotspots in the product lifecycle and quantifying the potential benefits of various improvement strategies. By providing a comprehensive view of environmental impacts, LCA enables informed decision-making in product design, manufacturing processes, and end-of-life management, ultimately contributing to more sustainable polyurethane solutions.

The production phase of polyurethane involves the synthesis of isocyanates and polyols, which are energy-intensive processes. LCA studies have shown that this stage contributes significantly to the overall environmental footprint. However, the long service life and excellent insulation properties of polyurethane products often offset these initial impacts, particularly in applications such as building insulation where energy savings are realized over time.

During the use phase, polyurethane products generally exhibit favorable environmental performance due to their durability and efficiency. For instance, polyurethane foams used in automotive seating reduce vehicle weight, leading to improved fuel efficiency and lower emissions over the vehicle's lifespan.

End-of-life management presents both challenges and opportunities for polyurethane products. While landfilling remains common, innovative recycling technologies are emerging. Mechanical recycling can recover materials for use in new products, while chemical recycling breaks down polyurethane into its chemical components for reuse in production.

Recent advancements in bio-based polyurethanes offer promising alternatives to traditional petroleum-based formulations. These materials, derived from renewable resources such as vegetable oils or agricultural waste, can significantly reduce the carbon footprint of polyurethane products. LCA studies comparing bio-based and conventional polyurethanes have demonstrated potential environmental benefits, particularly in terms of reduced greenhouse gas emissions and fossil resource depletion.

Water-based polyurethane systems represent another eco-friendly innovation, addressing concerns about volatile organic compound (VOC) emissions. These systems eliminate the need for solvent-based formulations, improving air quality during application and reducing the overall environmental impact of the product lifecycle.

To overcome environmental challenges, the polyurethane industry is increasingly focusing on circular economy principles. This involves designing products for easier disassembly and recycling, as well as developing more efficient recycling processes. Closed-loop systems, where post-consumer polyurethane waste is reintegrated into new production cycles, are being explored to minimize resource consumption and waste generation.

LCA studies play a vital role in guiding these sustainability efforts by identifying hotspots in the product lifecycle and quantifying the potential benefits of various improvement strategies. By providing a comprehensive view of environmental impacts, LCA enables informed decision-making in product design, manufacturing processes, and end-of-life management, ultimately contributing to more sustainable polyurethane solutions.

Regulatory Framework for Polyurethane Manufacturing

The regulatory framework for polyurethane manufacturing plays a crucial role in addressing environmental challenges associated with this versatile material. Governments and international organizations have implemented various regulations and standards to mitigate the environmental impact of polyurethane production and use.

One of the primary areas of focus is the reduction of volatile organic compound (VOC) emissions. Many countries have established strict limits on VOC emissions from polyurethane manufacturing processes. For instance, the European Union's Solvent Emissions Directive sets specific thresholds for VOC emissions in industrial activities, including polyurethane production. Manufacturers are required to implement best available techniques (BAT) to minimize emissions and comply with these regulations.

Another significant aspect of the regulatory framework is the control of hazardous substances used in polyurethane production. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU mandates the registration and assessment of chemical substances, including those used in polyurethane manufacturing. This regulation aims to protect human health and the environment by identifying and managing the risks associated with these substances.

Energy efficiency and carbon footprint reduction are also key components of the regulatory landscape. Many countries have implemented energy efficiency standards and carbon pricing mechanisms that impact polyurethane manufacturers. For example, the EU Emissions Trading System (ETS) includes the chemical industry, encouraging companies to adopt more sustainable production methods and invest in low-carbon technologies.

Waste management and recycling regulations are increasingly important in the polyurethane industry. The EU Waste Framework Directive sets targets for recycling and recovery of materials, including polyurethane waste. This has led to the development of innovative recycling technologies and the establishment of take-back schemes for end-of-life polyurethane products.

Product safety regulations also play a crucial role in addressing environmental challenges. For instance, fire safety standards for polyurethane foam products have led to the development of more environmentally friendly flame retardants. The EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, including polyurethane components.

Lastly, labeling and disclosure requirements are becoming more prevalent. These regulations aim to provide consumers with information about the environmental impact of polyurethane products, encouraging more sustainable purchasing decisions and driving manufacturers to improve their environmental performance.

One of the primary areas of focus is the reduction of volatile organic compound (VOC) emissions. Many countries have established strict limits on VOC emissions from polyurethane manufacturing processes. For instance, the European Union's Solvent Emissions Directive sets specific thresholds for VOC emissions in industrial activities, including polyurethane production. Manufacturers are required to implement best available techniques (BAT) to minimize emissions and comply with these regulations.

Another significant aspect of the regulatory framework is the control of hazardous substances used in polyurethane production. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU mandates the registration and assessment of chemical substances, including those used in polyurethane manufacturing. This regulation aims to protect human health and the environment by identifying and managing the risks associated with these substances.

Energy efficiency and carbon footprint reduction are also key components of the regulatory landscape. Many countries have implemented energy efficiency standards and carbon pricing mechanisms that impact polyurethane manufacturers. For example, the EU Emissions Trading System (ETS) includes the chemical industry, encouraging companies to adopt more sustainable production methods and invest in low-carbon technologies.

Waste management and recycling regulations are increasingly important in the polyurethane industry. The EU Waste Framework Directive sets targets for recycling and recovery of materials, including polyurethane waste. This has led to the development of innovative recycling technologies and the establishment of take-back schemes for end-of-life polyurethane products.

Product safety regulations also play a crucial role in addressing environmental challenges. For instance, fire safety standards for polyurethane foam products have led to the development of more environmentally friendly flame retardants. The EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, including polyurethane components.

Lastly, labeling and disclosure requirements are becoming more prevalent. These regulations aim to provide consumers with information about the environmental impact of polyurethane products, encouraging more sustainable purchasing decisions and driving manufacturers to improve their environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!