Silica-coated separators for enhanced Li–S battery cycling

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silica-Coated Separator Technology Background and Objectives

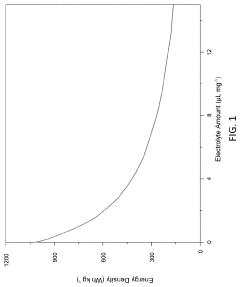

Lithium-sulfur (Li-S) batteries have emerged as a promising next-generation energy storage technology due to their theoretical energy density of 2600 Wh/kg, which significantly surpasses that of conventional lithium-ion batteries. The development trajectory of Li-S battery technology can be traced back to the 1960s when the first conceptual designs were proposed. However, substantial research momentum only gained traction in the early 2000s as the limitations of traditional lithium-ion batteries became increasingly apparent for advanced applications requiring higher energy densities.

The evolution of Li-S battery technology has been characterized by persistent challenges, particularly the "shuttle effect" where soluble polysulfide intermediates migrate between electrodes, causing capacity fading and shortened battery lifespan. This phenomenon has been the primary obstacle preventing widespread commercialization despite the technology's promising theoretical performance metrics.

Separator technology represents a critical component in the Li-S battery architecture, serving as both an electronic insulator and ionic conductor between electrodes. Traditional polyolefin separators (polypropylene, polyethylene) have proven inadequate for Li-S systems due to their inability to mitigate polysulfide shuttling. This technological gap has driven research toward functional separator modifications, with silica coating emerging as a particularly promising approach.

Silica-coated separators leverage the unique properties of silica nanoparticles, including high surface area, tunable pore structures, and abundant surface functional groups, to physically and chemically restrict polysulfide migration. The integration of silica into separator designs represents a convergence of materials science, electrochemistry, and surface engineering disciplines.

The primary technical objectives for silica-coated separator development include: achieving effective polysulfide trapping capabilities while maintaining optimal ionic conductivity; ensuring mechanical and electrochemical stability over extended cycling; developing scalable and cost-effective manufacturing processes; and optimizing silica morphology, distribution, and surface chemistry for maximum performance enhancement.

Recent technological trends indicate a shift toward multifunctional separator designs that combine silica with other materials such as carbon, metal oxides, or polymers to create synergistic effects. Additionally, there is growing interest in developing environmentally sustainable production methods for these advanced separators, aligning with broader industry movements toward greener battery technologies.

The ultimate goal of silica-coated separator research is to enable Li-S batteries that maintain high capacity retention over thousands of cycles while delivering energy densities approaching theoretical limits, thereby facilitating applications in electric vehicles, grid storage, and portable electronics where current lithium-ion technologies face inherent limitations.

The evolution of Li-S battery technology has been characterized by persistent challenges, particularly the "shuttle effect" where soluble polysulfide intermediates migrate between electrodes, causing capacity fading and shortened battery lifespan. This phenomenon has been the primary obstacle preventing widespread commercialization despite the technology's promising theoretical performance metrics.

Separator technology represents a critical component in the Li-S battery architecture, serving as both an electronic insulator and ionic conductor between electrodes. Traditional polyolefin separators (polypropylene, polyethylene) have proven inadequate for Li-S systems due to their inability to mitigate polysulfide shuttling. This technological gap has driven research toward functional separator modifications, with silica coating emerging as a particularly promising approach.

Silica-coated separators leverage the unique properties of silica nanoparticles, including high surface area, tunable pore structures, and abundant surface functional groups, to physically and chemically restrict polysulfide migration. The integration of silica into separator designs represents a convergence of materials science, electrochemistry, and surface engineering disciplines.

The primary technical objectives for silica-coated separator development include: achieving effective polysulfide trapping capabilities while maintaining optimal ionic conductivity; ensuring mechanical and electrochemical stability over extended cycling; developing scalable and cost-effective manufacturing processes; and optimizing silica morphology, distribution, and surface chemistry for maximum performance enhancement.

Recent technological trends indicate a shift toward multifunctional separator designs that combine silica with other materials such as carbon, metal oxides, or polymers to create synergistic effects. Additionally, there is growing interest in developing environmentally sustainable production methods for these advanced separators, aligning with broader industry movements toward greener battery technologies.

