How To Scale Electroporation For Industrial Bioprocessing

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electroporation Scaling Background and Objectives

Electroporation, a technique that uses electrical pulses to create temporary pores in cell membranes, has been a cornerstone in molecular biology and biotechnology for decades. Initially developed for small-scale laboratory applications, the technology has shown immense potential for industrial bioprocessing. The evolution of electroporation from bench-scale experiments to large-scale industrial applications represents a significant technological leap in the field of biotechnology.

The primary objective of scaling electroporation for industrial bioprocessing is to enhance the efficiency and throughput of genetic modification, protein production, and other bioprocessing applications. This scaling-up process aims to maintain or improve the effectiveness of electroporation while significantly increasing the volume of treated cells or biomass. The goal is to develop systems capable of processing large quantities of biological material in a cost-effective and time-efficient manner, suitable for industrial-scale production.

The journey of electroporation scaling has been marked by several key technological advancements. Early electroporation devices were limited to treating small volumes of cell suspensions, typically in the microliter to milliliter range. As the demand for larger-scale applications grew, researchers and engineers focused on developing flow-through systems and continuous processing methods. These innovations allowed for the treatment of larger volumes of cell suspensions, paving the way for industrial applications.

One of the critical challenges in scaling electroporation has been maintaining uniform electric field distribution across larger volumes. This challenge has driven research into electrode design, pulse generation technology, and flow dynamics. The development of specialized electrode configurations, such as plate-and-plate or coaxial electrode systems, has been crucial in addressing this issue. Additionally, advancements in pulse generator technology have enabled the delivery of precise and consistent electrical pulses across larger treatment volumes.

The scaling of electroporation also necessitated improvements in cell handling and post-treatment recovery processes. Industrial-scale applications require efficient methods for cell suspension preparation, post-electroporation recovery, and downstream processing. This has led to the integration of electroporation systems with other bioprocessing equipment, creating more streamlined and automated production lines.

As the technology continues to evolve, the focus is shifting towards developing more robust, scalable, and versatile electroporation systems. Current research aims to optimize parameters such as electric field strength, pulse duration, and frequency for different cell types and applications at industrial scales. The ultimate goal is to create electroporation platforms that can be easily adapted to various bioprocessing needs, from the production of biopharmaceuticals to the development of novel food products and biofuels.

The primary objective of scaling electroporation for industrial bioprocessing is to enhance the efficiency and throughput of genetic modification, protein production, and other bioprocessing applications. This scaling-up process aims to maintain or improve the effectiveness of electroporation while significantly increasing the volume of treated cells or biomass. The goal is to develop systems capable of processing large quantities of biological material in a cost-effective and time-efficient manner, suitable for industrial-scale production.

The journey of electroporation scaling has been marked by several key technological advancements. Early electroporation devices were limited to treating small volumes of cell suspensions, typically in the microliter to milliliter range. As the demand for larger-scale applications grew, researchers and engineers focused on developing flow-through systems and continuous processing methods. These innovations allowed for the treatment of larger volumes of cell suspensions, paving the way for industrial applications.

One of the critical challenges in scaling electroporation has been maintaining uniform electric field distribution across larger volumes. This challenge has driven research into electrode design, pulse generation technology, and flow dynamics. The development of specialized electrode configurations, such as plate-and-plate or coaxial electrode systems, has been crucial in addressing this issue. Additionally, advancements in pulse generator technology have enabled the delivery of precise and consistent electrical pulses across larger treatment volumes.

The scaling of electroporation also necessitated improvements in cell handling and post-treatment recovery processes. Industrial-scale applications require efficient methods for cell suspension preparation, post-electroporation recovery, and downstream processing. This has led to the integration of electroporation systems with other bioprocessing equipment, creating more streamlined and automated production lines.

As the technology continues to evolve, the focus is shifting towards developing more robust, scalable, and versatile electroporation systems. Current research aims to optimize parameters such as electric field strength, pulse duration, and frequency for different cell types and applications at industrial scales. The ultimate goal is to create electroporation platforms that can be easily adapted to various bioprocessing needs, from the production of biopharmaceuticals to the development of novel food products and biofuels.

