Optimize ICP-MS Ionization Efficiency for Accurate Results

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Ionization Technology Evolution and Objectives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the early 1980s. This analytical technique combines the high-temperature ICP source with a mass spectrometer to identify and quantify elements with exceptional sensitivity. The ionization process, which converts sample atoms into ions, represents a critical component determining the overall performance and accuracy of ICP-MS systems.

The evolution of ICP-MS ionization technology began with traditional argon plasma sources operating at atmospheric pressure. These early systems achieved ionization efficiencies of approximately 30-70% for most elements, with significant variations across the periodic table. Throughout the 1990s, advancements in radio frequency (RF) generators and torch designs led to more stable plasma conditions, improving ionization consistency and analytical precision.

A significant breakthrough occurred in the early 2000s with the development of collision/reaction cell technology, which addressed polyatomic interferences while maintaining efficient ionization. This innovation expanded the application scope of ICP-MS to previously challenging matrices. Subsequently, the introduction of high-temperature plasma conditions and improved sample introduction systems further enhanced ionization efficiency for elements with high ionization potentials.

Recent technological developments have focused on optimizing plasma conditions through advanced computer modeling and real-time monitoring systems. Machine learning algorithms now enable dynamic adjustment of plasma parameters based on sample composition, significantly improving ionization consistency across diverse sample types. Additionally, innovations in sample preparation techniques and introduction systems have contributed to more efficient sample transport and ionization.

The primary objective of current ICP-MS ionization research is to achieve consistent ionization efficiency exceeding 90% across all elements of interest, regardless of matrix complexity. This goal addresses the persistent challenge of differential ionization efficiencies that can compromise quantitative accuracy, particularly for multi-element analyses in complex samples.

Secondary objectives include reducing argon consumption through more efficient plasma designs, minimizing matrix effects that suppress ionization, and developing specialized ionization approaches for traditionally challenging elements such as mercury, arsenic, and selenium. Researchers are also exploring alternative plasma gas compositions and hybrid ionization techniques to overcome current limitations.

The ultimate aim is to develop "matrix-independent" ionization systems that deliver consistent analytical performance across diverse sample types without extensive method development or matrix-matched calibration. This would significantly expand the utility of ICP-MS in fields requiring rapid, accurate multi-element analysis such as environmental monitoring, pharmaceutical quality control, and clinical diagnostics.

The evolution of ICP-MS ionization technology began with traditional argon plasma sources operating at atmospheric pressure. These early systems achieved ionization efficiencies of approximately 30-70% for most elements, with significant variations across the periodic table. Throughout the 1990s, advancements in radio frequency (RF) generators and torch designs led to more stable plasma conditions, improving ionization consistency and analytical precision.

A significant breakthrough occurred in the early 2000s with the development of collision/reaction cell technology, which addressed polyatomic interferences while maintaining efficient ionization. This innovation expanded the application scope of ICP-MS to previously challenging matrices. Subsequently, the introduction of high-temperature plasma conditions and improved sample introduction systems further enhanced ionization efficiency for elements with high ionization potentials.

Recent technological developments have focused on optimizing plasma conditions through advanced computer modeling and real-time monitoring systems. Machine learning algorithms now enable dynamic adjustment of plasma parameters based on sample composition, significantly improving ionization consistency across diverse sample types. Additionally, innovations in sample preparation techniques and introduction systems have contributed to more efficient sample transport and ionization.

The primary objective of current ICP-MS ionization research is to achieve consistent ionization efficiency exceeding 90% across all elements of interest, regardless of matrix complexity. This goal addresses the persistent challenge of differential ionization efficiencies that can compromise quantitative accuracy, particularly for multi-element analyses in complex samples.

Secondary objectives include reducing argon consumption through more efficient plasma designs, minimizing matrix effects that suppress ionization, and developing specialized ionization approaches for traditionally challenging elements such as mercury, arsenic, and selenium. Researchers are also exploring alternative plasma gas compositions and hybrid ionization techniques to overcome current limitations.

The ultimate aim is to develop "matrix-independent" ionization systems that deliver consistent analytical performance across diverse sample types without extensive method development or matrix-matched calibration. This would significantly expand the utility of ICP-MS in fields requiring rapid, accurate multi-element analysis such as environmental monitoring, pharmaceutical quality control, and clinical diagnostics.