The ultimate goal of silica-coated separator research is to enable Li-S batteries that maintain high capacity retention over thousands of cycles while delivering energy densities approaching theoretical limits, thereby facilitating applications in electric vehicles, grid storage, and portable electronics where current lithium-ion technologies face inherent limitations.

Market Analysis for Advanced Li-S Battery Separators

The global market for lithium-sulfur (Li-S) battery separators is experiencing significant growth, driven by increasing demand for high-energy density storage solutions across multiple sectors. Current market valuations indicate that the advanced battery separator segment is expanding at a compound annual growth rate of 12.3%, with Li-S battery components representing an emerging but rapidly growing subsector.

The automotive industry constitutes the largest market segment for advanced Li-S battery separators, particularly as electric vehicle manufacturers seek batteries with higher energy density and lower weight profiles. The silica-coated separator technology addresses critical performance limitations that have previously hindered widespread Li-S battery adoption in commercial vehicles.

Consumer electronics represents the second largest market segment, where the demand for longer-lasting portable devices continues to drive innovation in battery technology. The aerospace and defense sectors also show substantial interest in Li-S technology due to its theoretical energy density advantages over conventional lithium-ion batteries.

Geographically, Asia-Pacific dominates the market landscape, with China, South Korea, and Japan leading in both production capacity and research initiatives for advanced battery separators. North America follows as the second-largest market, with significant research activities concentrated in the United States and Canada. European markets show accelerating adoption rates, particularly in Germany and the United Kingdom, where government initiatives supporting green energy technologies have created favorable market conditions.

Market analysis reveals that silica-coated separators specifically address the polysulfide shuttle effect—a key technical barrier to Li-S commercialization—creating substantial market potential. Industry forecasts suggest that successful commercialization of silica-coated separator technology could expand the total addressable market for Li-S batteries by 27% over the next five years.

Customer demand patterns indicate growing preference for battery technologies that offer improved cycle life without compromising on energy density. This trend aligns perfectly with the value proposition of silica-coated separators, which enhance cycling stability while maintaining the inherent high energy density of Li-S chemistry.

Pricing analysis shows that while silica-coated separators currently command a premium over conventional polyolefin separators, economies of scale and manufacturing improvements are expected to reduce this cost differential by approximately 40% within three years, further accelerating market penetration.

The automotive industry constitutes the largest market segment for advanced Li-S battery separators, particularly as electric vehicle manufacturers seek batteries with higher energy density and lower weight profiles. The silica-coated separator technology addresses critical performance limitations that have previously hindered widespread Li-S battery adoption in commercial vehicles.

Consumer electronics represents the second largest market segment, where the demand for longer-lasting portable devices continues to drive innovation in battery technology. The aerospace and defense sectors also show substantial interest in Li-S technology due to its theoretical energy density advantages over conventional lithium-ion batteries.

Geographically, Asia-Pacific dominates the market landscape, with China, South Korea, and Japan leading in both production capacity and research initiatives for advanced battery separators. North America follows as the second-largest market, with significant research activities concentrated in the United States and Canada. European markets show accelerating adoption rates, particularly in Germany and the United Kingdom, where government initiatives supporting green energy technologies have created favorable market conditions.

Market analysis reveals that silica-coated separators specifically address the polysulfide shuttle effect—a key technical barrier to Li-S commercialization—creating substantial market potential. Industry forecasts suggest that successful commercialization of silica-coated separator technology could expand the total addressable market for Li-S batteries by 27% over the next five years.

Customer demand patterns indicate growing preference for battery technologies that offer improved cycle life without compromising on energy density. This trend aligns perfectly with the value proposition of silica-coated separators, which enhance cycling stability while maintaining the inherent high energy density of Li-S chemistry.

Pricing analysis shows that while silica-coated separators currently command a premium over conventional polyolefin separators, economies of scale and manufacturing improvements are expected to reduce this cost differential by approximately 40% within three years, further accelerating market penetration.