Industrial Bioprocessing Market Analysis

The industrial bioprocessing market has been experiencing significant growth in recent years, driven by the increasing demand for biopharmaceuticals, biofuels, and other bio-based products. This market encompasses a wide range of applications, including the production of enzymes, proteins, antibodies, and other biological molecules for various industries such as healthcare, food and beverage, and energy.

The global industrial bioprocessing market was valued at $15.8 billion in 2020 and is projected to reach $28.7 billion by 2026, growing at a CAGR of 10.2% during the forecast period. This growth is primarily attributed to the rising adoption of biopharmaceuticals, advancements in bioprocessing technologies, and increasing investments in research and development.

The biopharmaceutical segment dominates the industrial bioprocessing market, accounting for the largest share of revenue. This is due to the growing prevalence of chronic diseases and the increasing demand for personalized medicine. The food and beverage industry is also a significant contributor to the market, with applications in the production of enzymes, flavors, and other bio-based ingredients.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States is the leading country in terms of market size and technological advancements in industrial bioprocessing. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the highest growth rates in the coming years due to increasing investments in biotechnology and favorable government initiatives.

Key players in the industrial bioprocessing market include Thermo Fisher Scientific, Danaher Corporation, Sartorius AG, and Merck KGaA, among others. These companies are focusing on strategic collaborations, mergers and acquisitions, and product innovations to maintain their competitive edge in the market.

The adoption of single-use technologies and continuous bioprocessing systems is a major trend in the industrial bioprocessing market. These technologies offer advantages such as reduced contamination risks, increased flexibility, and improved process efficiency. Additionally, the integration of artificial intelligence and machine learning in bioprocessing is expected to drive further advancements in process optimization and control.

Challenges in the industrial bioprocessing market include the high costs associated with bioprocessing equipment and the complexity of scaling up production processes. However, ongoing research and development efforts are focused on addressing these challenges and improving the overall efficiency and cost-effectiveness of industrial bioprocessing.

The global industrial bioprocessing market was valued at $15.8 billion in 2020 and is projected to reach $28.7 billion by 2026, growing at a CAGR of 10.2% during the forecast period. This growth is primarily attributed to the rising adoption of biopharmaceuticals, advancements in bioprocessing technologies, and increasing investments in research and development.

The biopharmaceutical segment dominates the industrial bioprocessing market, accounting for the largest share of revenue. This is due to the growing prevalence of chronic diseases and the increasing demand for personalized medicine. The food and beverage industry is also a significant contributor to the market, with applications in the production of enzymes, flavors, and other bio-based ingredients.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The United States is the leading country in terms of market size and technological advancements in industrial bioprocessing. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the highest growth rates in the coming years due to increasing investments in biotechnology and favorable government initiatives.

Key players in the industrial bioprocessing market include Thermo Fisher Scientific, Danaher Corporation, Sartorius AG, and Merck KGaA, among others. These companies are focusing on strategic collaborations, mergers and acquisitions, and product innovations to maintain their competitive edge in the market.

The adoption of single-use technologies and continuous bioprocessing systems is a major trend in the industrial bioprocessing market. These technologies offer advantages such as reduced contamination risks, increased flexibility, and improved process efficiency. Additionally, the integration of artificial intelligence and machine learning in bioprocessing is expected to drive further advancements in process optimization and control.

Challenges in the industrial bioprocessing market include the high costs associated with bioprocessing equipment and the complexity of scaling up production processes. However, ongoing research and development efforts are focused on addressing these challenges and improving the overall efficiency and cost-effectiveness of industrial bioprocessing.

Current Electroporation Technologies and Challenges

Electroporation is a widely used technique in bioprocessing for introducing foreign molecules into cells. However, scaling this technology for industrial applications presents significant challenges. Current electroporation technologies primarily rely on batch processes, which are limited in throughput and scalability. These systems typically use cuvettes or flow-through devices that can process only small volumes of cell suspensions at a time.

One of the main challenges in scaling electroporation is maintaining uniform electric field distribution across larger volumes. As the volume of cell suspension increases, it becomes increasingly difficult to ensure that all cells are exposed to the optimal electric field strength. This non-uniformity can lead to reduced transfection efficiency and increased cell death, compromising the overall yield and quality of the bioprocess.

Another significant challenge is heat generation during the electroporation process. When scaling up, the increased volume and higher total energy input can result in substantial heat accumulation. This excess heat can cause thermal damage to cells, further reducing viability and product yield. Current cooling systems struggle to dissipate heat effectively in large-scale operations, limiting the maximum achievable throughput.

