Hydroxyethylcellulose Effect in Lipid-Based Drug Delivery Systems

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC in LBDDSs: Background and Objectives

Hydroxyethylcellulose (HEC) has emerged as a significant component in the development of lipid-based drug delivery systems (LBDDSs) over the past few decades. This natural polymer, derived from cellulose, has garnered attention due to its unique properties that enhance the performance of LBDDSs. The evolution of HEC in this field can be traced back to the early 1990s when researchers began exploring its potential as a stabilizer and viscosity modifier in various pharmaceutical formulations.

The primary objective of incorporating HEC into LBDDSs is to improve the stability, bioavailability, and controlled release of lipophilic drugs. As the pharmaceutical industry continues to face challenges in delivering poorly water-soluble drugs, LBDDSs have become increasingly important. HEC's role in these systems is multifaceted, contributing to the overall efficacy and safety of drug formulations.

One of the key technological trends in this area is the development of novel HEC derivatives with enhanced properties. These modifications aim to optimize the polymer's interaction with lipid components and improve its performance in diverse physiological environments. The ongoing research focuses on tailoring HEC's molecular weight, degree of substitution, and chemical modifications to meet specific formulation requirements.

The market demand for HEC in LBDDSs has been driven by the growing prevalence of chronic diseases and the need for more effective drug delivery methods. The global lipid-based drug delivery systems market is projected to expand significantly in the coming years, with HEC playing a crucial role in this growth. This trend is further supported by the increasing adoption of personalized medicine and the development of complex biopharmaceuticals.

From a technological perspective, the integration of HEC into LBDDSs presents several challenges that researchers aim to address. These include optimizing the polymer's concentration to achieve desired rheological properties, ensuring compatibility with a wide range of lipid excipients, and maintaining stability under various storage conditions. Additionally, there is a growing interest in understanding the molecular interactions between HEC and lipid components to design more efficient drug delivery systems.

The geographical distribution of HEC technology in LBDDSs shows a concentration in North America and Europe, with emerging research hubs in Asia-Pacific regions. This global spread of expertise has led to collaborative efforts and knowledge exchange, accelerating the pace of innovation in the field.

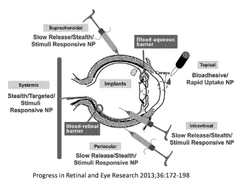

As we look towards the future, the technological goals for HEC in LBDDSs include developing "smart" formulations that respond to specific physiological triggers, enhancing the polymer's ability to protect sensitive drug molecules, and improving its performance in targeted drug delivery applications. These advancements are expected to significantly impact the efficacy and patient compliance of lipid-based drug formulations, ultimately contributing to better therapeutic outcomes.

The primary objective of incorporating HEC into LBDDSs is to improve the stability, bioavailability, and controlled release of lipophilic drugs. As the pharmaceutical industry continues to face challenges in delivering poorly water-soluble drugs, LBDDSs have become increasingly important. HEC's role in these systems is multifaceted, contributing to the overall efficacy and safety of drug formulations.

One of the key technological trends in this area is the development of novel HEC derivatives with enhanced properties. These modifications aim to optimize the polymer's interaction with lipid components and improve its performance in diverse physiological environments. The ongoing research focuses on tailoring HEC's molecular weight, degree of substitution, and chemical modifications to meet specific formulation requirements.

The market demand for HEC in LBDDSs has been driven by the growing prevalence of chronic diseases and the need for more effective drug delivery methods. The global lipid-based drug delivery systems market is projected to expand significantly in the coming years, with HEC playing a crucial role in this growth. This trend is further supported by the increasing adoption of personalized medicine and the development of complex biopharmaceuticals.

From a technological perspective, the integration of HEC into LBDDSs presents several challenges that researchers aim to address. These include optimizing the polymer's concentration to achieve desired rheological properties, ensuring compatibility with a wide range of lipid excipients, and maintaining stability under various storage conditions. Additionally, there is a growing interest in understanding the molecular interactions between HEC and lipid components to design more efficient drug delivery systems.