Current Challenges in Li-S Battery Separator Technology

Lithium-sulfur (Li-S) batteries face significant challenges related to separator technology that currently limit their commercial viability. The conventional polyolefin separators (polypropylene and polyethylene) widely used in lithium-ion batteries prove inadequate for Li-S systems due to their inability to effectively mitigate polysulfide shuttling. This phenomenon, where soluble lithium polysulfides migrate between electrodes, causes rapid capacity fading and shortened battery lifespan.

A critical challenge is the separator's poor selectivity toward polysulfide species. Standard separators possess large pores (30-100 nm) that allow easy passage of dissolved polysulfides, resulting in active material loss and parasitic reactions at the lithium anode. This not only reduces sulfur utilization but also accelerates battery degradation through continuous electrolyte depletion.

Mechanical stability presents another significant hurdle. Li-S batteries typically undergo larger volume changes during cycling compared to conventional lithium-ion batteries. These volumetric fluctuations place additional stress on separator materials, potentially leading to mechanical failure, internal short circuits, and safety hazards. Current separators lack the necessary elasticity and durability to withstand these conditions over extended cycling.

Electrolyte wettability issues further complicate separator performance. Many conventional separators exhibit poor compatibility with the ether-based electrolytes commonly used in Li-S batteries. This results in inadequate electrolyte distribution, increased internal resistance, and compromised ionic conductivity, all of which negatively impact power capability and rate performance.

The interface between separators and electrodes represents another challenge area. Poor adhesion and contact between these components can create resistance barriers that impede ion transport. This becomes particularly problematic during long-term cycling as physical gaps may develop, exacerbating polysulfide shuttling and increasing cell impedance.

Chemical stability concerns also plague current separator technologies. The highly reactive nature of lithium polysulfides can degrade certain separator materials over time, altering their physical properties and diminishing their effectiveness as barriers. This chemical incompatibility accelerates aging processes and contributes to premature battery failure.

Cost and scalability considerations further complicate the development of advanced separators for Li-S batteries. While functional modifications like silica coatings show promise in laboratory settings, translating these improvements to mass production remains challenging. The additional processing steps and materials required for such modifications increase manufacturing complexity and cost, potentially offsetting the inherent cost advantages of sulfur as a cathode material.

A critical challenge is the separator's poor selectivity toward polysulfide species. Standard separators possess large pores (30-100 nm) that allow easy passage of dissolved polysulfides, resulting in active material loss and parasitic reactions at the lithium anode. This not only reduces sulfur utilization but also accelerates battery degradation through continuous electrolyte depletion.

Mechanical stability presents another significant hurdle. Li-S batteries typically undergo larger volume changes during cycling compared to conventional lithium-ion batteries. These volumetric fluctuations place additional stress on separator materials, potentially leading to mechanical failure, internal short circuits, and safety hazards. Current separators lack the necessary elasticity and durability to withstand these conditions over extended cycling.

Electrolyte wettability issues further complicate separator performance. Many conventional separators exhibit poor compatibility with the ether-based electrolytes commonly used in Li-S batteries. This results in inadequate electrolyte distribution, increased internal resistance, and compromised ionic conductivity, all of which negatively impact power capability and rate performance.

The interface between separators and electrodes represents another challenge area. Poor adhesion and contact between these components can create resistance barriers that impede ion transport. This becomes particularly problematic during long-term cycling as physical gaps may develop, exacerbating polysulfide shuttling and increasing cell impedance.

Chemical stability concerns also plague current separator technologies. The highly reactive nature of lithium polysulfides can degrade certain separator materials over time, altering their physical properties and diminishing their effectiveness as barriers. This chemical incompatibility accelerates aging processes and contributes to premature battery failure.

Cost and scalability considerations further complicate the development of advanced separators for Li-S batteries. While functional modifications like silica coatings show promise in laboratory settings, translating these improvements to mass production remains challenging. The additional processing steps and materials required for such modifications increase manufacturing complexity and cost, potentially offsetting the inherent cost advantages of sulfur as a cathode material.

