ICP-MS Analysis: Reducing Memory Effects in Sample Testing

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Technology Background and Objectives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the early 1980s, becoming an indispensable analytical technique for elemental analysis. This technology combines a high-temperature ICP source with a mass spectrometer, allowing for precise detection of metals and several non-metals at concentrations as low as one part per trillion. The evolution of ICP-MS has been driven by the increasing demand for ultra-trace element analysis in various fields including environmental monitoring, pharmaceutical quality control, geological studies, and semiconductor manufacturing.

Memory effects in ICP-MS represent a persistent challenge that has plagued analysts since the technology's inception. These effects occur when analytes from previous samples remain within the system and contaminate subsequent measurements, leading to inaccurate results. This phenomenon is particularly problematic when analyzing elements that tend to adsorb onto surfaces within the sample introduction system, such as mercury, boron, and iodine, or when transitioning between samples with vastly different concentrations of the same element.

The technological trajectory of ICP-MS has been marked by continuous improvements in sensitivity, precision, and interference reduction. Early systems suffered from significant limitations in terms of matrix tolerance and spectral interferences. Modern instruments incorporate collision/reaction cells, improved interface designs, and enhanced sample introduction systems that have collectively elevated the capabilities of this analytical technique. However, memory effects remain a persistent challenge that requires innovative solutions.

Current research objectives in the field of ICP-MS memory effect reduction focus on several key areas: development of new materials for sample introduction systems that minimize analyte adsorption; optimization of wash protocols to efficiently remove residual analytes; implementation of intelligent software algorithms that can detect and correct for memory effects; and exploration of alternative sample introduction techniques that inherently minimize carryover.

The global analytical instrumentation market, valued at approximately $85 billion in 2022, continues to drive innovation in ICP-MS technology. Regulatory requirements for lower detection limits in environmental and food safety applications further accelerate the need for solutions to memory effect problems. As industries push toward higher throughput and automation, the economic impact of memory effects becomes increasingly significant due to extended analysis times and potential data quality issues.

The ultimate goal of current research efforts is to develop ICP-MS systems that deliver consistent, accurate results regardless of sample sequence or concentration differences, while maintaining high sample throughput and minimizing operator intervention. This would represent a significant advancement in analytical capabilities across multiple industries and scientific disciplines.

Memory effects in ICP-MS represent a persistent challenge that has plagued analysts since the technology's inception. These effects occur when analytes from previous samples remain within the system and contaminate subsequent measurements, leading to inaccurate results. This phenomenon is particularly problematic when analyzing elements that tend to adsorb onto surfaces within the sample introduction system, such as mercury, boron, and iodine, or when transitioning between samples with vastly different concentrations of the same element.

The technological trajectory of ICP-MS has been marked by continuous improvements in sensitivity, precision, and interference reduction. Early systems suffered from significant limitations in terms of matrix tolerance and spectral interferences. Modern instruments incorporate collision/reaction cells, improved interface designs, and enhanced sample introduction systems that have collectively elevated the capabilities of this analytical technique. However, memory effects remain a persistent challenge that requires innovative solutions.

Current research objectives in the field of ICP-MS memory effect reduction focus on several key areas: development of new materials for sample introduction systems that minimize analyte adsorption; optimization of wash protocols to efficiently remove residual analytes; implementation of intelligent software algorithms that can detect and correct for memory effects; and exploration of alternative sample introduction techniques that inherently minimize carryover.

The global analytical instrumentation market, valued at approximately $85 billion in 2022, continues to drive innovation in ICP-MS technology. Regulatory requirements for lower detection limits in environmental and food safety applications further accelerate the need for solutions to memory effect problems. As industries push toward higher throughput and automation, the economic impact of memory effects becomes increasingly significant due to extended analysis times and potential data quality issues.

The ultimate goal of current research efforts is to develop ICP-MS systems that deliver consistent, accurate results regardless of sample sequence or concentration differences, while maintaining high sample throughput and minimizing operator intervention. This would represent a significant advancement in analytical capabilities across multiple industries and scientific disciplines.