Market Demand for High-Precision Elemental Analysis

The global market for high-precision elemental analysis has experienced significant growth in recent years, driven by increasing demands across multiple industries for accurate trace element detection and quantification. ICP-MS (Inductively Coupled Plasma Mass Spectrometry) technology has emerged as the gold standard for elemental analysis due to its exceptional sensitivity, multi-element capabilities, and wide dynamic range.

The pharmaceutical industry represents one of the largest market segments, with stringent regulatory requirements necessitating precise elemental impurity testing in drug products. According to market research, the pharmaceutical elemental analysis segment is growing at a compound annual growth rate of 6.8%, reflecting the industry's commitment to quality control and patient safety.

Environmental monitoring constitutes another substantial market driver, with government agencies and private organizations requiring increasingly sensitive detection of heavy metals and other contaminants in water, soil, and air samples. The implementation of stricter environmental regulations globally has directly correlated with increased adoption of high-precision analytical technologies like optimized ICP-MS systems.

The food and beverage industry has also emerged as a significant market for elemental analysis, with consumers and regulatory bodies demanding greater transparency regarding potential contaminants. This sector's demand for rapid, multi-element screening capabilities has grown substantially, particularly in regions with evolving food safety standards.

Academic and research institutions continue to drive innovation in elemental analysis techniques, creating demand for instruments with enhanced ionization efficiency and detection capabilities. The ability to analyze increasingly complex matrices with minimal sample preparation represents a key market requirement across all sectors.

Geographically, North America and Europe currently dominate the high-precision elemental analysis market, though the Asia-Pacific region is experiencing the fastest growth rate, particularly in China, Japan, and South Korea. This growth is attributed to expanding industrial bases, increasing environmental concerns, and greater regulatory oversight.

The semiconductor and electronics manufacturing industries have become particularly dependent on ultra-trace elemental analysis, with detection limits in the parts-per-trillion range now essential for quality control in advanced chip fabrication. This specialized segment demands the highest possible ionization efficiency to achieve accurate results at these extreme sensitivity levels.

Market analysis indicates that end-users increasingly prioritize instruments offering improved ionization efficiency, as this directly translates to enhanced detection limits, better accuracy, and reduced interference effects. Vendors who can demonstrate superior performance in these areas command premium pricing and greater market share.

The pharmaceutical industry represents one of the largest market segments, with stringent regulatory requirements necessitating precise elemental impurity testing in drug products. According to market research, the pharmaceutical elemental analysis segment is growing at a compound annual growth rate of 6.8%, reflecting the industry's commitment to quality control and patient safety.

Environmental monitoring constitutes another substantial market driver, with government agencies and private organizations requiring increasingly sensitive detection of heavy metals and other contaminants in water, soil, and air samples. The implementation of stricter environmental regulations globally has directly correlated with increased adoption of high-precision analytical technologies like optimized ICP-MS systems.

The food and beverage industry has also emerged as a significant market for elemental analysis, with consumers and regulatory bodies demanding greater transparency regarding potential contaminants. This sector's demand for rapid, multi-element screening capabilities has grown substantially, particularly in regions with evolving food safety standards.

Academic and research institutions continue to drive innovation in elemental analysis techniques, creating demand for instruments with enhanced ionization efficiency and detection capabilities. The ability to analyze increasingly complex matrices with minimal sample preparation represents a key market requirement across all sectors.

Geographically, North America and Europe currently dominate the high-precision elemental analysis market, though the Asia-Pacific region is experiencing the fastest growth rate, particularly in China, Japan, and South Korea. This growth is attributed to expanding industrial bases, increasing environmental concerns, and greater regulatory oversight.

The semiconductor and electronics manufacturing industries have become particularly dependent on ultra-trace elemental analysis, with detection limits in the parts-per-trillion range now essential for quality control in advanced chip fabrication. This specialized segment demands the highest possible ionization efficiency to achieve accurate results at these extreme sensitivity levels.

Market analysis indicates that end-users increasingly prioritize instruments offering improved ionization efficiency, as this directly translates to enhanced detection limits, better accuracy, and reduced interference effects. Vendors who can demonstrate superior performance in these areas command premium pricing and greater market share.

