How to Prevent Degradation in Polyurethane Applications?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyurethane Degradation Background and Objectives

Polyurethane, a versatile polymer with applications ranging from flexible foams to durable coatings, has been a cornerstone in various industries since its discovery in the 1930s. The evolution of polyurethane technology has been driven by the need for materials with superior mechanical properties, chemical resistance, and longevity. However, the degradation of polyurethane remains a significant challenge, impacting product performance and lifespan across diverse applications.

The primary objective of this technical research is to comprehensively explore the mechanisms of polyurethane degradation and identify effective prevention strategies. By understanding the underlying causes of degradation, we aim to develop innovative solutions that enhance the durability and longevity of polyurethane-based products. This research is crucial for advancing the state of the art in polyurethane technology and meeting the growing demands for high-performance materials in industries such as automotive, construction, and medical devices.

Polyurethane degradation can occur through various pathways, including hydrolysis, oxidation, and photodegradation. These processes are influenced by environmental factors such as moisture, temperature, UV radiation, and chemical exposure. The complexity of polyurethane chemistry, with its diverse range of formulations and structures, further complicates the degradation landscape. As a result, a multifaceted approach is necessary to address this challenge effectively.

Recent technological advancements have shed light on the molecular-level changes that occur during polyurethane degradation. These insights have paved the way for the development of novel stabilizers, additives, and structural modifications that can significantly improve the material's resistance to degradation. Additionally, emerging techniques in polymer science, such as nanocomposite integration and surface modification, offer promising avenues for enhancing polyurethane stability.

The global polyurethane market is projected to grow significantly in the coming years, driven by increasing demand in key sectors such as construction, automotive, and furniture. This growth underscores the critical importance of addressing degradation issues to ensure the long-term viability and sustainability of polyurethane applications. By focusing on degradation prevention, we not only aim to improve product performance but also to reduce environmental impact through extended product lifecycles and reduced waste generation.

In this technical research, we will explore cutting-edge approaches to mitigate polyurethane degradation, drawing from recent scientific literature, industry reports, and expert insights. Our investigation will encompass both chemical and physical strategies, including the development of new polyurethane formulations, the incorporation of advanced stabilizers, and the application of protective coatings. By synthesizing this information, we aim to provide a comprehensive roadmap for enhancing polyurethane durability across diverse applications.

The primary objective of this technical research is to comprehensively explore the mechanisms of polyurethane degradation and identify effective prevention strategies. By understanding the underlying causes of degradation, we aim to develop innovative solutions that enhance the durability and longevity of polyurethane-based products. This research is crucial for advancing the state of the art in polyurethane technology and meeting the growing demands for high-performance materials in industries such as automotive, construction, and medical devices.

Polyurethane degradation can occur through various pathways, including hydrolysis, oxidation, and photodegradation. These processes are influenced by environmental factors such as moisture, temperature, UV radiation, and chemical exposure. The complexity of polyurethane chemistry, with its diverse range of formulations and structures, further complicates the degradation landscape. As a result, a multifaceted approach is necessary to address this challenge effectively.

Recent technological advancements have shed light on the molecular-level changes that occur during polyurethane degradation. These insights have paved the way for the development of novel stabilizers, additives, and structural modifications that can significantly improve the material's resistance to degradation. Additionally, emerging techniques in polymer science, such as nanocomposite integration and surface modification, offer promising avenues for enhancing polyurethane stability.

The global polyurethane market is projected to grow significantly in the coming years, driven by increasing demand in key sectors such as construction, automotive, and furniture. This growth underscores the critical importance of addressing degradation issues to ensure the long-term viability and sustainability of polyurethane applications. By focusing on degradation prevention, we not only aim to improve product performance but also to reduce environmental impact through extended product lifecycles and reduced waste generation.

In this technical research, we will explore cutting-edge approaches to mitigate polyurethane degradation, drawing from recent scientific literature, industry reports, and expert insights. Our investigation will encompass both chemical and physical strategies, including the development of new polyurethane formulations, the incorporation of advanced stabilizers, and the application of protective coatings. By synthesizing this information, we aim to provide a comprehensive roadmap for enhancing polyurethane durability across diverse applications.