The geographical distribution of HEC technology in LBDDSs shows a concentration in North America and Europe, with emerging research hubs in Asia-Pacific regions. This global spread of expertise has led to collaborative efforts and knowledge exchange, accelerating the pace of innovation in the field.

As we look towards the future, the technological goals for HEC in LBDDSs include developing "smart" formulations that respond to specific physiological triggers, enhancing the polymer's ability to protect sensitive drug molecules, and improving its performance in targeted drug delivery applications. These advancements are expected to significantly impact the efficacy and patient compliance of lipid-based drug formulations, ultimately contributing to better therapeutic outcomes.

Market Analysis for HEC-Enhanced LBDDSs

The market for Hydroxyethylcellulose (HEC)-enhanced Lipid-Based Drug Delivery Systems (LBDDSs) has shown significant growth potential in recent years. This surge is primarily driven by the increasing demand for more effective and targeted drug delivery methods across various therapeutic areas. The pharmaceutical industry's focus on improving bioavailability and reducing side effects of drugs has led to a heightened interest in LBDDSs, with HEC emerging as a promising excipient.

The global LBDDS market is expected to expand substantially, with HEC-enhanced formulations playing a crucial role in this growth. Key therapeutic areas driving this market include oncology, cardiovascular diseases, and central nervous system disorders. These fields require advanced drug delivery systems to overcome challenges such as poor solubility and limited absorption of active pharmaceutical ingredients.

Geographically, North America and Europe currently dominate the market for HEC-enhanced LBDDSs, owing to their advanced healthcare infrastructure and higher investment in pharmaceutical research and development. However, the Asia-Pacific region is anticipated to witness the fastest growth rate in the coming years, fueled by increasing healthcare expenditure and a growing emphasis on innovative drug delivery technologies.

The incorporation of HEC in LBDDSs offers several advantages that are driving market demand. These include improved stability of formulations, enhanced drug solubility, and controlled release profiles. Such benefits are particularly valuable in the development of oral drug delivery systems, which constitute a significant portion of the pharmaceutical market.

Key market players in this sector include major pharmaceutical companies and specialized drug delivery technology firms. These organizations are investing heavily in research and development to optimize HEC-enhanced LBDDS formulations and expand their application across various drug classes.

Despite the promising outlook, the market faces certain challenges. Regulatory hurdles and the complexity of developing HEC-enhanced LBDDSs may slow down market growth to some extent. Additionally, the high cost associated with advanced drug delivery technologies could limit adoption in price-sensitive markets.

Looking ahead, the market for HEC-enhanced LBDDSs is poised for continued growth. Factors such as the increasing prevalence of chronic diseases, the rise in geriatric populations, and the ongoing need for more efficient drug delivery systems are expected to sustain market expansion. Furthermore, the trend towards personalized medicine and the development of novel biopharmaceuticals are likely to create new opportunities for HEC-enhanced LBDDSs in the coming years.

The global LBDDS market is expected to expand substantially, with HEC-enhanced formulations playing a crucial role in this growth. Key therapeutic areas driving this market include oncology, cardiovascular diseases, and central nervous system disorders. These fields require advanced drug delivery systems to overcome challenges such as poor solubility and limited absorption of active pharmaceutical ingredients.

Geographically, North America and Europe currently dominate the market for HEC-enhanced LBDDSs, owing to their advanced healthcare infrastructure and higher investment in pharmaceutical research and development. However, the Asia-Pacific region is anticipated to witness the fastest growth rate in the coming years, fueled by increasing healthcare expenditure and a growing emphasis on innovative drug delivery technologies.

The incorporation of HEC in LBDDSs offers several advantages that are driving market demand. These include improved stability of formulations, enhanced drug solubility, and controlled release profiles. Such benefits are particularly valuable in the development of oral drug delivery systems, which constitute a significant portion of the pharmaceutical market.