Current Ionization Efficiency Challenges in ICP-MS

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) faces significant ionization efficiency challenges that impact analytical accuracy and reliability. The ionization process, occurring in the plasma torch at temperatures of 6,000-10,000K, represents a critical bottleneck in the analytical workflow. Current systems typically achieve only 1-2% overall ionization efficiency for many elements, with substantial variations across the periodic table. This inefficiency directly affects detection limits, quantification accuracy, and reproducibility of results.

Matrix effects present a persistent challenge, where sample composition influences ionization dynamics. High salt concentrations, organic matrices, and complex biological samples can suppress ionization of target analytes by competing for available energy in the plasma. These matrix-induced variations necessitate extensive calibration procedures and often compromise measurement accuracy, particularly in complex environmental and biological samples.

Plasma instability further exacerbates ionization challenges. Fluctuations in RF power delivery, gas flow rates, and sample introduction rates create temporal variations in ionization conditions. Current systems struggle to maintain consistent plasma conditions over extended analytical runs, leading to signal drift and deteriorating precision during high-throughput analyses.

Element-specific ionization behaviors add another layer of complexity. Elements with high ionization potentials (>9eV) such as arsenic, selenium, and mercury exhibit significantly lower ionization efficiencies compared to easily ionized elements like sodium or potassium. This differential behavior necessitates element-specific optimization strategies and complicates multi-element analyses.

Sample introduction inefficiencies compound ionization challenges. Conventional nebulizer systems typically deliver only 1-3% of the sample to the plasma, with the remainder lost as waste. This upstream inefficiency magnifies the impact of subsequent ionization limitations, particularly for precious or limited-volume samples in clinical and forensic applications.

Space-charge effects in the ion beam further compromise ionization efficiency. After ions form in the plasma, mutual electrostatic repulsion causes beam defocusing and ion loss during transport through the interface and ion optics. This phenomenon disproportionately affects lighter elements, creating mass-dependent transmission biases that complicate accurate quantification across the mass range.

Instrument manufacturers have implemented partial solutions including improved interface designs, enhanced RF generators, and advanced ion optics, but fundamental ionization efficiency limitations persist. These challenges collectively represent a significant barrier to achieving lower detection limits, higher sample throughput, and more reliable quantitative results in modern ICP-MS applications.

Matrix effects present a persistent challenge, where sample composition influences ionization dynamics. High salt concentrations, organic matrices, and complex biological samples can suppress ionization of target analytes by competing for available energy in the plasma. These matrix-induced variations necessitate extensive calibration procedures and often compromise measurement accuracy, particularly in complex environmental and biological samples.

Plasma instability further exacerbates ionization challenges. Fluctuations in RF power delivery, gas flow rates, and sample introduction rates create temporal variations in ionization conditions. Current systems struggle to maintain consistent plasma conditions over extended analytical runs, leading to signal drift and deteriorating precision during high-throughput analyses.

Element-specific ionization behaviors add another layer of complexity. Elements with high ionization potentials (>9eV) such as arsenic, selenium, and mercury exhibit significantly lower ionization efficiencies compared to easily ionized elements like sodium or potassium. This differential behavior necessitates element-specific optimization strategies and complicates multi-element analyses.

Sample introduction inefficiencies compound ionization challenges. Conventional nebulizer systems typically deliver only 1-3% of the sample to the plasma, with the remainder lost as waste. This upstream inefficiency magnifies the impact of subsequent ionization limitations, particularly for precious or limited-volume samples in clinical and forensic applications.

Space-charge effects in the ion beam further compromise ionization efficiency. After ions form in the plasma, mutual electrostatic repulsion causes beam defocusing and ion loss during transport through the interface and ion optics. This phenomenon disproportionately affects lighter elements, creating mass-dependent transmission biases that complicate accurate quantification across the mass range.

Instrument manufacturers have implemented partial solutions including improved interface designs, enhanced RF generators, and advanced ion optics, but fundamental ionization efficiency limitations persist. These challenges collectively represent a significant barrier to achieving lower detection limits, higher sample throughput, and more reliable quantitative results in modern ICP-MS applications.

