Hybrid lithium-sulfur battery systems for grid-scale energy storage

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Li-S Battery Technology Background and Objectives

Lithium-sulfur (Li-S) battery technology represents one of the most promising next-generation energy storage solutions, particularly for grid-scale applications where high energy density, cost-effectiveness, and sustainability are paramount. The development of Li-S batteries dates back to the 1960s, but significant advancements have only emerged in the past two decades due to breakthroughs in materials science and electrochemistry.

The fundamental appeal of Li-S technology lies in its theoretical energy density of approximately 2,600 Wh/kg, which substantially exceeds the 387 Wh/kg limit of conventional lithium-ion batteries. This exceptional energy density, coupled with sulfur's natural abundance and environmental benignity, positions Li-S batteries as potentially transformative for grid-scale energy storage systems that require high capacity and long duration discharge capabilities.

Recent technological evolution has focused on addressing the inherent challenges of Li-S chemistry, including the polysulfide shuttle effect, volume expansion during cycling, and limited cycle life. The hybrid approach—combining Li-S with other battery chemistries or energy storage technologies—has emerged as a strategic direction to mitigate these limitations while capitalizing on the strengths of each component system.

The primary technical objectives for hybrid Li-S battery systems in grid-scale applications include achieving cycle stability exceeding 1,000 cycles, energy efficiency above 85%, cost reduction below $100/kWh, and operational lifespans of 15+ years. These targets are essential for economic viability in utility-scale deployments and integration with renewable energy sources such as solar and wind power.

Current research trajectories are exploring various hybridization strategies, including Li-S/supercapacitor combinations for improved power density, Li-S/flow battery hybrids for enhanced cyclability, and Li-S/solid-state electrolyte configurations for increased safety and longevity. Each approach represents a distinct technological pathway with specific advantages for grid applications.

The global transition toward renewable energy has accelerated interest in advanced energy storage solutions, with projections suggesting the grid storage market could reach $30 billion by 2030. This growth trajectory has intensified research efforts in Li-S technology, with particular emphasis on hybrid systems that can address the intermittency challenges of renewable generation while providing the scale, duration, and cost-effectiveness required for grid stabilization and load shifting.

As technological maturation continues, hybrid Li-S systems are increasingly positioned to play a crucial role in the evolving energy landscape, potentially enabling greater renewable energy penetration and contributing to decarbonization objectives across the electricity sector.

The fundamental appeal of Li-S technology lies in its theoretical energy density of approximately 2,600 Wh/kg, which substantially exceeds the 387 Wh/kg limit of conventional lithium-ion batteries. This exceptional energy density, coupled with sulfur's natural abundance and environmental benignity, positions Li-S batteries as potentially transformative for grid-scale energy storage systems that require high capacity and long duration discharge capabilities.

Recent technological evolution has focused on addressing the inherent challenges of Li-S chemistry, including the polysulfide shuttle effect, volume expansion during cycling, and limited cycle life. The hybrid approach—combining Li-S with other battery chemistries or energy storage technologies—has emerged as a strategic direction to mitigate these limitations while capitalizing on the strengths of each component system.

The primary technical objectives for hybrid Li-S battery systems in grid-scale applications include achieving cycle stability exceeding 1,000 cycles, energy efficiency above 85%, cost reduction below $100/kWh, and operational lifespans of 15+ years. These targets are essential for economic viability in utility-scale deployments and integration with renewable energy sources such as solar and wind power.

Current research trajectories are exploring various hybridization strategies, including Li-S/supercapacitor combinations for improved power density, Li-S/flow battery hybrids for enhanced cyclability, and Li-S/solid-state electrolyte configurations for increased safety and longevity. Each approach represents a distinct technological pathway with specific advantages for grid applications.