Key market players in this sector include major pharmaceutical companies and specialized drug delivery technology firms. These organizations are investing heavily in research and development to optimize HEC-enhanced LBDDS formulations and expand their application across various drug classes.

Despite the promising outlook, the market faces certain challenges. Regulatory hurdles and the complexity of developing HEC-enhanced LBDDSs may slow down market growth to some extent. Additionally, the high cost associated with advanced drug delivery technologies could limit adoption in price-sensitive markets.

Looking ahead, the market for HEC-enhanced LBDDSs is poised for continued growth. Factors such as the increasing prevalence of chronic diseases, the rise in geriatric populations, and the ongoing need for more efficient drug delivery systems are expected to sustain market expansion. Furthermore, the trend towards personalized medicine and the development of novel biopharmaceuticals are likely to create new opportunities for HEC-enhanced LBDDSs in the coming years.

Current Challenges in HEC Integration

The integration of Hydroxyethylcellulose (HEC) into lipid-based drug delivery systems presents several significant challenges that researchers and formulators must address. One of the primary obstacles is achieving uniform dispersion of HEC within the lipid matrix. Due to its hydrophilic nature, HEC tends to form aggregates or clumps when introduced into lipophilic environments, leading to inconsistent distribution and potential instability of the formulation.

Another critical challenge is maintaining the stability of the drug delivery system over time. HEC can absorb moisture from the environment, which may lead to changes in the physical properties of the formulation, such as viscosity and rheological behavior. This hygroscopic nature of HEC can also affect the release profile of the encapsulated drug, potentially compromising the intended therapeutic efficacy.

The impact of HEC on the encapsulation efficiency of drugs within lipid-based systems is also a significant concern. The presence of HEC may interfere with the ability of lipids to effectively entrap hydrophobic drugs, potentially reducing the overall drug loading capacity of the system. This challenge is particularly pronounced for highly lipophilic compounds, where the hydrophilic domains created by HEC can disrupt the lipid organization.

Researchers face difficulties in optimizing the concentration of HEC to achieve the desired rheological properties without compromising the integrity of the lipid-based system. Too little HEC may not provide sufficient viscosity or stability, while excessive amounts can lead to phase separation or alter the release kinetics of the drug. Striking the right balance is crucial for developing effective and stable formulations.

The interaction between HEC and other excipients in the formulation poses another challenge. HEC may compete with surfactants or co-solvents for interaction with the lipid components, potentially altering the microstructure of the delivery system. This can lead to changes in the solubilization capacity and release characteristics of the formulation.

Lastly, the processing conditions required for incorporating HEC into lipid-based systems can be complex. High-energy methods may be necessary to ensure proper dispersion, but these processes can also lead to degradation of heat-sensitive drugs or alterations in the lipid structure. Developing scalable and reproducible manufacturing processes that maintain the integrity of all components remains a significant hurdle in the successful integration of HEC into lipid-based drug delivery systems.

Another critical challenge is maintaining the stability of the drug delivery system over time. HEC can absorb moisture from the environment, which may lead to changes in the physical properties of the formulation, such as viscosity and rheological behavior. This hygroscopic nature of HEC can also affect the release profile of the encapsulated drug, potentially compromising the intended therapeutic efficacy.

The impact of HEC on the encapsulation efficiency of drugs within lipid-based systems is also a significant concern. The presence of HEC may interfere with the ability of lipids to effectively entrap hydrophobic drugs, potentially reducing the overall drug loading capacity of the system. This challenge is particularly pronounced for highly lipophilic compounds, where the hydrophilic domains created by HEC can disrupt the lipid organization.

Researchers face difficulties in optimizing the concentration of HEC to achieve the desired rheological properties without compromising the integrity of the lipid-based system. Too little HEC may not provide sufficient viscosity or stability, while excessive amounts can lead to phase separation or alter the release kinetics of the drug. Striking the right balance is crucial for developing effective and stable formulations.