Current Approaches to Optimize Ionization Efficiency

01 Plasma source optimization for ICP-MS ionization efficiency

Optimizing the plasma source in ICP-MS systems can significantly improve ionization efficiency. This includes adjustments to plasma temperature, gas flow rates, and RF power settings to create optimal conditions for sample ionization. Advanced plasma source designs incorporate features that enhance energy transfer to the sample, resulting in more complete ionization of analytes and improved detection sensitivity.- Plasma source optimization for ICP-MS: Optimizing the plasma source in ICP-MS systems can significantly improve ionization efficiency. This includes adjustments to plasma temperature, gas flow rates, and RF power settings to create optimal conditions for sample ionization. Advanced plasma configurations and specialized torches can enhance the energy transfer to the sample, resulting in more complete ionization of analytes and improved detection sensitivity.

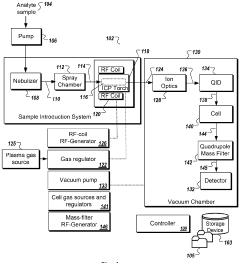

- Sample introduction and aerosol generation techniques: The efficiency of sample introduction systems directly impacts ionization efficiency in ICP-MS. Innovations in nebulizer design, spray chamber configurations, and aerosol generation methods can improve the delivery of sample to the plasma. Techniques such as desolvation, ultrasonic nebulization, and laser ablation can enhance the quality and consistency of the aerosol, leading to more efficient ionization and reduced matrix effects.

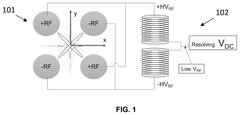

- Interface design and ion transmission optimization: The interface between the plasma source and the mass analyzer plays a crucial role in ionization efficiency. Improved designs of sampling cones, skimmer cones, and ion optics can enhance ion extraction and transmission. Modifications to the vacuum system and interface geometry can reduce space-charge effects and ion losses, resulting in higher sensitivity and more efficient ionization of the sample components.

- Matrix effect reduction and ionization enhancement: Various techniques can be employed to minimize matrix effects and enhance ionization efficiency in ICP-MS. These include the use of internal standards, matrix-matched calibration, collision/reaction cells, and chemical modifiers. Advanced sample preparation methods such as matrix separation, dilution protocols, and chelation can also improve ionization consistency across different sample types and reduce signal suppression or enhancement.

- Hybrid and complementary ionization techniques: Combining ICP with alternative or supplementary ionization methods can enhance overall ionization efficiency. Approaches such as dual ionization sources, auxiliary discharge devices, and pre-ionization techniques can improve the ionization of elements that are traditionally difficult to analyze by conventional ICP-MS. These hybrid systems can extend the analytical capabilities of ICP-MS to a wider range of elements and concentration levels.

02 Sample introduction and aerosol generation techniques

The efficiency of sample introduction systems directly impacts ionization efficiency in ICP-MS. Innovations in nebulizer design, spray chamber configurations, and aerosol generation techniques can improve the delivery of sample to the plasma, resulting in more consistent and efficient ionization. These techniques focus on producing smaller, more uniform droplets and reducing sample loss before reaching the plasma.Expand Specific Solutions03 Matrix modification and interference reduction methods

Chemical modifications to the sample matrix can enhance ionization efficiency by reducing interferences and promoting more complete ionization. This includes the use of specific reagents to modify sample chemistry, techniques to separate analytes from interfering species, and methods to stabilize elements in solution. These approaches help overcome matrix effects that can suppress ionization in complex samples.Expand Specific Solutions04 Integration of collision/reaction cell technology

Collision and reaction cell technologies can be integrated into ICP-MS systems to improve ionization efficiency and reduce spectral interferences. These cells use specific gases to selectively react with or collide with ions, helping to eliminate polyatomic interferences and improve the transmission of analyte ions. This technology enhances the specificity and sensitivity of ICP-MS measurements.Expand Specific Solutions05 Advanced ion optics and mass analyzer designs

Innovations in ion optics and mass analyzer designs can significantly improve the transmission and detection of ions after ionization. These include improved ion lens configurations, enhanced ion guide systems, and more efficient mass analyzers that can better capture and analyze the ions produced in the plasma. These advancements help maximize the utilization of ions generated during the ionization process.Expand Specific Solutions