The pulsing systems used in electroporation also face limitations when scaling up. Most commercial systems are designed for small-scale applications and lack the power output and precise control required for industrial-scale processes. Developing pulsing systems capable of delivering consistent, high-energy pulses to large volumes of cell suspension remains a significant engineering challenge.

Furthermore, the electrode design and configuration play a crucial role in electroporation efficiency. Scaling up electrode systems while maintaining optimal field distribution and minimizing electrode degradation is a complex task. Current electrode materials and designs may not be suitable for long-term, high-throughput industrial applications.

Continuous flow electroporation systems have emerged as a potential solution for scaling up, but they face their own set of challenges. These systems must balance flow rate, electric field strength, and exposure time to achieve efficient transfection. Maintaining consistent cell concentration and preventing cell aggregation in continuous flow setups are additional hurdles that need to be addressed.

Lastly, the integration of electroporation into existing bioprocessing workflows presents logistical and operational challenges. Large-scale electroporation systems must be compatible with upstream and downstream processes, requiring careful consideration of factors such as sterility, process control, and automation. The development of robust, scalable electroporation technologies that can seamlessly integrate into industrial bioprocessing pipelines remains an active area of research and development.

One of the main challenges in scaling electroporation is maintaining uniform electric field distribution across larger volumes. As the volume of cell suspension increases, it becomes increasingly difficult to ensure that all cells are exposed to the optimal electric field strength. This non-uniformity can lead to reduced transfection efficiency and increased cell death, compromising the overall yield and quality of the bioprocess.

Another significant challenge is heat generation during the electroporation process. When scaling up, the increased volume and higher total energy input can result in substantial heat accumulation. This excess heat can cause thermal damage to cells, further reducing viability and product yield. Current cooling systems struggle to dissipate heat effectively in large-scale operations, limiting the maximum achievable throughput.

The pulsing systems used in electroporation also face limitations when scaling up. Most commercial systems are designed for small-scale applications and lack the power output and precise control required for industrial-scale processes. Developing pulsing systems capable of delivering consistent, high-energy pulses to large volumes of cell suspension remains a significant engineering challenge.

Furthermore, the electrode design and configuration play a crucial role in electroporation efficiency. Scaling up electrode systems while maintaining optimal field distribution and minimizing electrode degradation is a complex task. Current electrode materials and designs may not be suitable for long-term, high-throughput industrial applications.

Continuous flow electroporation systems have emerged as a potential solution for scaling up, but they face their own set of challenges. These systems must balance flow rate, electric field strength, and exposure time to achieve efficient transfection. Maintaining consistent cell concentration and preventing cell aggregation in continuous flow setups are additional hurdles that need to be addressed.

Lastly, the integration of electroporation into existing bioprocessing workflows presents logistical and operational challenges. Large-scale electroporation systems must be compatible with upstream and downstream processes, requiring careful consideration of factors such as sterility, process control, and automation. The development of robust, scalable electroporation technologies that can seamlessly integrate into industrial bioprocessing pipelines remains an active area of research and development.

Existing Industrial-Scale Electroporation Solutions

01 Large-scale electroporation systems

Development of electroporation systems capable of handling large volumes or high-throughput applications. These systems are designed to scale up the electroporation process for industrial or commercial use, allowing for the treatment of larger cell populations or increased production capacity.- Large-scale electroporation systems: Development of electroporation systems capable of handling large volumes or high-throughput applications. These systems are designed to scale up the electroporation process for industrial or research purposes, allowing for the treatment of larger cell populations or increased sample processing capacity.

- Microfluidic electroporation devices: Integration of electroporation technology into microfluidic platforms for precise control and manipulation of small-scale samples. These devices enable efficient electroporation of individual cells or small cell populations, offering advantages in terms of reduced sample volume requirements and improved uniformity of treatment.

- Electrode design and configuration: Innovations in electrode design and configuration to optimize electroporation efficiency and scalability. This includes the development of novel electrode materials, geometries, and arrangements to enhance electric field distribution and cell membrane permeabilization across different scales of operation.