Current Silica Coating Solutions for Li-S Battery Separators

01 Silica coating composition and structure for Li-S battery separators

Silica coatings on separators for lithium-sulfur batteries can be formulated with specific compositions and structures to enhance cycling performance. These coatings typically consist of silica nanoparticles or sol-gel derived silica layers that create a physical barrier against polysulfide shuttling. The structure of the coating, including thickness, porosity, and distribution, significantly impacts the separator's effectiveness in preventing capacity fade while maintaining ion conductivity.- Silica coating methods for Li-S battery separators: Various methods can be employed to apply silica coatings to separators for lithium-sulfur batteries. These include sol-gel processes, atomic layer deposition, and direct coating with silica nanoparticles. The silica coating creates a physical barrier that prevents polysulfide shuttling while maintaining ion conductivity. The coating thickness and uniformity are critical factors that affect the overall performance of the battery.

- Impact of silica-coated separators on cycling stability: Silica-coated separators significantly improve the cycling stability of Li-S batteries by effectively suppressing the polysulfide shuttle effect. The silica coating acts as a physical barrier that prevents polysulfides from migrating between electrodes while allowing lithium ions to pass through. This results in reduced capacity fading over multiple charge-discharge cycles and extends the overall battery lifespan, making Li-S batteries more viable for practical applications.

- Silica-polymer composite separators for enhanced performance: Combining silica with polymeric materials creates composite separators with superior properties for Li-S batteries. These hybrid separators benefit from the mechanical strength of polymers and the polysulfide-blocking capabilities of silica. The polymer matrix provides flexibility and structural integrity, while the embedded silica particles create tortuous pathways that inhibit polysulfide diffusion. This synergistic effect results in improved cycling performance and higher capacity retention.

- Functionalized silica coatings for improved electrolyte wettability: Functionalized silica coatings can enhance the wettability of separators with electrolytes in Li-S batteries. By modifying the surface properties of silica particles with functional groups, the hydrophilicity of the separator can be controlled. This improved wettability facilitates better electrolyte penetration and distribution throughout the separator, leading to enhanced ionic conductivity and reduced internal resistance. The result is improved rate capability and more stable cycling performance.

- Hierarchical porous silica structures for optimized ion transport: Hierarchical porous silica structures incorporated into separators can optimize ion transport while blocking polysulfides. These structures feature multi-scale porosity with macropores, mesopores, and micropores that create efficient channels for lithium ion transport while effectively trapping polysulfide species. The controlled pore size distribution allows for selective permeability, enhancing the separator's ability to prevent shuttle effect while maintaining high ionic conductivity, resulting in improved cycling performance.

02 Functional additives in silica-coated separators

Incorporating functional additives into silica coatings can significantly improve the cycling performance of Li-S batteries. These additives include conductive materials, catalytic components, and binding agents that work synergistically with silica to enhance polysulfide trapping, improve ionic conductivity, and strengthen the mechanical properties of the separator. The combination of silica with these functional additives creates multifunctional separators that address multiple failure mechanisms in Li-S batteries simultaneously.Expand Specific Solutions03 Fabrication methods for silica-coated separators

Various fabrication techniques can be employed to apply silica coatings onto battery separators, each affecting the cycling performance differently. Methods include dip-coating, spray coating, atomic layer deposition, and in-situ growth processes. The fabrication approach determines the uniformity, adhesion, and thickness control of the silica layer, which directly impacts the separator's ability to block polysulfides while maintaining lithium-ion transport pathways, ultimately affecting the battery's cycling stability.Expand Specific Solutions04 Hybrid and composite silica-based separator coatings

Hybrid and composite coatings that combine silica with other materials such as polymers, metal oxides, or carbon-based materials can significantly enhance the cycling performance of Li-S batteries. These composite structures leverage the advantages of each component: silica provides polysulfide blocking properties, polymers add flexibility, metal oxides contribute additional functionality, and carbon materials enhance conductivity. The synergistic effects of these hybrid coatings result in improved capacity retention and extended cycle life.Expand Specific Solutions05 Performance optimization and characterization of silica-coated separators

Optimizing the performance of silica-coated separators involves careful characterization and testing under various operating conditions. Parameters such as silica content, coating thickness, pore structure, and surface modifications can be tuned to achieve the optimal balance between polysulfide blocking efficiency and lithium-ion conductivity. Advanced characterization techniques help understand the separator's behavior during cycling, enabling the development of tailored silica coatings that maximize capacity retention and cycling stability in Li-S batteries.Expand Specific Solutions