Market Demand for High-Precision Elemental Analysis

The global market for high-precision elemental analysis has experienced substantial growth over the past decade, driven primarily by increasing demands across pharmaceutical, environmental monitoring, semiconductor manufacturing, and food safety sectors. ICP-MS (Inductively Coupled Plasma Mass Spectrometry) technology has emerged as the gold standard for trace element analysis due to its exceptional sensitivity, multi-element capabilities, and wide dynamic range.

Market research indicates that the global ICP-MS market was valued at approximately 3.2 billion USD in 2022 and is projected to reach 4.8 billion USD by 2028, representing a compound annual growth rate of 7.1%. This growth trajectory is particularly pronounced in regions with stringent regulatory frameworks governing environmental protection and product safety.

The pharmaceutical and biotechnology sectors constitute the largest market segment, accounting for nearly 35% of the total market share. These industries require ultra-trace elemental analysis for quality control in drug manufacturing, ensuring compliance with increasingly strict regulatory standards regarding elemental impurities in pharmaceutical products.

Environmental monitoring represents the fastest-growing application segment, with a growth rate exceeding 9% annually. This surge is attributed to heightened awareness of environmental contamination and the implementation of more comprehensive monitoring programs by governmental agencies worldwide. The ability to detect heavy metals and other toxic elements at parts-per-trillion levels has become essential for effective environmental management.

The semiconductor industry has also emerged as a critical market driver, as manufacturers require increasingly precise contamination control in their production processes. Even minute elemental impurities can significantly impact semiconductor performance, making high-precision analysis indispensable.

Customer surveys reveal that laboratories are increasingly prioritizing analytical instruments that offer not only superior detection limits but also enhanced operational efficiency. Memory effects in ICP-MS analysis represent a significant pain point, as they can lead to extended analysis times, increased reagent consumption, and potential data quality issues.

Market feedback indicates that solutions addressing memory effects could potentially reduce analysis times by 30-40% and decrease operational costs by 25%, representing substantial value for high-throughput laboratories. This efficiency gain translates to an estimated annual savings of 50,000-100,000 USD for medium to large analytical facilities.

The competitive landscape shows that instrument manufacturers who successfully address these operational challenges can command premium pricing, with customers demonstrating willingness to invest in technologies that improve workflow efficiency and data reliability. This market dynamic creates a compelling opportunity for innovations specifically targeting memory effect reduction in ICP-MS analysis.

Market research indicates that the global ICP-MS market was valued at approximately 3.2 billion USD in 2022 and is projected to reach 4.8 billion USD by 2028, representing a compound annual growth rate of 7.1%. This growth trajectory is particularly pronounced in regions with stringent regulatory frameworks governing environmental protection and product safety.

The pharmaceutical and biotechnology sectors constitute the largest market segment, accounting for nearly 35% of the total market share. These industries require ultra-trace elemental analysis for quality control in drug manufacturing, ensuring compliance with increasingly strict regulatory standards regarding elemental impurities in pharmaceutical products.

Environmental monitoring represents the fastest-growing application segment, with a growth rate exceeding 9% annually. This surge is attributed to heightened awareness of environmental contamination and the implementation of more comprehensive monitoring programs by governmental agencies worldwide. The ability to detect heavy metals and other toxic elements at parts-per-trillion levels has become essential for effective environmental management.

The semiconductor industry has also emerged as a critical market driver, as manufacturers require increasingly precise contamination control in their production processes. Even minute elemental impurities can significantly impact semiconductor performance, making high-precision analysis indispensable.

Customer surveys reveal that laboratories are increasingly prioritizing analytical instruments that offer not only superior detection limits but also enhanced operational efficiency. Memory effects in ICP-MS analysis represent a significant pain point, as they can lead to extended analysis times, increased reagent consumption, and potential data quality issues.

Market feedback indicates that solutions addressing memory effects could potentially reduce analysis times by 30-40% and decrease operational costs by 25%, representing substantial value for high-throughput laboratories. This efficiency gain translates to an estimated annual savings of 50,000-100,000 USD for medium to large analytical facilities.