The interaction between HEC and other excipients in the formulation poses another challenge. HEC may compete with surfactants or co-solvents for interaction with the lipid components, potentially altering the microstructure of the delivery system. This can lead to changes in the solubilization capacity and release characteristics of the formulation.

Lastly, the processing conditions required for incorporating HEC into lipid-based systems can be complex. High-energy methods may be necessary to ensure proper dispersion, but these processes can also lead to degradation of heat-sensitive drugs or alterations in the lipid structure. Developing scalable and reproducible manufacturing processes that maintain the integrity of all components remains a significant hurdle in the successful integration of HEC into lipid-based drug delivery systems.

Current HEC-LBDDS Formulation Strategies

01 Viscosity modification in fluids

Hydroxyethylcellulose is widely used as a viscosity modifier in various fluids, including drilling fluids, cosmetic formulations, and pharmaceutical preparations. It helps to control the rheological properties of these fluids, improving their stability and performance in different applications.- Viscosity modification in fluids: Hydroxyethylcellulose is widely used as a viscosity modifier in various fluids, including drilling fluids, fracturing fluids, and other industrial applications. It helps control fluid properties, improve stability, and enhance performance in different environments.

- Pharmaceutical and cosmetic applications: In pharmaceutical and cosmetic formulations, hydroxyethylcellulose serves as a thickening agent, stabilizer, and emulsifier. It improves the texture, consistency, and shelf life of various products such as creams, lotions, and gels.

- Film-forming and adhesive properties: Hydroxyethylcellulose exhibits excellent film-forming and adhesive properties, making it suitable for use in coatings, adhesives, and binders. It enhances the durability and performance of various products in construction and manufacturing industries.

- Water retention and soil stabilization: In agriculture and construction, hydroxyethylcellulose is used for its water retention capabilities and soil stabilization properties. It helps improve soil structure, reduce erosion, and enhance plant growth in challenging environments.

- Rheology modification in cement-based materials: Hydroxyethylcellulose acts as a rheology modifier in cement-based materials, improving workability, reducing water demand, and enhancing the overall performance of concrete and mortar mixtures. It contributes to better consistency and strength development in construction applications.

02 Film-forming and thickening agent

In personal care and cosmetic products, hydroxyethylcellulose acts as a film-forming and thickening agent. It enhances the texture and consistency of formulations, providing a smooth feel and improving product stability. This property is particularly useful in hair care products, skin creams, and lotions.Expand Specific Solutions03 Controlled release in drug delivery

Hydroxyethylcellulose is employed in pharmaceutical formulations for controlled drug release. It forms a gel-like matrix when in contact with aqueous media, allowing for the gradual release of active ingredients. This property is beneficial in developing sustained-release oral dosage forms and topical preparations.Expand Specific Solutions04 Adhesive and binding properties

The adhesive and binding properties of hydroxyethylcellulose make it useful in various industrial applications. It is used as a binder in ceramics, a thickener in adhesives, and a stabilizer in emulsions. These properties contribute to improved product performance and stability in diverse manufacturing processes.Expand Specific Solutions05 Water retention and soil stabilization

Hydroxyethylcellulose exhibits excellent water retention capabilities, making it valuable in soil stabilization applications. It helps to improve soil structure, reduce erosion, and enhance water retention in agricultural and construction settings. This property also finds use in personal care products for moisture retention.Expand Specific Solutions

Key Players in HEC-LBDDS Development

The competitive landscape for hydroxyethylcellulose in lipid-based drug delivery systems is evolving rapidly, reflecting the growing interest in advanced drug delivery technologies. The market is in a growth phase, with increasing demand for more efficient and targeted drug delivery solutions. Key players like PolyPid Ltd., Thermosome GmbH, and Celator Pharmaceuticals are driving innovation in this field, leveraging their expertise in polymer-lipid combinations and controlled release technologies. The market size is expanding, fueled by the pharmaceutical industry's need for improved bioavailability and reduced side effects. While the technology is advancing, it is not yet fully mature, with ongoing research at institutions like Southeast University and the University of Hong Kong contributing to its development.