The global transition toward renewable energy has accelerated interest in advanced energy storage solutions, with projections suggesting the grid storage market could reach $30 billion by 2030. This growth trajectory has intensified research efforts in Li-S technology, with particular emphasis on hybrid systems that can address the intermittency challenges of renewable generation while providing the scale, duration, and cost-effectiveness required for grid stabilization and load shifting.

As technological maturation continues, hybrid Li-S systems are increasingly positioned to play a crucial role in the evolving energy landscape, potentially enabling greater renewable energy penetration and contributing to decarbonization objectives across the electricity sector.

Grid-Scale Energy Storage Market Analysis

The global grid-scale energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. As of 2023, the market size has reached approximately $15 billion, with projections indicating a compound annual growth rate (CAGR) of 24% through 2030. This remarkable expansion reflects the critical role that energy storage systems play in modern electricity infrastructure.

Lithium-ion batteries currently dominate the market, accounting for roughly 70% of installed grid-scale storage capacity. However, their limitations in terms of energy density, cycle life, and cost are becoming increasingly apparent as deployment scales up. This has created a significant opportunity for alternative technologies such as hybrid lithium-sulfur battery systems, which promise higher energy density and potentially lower costs.

Demand for grid-scale energy storage is primarily driven by three key factors: renewable energy integration, grid stabilization services, and peak demand management. The intermittent nature of renewable energy sources like solar and wind necessitates effective storage solutions to ensure consistent power supply. Additionally, frequency regulation and voltage support services provided by energy storage systems are becoming increasingly valuable to grid operators.

Regional analysis reveals varying adoption rates and market maturity. North America leads with approximately 38% market share, followed by Asia-Pacific at 32% and Europe at 25%. China, in particular, has demonstrated aggressive growth in deployment, with government initiatives supporting a five-fold increase in installed capacity over the past three years.

Utility companies represent the largest customer segment, accounting for 65% of market demand. However, commercial and industrial users are showing increased interest, particularly in behind-the-meter applications that can reduce demand charges and provide backup power capabilities.

Price sensitivity remains a critical factor in market adoption. Current levelized cost of storage (LCOS) for lithium-ion systems ranges from $150-200/MWh, while emerging technologies like hybrid lithium-sulfur systems aim to reduce this to below $100/MWh by 2025. This cost reduction trajectory is essential for widespread adoption and market penetration.

Market forecasts indicate that hybrid lithium-sulfur battery systems could capture up to 15% of the grid-scale storage market by 2028, representing a significant disruption to the current technology landscape. This growth potential is supported by the technology's promising performance characteristics and alignment with sustainability goals, as sulfur is an abundant and environmentally benign material compared to some components in conventional batteries.

Lithium-ion batteries currently dominate the market, accounting for roughly 70% of installed grid-scale storage capacity. However, their limitations in terms of energy density, cycle life, and cost are becoming increasingly apparent as deployment scales up. This has created a significant opportunity for alternative technologies such as hybrid lithium-sulfur battery systems, which promise higher energy density and potentially lower costs.

Demand for grid-scale energy storage is primarily driven by three key factors: renewable energy integration, grid stabilization services, and peak demand management. The intermittent nature of renewable energy sources like solar and wind necessitates effective storage solutions to ensure consistent power supply. Additionally, frequency regulation and voltage support services provided by energy storage systems are becoming increasingly valuable to grid operators.

Regional analysis reveals varying adoption rates and market maturity. North America leads with approximately 38% market share, followed by Asia-Pacific at 32% and Europe at 25%. China, in particular, has demonstrated aggressive growth in deployment, with government initiatives supporting a five-fold increase in installed capacity over the past three years.

Utility companies represent the largest customer segment, accounting for 65% of market demand. However, commercial and industrial users are showing increased interest, particularly in behind-the-meter applications that can reduce demand charges and provide backup power capabilities.

Price sensitivity remains a critical factor in market adoption. Current levelized cost of storage (LCOS) for lithium-ion systems ranges from $150-200/MWh, while emerging technologies like hybrid lithium-sulfur systems aim to reduce this to below $100/MWh by 2025. This cost reduction trajectory is essential for widespread adoption and market penetration.