The competitive landscape shows that instrument manufacturers who successfully address these operational challenges can command premium pricing, with customers demonstrating willingness to invest in technologies that improve workflow efficiency and data reliability. This market dynamic creates a compelling opportunity for innovations specifically targeting memory effect reduction in ICP-MS analysis.

Memory Effect Challenges in ICP-MS Analysis

Memory effects represent one of the most persistent challenges in Inductively Coupled Plasma Mass Spectrometry (ICP-MS) analysis, significantly impacting measurement accuracy and reliability. These effects occur when residues from previous samples remain in the sample introduction system, causing signal carryover that contaminates subsequent measurements. The severity of memory effects varies considerably depending on the elements being analyzed, with certain elements such as boron, mercury, iodine, and platinum group metals being particularly problematic due to their tendency to adhere to system components.

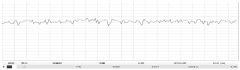

The primary mechanisms behind memory effects include physical adsorption onto tubing surfaces, chemical interactions with system components, and formation of volatile compounds that persist in the spray chamber. These mechanisms are exacerbated by specific sample matrices, particularly those with high dissolved solid content or extreme pH values. The consequences for analytical work are significant, including elevated detection limits, compromised precision, and extended analysis times due to necessary washout procedures.

Traditional approaches to mitigate memory effects have focused on extended washout periods between samples, which substantially reduces laboratory throughput and efficiency. Analysts often employ specialized wash solutions containing dilute acids, complexing agents, or surfactants to accelerate the removal of persistent elements. However, these methods frequently prove insufficient for elements with strong memory effects, necessitating more advanced solutions.

The financial implications of memory effects extend beyond the obvious costs of reagents and extended instrument time. Hidden costs include reduced sample throughput, increased quality control requirements, and potential for erroneous results leading to repeated analyses. For laboratories conducting high-precision trace element analysis, these effects can compromise data integrity and lead to significant interpretation errors, particularly in applications such as environmental monitoring, clinical diagnostics, and pharmaceutical quality control.

Recent research has identified several critical factors that influence the severity of memory effects, including sample introduction system design, nebulizer type, spray chamber configuration, and plasma operating conditions. Temperature control of the spray chamber has emerged as a particularly important parameter, with cooled spray chambers often exacerbating memory effects for volatile elements while reducing them for others.

The challenge of memory effects becomes particularly acute in specialized applications such as speciation analysis, isotope ratio measurements, and ultra-trace determinations where even minimal carryover can significantly impact results. As analytical requirements continue to become more stringent across industries, addressing memory effects has evolved from a technical inconvenience to a fundamental requirement for maintaining analytical integrity in modern ICP-MS applications.

The primary mechanisms behind memory effects include physical adsorption onto tubing surfaces, chemical interactions with system components, and formation of volatile compounds that persist in the spray chamber. These mechanisms are exacerbated by specific sample matrices, particularly those with high dissolved solid content or extreme pH values. The consequences for analytical work are significant, including elevated detection limits, compromised precision, and extended analysis times due to necessary washout procedures.

Traditional approaches to mitigate memory effects have focused on extended washout periods between samples, which substantially reduces laboratory throughput and efficiency. Analysts often employ specialized wash solutions containing dilute acids, complexing agents, or surfactants to accelerate the removal of persistent elements. However, these methods frequently prove insufficient for elements with strong memory effects, necessitating more advanced solutions.

The financial implications of memory effects extend beyond the obvious costs of reagents and extended instrument time. Hidden costs include reduced sample throughput, increased quality control requirements, and potential for erroneous results leading to repeated analyses. For laboratories conducting high-precision trace element analysis, these effects can compromise data integrity and lead to significant interpretation errors, particularly in applications such as environmental monitoring, clinical diagnostics, and pharmaceutical quality control.