Market Analysis for Durable Polyurethane Products

The market for durable polyurethane products has shown significant growth in recent years, driven by increasing demand across various industries such as construction, automotive, and furniture. The global polyurethane market size was valued at USD 70.53 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 3.8% from 2021 to 2028. This growth is primarily attributed to the versatile properties of polyurethane, including its durability, flexibility, and resistance to wear and tear.

In the construction sector, polyurethane-based products are gaining traction due to their excellent insulation properties and ability to enhance energy efficiency in buildings. The automotive industry is another major consumer of durable polyurethane products, utilizing them in various applications such as seating, interior components, and exterior body parts. The furniture industry also contributes significantly to the market demand, with polyurethane foams being widely used in upholstery and mattresses.

The Asia-Pacific region dominates the global polyurethane market, accounting for the largest share of consumption. This is primarily due to rapid industrialization, urbanization, and increasing disposable income in countries like China and India. North America and Europe follow closely, with mature markets and a strong focus on innovation and sustainability in polyurethane applications.

One of the key trends driving the market for durable polyurethane products is the increasing emphasis on sustainability and environmental concerns. Manufacturers are investing in research and development to create bio-based polyurethanes and improve recycling technologies. This shift towards eco-friendly alternatives is expected to open up new opportunities in the market and address the growing consumer demand for sustainable products.

The market is also witnessing a rise in demand for high-performance polyurethane products with enhanced durability and resistance to degradation. This trend is particularly evident in industries where products are exposed to harsh environmental conditions or subjected to frequent use. As a result, there is a growing focus on developing advanced formulations and manufacturing techniques to improve the longevity and performance of polyurethane-based products.

However, the market faces challenges such as volatile raw material prices and stringent environmental regulations. The fluctuating costs of key raw materials like isocyanates and polyols can impact profit margins and pricing strategies for manufacturers. Additionally, concerns over the environmental impact of certain polyurethane products and their disposal have led to increased regulatory scrutiny, driving the need for more sustainable solutions.

In the construction sector, polyurethane-based products are gaining traction due to their excellent insulation properties and ability to enhance energy efficiency in buildings. The automotive industry is another major consumer of durable polyurethane products, utilizing them in various applications such as seating, interior components, and exterior body parts. The furniture industry also contributes significantly to the market demand, with polyurethane foams being widely used in upholstery and mattresses.

The Asia-Pacific region dominates the global polyurethane market, accounting for the largest share of consumption. This is primarily due to rapid industrialization, urbanization, and increasing disposable income in countries like China and India. North America and Europe follow closely, with mature markets and a strong focus on innovation and sustainability in polyurethane applications.

One of the key trends driving the market for durable polyurethane products is the increasing emphasis on sustainability and environmental concerns. Manufacturers are investing in research and development to create bio-based polyurethanes and improve recycling technologies. This shift towards eco-friendly alternatives is expected to open up new opportunities in the market and address the growing consumer demand for sustainable products.

The market is also witnessing a rise in demand for high-performance polyurethane products with enhanced durability and resistance to degradation. This trend is particularly evident in industries where products are exposed to harsh environmental conditions or subjected to frequent use. As a result, there is a growing focus on developing advanced formulations and manufacturing techniques to improve the longevity and performance of polyurethane-based products.

However, the market faces challenges such as volatile raw material prices and stringent environmental regulations. The fluctuating costs of key raw materials like isocyanates and polyols can impact profit margins and pricing strategies for manufacturers. Additionally, concerns over the environmental impact of certain polyurethane products and their disposal have led to increased regulatory scrutiny, driving the need for more sustainable solutions.

Current Challenges in Polyurethane Stability

Polyurethane applications face significant challenges in maintaining long-term stability and performance. One of the primary issues is oxidative degradation, which occurs when oxygen molecules react with the polymer chains, leading to chain scission and deterioration of mechanical properties. This process is often accelerated by exposure to UV radiation, heat, and environmental pollutants, resulting in discoloration, loss of flexibility, and reduced durability.

Another major challenge is hydrolytic degradation, particularly in environments with high humidity or direct water contact. Water molecules can attack the ester or ether linkages in polyurethane, causing the polymer to break down and lose its structural integrity. This is especially problematic in applications such as coatings, adhesives, and sealants, where moisture resistance is crucial for long-term performance.