Market forecasts indicate that hybrid lithium-sulfur battery systems could capture up to 15% of the grid-scale storage market by 2028, representing a significant disruption to the current technology landscape. This growth potential is supported by the technology's promising performance characteristics and alignment with sustainability goals, as sulfur is an abundant and environmentally benign material compared to some components in conventional batteries.

Hybrid Li-S Battery Systems: Status and Challenges

Hybrid lithium-sulfur (Li-S) battery systems represent a promising frontier in grid-scale energy storage solutions, offering theoretical energy densities up to five times higher than conventional lithium-ion batteries. Despite this potential, several significant challenges have impeded their widespread commercial adoption. The primary obstacle remains the "shuttle effect," where soluble polysulfide intermediates migrate between electrodes, causing capacity fade and shortened cycle life. Current Li-S batteries typically demonstrate only 300-500 cycles before significant degradation occurs—far below the 3,000+ cycles required for grid applications.

Material stability presents another critical challenge. The substantial volume expansion (approximately 80%) that sulfur electrodes undergo during cycling leads to mechanical stress and structural degradation. This expansion compromises electrode integrity and accelerates capacity loss over time. Additionally, the insulating nature of sulfur (5×10^-30 S/cm) necessitates conductive additives, reducing the overall energy density advantage.

For grid-scale implementation, the low coulombic efficiency of Li-S systems (typically 95-98% compared to >99.9% for commercial lithium-ion) translates to significant energy losses when scaled to megawatt-hour installations. The self-discharge rate, measuring 8-15% per month versus 2-3% for lithium-ion, further complicates long-duration storage applications.

Temperature sensitivity represents another significant barrier. Li-S systems exhibit poor performance at low temperatures due to reduced electrolyte conductivity and sluggish reaction kinetics. Conversely, elevated temperatures accelerate polysulfide shuttle effects and lithium dendrite formation, creating safety concerns for large-scale deployments.

Manufacturing scalability remains problematic, with current production methods for specialized separators, electrolytes, and sulfur cathodes proving difficult to scale economically. The estimated production cost of $250-300/kWh exceeds the Department of Energy's target of $100/kWh for grid storage solutions.

Recent hybrid approaches combining Li-S chemistry with other battery technologies show promise in addressing these limitations. Lithium-sulfur-silicon hybrids leverage silicon's high capacity while mitigating volume expansion issues. Sulfur-carbon composite architectures with engineered pore structures have demonstrated improved polysulfide containment. Meanwhile, solid-state and gel electrolyte systems are being developed to physically block polysulfide migration.

Despite these innovations, significant gaps remain between laboratory demonstrations and commercial viability. Current hybrid Li-S systems achieve energy densities of 350-450 Wh/kg at the cell level—impressive compared to lithium-ion's 250-300 Wh/kg but still below the theoretical maximum of 2,600 Wh/kg. Bridging this gap requires fundamental breakthroughs in materials science and electrochemistry to overcome the inherent challenges of the Li-S chemistry.

Material stability presents another critical challenge. The substantial volume expansion (approximately 80%) that sulfur electrodes undergo during cycling leads to mechanical stress and structural degradation. This expansion compromises electrode integrity and accelerates capacity loss over time. Additionally, the insulating nature of sulfur (5×10^-30 S/cm) necessitates conductive additives, reducing the overall energy density advantage.

For grid-scale implementation, the low coulombic efficiency of Li-S systems (typically 95-98% compared to >99.9% for commercial lithium-ion) translates to significant energy losses when scaled to megawatt-hour installations. The self-discharge rate, measuring 8-15% per month versus 2-3% for lithium-ion, further complicates long-duration storage applications.