- Pulse parameters and waveform optimization: Research into optimizing electroporation pulse parameters and waveforms for different scales of operation. This involves investigating the effects of pulse duration, amplitude, frequency, and shape on electroporation efficiency and cell viability, with the goal of developing scalable protocols for various applications.

- Automation and control systems: Development of automated systems and control mechanisms for scalable electroporation processes. These innovations focus on improving the reproducibility, efficiency, and ease of use of electroporation equipment across different scales, from benchtop devices to industrial-scale systems.

02 Microfluidic electroporation devices

Creation of miniaturized electroporation devices using microfluidic technology. These devices allow for precise control over cell manipulation and electroporation parameters, enabling efficient transfection of small sample volumes or single cells.Expand Specific Solutions03 Electrode design and configuration

Innovations in electrode design and configuration to improve electroporation efficiency and scalability. This includes the development of novel electrode materials, shapes, and arrangements to optimize electric field distribution and cell permeabilization across different scales of operation.Expand Specific Solutions04 Pulse generation and control systems

Advancements in pulse generation and control systems for electroporation. These developments focus on creating more precise, flexible, and scalable pulse delivery methods to accommodate various cell types and experimental conditions across different scales.Expand Specific Solutions05 Integration with other technologies

Integration of electroporation with other technologies to enhance its scalability and effectiveness. This includes combining electroporation with acoustic, optical, or chemical methods to improve cell permeabilization, transfection efficiency, or throughput at various scales.Expand Specific Solutions

Key Players in Industrial Electroporation

The electroporation technology for industrial bioprocessing is in a growth phase, with increasing market demand driven by biopharmaceutical and cell therapy applications. The global market size is projected to expand significantly in the coming years. Technologically, electroporation is advancing from lab-scale to industrial-scale applications, with companies like MaxCyte, Cellares, and Cytequest developing automated, high-throughput systems. Established players such as Bio-Rad Laboratories and Life Technologies offer a range of electroporation products, while newer entrants like Suzhou Yida Biotechnology are innovating with flow electroporation instruments. Academic institutions like MIT and Tsinghua University contribute to fundamental research, potentially leading to future breakthroughs in scalability and efficiency.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed microfluidic devices for continuous-flow electroporation, which can be scaled up for industrial bioprocessing. These devices use a series of microchannels to expose cells to electric fields as they flow through, allowing for high-throughput electroporation[12]. The design incorporates electrode configurations that create uniform electric fields, improving transfection efficiency and cell viability[13]. MIT's approach also includes the use of 3D-printed microfluidic devices, which can be rapidly prototyped and customized for different cell types and applications[14]. This technology has shown promise for scaling up the production of CAR-T cells and other cell therapies.

Strengths: Continuous-flow process, customizable for different applications, potential for high-throughput. Weaknesses: May require further development for large-scale industrial use, potential challenges in maintaining sterility in microfluidic systems.

The Regents of the University of California

Technical Solution: Researchers at the University of California have developed several approaches to scale electroporation for industrial bioprocessing. One notable innovation is the use of nanochannels for precise control of electroporation parameters[15]. This technology allows for uniform treatment of cells and can be parallelized for high-throughput applications. Another approach involves the use of 3D-printed flow-through electroporation devices that can process large volumes of cell suspension continuously[16]. The university has also explored the use of pulsed electric fields in combination with microfluidics to enhance the efficiency and scalability of electroporation[17]. These technologies have shown potential for applications in cell therapy manufacturing and large-scale protein production.

Strengths: Diverse range of innovative approaches, potential for high precision and efficiency. Weaknesses: Some technologies still in early stages of development, may require significant optimization for industrial-scale use.

Core Innovations in Electroporation Scaling

Method and reactor for the non-thermal decomposition and pasteurisation of organic process materials by electroporation

PatentInactiveEP1425104A1

Innovation

- A reactor design using pulsed electric fields with varying directions and a Marx generator to apply high-voltage pulses to biological cells, ensuring that each cell experiences a threshold potential difference for electroporation, allowing for efficient disruption and pasteurization of large quantities with minimal energy consumption.