Recent research has identified several critical factors that influence the severity of memory effects, including sample introduction system design, nebulizer type, spray chamber configuration, and plasma operating conditions. Temperature control of the spray chamber has emerged as a particularly important parameter, with cooled spray chambers often exacerbating memory effects for volatile elements while reducing them for others.

The challenge of memory effects becomes particularly acute in specialized applications such as speciation analysis, isotope ratio measurements, and ultra-trace determinations where even minimal carryover can significantly impact results. As analytical requirements continue to become more stringent across industries, addressing memory effects has evolved from a technical inconvenience to a fundamental requirement for maintaining analytical integrity in modern ICP-MS applications.

Current Memory Effect Mitigation Strategies

01 Washing and cleaning solutions for reducing memory effects

Various washing and cleaning solutions can be used to reduce memory effects in ICP-MS analysis. These solutions typically contain acids, chelating agents, or other compounds that help remove residual analytes from the sample introduction system. Effective cleaning between samples minimizes carryover and improves measurement accuracy, particularly for elements that tend to adhere to system components.- Washing and cleaning solutions for reducing memory effects: Various washing and cleaning solutions can be used to reduce memory effects in ICP-MS analysis. These solutions help to remove residual analytes from the sample introduction system, preventing carryover between samples. Common washing agents include dilute acids, organic solvents, and specialized cleaning agents that can effectively remove persistent elements from the system components.

- Sample introduction system modifications: Modifications to the sample introduction system can significantly reduce memory effects in ICP-MS. These include specialized nebulizers, spray chambers, and sample introduction interfaces designed to minimize sample retention. Optimized flow paths, materials with low adsorption properties, and improved geometries help to reduce areas where analytes can accumulate and cause memory effects.

- Signal processing and correction algorithms: Advanced signal processing and mathematical correction algorithms can be employed to compensate for memory effects in ICP-MS data. These computational approaches can identify and subtract background contributions from previous samples, apply washout models, and implement statistical methods to distinguish between true signals and memory-related artifacts, improving the accuracy of analytical results.

- Specialized hardware components and materials: The use of specialized hardware components and materials can minimize memory effects in ICP-MS systems. These include inert materials for sample pathways, optimized torch designs, interface components with reduced adsorption properties, and specialized cones that resist buildup of deposits. Materials such as PFA, PEEK, and certain metal alloys can significantly reduce element retention in the system.

- Optimized analytical protocols and procedures: Implementing optimized analytical protocols and procedures can effectively manage memory effects in ICP-MS analysis. These include strategic sample sequencing, extended washout times for problematic elements, internal standardization techniques, and specialized calibration approaches. Proper method development with consideration of potential memory effects for specific analytes can significantly improve analytical performance and data quality.

02 Sample introduction system modifications

Modifications to the sample introduction system can significantly reduce memory effects in ICP-MS. These include specialized nebulizers, spray chambers, and interface designs that minimize sample contact with surfaces where analytes might adhere. Some designs incorporate materials resistant to adsorption or implement flow patterns that reduce dead volumes where sample residues can accumulate.Expand Specific Solutions03 Software and signal processing techniques

Advanced software algorithms and signal processing techniques can be employed to compensate for memory effects in ICP-MS analysis. These methods may include mathematical correction models, baseline subtraction techniques, and specialized calibration procedures that account for carryover between samples. Such approaches help improve data quality without requiring physical modifications to the instrument.Expand Specific Solutions04 Specialized reagents and additives

Certain reagents and additives can be incorporated into sample preparation protocols or wash solutions to minimize memory effects. These compounds may include surfactants that reduce surface tension, complexing agents that prevent analyte adsorption, or competing ions that displace strongly bound elements from surfaces. The strategic use of these additives can significantly improve washout efficiency between samples.Expand Specific Solutions05 Automated washing procedures and system design

Automated washing procedures and optimized system designs can effectively address memory effects in ICP-MS. These include programmable wash cycles with varying solution compositions, temperature-controlled components to enhance desorption of analytes, and integrated flow paths that minimize dead volumes. Such systems often incorporate sensors to monitor washout efficiency and adjust procedures accordingly.Expand Specific Solutions