Thermal degradation poses a significant threat to polyurethane stability, especially in high-temperature applications. As temperatures rise, the polymer chains can undergo various chemical reactions, including depolymerization and cross-linking, which alter the material's properties and compromise its functionality. This is particularly challenging in automotive and industrial applications where polyurethanes are exposed to elevated temperatures.

Microbial attack is another concern, especially in polyurethane foams used in furniture, bedding, and insulation. Certain microorganisms can metabolize components of the polyurethane, leading to material breakdown and potential health hazards. This issue is compounded by the fact that many additives used to improve other properties of polyurethanes can inadvertently promote microbial growth.

The use of flame retardants in polyurethane formulations, while necessary for safety in many applications, can introduce additional stability challenges. These additives can migrate to the surface over time, reducing their effectiveness and potentially altering the material's properties. Moreover, some flame retardants can accelerate other degradation processes, creating a complex balance between fire safety and long-term stability.

Mechanical stress and fatigue represent ongoing challenges, particularly in applications such as footwear, automotive parts, and industrial machinery components. Repeated loading and unloading cycles can lead to micro-cracks and eventual failure of the polyurethane material. This is exacerbated by environmental factors that can weaken the polymer structure, making it more susceptible to mechanical degradation.

Another major challenge is hydrolytic degradation, particularly in environments with high humidity or direct water contact. Water molecules can attack the ester or ether linkages in polyurethane, causing the polymer to break down and lose its structural integrity. This is especially problematic in applications such as coatings, adhesives, and sealants, where moisture resistance is crucial for long-term performance.

Thermal degradation poses a significant threat to polyurethane stability, especially in high-temperature applications. As temperatures rise, the polymer chains can undergo various chemical reactions, including depolymerization and cross-linking, which alter the material's properties and compromise its functionality. This is particularly challenging in automotive and industrial applications where polyurethanes are exposed to elevated temperatures.

Microbial attack is another concern, especially in polyurethane foams used in furniture, bedding, and insulation. Certain microorganisms can metabolize components of the polyurethane, leading to material breakdown and potential health hazards. This issue is compounded by the fact that many additives used to improve other properties of polyurethanes can inadvertently promote microbial growth.

The use of flame retardants in polyurethane formulations, while necessary for safety in many applications, can introduce additional stability challenges. These additives can migrate to the surface over time, reducing their effectiveness and potentially altering the material's properties. Moreover, some flame retardants can accelerate other degradation processes, creating a complex balance between fire safety and long-term stability.

Mechanical stress and fatigue represent ongoing challenges, particularly in applications such as footwear, automotive parts, and industrial machinery components. Repeated loading and unloading cycles can lead to micro-cracks and eventual failure of the polyurethane material. This is exacerbated by environmental factors that can weaken the polymer structure, making it more susceptible to mechanical degradation.

Existing Degradation Prevention Methods

01 Microbial degradation of polyurethane

Certain microorganisms can break down polyurethane through enzymatic processes. This biological approach to polyurethane degradation is environmentally friendly and can be optimized for various types of polyurethane materials. The process involves the use of specific bacteria or fungi that produce enzymes capable of cleaving the chemical bonds in polyurethane.- Microbial degradation of polyurethane: Utilizing microorganisms to break down polyurethane materials. This approach involves identifying and cultivating specific bacteria or fungi that can effectively degrade polyurethane polymers. The process can be enhanced by optimizing environmental conditions and nutrient availability for the microorganisms.

- Chemical degradation methods: Employing chemical processes to break down polyurethane structures. This can include hydrolysis, oxidation, or the use of specific solvents that target the polymer bonds. Chemical degradation methods often involve controlled conditions such as temperature and pH to optimize the breakdown process.

- Enzymatic degradation of polyurethane: Using specific enzymes to catalyze the breakdown of polyurethane materials. This method involves identifying and isolating enzymes capable of cleaving the chemical bonds in polyurethane polymers. Enzymatic degradation can be more selective and environmentally friendly compared to chemical methods.

- Thermal degradation techniques: Applying heat to break down polyurethane materials. This approach involves exposing polyurethane to high temperatures, which causes the polymer chains to break apart. Thermal degradation can be combined with other methods to enhance efficiency and control the breakdown products.

- Biodegradable polyurethane formulations: Developing new polyurethane formulations that are inherently more susceptible to degradation. This involves incorporating biodegradable components or modifying the polymer structure to make it more easily broken down by natural processes. These formulations aim to maintain the desired properties of polyurethane while improving its end-of-life environmental impact.