Large volume ex vivo electroporation method

PatentInactiveEP1620537B1

Innovation

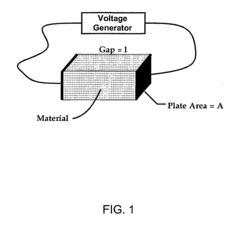

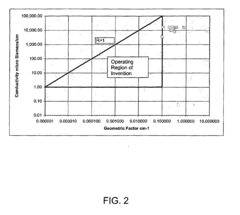

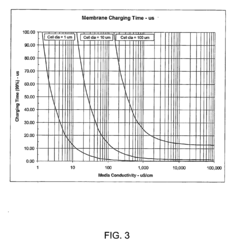

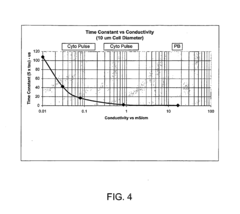

- A static chamber with parallel plate electrodes and low conductivity medium is used, allowing for uniform electric fields and scalable processing of large cell volumes without excessive amperage, using a defined conductivity range to minimize heating and enable variable pulse waveforms.

Regulatory Considerations for Bioprocessing

Regulatory considerations play a crucial role in the scaling of electroporation for industrial bioprocessing. As this technology advances and becomes more widely adopted, it is essential to navigate the complex landscape of regulations governing its use in large-scale production environments.

The primary regulatory bodies overseeing bioprocessing and related technologies include the Food and Drug Administration (FDA) in the United States, the European Medicines Agency (EMA) in Europe, and similar organizations in other regions. These agencies have established guidelines and requirements for the use of novel technologies in the production of biopharmaceuticals and other biological products.

One of the key regulatory challenges for scaling electroporation is ensuring the consistency and reproducibility of the process at an industrial scale. Regulatory agencies require robust validation protocols to demonstrate that the scaled-up process maintains the same level of efficacy and safety as smaller-scale operations. This includes providing detailed documentation on process parameters, equipment specifications, and quality control measures.

Another important consideration is the potential impact of electroporation on product quality and safety. Regulatory bodies will scrutinize how the scaled-up process affects the integrity of cellular membranes, protein structures, and genetic material. Manufacturers must provide comprehensive data on the effects of electroporation on the final product, including any potential changes in biological activity or the introduction of unwanted byproducts.

The use of electroporation in the production of genetically modified organisms (GMOs) or gene therapies may trigger additional regulatory requirements. In many jurisdictions, there are specific regulations governing the development, production, and release of GMOs, which must be carefully addressed when scaling up electroporation processes for these applications.

Regulatory agencies also focus on the safety aspects of large-scale electroporation equipment. This includes assessing the potential risks associated with high-voltage systems, electromagnetic fields, and the handling of biological materials. Manufacturers must demonstrate that their scaled-up electroporation systems comply with relevant safety standards and incorporate appropriate safeguards to protect operators and the environment.

As the technology evolves, regulatory frameworks may need to adapt to keep pace with new developments. Industry stakeholders should engage in ongoing dialogue with regulatory agencies to ensure that guidelines remain relevant and supportive of innovation while maintaining high standards of safety and efficacy.

The primary regulatory bodies overseeing bioprocessing and related technologies include the Food and Drug Administration (FDA) in the United States, the European Medicines Agency (EMA) in Europe, and similar organizations in other regions. These agencies have established guidelines and requirements for the use of novel technologies in the production of biopharmaceuticals and other biological products.

One of the key regulatory challenges for scaling electroporation is ensuring the consistency and reproducibility of the process at an industrial scale. Regulatory agencies require robust validation protocols to demonstrate that the scaled-up process maintains the same level of efficacy and safety as smaller-scale operations. This includes providing detailed documentation on process parameters, equipment specifications, and quality control measures.

Another important consideration is the potential impact of electroporation on product quality and safety. Regulatory bodies will scrutinize how the scaled-up process affects the integrity of cellular membranes, protein structures, and genetic material. Manufacturers must provide comprehensive data on the effects of electroporation on the final product, including any potential changes in biological activity or the introduction of unwanted byproducts.

The use of electroporation in the production of genetically modified organisms (GMOs) or gene therapies may trigger additional regulatory requirements. In many jurisdictions, there are specific regulations governing the development, production, and release of GMOs, which must be carefully addressed when scaling up electroporation processes for these applications.

Regulatory agencies also focus on the safety aspects of large-scale electroporation equipment. This includes assessing the potential risks associated with high-voltage systems, electromagnetic fields, and the handling of biological materials. Manufacturers must demonstrate that their scaled-up electroporation systems comply with relevant safety standards and incorporate appropriate safeguards to protect operators and the environment.