Leading Manufacturers and Research Institutions in ICP-MS

The ICP-MS ionization efficiency optimization market is in a growth phase, with increasing demand driven by analytical precision requirements across industries. The market is characterized by established players like Thermo Fisher Scientific, Agilent Technologies, and Shimadzu Corporation dominating with comprehensive solutions, while specialized innovators such as Kimia Analytics are emerging with targeted technologies. Technical maturity varies, with major manufacturers focusing on enhancing plasma stability and interface designs, while academic institutions like Sun Yat-Sen University and Swiss Federal Institute of Technology contribute fundamental research. Collaborative development between commercial entities and research institutions is accelerating advancement in sample introduction systems and plasma generation technologies, pushing the boundaries of detection limits and analytical accuracy.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has pioneered the Enhanced Sensitivity Interface (ESI) technology for ICP-MS, which optimizes ionization efficiency through a combination of improved plasma coupling and ion extraction. Their approach utilizes a specialized interface design with optimized sampling cone geometry and skimmer cone configurations that significantly enhance ion transmission from the plasma to the mass analyzer. The company's iCAP RQ and iCAP TQ ICP-MS systems feature their proprietary QCell technology with helium collision cell that operates at low kinetic energy discrimination (KED) mode, allowing for efficient removal of polyatomic interferences while maintaining high sensitivity[3]. Additionally, Thermo Fisher has developed the High Matrix Interface (HMI) that incorporates a unique plasma torch position optimization system and automated gas flow controllers to maintain stable plasma conditions even with challenging sample matrices, ensuring consistent ionization efficiency across diverse sample types[4].

Strengths: Exceptional sensitivity across the mass range; robust performance with high total dissolved solids; excellent interference removal capabilities; intuitive software interface for method development. Weaknesses: Higher gas consumption compared to some competitors; requires more frequent maintenance of interface components in high-matrix applications; premium pricing structure.

Agilent Technologies, Inc.

Technical Solution: Agilent has developed the Ultra High Matrix Introduction (UHMI) technology for ICP-MS that significantly improves ionization efficiency in complex matrices. Their approach utilizes a specialized plasma torch design with optimized gas flows that creates a higher temperature plasma core, enhancing ionization of elements across the periodic table. The technology incorporates a unique aerosol dilution system that can handle samples with up to 25% total dissolved solids without physical dilution, maintaining sensitivity while reducing matrix effects[1]. Agilent's ICP-MS systems also feature the High Matrix Introduction (HMI) system which uses controlled dilution of the aerosol before it enters the plasma, improving ionization efficiency by reducing plasma loading. Their latest instruments incorporate advanced RF generators operating at 27 MHz with improved impedance matching that delivers more efficient energy transfer to the plasma, resulting in more robust ionization even for elements with high ionization potentials[2].

Strengths: Superior matrix tolerance allowing direct analysis of complex samples without extensive preparation; consistent ionization across a wide range of elements; reduced oxide formation leading to fewer interferences. Weaknesses: Higher initial investment cost compared to some competitors; may require more specialized training for operators to fully utilize advanced features; higher gas consumption in some operational modes.

Key Patents and Innovations in ICP-MS Ionization

Method and apparatus to increase sensitivity of inductively coupled plasma mass spectrometry

PatentPendingUS20250226199A1

Innovation

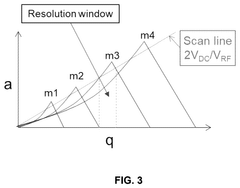

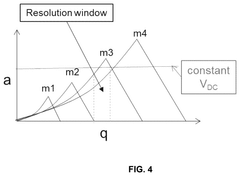

- Implementing time-varying RF and DC fields in the ion guide to selectively eject unwanted ions, reduce charge density, and enhance the transmission of desired ions by applying auxiliary excitation methods such as resolving DC potential, RF dipolar/quadrupolar fields, and segmenting the ion guide to separate and trap ions of interest.