Key Industry Players in Li-S Battery Separator Development

The lithium-sulfur battery separator market is currently in an early growth phase, with significant research momentum but limited commercial deployment. Market size is projected to expand rapidly as Li-S technology approaches commercialization, driven by its theoretical energy density advantages over conventional lithium-ion batteries. Technical maturity remains moderate, with key players pursuing different approaches to silica-coated separator technology. Industry leaders like LG Energy Solution, Samsung SDI, and CATL (Ningde Amperex) are investing heavily in R&D, while specialized separator manufacturers such as Celgard, Daramic, and Hebei Gellec focus on technical innovations. Academic institutions including Central South University and Hong Kong Polytechnic University are contributing fundamental research, creating a competitive landscape balanced between established battery manufacturers and materials science specialists.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced silica-coated separators specifically designed for lithium-sulfur batteries to address the polysulfide shuttle effect. Their technology involves a dual-layer coating approach where silica nanoparticles are first deposited on conventional polyolefin separators, followed by a thin layer of conductive polymer. The silica layer creates a physical barrier with tortuous pathways that effectively trap polysulfide intermediates while maintaining adequate lithium-ion conductivity. Their proprietary sol-gel process ensures uniform silica distribution with controlled porosity (typically 40-60nm pores) that balances polysulfide blocking and ion transport. The company has demonstrated that their silica-coated separators can extend Li-S battery cycling life by over 500 cycles with capacity retention above 80%, compared to conventional separators that typically fail after 100-200 cycles. The technology also incorporates functional groups on the silica surface that chemically interact with polysulfides, providing both physical and chemical protection mechanisms.

Strengths: Superior polysulfide trapping capability while maintaining high ionic conductivity; established manufacturing infrastructure allowing for scale-up; demonstrated long-term cycling stability in commercial-sized cells. Weaknesses: Higher production costs compared to conventional separators; potential for increased internal resistance over extended cycling; requires precise control of silica particle size and distribution to maintain performance consistency.

Central South University

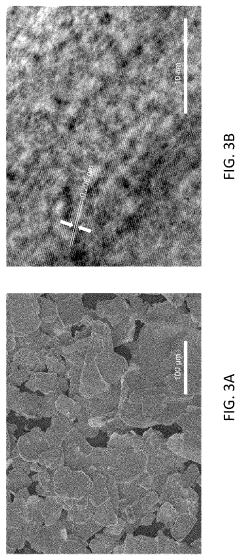

Technical Solution: Central South University has developed an innovative silica-coated separator technology for Li-S batteries that employs a biomimetic approach inspired by natural filtration systems. Their research team has created a hierarchically structured silica coating with multi-scale porosity that mimics biological membranes. The coating consists of mesoporous silica spheres (50-200nm diameter) with internal pores of 2-5nm, interconnected by a network of silica nanowires. This structure creates a tortuous path for polysulfides while maintaining efficient lithium-ion transport channels. The university's approach incorporates amino-functionalized silica that forms hydrogen bonds with polysulfide species, providing both physical blocking and chemical immobilization. Their research has demonstrated that these biomimetic silica-coated separators can enable Li-S cells to achieve over 500 stable cycles with capacity retention above 75%, even at elevated temperatures (45°C). The team has also developed a scalable sol-gel synthesis method that allows precise control over the silica morphology and pore structure, with potential for industrial-scale production. Recent publications from the university show that their silica-coated separators reduce the shuttle current by approximately 85% compared to conventional separators.

Strengths: Highly effective polysulfide trapping through biomimetic hierarchical structure; good thermal and mechanical stability; potential for low-cost manufacturing using earth-abundant materials. Weaknesses: Currently at research/prototype stage rather than commercial production; potential challenges in quality control for large-scale manufacturing; may require optimization for different electrolyte systems.

Critical Patents in Silica-Coated Separator Technology

High energy-density lithium-sulfur battery and method for making the same

PatentPendingUS20240113388A1

Innovation

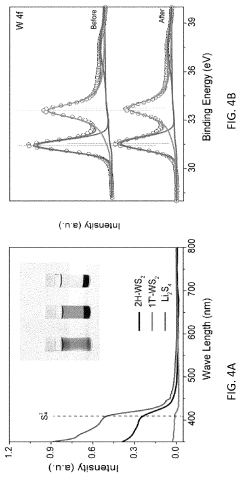

- The use of 1T′-phase transition metal dichalcogenides, such as WS2, to modify separators, which self-assemble into a dense layer on porous separators, enhancing catalytic activity, mechanical integrity, and reducing internal porosity, thereby improving energy density and preventing polysulfide shuttling without the need for conductive additives.