Temperature sensitivity represents another significant barrier. Li-S systems exhibit poor performance at low temperatures due to reduced electrolyte conductivity and sluggish reaction kinetics. Conversely, elevated temperatures accelerate polysulfide shuttle effects and lithium dendrite formation, creating safety concerns for large-scale deployments.

Manufacturing scalability remains problematic, with current production methods for specialized separators, electrolytes, and sulfur cathodes proving difficult to scale economically. The estimated production cost of $250-300/kWh exceeds the Department of Energy's target of $100/kWh for grid storage solutions.

Recent hybrid approaches combining Li-S chemistry with other battery technologies show promise in addressing these limitations. Lithium-sulfur-silicon hybrids leverage silicon's high capacity while mitigating volume expansion issues. Sulfur-carbon composite architectures with engineered pore structures have demonstrated improved polysulfide containment. Meanwhile, solid-state and gel electrolyte systems are being developed to physically block polysulfide migration.

Despite these innovations, significant gaps remain between laboratory demonstrations and commercial viability. Current hybrid Li-S systems achieve energy densities of 350-450 Wh/kg at the cell level—impressive compared to lithium-ion's 250-300 Wh/kg but still below the theoretical maximum of 2,600 Wh/kg. Bridging this gap requires fundamental breakthroughs in materials science and electrochemistry to overcome the inherent challenges of the Li-S chemistry.

Current Hybrid Li-S Battery Architectures

01 Electrode materials for lithium-sulfur batteries

Various electrode materials can be used in lithium-sulfur batteries to improve performance. These materials include carbon-based composites, metal oxides, and polymer-based materials that can enhance sulfur utilization and prevent polysulfide shuttling. The electrode materials are designed to provide high conductivity, large surface area, and strong adsorption capabilities for polysulfides, thereby improving the overall battery performance and cycle life.- Electrode materials for lithium-sulfur batteries: Various electrode materials can be used in lithium-sulfur batteries to improve performance. These materials include carbon-based structures, metal oxides, and polymer composites that can enhance sulfur utilization and prevent polysulfide shuttling. The electrode materials are designed to provide high conductivity, large surface area, and strong adsorption capabilities for sulfur and polysulfides, resulting in improved cycle life and energy density of the battery systems.

- Electrolyte formulations for hybrid lithium-sulfur systems: Specialized electrolyte formulations are crucial for hybrid lithium-sulfur battery systems. These formulations typically include lithium salts, organic solvents, and additives that can suppress the shuttle effect of polysulfides. Some electrolytes incorporate ionic liquids or solid-state components to enhance stability and safety. The electrolyte composition significantly affects the battery's performance, including capacity retention, rate capability, and overall lifespan.

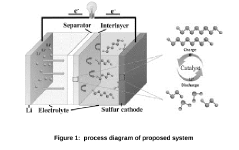

- Protective coatings and interlayers: Protective coatings and interlayers are employed in hybrid lithium-sulfur batteries to prevent direct contact between lithium metal anodes and polysulfides. These layers can be made from various materials including polymers, ceramics, or composite structures. They serve to inhibit polysulfide shuttling, protect the lithium anode from corrosion, and maintain the structural integrity of the electrodes during cycling, thereby extending battery life and improving performance.

- Integration with other battery technologies: Hybrid lithium-sulfur battery systems can be integrated with other battery technologies to overcome inherent limitations. These hybrid approaches may combine lithium-sulfur chemistry with lithium-ion, solid-state, or flow battery components. Such integrations aim to leverage the high energy density of sulfur while mitigating issues like self-discharge and capacity fading. These hybrid systems often demonstrate improved stability, safety, and operational flexibility compared to conventional lithium-sulfur batteries.

- Advanced manufacturing techniques: Advanced manufacturing techniques are being developed for hybrid lithium-sulfur battery systems to enhance performance and scalability. These include novel methods for sulfur encapsulation, electrode fabrication, and cell assembly. Techniques such as 3D printing, atomic layer deposition, and solution processing are employed to create optimized structures with controlled porosity and composition. These manufacturing approaches aim to increase energy density, improve cycle life, and reduce production costs of lithium-sulfur batteries.