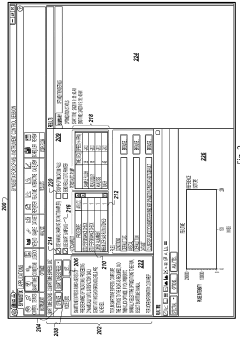

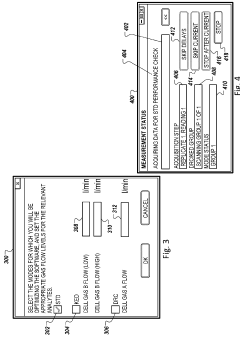

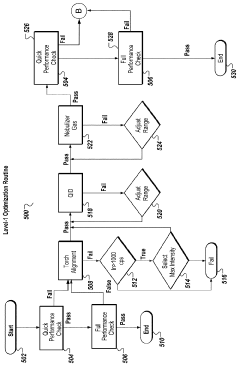

Systems and methods for automated optimization of a multi-mode inductively coupled plasma mass spectrometer

PatentActiveCA2938675C

Innovation

- An automated optimization system for multi-mode ICP-MS that allows for 'single click' operation, using a processor and non-transitory computer-readable medium to execute user inputs for automated tuning routines, including performance assessments and dynamic range optimization, to adjust settings such as torch alignment, quadrupole ion deflector calibration, and nebulizer gas flow, ensuring optimal instrument performance across various modes.

Matrix Effect Mitigation Strategies

Matrix effects represent one of the most significant challenges in ICP-MS analysis, causing signal suppression or enhancement that can severely compromise measurement accuracy. These effects occur when sample components alter the ionization efficiency of analytes, leading to unpredictable analytical results. Effective mitigation strategies are therefore essential for reliable quantitative analysis.

Sample preparation techniques form the first line of defense against matrix effects. Dilution represents the simplest approach, reducing the concentration of matrix components below interference thresholds. However, this simultaneously decreases analyte concentrations, potentially compromising detection limits. Matrix matching, where calibration standards are prepared in solutions mimicking the sample matrix, offers an alternative approach that compensates for matrix-induced signal variations.

Chemical separation methods provide more targeted solutions for complex matrices. Techniques such as solid-phase extraction, liquid-liquid extraction, and precipitation can selectively remove interfering components while preserving analytes of interest. These approaches are particularly valuable for environmental and biological samples where matrix complexity is high.

Internal standardization remains a cornerstone strategy for matrix effect compensation. By adding elements with similar mass and ionization potential to the analytes, analysts can track and correct for matrix-induced signal fluctuations. The effectiveness of this approach depends critically on selecting appropriate internal standards that behave similarly to target analytes under varying matrix conditions.

Mathematical correction models have gained prominence with advances in computational capabilities. Multivariate statistical methods can model complex relationships between matrix composition and signal response, enabling more sophisticated correction algorithms. Machine learning approaches show particular promise, with neural networks demonstrating ability to predict and compensate for non-linear matrix effects across diverse sample types.

Instrumental modifications offer hardware-based solutions to matrix challenges. High-resolution mass spectrometers can separate analyte signals from matrix-induced interferences based on small mass differences. Collision/reaction cell technologies selectively remove polyatomic interferences through gas-phase reactions, while optimized plasma conditions (adjusted RF power, gas flows, and sampling depth) can enhance ionization efficiency even in challenging matrices.

Standard addition methods provide reliable quantification when matrix matching proves impractical. By adding known quantities of analytes to the sample itself, analysts create calibration curves specific to each individual sample matrix, effectively normalizing for matrix-specific ionization effects.

Sample preparation techniques form the first line of defense against matrix effects. Dilution represents the simplest approach, reducing the concentration of matrix components below interference thresholds. However, this simultaneously decreases analyte concentrations, potentially compromising detection limits. Matrix matching, where calibration standards are prepared in solutions mimicking the sample matrix, offers an alternative approach that compensates for matrix-induced signal variations.

Chemical separation methods provide more targeted solutions for complex matrices. Techniques such as solid-phase extraction, liquid-liquid extraction, and precipitation can selectively remove interfering components while preserving analytes of interest. These approaches are particularly valuable for environmental and biological samples where matrix complexity is high.

Internal standardization remains a cornerstone strategy for matrix effect compensation. By adding elements with similar mass and ionization potential to the analytes, analysts can track and correct for matrix-induced signal fluctuations. The effectiveness of this approach depends critically on selecting appropriate internal standards that behave similarly to target analytes under varying matrix conditions.