Leading Manufacturers and Research Institutions

ICP-MS Analysis for reducing memory effects in sample testing is currently in a growth phase, with the market expanding due to increasing demand for precise analytical techniques across pharmaceutical, environmental, and semiconductor industries. The global market size for ICP-MS technology is projected to reach significant growth, driven by advancements in sample introduction systems and collision/reaction cell technologies. Leading companies like Agilent Technologies, Thermo Fisher, and PerkinElmer have developed mature solutions addressing memory effects through improved washout procedures and specialized sample introduction systems. Emerging players including Bureau Veritas Commodities Canada and academic institutions like Baylor College of Medicine and Rice University are contributing innovative approaches to minimize carryover contamination, while semiconductor manufacturers such as Intel, Micron, and Infineon are implementing these technologies for quality control in their production processes.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed comprehensive solutions for reducing memory effects in ICP-MS analysis through their Ultra High Matrix Introduction (UHMI) technology. This system dilutes aerosols with argon gas before they enter the plasma, significantly reducing matrix deposition on interface cones. Their ICP-MS instruments incorporate advanced washout systems with optimized spray chambers and injectors designed to minimize surface area where analytes can adhere. Agilent's Integrated Sample Introduction System (ISIS 3) features high-speed vacuum pumps and specialized rinse stations that reduce washout times by up to 50%. Additionally, their HMI aerosol dilution technology allows for direct analysis of samples containing up to 25% total dissolved solids without significant memory effects, representing a 10-fold improvement over conventional systems.

Strengths: Industry-leading expertise in mass spectrometry with specialized solutions specifically designed for memory effect reduction; comprehensive integration of hardware and software solutions. Weaknesses: Higher initial investment costs compared to some competitors; some solutions may require additional training for laboratory personnel to fully optimize performance.

Bureau Veritas Commodities Canada Ltd.

Technical Solution: Bureau Veritas has implemented a multi-faceted approach to reducing memory effects in ICP-MS analysis, particularly for environmental and mining samples. Their methodology includes specialized sample introduction systems with low-memory tubing materials and optimized nebulizer designs that reduce sample contact with surfaces. They employ automated intelligent rinse protocols that adjust rinse times and solutions based on previous sample composition, reducing carryover by up to 85% for problematic elements like mercury and boron. Bureau Veritas laboratories utilize specialized cleaning solutions containing complexing agents that effectively remove persistent analytes from sample introduction components. Their validated protocols include strategic internal standardization and careful sample sequencing to minimize the impact of any residual memory effects on analytical results.

Strengths: Extensive practical experience with challenging environmental and mining samples; proven protocols for difficult matrices. Weaknesses: Solutions are more focused on procedural approaches rather than proprietary hardware innovations; may require longer analysis times for certain challenging elements.

Key Innovations in Washout Techniques

Method for rapidly reducing Hf memory effect in ICP-MS (Inductively Coupled Plasma Mass Spectrometry) determination

PatentPendingCN115656309A

Innovation

- Use mixed solutions of HF, HF and HNO3, HF and H2O2 with different concentrations to clean the ICP-MS sampling system in sequence, destroy the Hf oxide film and deeply remove the residues, and monitor the Hf element signal value until it meets the requirements.

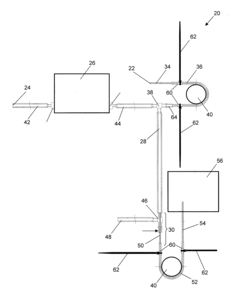

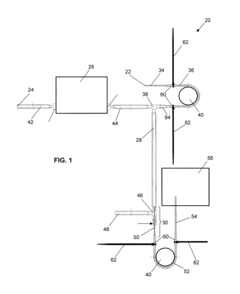

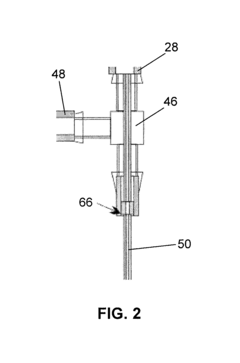

System and method for dilution of a sample for introduction to a quantitative analysis apparatus

PatentInactiveUS20130112862A1

Innovation

- A system comprising a first inlet for the sample, a second inlet for a diluent, a mixing chamber for homogeneous mixing, and a separator to reduce the solution volume for precise introduction into an ICP-MS instrument, utilizing a peristaltic pump for controlled flow and automatic dilution with minimal contamination and precipitation.