02 Chemical degradation methods

Chemical processes can be employed to degrade polyurethane materials. These methods often involve the use of solvents, acids, or bases to break down the polymer structure. The choice of chemical agents and reaction conditions can be tailored to the specific type of polyurethane being degraded, allowing for controlled decomposition and potential recovery of valuable components.Expand Specific Solutions03 Thermal degradation techniques

Heat can be used to break down polyurethane materials. Thermal degradation processes involve exposing the polyurethane to high temperatures, which causes the polymer chains to break apart. This method can be combined with other techniques to enhance the degradation efficiency and potentially recover useful byproducts.Expand Specific Solutions04 Photodegradation of polyurethane

Exposure to light, particularly ultraviolet radiation, can induce degradation in polyurethane materials. This process, known as photodegradation, involves the absorption of light energy by the polymer, leading to chemical changes and breakdown of the material. Photodegradation can be enhanced by incorporating photosensitive additives into the polyurethane formulation.Expand Specific Solutions05 Recycling and upcycling of degraded polyurethane

After degradation, the resulting products from polyurethane breakdown can be recycled or upcycled into new materials. This approach aims to create a circular economy for polyurethane products, reducing waste and environmental impact. The recycling process may involve chemical transformation of the degraded components or their incorporation into new polymer formulations.Expand Specific Solutions

Key Players in Polyurethane Industry and Research

The polyurethane applications market is in a mature growth stage, with a global market size expected to reach $91.68 billion by 2028. The technology to prevent degradation in polyurethane applications is advancing rapidly, driven by increasing demand for durable and high-performance materials. Companies like BASF Corp., Covestro Deutschland AG, and Wanhua Chemical Group Co., Ltd. are at the forefront of developing innovative solutions. These industry leaders are investing heavily in research and development to enhance polyurethane stability and longevity. Emerging players such as PolyNovo Biomaterials Pty Ltd. and Aidasuo Advanced Materials Wuxi Co., Ltd. are also contributing to technological advancements, focusing on specialized applications and niche markets. The competitive landscape is characterized by a mix of established chemical giants and specialized materials companies, all striving to address the critical challenge of polyurethane degradation.

BASF Corp.

Technical Solution: BASF has developed a range of polyurethane solutions to prevent degradation in various applications. Their approach includes the use of advanced stabilizers and antioxidants specifically designed for polyurethane systems. These additives are incorporated into the polyurethane formulation to protect against UV radiation, heat, and oxidation. BASF's technology also involves the development of moisture-curing systems that form a protective barrier against environmental factors. Additionally, they have introduced bio-based polyols that enhance the overall durability and resistance of polyurethane products.

Strengths: Comprehensive range of solutions, expertise in chemical formulations, global research capabilities. Weaknesses: Potential higher costs, dependency on petrochemical resources for some products.

3M Innovative Properties Co.

Technical Solution: 3M has developed a multi-layered approach to prevent degradation in polyurethane applications. Their technology involves the use of specialized surface treatments and coatings that create a protective barrier on polyurethane products. These coatings are designed to resist UV radiation, chemical exposure, and abrasion. 3M also employs nanotechnology in their solutions, incorporating nanoparticles into polyurethane formulations to enhance durability and resistance to environmental factors. Furthermore, they have developed advanced adhesive systems that improve the bonding between polyurethane layers, reducing the risk of delamination and degradation over time.

Strengths: Diverse product portfolio, strong focus on innovation, extensive experience in surface technologies. Weaknesses: Some solutions may be application-specific, potentially limiting broader use.