PolyPid Ltd.

Technical Solution: PolyPid Ltd. has developed a novel lipid-based drug delivery system called PLEX (Polymer-Lipid Encapsulation matriX). This technology combines lipids with polymers to create a matrix that can encapsulate various drugs, including hydrophilic and hydrophobic compounds. While not specifically using hydroxyethylcellulose, their approach demonstrates advanced capabilities in lipid-based drug delivery. The PLEX platform allows for controlled and prolonged release of drugs, with the ability to tailor the release profile based on the specific therapeutic needs[1]. This system has shown promise in various applications, including local antibiotic delivery for surgical site infections[2].

Strengths: Versatile platform for various drug types, controlled release profiles, potential for reducing systemic side effects. Weaknesses: May require complex manufacturing processes, potential limitations in systemic delivery applications.

Thermosome GmbH

Technical Solution: Thermosome GmbH specializes in thermosensitive liposomal drug delivery systems. While not directly using hydroxyethylcellulose, their technology represents an advanced approach in lipid-based drug delivery. Their TSLs (Thermosensitive Liposomes) are designed to release their drug payload upon exposure to mild hyperthermia (40-42°C)[3]. This allows for targeted drug release at specific sites in the body where local heating is applied. The company has developed formulations that can encapsulate various drugs, including small molecules and biologics. Their lead product, THE001, is being developed for the treatment of solid tumors[4].

Strengths: Highly targeted drug delivery, potential for reduced systemic toxicity, applicable to various therapeutic areas. Weaknesses: Requires specialized heating equipment for activation, may have limitations in deep-seated or hard-to-reach tissues.

Innovative HEC Applications in LBDDSs

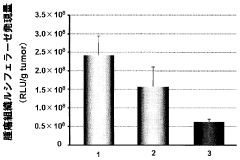

High-density lipoprotein, and delivery of drug to posterior segment of eye by ocular instillation of said cytophilic peptide-fused high-density lipoprotein

PatentWO2016104690A1

Innovation

- Development of high-density lipoproteins (HDL) fused with cell-friendly peptides, which act as carriers for drug delivery to the posterior segment of the eye, utilizing their small size and ability to accumulate in vascular endothelial cells, enhancing drug accumulation and reducing cytotoxicity.

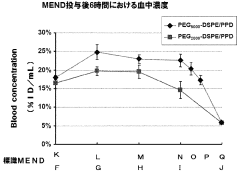

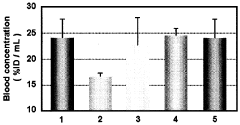

Element retained in blood showing degradability selectively in tumor tissue

PatentWO2009075349A1

Innovation

- A lipid membrane structure containing phospholipid derivatives with polyethylene glycol (PEG) residues of specific molecular weights, combined with peptides that can be cleaved by matrix metalloproteases, enhances blood retention and intracellular translocation by stabilizing the liposomes in the bloodstream until they reach target cells.

Regulatory Considerations for HEC-LBDDSs

The regulatory landscape for Hydroxyethylcellulose (HEC) in Lipid-Based Drug Delivery Systems (LBDDSs) is complex and multifaceted, requiring careful consideration by pharmaceutical companies and researchers. The use of HEC in LBDDSs falls under the purview of various regulatory bodies, including the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and other international health authorities.

One of the primary regulatory considerations for HEC-LBDDSs is the classification of HEC as an excipient. Regulatory agencies typically require extensive documentation on the safety, quality, and functionality of excipients used in drug formulations. Manufacturers must provide detailed information on the source, manufacturing process, and specifications of HEC used in their LBDDSs.

The FDA's Inactive Ingredient Database (IID) lists HEC as an approved excipient for various routes of administration, including oral and topical. However, its use in novel LBDDSs may require additional safety and efficacy data, particularly if the formulation results in a new delivery mechanism or altered bioavailability of the active pharmaceutical ingredient (API).