Environmental Impact of Silica-Coated Separator Production

The production of silica-coated separators for lithium-sulfur batteries presents significant environmental considerations that must be evaluated within the broader context of sustainable battery manufacturing. The coating process typically involves chemical vapor deposition (CVD), sol-gel methods, or atomic layer deposition (ALD), each carrying distinct environmental footprints.

Primary environmental concerns include the substantial energy consumption during high-temperature silica deposition processes, which can range from 300-800°C depending on the technique employed. This energy demand contributes to greenhouse gas emissions when non-renewable energy sources power manufacturing facilities. Additionally, precursor chemicals such as tetraethyl orthosilicate (TEOS) and tetramethyl orthosilicate (TMOS) used in sol-gel processes pose potential environmental hazards if released untreated.

Water usage represents another critical environmental factor, particularly in wet chemical coating methods where significant volumes are required for synthesis, washing, and purification stages. The resulting wastewater often contains silica particles, organic solvents, and chemical residues that necessitate specialized treatment before discharge.

Comparative lifecycle assessments indicate that silica-coated separators may offer environmental advantages despite these production impacts. The enhanced cycling stability they provide extends battery lifespan by 2-3 times compared to conventional separators, potentially reducing the overall material demand and waste generation from battery replacement. This longevity effect partially offsets the initial environmental costs of production.

Recent innovations are addressing these environmental challenges through green chemistry approaches. Water-based silica coating formulations have emerged that reduce volatile organic compound (VOC) emissions by up to 85% compared to traditional solvent-based methods. Room-temperature processing techniques are also gaining traction, with research demonstrating energy savings of approximately 40-60% while maintaining comparable separator performance.

Recycling considerations present both challenges and opportunities. The silica coating can complicate end-of-life battery recycling processes, potentially requiring additional separation steps. However, research indicates that silica components can be recovered and repurposed in construction materials or as precursors for new separator production, creating potential circular economy pathways.

Regulatory frameworks increasingly influence production methods, with stricter emissions standards in Europe and parts of Asia driving adoption of cleaner manufacturing technologies. Companies investing in environmentally optimized silica coating processes may gain competitive advantages as sustainability becomes a more significant factor in battery supply chain decisions.

Primary environmental concerns include the substantial energy consumption during high-temperature silica deposition processes, which can range from 300-800°C depending on the technique employed. This energy demand contributes to greenhouse gas emissions when non-renewable energy sources power manufacturing facilities. Additionally, precursor chemicals such as tetraethyl orthosilicate (TEOS) and tetramethyl orthosilicate (TMOS) used in sol-gel processes pose potential environmental hazards if released untreated.

Water usage represents another critical environmental factor, particularly in wet chemical coating methods where significant volumes are required for synthesis, washing, and purification stages. The resulting wastewater often contains silica particles, organic solvents, and chemical residues that necessitate specialized treatment before discharge.

Comparative lifecycle assessments indicate that silica-coated separators may offer environmental advantages despite these production impacts. The enhanced cycling stability they provide extends battery lifespan by 2-3 times compared to conventional separators, potentially reducing the overall material demand and waste generation from battery replacement. This longevity effect partially offsets the initial environmental costs of production.

Recent innovations are addressing these environmental challenges through green chemistry approaches. Water-based silica coating formulations have emerged that reduce volatile organic compound (VOC) emissions by up to 85% compared to traditional solvent-based methods. Room-temperature processing techniques are also gaining traction, with research demonstrating energy savings of approximately 40-60% while maintaining comparable separator performance.

Recycling considerations present both challenges and opportunities. The silica coating can complicate end-of-life battery recycling processes, potentially requiring additional separation steps. However, research indicates that silica components can be recovered and repurposed in construction materials or as precursors for new separator production, creating potential circular economy pathways.