Innovative Approaches to Polyurethane Stabilization

Degradation resistant polyurethanes

PatentInactiveUS20060063894A1

Innovation

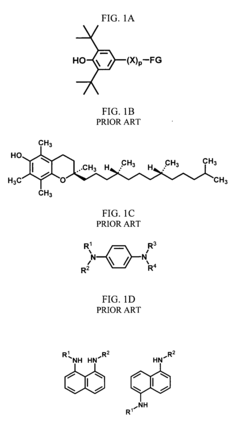

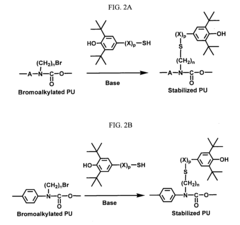

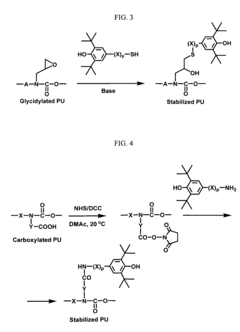

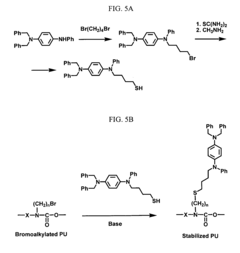

- Development of degradation-resistant polyurethanes with antioxidants covalently bound to the polymer backbone, using phenol-derived substituents like 2,6-di-tert-butylphenol, phenylendiamine, or Vitamin E derivatives pendant from urethane nitrogens, to prevent oxidative destruction.

Polyurethane-based retention, covering, filling and reinforcement composition

PatentWO2007087348A1

Innovation

- A polyurethane compound comprising hydrogenated elastomer with hydroxyl functional groups, a polybutadiene-based prepolymer, fillers such as sand or calcium carbonate, and additives like antioxidants and rheological modifiers, which enhances mechanical properties and resistance to hydrolysis and environmental degradation.

Environmental Impact of Polyurethane Degradation

The environmental impact of polyurethane degradation is a significant concern in the lifecycle of polyurethane-based products. As these materials break down over time, they release various compounds that can have detrimental effects on ecosystems and human health. One of the primary issues is the release of volatile organic compounds (VOCs) during the degradation process. These VOCs can contribute to air pollution and potentially harm both terrestrial and aquatic organisms.

Polyurethane degradation also leads to the formation of microplastics, which have become a pervasive environmental problem. These tiny plastic particles can accumulate in water bodies, soil, and even the atmosphere, posing risks to wildlife through ingestion and potential bioaccumulation in food chains. Marine ecosystems are particularly vulnerable, as polyurethane fragments can be mistaken for food by marine organisms, leading to malnutrition and other health issues.

The breakdown of polyurethanes can result in the leaching of toxic chemicals, including isocyanates and polyols, into soil and water systems. These substances can alter soil chemistry, affecting plant growth and microbial communities. In aquatic environments, they may disrupt the delicate balance of ecosystems, potentially causing long-term damage to biodiversity.

Furthermore, the degradation of polyurethane foams used in insulation and furniture can release flame retardants and other additives into the environment. Some of these compounds are known to be persistent organic pollutants (POPs), which can accumulate in living organisms and have long-lasting effects on environmental and human health.

The disposal of polyurethane products at the end of their lifecycle presents additional environmental challenges. Incineration of polyurethane waste can produce toxic fumes and contribute to air pollution, while landfilling leads to slow degradation and potential groundwater contamination. Recycling efforts for polyurethanes are often complicated by the presence of various additives and the cross-linked nature of the polymer, making it difficult to recover and reuse the material effectively.

To address these environmental concerns, research into more sustainable polyurethane formulations and improved degradation management is crucial. Developing bio-based polyurethanes, enhancing recycling technologies, and implementing proper disposal methods are key areas of focus to mitigate the environmental impact of polyurethane degradation. Additionally, exploring alternative materials and designs that can replace polyurethanes in certain applications may help reduce the overall environmental footprint of these widely used polymers.

Polyurethane degradation also leads to the formation of microplastics, which have become a pervasive environmental problem. These tiny plastic particles can accumulate in water bodies, soil, and even the atmosphere, posing risks to wildlife through ingestion and potential bioaccumulation in food chains. Marine ecosystems are particularly vulnerable, as polyurethane fragments can be mistaken for food by marine organisms, leading to malnutrition and other health issues.

The breakdown of polyurethanes can result in the leaching of toxic chemicals, including isocyanates and polyols, into soil and water systems. These substances can alter soil chemistry, affecting plant growth and microbial communities. In aquatic environments, they may disrupt the delicate balance of ecosystems, potentially causing long-term damage to biodiversity.

Furthermore, the degradation of polyurethane foams used in insulation and furniture can release flame retardants and other additives into the environment. Some of these compounds are known to be persistent organic pollutants (POPs), which can accumulate in living organisms and have long-lasting effects on environmental and human health.