Regulatory bodies also focus on the potential impact of HEC on the stability and performance of LBDDSs. Manufacturers must demonstrate that the inclusion of HEC does not adversely affect the drug product's shelf life, release profile, or overall efficacy. This often involves conducting comprehensive stability studies and in vitro release testing under various conditions.

Another critical regulatory aspect is the evaluation of potential interactions between HEC and other components of the LBDDS, as well as with the API itself. Regulatory agencies may require extensive compatibility studies to ensure that HEC does not interfere with the intended function of the lipid-based system or alter the drug's pharmacokinetics.

The manufacturing process for HEC-LBDDSs is subject to stringent Good Manufacturing Practice (GMP) regulations. Manufacturers must establish and maintain robust quality control systems to ensure consistency in the production of HEC-containing formulations. This includes validated analytical methods for HEC quantification and characterization within the final drug product.

Regulatory bodies also emphasize the importance of thorough characterization of the physicochemical properties of HEC within the LBDDS. This may include assessments of viscosity, particle size distribution, and rheological behavior, as these factors can significantly influence the drug delivery system's performance.

For novel HEC-LBDDSs, regulatory agencies may require additional preclinical and clinical studies to establish the safety and efficacy of the formulation. This could involve comparative bioavailability studies, pharmacokinetic evaluations, and potentially long-term safety assessments, depending on the intended use and route of administration.

One of the primary regulatory considerations for HEC-LBDDSs is the classification of HEC as an excipient. Regulatory agencies typically require extensive documentation on the safety, quality, and functionality of excipients used in drug formulations. Manufacturers must provide detailed information on the source, manufacturing process, and specifications of HEC used in their LBDDSs.

The FDA's Inactive Ingredient Database (IID) lists HEC as an approved excipient for various routes of administration, including oral and topical. However, its use in novel LBDDSs may require additional safety and efficacy data, particularly if the formulation results in a new delivery mechanism or altered bioavailability of the active pharmaceutical ingredient (API).

Regulatory bodies also focus on the potential impact of HEC on the stability and performance of LBDDSs. Manufacturers must demonstrate that the inclusion of HEC does not adversely affect the drug product's shelf life, release profile, or overall efficacy. This often involves conducting comprehensive stability studies and in vitro release testing under various conditions.

Another critical regulatory aspect is the evaluation of potential interactions between HEC and other components of the LBDDS, as well as with the API itself. Regulatory agencies may require extensive compatibility studies to ensure that HEC does not interfere with the intended function of the lipid-based system or alter the drug's pharmacokinetics.

The manufacturing process for HEC-LBDDSs is subject to stringent Good Manufacturing Practice (GMP) regulations. Manufacturers must establish and maintain robust quality control systems to ensure consistency in the production of HEC-containing formulations. This includes validated analytical methods for HEC quantification and characterization within the final drug product.

Regulatory bodies also emphasize the importance of thorough characterization of the physicochemical properties of HEC within the LBDDS. This may include assessments of viscosity, particle size distribution, and rheological behavior, as these factors can significantly influence the drug delivery system's performance.

For novel HEC-LBDDSs, regulatory agencies may require additional preclinical and clinical studies to establish the safety and efficacy of the formulation. This could involve comparative bioavailability studies, pharmacokinetic evaluations, and potentially long-term safety assessments, depending on the intended use and route of administration.

Environmental Impact of HEC in LBDDSs

The environmental impact of hydroxyethylcellulose (HEC) in lipid-based drug delivery systems (LBDDSs) is an important consideration in the development and application of these pharmaceutical formulations. HEC, a cellulose derivative, is widely used as a thickening agent and stabilizer in various industries, including pharmaceuticals.