Validation Protocols for Memory Effect Reduction

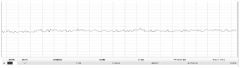

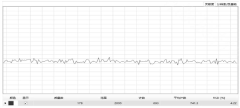

To establish robust validation protocols for memory effect reduction in ICP-MS analysis, systematic approaches must be implemented across multiple testing phases. These protocols should begin with baseline measurements to quantify existing memory effects before any reduction strategies are applied. This involves analyzing blank solutions after high-concentration samples and documenting carryover percentages, which serves as a reference point for subsequent optimization efforts.

Standard validation procedures should include wash solution efficacy tests, comparing different compositions (e.g., dilute acids, complexing agents) and determining optimal concentrations for specific analytes. The protocol must specify minimum washing times between samples and establish acceptance criteria for background reduction, typically requiring signals to return to within 1-3% of pre-sample baseline levels.

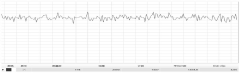

Cross-validation using multiple analyte concentrations is essential to ensure protocol robustness across varying sample matrices. This should include testing with both trace and high-concentration samples to verify the protocol's effectiveness under different analytical conditions. Sequential testing with alternating high and low concentration standards provides quantitative data on memory effect reduction efficiency.

Time-resolved validation represents a critical component, measuring signal decay curves after sample introduction to determine optimal washout times for different elements. This data should be incorporated into automated sampling protocols, with element-specific waiting periods programmed into the analytical sequence.

Statistical validation frameworks must be established to quantify protocol performance, including calculation of carryover percentages, relative standard deviations, and detection limit impacts. These metrics should be documented in standard operating procedures with clear pass/fail criteria for routine quality control.

Long-term validation through stability testing ensures protocols remain effective over extended analytical campaigns. This involves periodic verification using reference materials and tracking memory effect trends over time, which helps identify system degradation requiring maintenance intervention.

Documentation requirements should specify detailed records of all validation experiments, including raw data, statistical analyses, and acceptance criteria. These records must be maintained as part of the laboratory's quality assurance system and referenced during method validation or accreditation processes.

Standard validation procedures should include wash solution efficacy tests, comparing different compositions (e.g., dilute acids, complexing agents) and determining optimal concentrations for specific analytes. The protocol must specify minimum washing times between samples and establish acceptance criteria for background reduction, typically requiring signals to return to within 1-3% of pre-sample baseline levels.

Cross-validation using multiple analyte concentrations is essential to ensure protocol robustness across varying sample matrices. This should include testing with both trace and high-concentration samples to verify the protocol's effectiveness under different analytical conditions. Sequential testing with alternating high and low concentration standards provides quantitative data on memory effect reduction efficiency.

Time-resolved validation represents a critical component, measuring signal decay curves after sample introduction to determine optimal washout times for different elements. This data should be incorporated into automated sampling protocols, with element-specific waiting periods programmed into the analytical sequence.

Statistical validation frameworks must be established to quantify protocol performance, including calculation of carryover percentages, relative standard deviations, and detection limit impacts. These metrics should be documented in standard operating procedures with clear pass/fail criteria for routine quality control.

Long-term validation through stability testing ensures protocols remain effective over extended analytical campaigns. This involves periodic verification using reference materials and tracking memory effect trends over time, which helps identify system degradation requiring maintenance intervention.

Documentation requirements should specify detailed records of all validation experiments, including raw data, statistical analyses, and acceptance criteria. These records must be maintained as part of the laboratory's quality assurance system and referenced during method validation or accreditation processes.