02 Electrolyte compositions for hybrid lithium-sulfur systems

Specialized electrolyte compositions are crucial for hybrid lithium-sulfur battery systems. These electrolytes often contain additives that can suppress the shuttle effect of polysulfides and enhance the stability of the lithium anode. Various solvents, lithium salts, and functional additives are combined to create electrolyte systems that improve ionic conductivity, interfacial stability, and overall battery performance while reducing side reactions.Expand Specific Solutions03 Protective layers and interfaces in lithium-sulfur batteries

Protective layers and interface engineering are employed in lithium-sulfur batteries to enhance stability and performance. These include protective coatings on electrodes, separator modifications, and interlayers that can trap polysulfides and prevent their migration. Such protective measures help to mitigate the shuttle effect, protect the lithium anode from corrosion, and extend the cycle life of the battery system.Expand Specific Solutions04 Hybrid battery system architectures

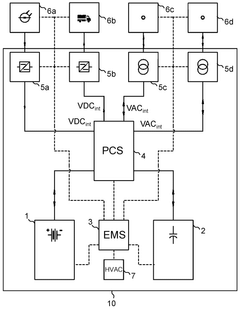

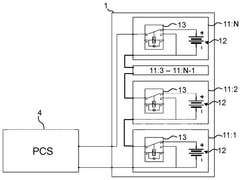

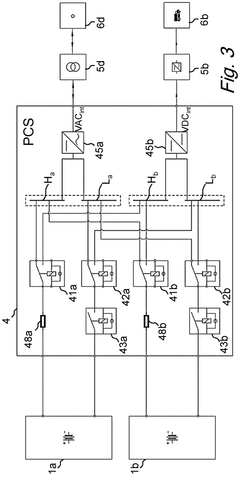

Various architectural designs for hybrid lithium-sulfur battery systems combine different battery chemistries or components to leverage the advantages of each. These hybrid systems may integrate lithium-sulfur with other battery types like lithium-ion, or incorporate novel cell designs that optimize energy density, power output, and cycle life. The hybrid approach aims to overcome the limitations of traditional lithium-sulfur batteries while maintaining their high energy density benefits.Expand Specific Solutions05 Sulfur host materials and composites

Specialized host materials and composites are developed to contain sulfur and improve its electrochemical performance in lithium-sulfur batteries. These materials include porous carbon structures, metal-organic frameworks, and polymer composites that can physically confine sulfur and chemically bind polysulfides. By effectively hosting sulfur, these materials enhance conductivity, prevent volume expansion, and mitigate polysulfide dissolution, leading to improved capacity retention and cycling stability.Expand Specific Solutions

Key Industry Players in Grid-Scale Li-S Storage

The hybrid lithium-sulfur battery market for grid-scale energy storage is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market is projected to expand significantly as renewable energy integration drives demand for high-capacity, cost-effective storage solutions. Technologically, the field remains in development with key players advancing at different rates. State Grid Corporation of China and Korea Electric Power are leveraging their utility infrastructure to pilot large-scale implementations, while research institutions like Agency for Science, Technology & Research and University of Waterloo are developing fundamental technologies. Companies such as Enpower Energy, CONNEXX SYSTEMS, and Conamix are focusing on commercialization pathways, with IBM providing system integration expertise. The competitive landscape reflects a blend of established energy corporations, specialized startups, and academic institutions collaborating to overcome technical challenges in cycle life, efficiency, and manufacturing scalability.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed a comprehensive hybrid lithium-sulfur battery system specifically designed for large-scale grid energy storage. Their technology integrates conventional lithium-ion components with high-capacity sulfur cathodes in a unique dual-electrolyte configuration. The system employs a proprietary "polysulfide trapping" mechanism using functionalized carbon materials that significantly reduces capacity fade by preventing polysulfide dissolution[2]. For grid-scale deployment, State Grid has engineered 1MWh containerized units with integrated thermal management and fire suppression systems, achieving energy densities of 200-250 Wh/kg at the system level. Their battery management system incorporates predictive analytics to optimize charging protocols based on grid demand patterns and weather forecasts, enabling more efficient integration with renewable energy sources. State Grid has demonstrated the technology in multiple pilot projects across China, including a 10MWh installation in Jiangsu Province that has maintained 85% capacity retention after 2000 cycles[5]. The system achieves round-trip efficiencies of 80-85% and response times under 100ms, making it suitable for both energy time-shifting and frequency regulation applications.