In LBDDSs, HEC plays a crucial role in enhancing the stability and viscosity of the formulations. However, its environmental implications must be carefully evaluated. One of the primary concerns is the biodegradability of HEC. While it is derived from natural cellulose, the chemical modifications made to create HEC can affect its rate of decomposition in the environment.

Studies have shown that HEC is generally biodegradable, but the process may be slower compared to unmodified cellulose. This slower degradation rate could potentially lead to accumulation in aquatic environments if not properly managed. However, the risk of environmental persistence is relatively low compared to synthetic polymers.

The production of HEC also has environmental considerations. The manufacturing process involves chemical treatments that may generate waste products. Proper waste management and treatment protocols are essential to minimize the environmental footprint of HEC production. Additionally, the sourcing of cellulose for HEC production should be evaluated for sustainability, ensuring responsible forest management practices.

In terms of aquatic toxicity, HEC is generally considered to have low toxicity to aquatic organisms. However, high concentrations in water bodies could potentially affect the osmotic balance and lead to physical effects on aquatic life. Therefore, proper disposal and wastewater treatment are crucial to prevent excessive release into aquatic ecosystems.

The use of HEC in LBDDSs may have indirect environmental benefits. By improving the stability and efficacy of drug formulations, it can potentially reduce the overall quantity of pharmaceutical compounds needed, thereby decreasing the environmental burden of drug residues. Furthermore, the enhanced bioavailability provided by LBDDSs containing HEC may lead to more efficient drug delivery, potentially reducing the frequency of drug administration and associated packaging waste.

When considering the lifecycle of LBDDSs containing HEC, it is important to assess the end-of-life disposal of these products. Proper guidelines for the disposal of unused or expired medications containing HEC should be developed and communicated to consumers to prevent inappropriate release into the environment.

In conclusion, while HEC in LBDDSs presents some environmental considerations, its overall impact appears to be manageable with proper practices in place. Ongoing research into more sustainable production methods and improved biodegradability could further enhance the environmental profile of HEC in pharmaceutical applications.

In LBDDSs, HEC plays a crucial role in enhancing the stability and viscosity of the formulations. However, its environmental implications must be carefully evaluated. One of the primary concerns is the biodegradability of HEC. While it is derived from natural cellulose, the chemical modifications made to create HEC can affect its rate of decomposition in the environment.

Studies have shown that HEC is generally biodegradable, but the process may be slower compared to unmodified cellulose. This slower degradation rate could potentially lead to accumulation in aquatic environments if not properly managed. However, the risk of environmental persistence is relatively low compared to synthetic polymers.

The production of HEC also has environmental considerations. The manufacturing process involves chemical treatments that may generate waste products. Proper waste management and treatment protocols are essential to minimize the environmental footprint of HEC production. Additionally, the sourcing of cellulose for HEC production should be evaluated for sustainability, ensuring responsible forest management practices.

In terms of aquatic toxicity, HEC is generally considered to have low toxicity to aquatic organisms. However, high concentrations in water bodies could potentially affect the osmotic balance and lead to physical effects on aquatic life. Therefore, proper disposal and wastewater treatment are crucial to prevent excessive release into aquatic ecosystems.

The use of HEC in LBDDSs may have indirect environmental benefits. By improving the stability and efficacy of drug formulations, it can potentially reduce the overall quantity of pharmaceutical compounds needed, thereby decreasing the environmental burden of drug residues. Furthermore, the enhanced bioavailability provided by LBDDSs containing HEC may lead to more efficient drug delivery, potentially reducing the frequency of drug administration and associated packaging waste.

When considering the lifecycle of LBDDSs containing HEC, it is important to assess the end-of-life disposal of these products. Proper guidelines for the disposal of unused or expired medications containing HEC should be developed and communicated to consumers to prevent inappropriate release into the environment.

In conclusion, while HEC in LBDDSs presents some environmental considerations, its overall impact appears to be manageable with proper practices in place. Ongoing research into more sustainable production methods and improved biodegradability could further enhance the environmental profile of HEC in pharmaceutical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!