Environmental Impact of ICP-MS Reagents

The environmental impact of reagents used in ICP-MS analysis represents a significant concern for laboratories implementing this technology. Acids such as nitric, hydrochloric, and hydrofluoric acid are extensively utilized in sample preparation and system cleaning procedures, with substantial volumes consumed during routine operations. These chemicals, particularly concentrated acids, pose serious environmental hazards when improperly disposed of, potentially contaminating water systems and disrupting aquatic ecosystems.

Laboratory waste management practices for ICP-MS reagents have evolved considerably, with modern facilities implementing sophisticated neutralization systems before discharge. However, studies indicate that even trace amounts of these reagents can accumulate in water treatment systems and potentially bypass conventional filtration methods. Recent environmental assessments have detected elevated levels of acid compounds in watershed areas surrounding facilities with high concentrations of analytical laboratories.

The argon gas consumption in ICP-MS represents another environmental consideration, with typical systems requiring 15-20 L/min during operation. While argon itself is environmentally inert, its production, compression, and transportation generate significant carbon footprints. Calculations suggest that a laboratory running ICP-MS analyses for 8 hours daily consumes approximately 7,200-9,600 L of argon, contributing to greenhouse gas emissions through the energy-intensive production process.

Calibration standards and reference materials containing heavy metals and other toxic elements present additional environmental challenges. These solutions, though used in small volumes, contain concentrated amounts of potentially harmful substances that require specialized disposal protocols. Research indicates that improper handling of these materials has resulted in localized soil contamination around laboratory facilities.

Recent innovations have focused on developing "green chemistry" approaches for ICP-MS analysis. These include the implementation of microwave-assisted digestion techniques that reduce acid consumption by up to 60%, and the development of closed-loop cooling systems that minimize water usage. Additionally, some laboratories have adopted reagent recycling programs that purify and reuse acids, significantly reducing waste volumes.

The economic implications of environmentally responsible reagent management are substantial. While implementing proper disposal systems and adopting greener technologies requires initial investment, long-term cost savings through reduced reagent consumption and waste management expenses can offset these expenditures. Furthermore, regulatory compliance with increasingly stringent environmental protection laws necessitates proactive approaches to minimizing the environmental footprint of ICP-MS operations.

Laboratory waste management practices for ICP-MS reagents have evolved considerably, with modern facilities implementing sophisticated neutralization systems before discharge. However, studies indicate that even trace amounts of these reagents can accumulate in water treatment systems and potentially bypass conventional filtration methods. Recent environmental assessments have detected elevated levels of acid compounds in watershed areas surrounding facilities with high concentrations of analytical laboratories.

The argon gas consumption in ICP-MS represents another environmental consideration, with typical systems requiring 15-20 L/min during operation. While argon itself is environmentally inert, its production, compression, and transportation generate significant carbon footprints. Calculations suggest that a laboratory running ICP-MS analyses for 8 hours daily consumes approximately 7,200-9,600 L of argon, contributing to greenhouse gas emissions through the energy-intensive production process.

Calibration standards and reference materials containing heavy metals and other toxic elements present additional environmental challenges. These solutions, though used in small volumes, contain concentrated amounts of potentially harmful substances that require specialized disposal protocols. Research indicates that improper handling of these materials has resulted in localized soil contamination around laboratory facilities.

Recent innovations have focused on developing "green chemistry" approaches for ICP-MS analysis. These include the implementation of microwave-assisted digestion techniques that reduce acid consumption by up to 60%, and the development of closed-loop cooling systems that minimize water usage. Additionally, some laboratories have adopted reagent recycling programs that purify and reuse acids, significantly reducing waste volumes.

The economic implications of environmentally responsible reagent management are substantial. While implementing proper disposal systems and adopting greener technologies requires initial investment, long-term cost savings through reduced reagent consumption and waste management expenses can offset these expenditures. Furthermore, regulatory compliance with increasingly stringent environmental protection laws necessitates proactive approaches to minimizing the environmental footprint of ICP-MS operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!