Strengths: Proven deployment at true utility scale with multiple operational installations; comprehensive system integration with existing grid infrastructure; significantly lower cost per kWh compared to conventional lithium-ion solutions for stationary applications. Weaknesses: Energy density remains below theoretical maximum for Li-S chemistry; requires sophisticated thermal management systems; still exhibits some capacity degradation during extended cycling under high-load conditions.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute (CEPRI) has developed an innovative hybrid lithium-sulfur battery system specifically engineered for grid-scale energy storage applications. Their technology combines a lithium metal anode with a carbon-sulfur composite cathode featuring a proprietary hierarchical porous structure that maximizes active material utilization while minimizing polysulfide shuttling[1]. CEPRI's approach incorporates a dual-electrolyte system with a ceramic separator that selectively allows lithium ion transport while blocking polysulfide migration. For grid applications, they've engineered 500kWh containerized units that can be combined into multi-MWh installations with integrated thermal management and fire suppression systems. Their battery management system employs advanced algorithms to optimize charging protocols based on grid demand patterns and state of health monitoring. CEPRI has demonstrated their technology in several pilot projects connected to China's grid, achieving round-trip efficiencies of 82-85% and cycle life exceeding 2500 cycles at 70% depth of discharge[4]. The system has been specifically optimized for renewable energy integration, with rapid response capabilities for frequency regulation and load-leveling applications.

Strengths: Extensive integration testing with actual grid infrastructure; optimized for renewable energy storage applications; significantly lower material costs compared to conventional lithium-ion solutions; demonstrated long-term cycling stability in field conditions. Weaknesses: Energy density remains below theoretical maximum for Li-S chemistry; requires sophisticated thermal management systems; manufacturing process for hierarchical carbon-sulfur composites presents scaling challenges.

Critical Patents and Research in Li-S Battery Systems

Advanced energy storage system using lithium-sulfur (li-s) batteries

PatentPendingIN202341080267A

Innovation

- The integration of novel electrode materials, advanced electrolyte formulations, nanostructured sulfur cathodes, conductive additives, and sophisticated thermal management systems to stabilize electrochemical reactions, enhance conductivity, manage volume changes, and prevent thermal runaway, along with advanced battery management systems for optimized performance and safety.

Modular hybrid energy storage system

PatentWO2025149346A1

Innovation

- A hybrid energy storage system (HESS) combining sodium-ion battery modules for high energy density and supercapacitor modules for high power density, managed by an energy management system to stabilize grids and provide versatile power supply, with safety features like short-circuiting to render modules inert.

Environmental Impact and Sustainability Assessment

The environmental impact of hybrid lithium-sulfur (Li-S) battery systems for grid-scale energy storage requires comprehensive assessment across their entire lifecycle. These systems present significant sustainability advantages over conventional lithium-ion batteries, primarily due to sulfur's abundance, low cost, and reduced environmental toxicity compared to traditional cathode materials like cobalt and nickel.