The disposal of polyurethane products at the end of their lifecycle presents additional environmental challenges. Incineration of polyurethane waste can produce toxic fumes and contribute to air pollution, while landfilling leads to slow degradation and potential groundwater contamination. Recycling efforts for polyurethanes are often complicated by the presence of various additives and the cross-linked nature of the polymer, making it difficult to recover and reuse the material effectively.

To address these environmental concerns, research into more sustainable polyurethane formulations and improved degradation management is crucial. Developing bio-based polyurethanes, enhancing recycling technologies, and implementing proper disposal methods are key areas of focus to mitigate the environmental impact of polyurethane degradation. Additionally, exploring alternative materials and designs that can replace polyurethanes in certain applications may help reduce the overall environmental footprint of these widely used polymers.

Regulatory Framework for Polyurethane Applications

The regulatory framework for polyurethane applications plays a crucial role in preventing degradation and ensuring the safety, quality, and environmental sustainability of these materials. In the United States, the Environmental Protection Agency (EPA) oversees the regulation of polyurethanes under the Toxic Substances Control Act (TSCA). This act requires manufacturers to submit premanufacture notices for new chemical substances, including polyurethanes, and to comply with reporting, record-keeping, and testing requirements.

The Occupational Safety and Health Administration (OSHA) has established guidelines for the safe handling and use of polyurethane materials in workplace settings. These regulations address exposure limits, personal protective equipment, and proper ventilation systems to minimize health risks associated with isocyanates, a key component in polyurethane production.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of polyurethanes. REACH mandates that manufacturers and importers register chemicals, including those used in polyurethane applications, and provide information on their properties, hazards, and safe use. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

The International Organization for Standardization (ISO) has developed several standards specific to polyurethane applications. These standards, such as ISO 14932 for polyurethane adhesives and ISO 2440 for flexible polyurethane foams, provide guidelines for testing methods, performance requirements, and quality control measures to prevent degradation and ensure product consistency.

Many countries have implemented regulations to address the end-of-life management of polyurethane products. For instance, the European Union's Waste Framework Directive and the End-of-Life Vehicles Directive promote the recycling and proper disposal of polyurethane materials. These regulations aim to reduce environmental impact and encourage the development of more sustainable polyurethane applications.

Industry associations, such as the American Chemistry Council's Center for the Polyurethanes Industry, have established voluntary product stewardship programs. These initiatives promote best practices in the manufacture, use, and disposal of polyurethane products, complementing regulatory frameworks and addressing emerging concerns related to degradation prevention.

As environmental concerns grow, regulations are evolving to address the lifecycle impact of polyurethanes. For example, some jurisdictions are implementing extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal or recycling. This approach incentivizes the development of more durable and easily recyclable polyurethane applications.

The Occupational Safety and Health Administration (OSHA) has established guidelines for the safe handling and use of polyurethane materials in workplace settings. These regulations address exposure limits, personal protective equipment, and proper ventilation systems to minimize health risks associated with isocyanates, a key component in polyurethane production.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of polyurethanes. REACH mandates that manufacturers and importers register chemicals, including those used in polyurethane applications, and provide information on their properties, hazards, and safe use. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

The International Organization for Standardization (ISO) has developed several standards specific to polyurethane applications. These standards, such as ISO 14932 for polyurethane adhesives and ISO 2440 for flexible polyurethane foams, provide guidelines for testing methods, performance requirements, and quality control measures to prevent degradation and ensure product consistency.

Many countries have implemented regulations to address the end-of-life management of polyurethane products. For instance, the European Union's Waste Framework Directive and the End-of-Life Vehicles Directive promote the recycling and proper disposal of polyurethane materials. These regulations aim to reduce environmental impact and encourage the development of more sustainable polyurethane applications.

Industry associations, such as the American Chemistry Council's Center for the Polyurethanes Industry, have established voluntary product stewardship programs. These initiatives promote best practices in the manufacture, use, and disposal of polyurethane products, complementing regulatory frameworks and addressing emerging concerns related to degradation prevention.

As environmental concerns grow, regulations are evolving to address the lifecycle impact of polyurethanes. For example, some jurisdictions are implementing extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal or recycling. This approach incentivizes the development of more durable and easily recyclable polyurethane applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!