As the technology evolves, regulatory frameworks may need to adapt to keep pace with new developments. Industry stakeholders should engage in ongoing dialogue with regulatory agencies to ensure that guidelines remain relevant and supportive of innovation while maintaining high standards of safety and efficacy.

Economic Feasibility of Scaled Electroporation

The economic feasibility of scaled electroporation for industrial bioprocessing hinges on several key factors. Firstly, the capital investment required for large-scale electroporation equipment is substantial, necessitating careful consideration of return on investment. Industrial-scale electroporation systems can cost millions of dollars, depending on their capacity and sophistication. However, these costs may be offset by increased productivity and efficiency in bioprocessing operations.

Operational costs are another critical aspect of economic feasibility. Electricity consumption is a significant factor, as electroporation requires high-voltage pulses. The energy costs can be considerable, especially for continuous large-scale operations. However, advancements in pulse generator technology and energy recovery systems are gradually improving energy efficiency, potentially reducing long-term operational expenses.

Labor costs associated with scaled electroporation are relatively low compared to traditional bioprocessing methods. The process can be highly automated, reducing the need for manual intervention and minimizing human error. This automation not only improves consistency but also contributes to cost savings in terms of personnel requirements.

The economic viability of scaled electroporation is further enhanced by its potential to increase product yield and quality. By improving cell permeabilization and transfection efficiency, electroporation can lead to higher production rates of biologics, enzymes, and other valuable biomolecules. This increased yield can significantly impact the overall economics of bioprocessing operations, potentially justifying the initial capital investment.

Scalability itself presents both challenges and opportunities from an economic perspective. While scaling up electroporation systems requires careful engineering and potentially custom-designed equipment, it also offers economies of scale. Larger systems can process greater volumes of material more efficiently, potentially reducing per-unit production costs.

Regulatory considerations also play a role in the economic feasibility of scaled electroporation. The technology must meet stringent safety and quality standards for industrial bioprocessing applications. While achieving regulatory compliance may incur additional costs, it also opens up opportunities for high-value applications in pharmaceutical and biotechnology industries.

In conclusion, while the initial investment for scaled electroporation in industrial bioprocessing is significant, the potential for increased productivity, reduced operational costs, and improved product quality makes it an economically attractive option for many bioprocessing applications. As the technology continues to advance and become more efficient, its economic feasibility is likely to improve further, making it an increasingly viable choice for industrial-scale bioprocessing operations.

Operational costs are another critical aspect of economic feasibility. Electricity consumption is a significant factor, as electroporation requires high-voltage pulses. The energy costs can be considerable, especially for continuous large-scale operations. However, advancements in pulse generator technology and energy recovery systems are gradually improving energy efficiency, potentially reducing long-term operational expenses.

Labor costs associated with scaled electroporation are relatively low compared to traditional bioprocessing methods. The process can be highly automated, reducing the need for manual intervention and minimizing human error. This automation not only improves consistency but also contributes to cost savings in terms of personnel requirements.

The economic viability of scaled electroporation is further enhanced by its potential to increase product yield and quality. By improving cell permeabilization and transfection efficiency, electroporation can lead to higher production rates of biologics, enzymes, and other valuable biomolecules. This increased yield can significantly impact the overall economics of bioprocessing operations, potentially justifying the initial capital investment.

Scalability itself presents both challenges and opportunities from an economic perspective. While scaling up electroporation systems requires careful engineering and potentially custom-designed equipment, it also offers economies of scale. Larger systems can process greater volumes of material more efficiently, potentially reducing per-unit production costs.

Regulatory considerations also play a role in the economic feasibility of scaled electroporation. The technology must meet stringent safety and quality standards for industrial bioprocessing applications. While achieving regulatory compliance may incur additional costs, it also opens up opportunities for high-value applications in pharmaceutical and biotechnology industries.

In conclusion, while the initial investment for scaled electroporation in industrial bioprocessing is significant, the potential for increased productivity, reduced operational costs, and improved product quality makes it an economically attractive option for many bioprocessing applications. As the technology continues to advance and become more efficient, its economic feasibility is likely to improve further, making it an increasingly viable choice for industrial-scale bioprocessing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!