From a raw material perspective, sulfur represents a sustainable choice as it is widely available as a byproduct of petroleum refining processes. This utilization of industrial waste streams contributes to circular economy principles and reduces the environmental burden associated with battery material sourcing. Additionally, the lithium requirements for Li-S batteries can be potentially lower per unit of energy storage compared to conventional lithium-ion technologies.

Manufacturing processes for hybrid Li-S systems currently demonstrate mixed environmental profiles. While the production of sulfur cathodes typically requires less energy than metal oxide alternatives, the specialized electrolytes and lithium metal anodes in these hybrid systems may involve energy-intensive manufacturing steps. Life cycle assessments indicate that optimization of production techniques could significantly reduce the carbon footprint associated with manufacturing.

During operational phases, hybrid Li-S batteries exhibit minimal direct environmental impacts. The absence of toxic heavy metals reduces risks associated with leakage or damage events. However, the energy efficiency of current Li-S systems remains lower than some competing technologies, which may indirectly increase environmental impacts through higher energy requirements for equivalent storage capacity.

End-of-life management presents both challenges and opportunities. The recyclability of sulfur components is theoretically high, with potential for nearly complete recovery and reuse. Current recycling infrastructure, however, requires adaptation to efficiently process these hybrid systems. The lithium components maintain similar recycling pathways to conventional lithium-ion batteries, though separation techniques may need refinement for hybrid architectures.

Carbon footprint analyses suggest that scaled deployment of hybrid Li-S systems could contribute to significant greenhouse gas reductions in grid applications, particularly when paired with renewable energy sources. The lower embodied energy in sulfur-based cathodes translates to faster carbon payback periods compared to conventional battery technologies.

Water usage metrics for Li-S battery production show promising reductions compared to conventional lithium-ion manufacturing, though electrolyte production remains water-intensive. Land use impacts are generally favorable due to the reduced mining requirements for cathode materials, potentially decreasing habitat disruption and biodiversity impacts associated with battery material extraction.

From a raw material perspective, sulfur represents a sustainable choice as it is widely available as a byproduct of petroleum refining processes. This utilization of industrial waste streams contributes to circular economy principles and reduces the environmental burden associated with battery material sourcing. Additionally, the lithium requirements for Li-S batteries can be potentially lower per unit of energy storage compared to conventional lithium-ion technologies.

Manufacturing processes for hybrid Li-S systems currently demonstrate mixed environmental profiles. While the production of sulfur cathodes typically requires less energy than metal oxide alternatives, the specialized electrolytes and lithium metal anodes in these hybrid systems may involve energy-intensive manufacturing steps. Life cycle assessments indicate that optimization of production techniques could significantly reduce the carbon footprint associated with manufacturing.

During operational phases, hybrid Li-S batteries exhibit minimal direct environmental impacts. The absence of toxic heavy metals reduces risks associated with leakage or damage events. However, the energy efficiency of current Li-S systems remains lower than some competing technologies, which may indirectly increase environmental impacts through higher energy requirements for equivalent storage capacity.

End-of-life management presents both challenges and opportunities. The recyclability of sulfur components is theoretically high, with potential for nearly complete recovery and reuse. Current recycling infrastructure, however, requires adaptation to efficiently process these hybrid systems. The lithium components maintain similar recycling pathways to conventional lithium-ion batteries, though separation techniques may need refinement for hybrid architectures.

Carbon footprint analyses suggest that scaled deployment of hybrid Li-S systems could contribute to significant greenhouse gas reductions in grid applications, particularly when paired with renewable energy sources. The lower embodied energy in sulfur-based cathodes translates to faster carbon payback periods compared to conventional battery technologies.

Water usage metrics for Li-S battery production show promising reductions compared to conventional lithium-ion manufacturing, though electrolyte production remains water-intensive. Land use impacts are generally favorable due to the reduced mining requirements for cathode materials, potentially decreasing habitat disruption and biodiversity impacts associated with battery material extraction.