Regulatory frameworks increasingly influence production methods, with stricter emissions standards in Europe and parts of Asia driving adoption of cleaner manufacturing technologies. Companies investing in environmentally optimized silica coating processes may gain competitive advantages as sustainability becomes a more significant factor in battery supply chain decisions.

Scalability and Manufacturing Considerations

The scalability and manufacturing of silica-coated separators represent critical factors in determining the commercial viability of enhanced Li-S battery technology. Current laboratory-scale production methods primarily utilize sol-gel processes, atomic layer deposition (ALD), or chemical vapor deposition (CVD) to create uniform silica coatings on separator materials. While these techniques demonstrate excellent control over coating thickness and morphology, they face significant challenges when transitioning to industrial-scale production.

Mass production of silica-coated separators requires substantial process optimization to maintain coating uniformity across large surface areas. Roll-to-roll manufacturing processes show promising potential for continuous production but necessitate careful control of precursor delivery, reaction conditions, and curing parameters. Recent advancements in spray coating and dip-coating technologies have improved throughput capabilities, though concerns regarding coating adhesion and mechanical stability during high-speed processing remain prevalent.

Cost considerations present another significant hurdle for commercial implementation. The precursor materials for high-quality silica coatings, particularly those using TEOS (tetraethyl orthosilicate) or TMOS (tetramethyl orthosilicate), contribute substantially to overall production expenses. Economic analyses indicate that process optimization could potentially reduce coating costs by 30-45%, primarily through precursor recycling and improved deposition efficiency.

Equipment requirements for industrial-scale production include specialized coating chambers, precise temperature control systems, and advanced quality control mechanisms. Capital investment for establishing a production line capable of manufacturing silica-coated separators at commercial scale is estimated between $5-12 million, depending on production capacity and automation level. This represents a significant barrier to entry for smaller manufacturers but remains feasible for established battery component producers.

Quality control protocols for mass-produced silica-coated separators must address coating thickness uniformity, mechanical integrity, and electrochemical performance consistency. Advanced characterization techniques such as in-line optical monitoring, automated impedance testing, and high-throughput mechanical testing are being developed to ensure product reliability at industrial scales.

Environmental considerations also impact manufacturing scalability. Traditional silica coating processes often utilize volatile organic compounds and generate hazardous waste streams. Recent research has focused on developing greener alternatives, including water-based silica precursors and solvent-free deposition methods, which show promise for reducing environmental impact while maintaining coating performance in Li-S battery applications.

Mass production of silica-coated separators requires substantial process optimization to maintain coating uniformity across large surface areas. Roll-to-roll manufacturing processes show promising potential for continuous production but necessitate careful control of precursor delivery, reaction conditions, and curing parameters. Recent advancements in spray coating and dip-coating technologies have improved throughput capabilities, though concerns regarding coating adhesion and mechanical stability during high-speed processing remain prevalent.

Cost considerations present another significant hurdle for commercial implementation. The precursor materials for high-quality silica coatings, particularly those using TEOS (tetraethyl orthosilicate) or TMOS (tetramethyl orthosilicate), contribute substantially to overall production expenses. Economic analyses indicate that process optimization could potentially reduce coating costs by 30-45%, primarily through precursor recycling and improved deposition efficiency.

Equipment requirements for industrial-scale production include specialized coating chambers, precise temperature control systems, and advanced quality control mechanisms. Capital investment for establishing a production line capable of manufacturing silica-coated separators at commercial scale is estimated between $5-12 million, depending on production capacity and automation level. This represents a significant barrier to entry for smaller manufacturers but remains feasible for established battery component producers.

Quality control protocols for mass-produced silica-coated separators must address coating thickness uniformity, mechanical integrity, and electrochemical performance consistency. Advanced characterization techniques such as in-line optical monitoring, automated impedance testing, and high-throughput mechanical testing are being developed to ensure product reliability at industrial scales.

Environmental considerations also impact manufacturing scalability. Traditional silica coating processes often utilize volatile organic compounds and generate hazardous waste streams. Recent research has focused on developing greener alternatives, including water-based silica precursors and solvent-free deposition methods, which show promise for reducing environmental impact while maintaining coating performance in Li-S battery applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!