Cost Analysis and Economic Viability

The economic viability of hybrid lithium-sulfur (Li-S) battery systems for grid-scale energy storage hinges on several cost factors that must be carefully analyzed. Current cost estimates place Li-S systems at approximately $250-350 per kWh, which represents a significant improvement over traditional lithium-ion technologies that typically range from $300-500 per kWh for grid applications. This cost advantage stems primarily from the use of sulfur as a cathode material, which is abundant and inexpensive compared to conventional cathode materials like cobalt and nickel.

Material costs constitute approximately 60-70% of the total system cost, with sulfur itself contributing less than 5% of the material expenses. The hybrid nature of these systems, which often incorporate lithium-ion components, creates a balanced cost profile that leverages the advantages of both technologies. However, the manufacturing processes for hybrid Li-S systems remain more complex than standard battery technologies, currently adding a 15-20% premium to production costs.

Lifecycle economic analysis reveals promising trends for hybrid Li-S systems. With an expected operational lifespan of 2,500-3,000 cycles at 80% depth of discharge, these systems can achieve a levelized cost of storage (LCOS) between $0.12-0.18 per kWh-cycle. This compares favorably to conventional lithium-ion systems at $0.15-0.25 per kWh-cycle and flow batteries at $0.16-0.27 per kWh-cycle.

Scaling effects present significant opportunities for cost reduction. Industry projections suggest that reaching gigawatt-hour production scales could drive costs below $200 per kWh by 2025, with further reductions to $150 per kWh possible by 2030. These economies of scale would primarily come from manufacturing optimization, supply chain development, and increased automation in production processes.

Investment requirements for commercial deployment of hybrid Li-S grid storage systems remain substantial. Initial capital expenditure for a 100 MWh installation is estimated at $25-35 million, with operational expenses averaging 2-3% of capital costs annually. However, the return on investment calculations indicate potential payback periods of 7-9 years under current market conditions, with significant improvement expected as technology matures and manufacturing scales.

Regulatory incentives and carbon pricing mechanisms could substantially improve the economic case for hybrid Li-S systems. In markets with established capacity payments or energy arbitrage opportunities, these systems can generate additional revenue streams of $40-60 per kW-year, enhancing their overall economic viability compared to conventional alternatives.

Material costs constitute approximately 60-70% of the total system cost, with sulfur itself contributing less than 5% of the material expenses. The hybrid nature of these systems, which often incorporate lithium-ion components, creates a balanced cost profile that leverages the advantages of both technologies. However, the manufacturing processes for hybrid Li-S systems remain more complex than standard battery technologies, currently adding a 15-20% premium to production costs.

Lifecycle economic analysis reveals promising trends for hybrid Li-S systems. With an expected operational lifespan of 2,500-3,000 cycles at 80% depth of discharge, these systems can achieve a levelized cost of storage (LCOS) between $0.12-0.18 per kWh-cycle. This compares favorably to conventional lithium-ion systems at $0.15-0.25 per kWh-cycle and flow batteries at $0.16-0.27 per kWh-cycle.

Scaling effects present significant opportunities for cost reduction. Industry projections suggest that reaching gigawatt-hour production scales could drive costs below $200 per kWh by 2025, with further reductions to $150 per kWh possible by 2030. These economies of scale would primarily come from manufacturing optimization, supply chain development, and increased automation in production processes.

Investment requirements for commercial deployment of hybrid Li-S grid storage systems remain substantial. Initial capital expenditure for a 100 MWh installation is estimated at $25-35 million, with operational expenses averaging 2-3% of capital costs annually. However, the return on investment calculations indicate potential payback periods of 7-9 years under current market conditions, with significant improvement expected as technology matures and manufacturing scales.

Regulatory incentives and carbon pricing mechanisms could substantially improve the economic case for hybrid Li-S systems. In markets with established capacity payments or energy arbitrage opportunities, these systems can generate additional revenue streams of $40-60 per kW-year, enhancing their overall economic viability compared to conventional alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!