Mathematical correction models have gained prominence with advances in computational capabilities. Multivariate statistical methods can model complex relationships between matrix composition and signal response, enabling more sophisticated correction algorithms. Machine learning approaches show particular promise, with neural networks demonstrating ability to predict and compensate for non-linear matrix effects across diverse sample types.

Instrumental modifications offer hardware-based solutions to matrix challenges. High-resolution mass spectrometers can separate analyte signals from matrix-induced interferences based on small mass differences. Collision/reaction cell technologies selectively remove polyatomic interferences through gas-phase reactions, while optimized plasma conditions (adjusted RF power, gas flows, and sampling depth) can enhance ionization efficiency even in challenging matrices.

Standard addition methods provide reliable quantification when matrix matching proves impractical. By adding known quantities of analytes to the sample itself, analysts create calibration curves specific to each individual sample matrix, effectively normalizing for matrix-specific ionization effects.

Calibration and Quality Control Methodologies

Calibration and quality control methodologies form the backbone of reliable ICP-MS analysis, particularly when optimizing ionization efficiency. The implementation of robust calibration strategies begins with the selection of appropriate calibration standards that match the matrix composition of the samples being analyzed. External calibration using multi-element standards remains the most common approach, where a series of standards with increasing concentrations are measured to establish calibration curves. For complex matrices, matrix-matched calibration standards are essential to compensate for potential matrix effects that can significantly impact ionization efficiency.

Internal standardization represents another critical calibration methodology, wherein elements with similar mass and ionization potential to the analytes of interest are added at constant concentrations to all samples and standards. This approach effectively compensates for signal drift, matrix effects, and variations in sample introduction efficiency. Elements such as Indium (In), Rhodium (Rh), and Yttrium (Y) are commonly employed as internal standards due to their stability and minimal natural occurrence in most samples.

Quality control protocols must be rigorously implemented throughout the analytical process. Method validation parameters including detection limits, quantification limits, precision, accuracy, and linearity should be established prior to routine analysis. Regular measurement of certified reference materials (CRMs) that closely match sample matrices provides ongoing verification of method performance and ionization efficiency optimization. The frequency of CRM analysis should be determined based on sample batch size, with at least one CRM measurement per 20 samples recommended for most applications.

Instrument performance checks represent another essential component of quality control. Daily tuning procedures should include monitoring sensitivity, oxide formation rates, and doubly charged ion formation, all of which directly reflect ionization efficiency. The measurement of specific performance indicators such as the 115In/238U ratio can provide valuable insights into plasma conditions and ionization stability. Establishing control charts for these parameters enables the identification of trends that may indicate deteriorating performance before it impacts analytical results.

Blank analysis and contamination control are equally important aspects of quality assurance. Procedural blanks should be processed alongside samples to identify potential sources of contamination that could affect low-level measurements. Regular analysis of instrument blanks helps monitor and correct for background signals that may arise from memory effects or impurities in reagents. The implementation of clean laboratory protocols, including the use of ultra-pure reagents and acid-cleaned labware, further minimizes contamination risks.

Internal standardization represents another critical calibration methodology, wherein elements with similar mass and ionization potential to the analytes of interest are added at constant concentrations to all samples and standards. This approach effectively compensates for signal drift, matrix effects, and variations in sample introduction efficiency. Elements such as Indium (In), Rhodium (Rh), and Yttrium (Y) are commonly employed as internal standards due to their stability and minimal natural occurrence in most samples.

Quality control protocols must be rigorously implemented throughout the analytical process. Method validation parameters including detection limits, quantification limits, precision, accuracy, and linearity should be established prior to routine analysis. Regular measurement of certified reference materials (CRMs) that closely match sample matrices provides ongoing verification of method performance and ionization efficiency optimization. The frequency of CRM analysis should be determined based on sample batch size, with at least one CRM measurement per 20 samples recommended for most applications.

Instrument performance checks represent another essential component of quality control. Daily tuning procedures should include monitoring sensitivity, oxide formation rates, and doubly charged ion formation, all of which directly reflect ionization efficiency. The measurement of specific performance indicators such as the 115In/238U ratio can provide valuable insights into plasma conditions and ionization stability. Establishing control charts for these parameters enables the identification of trends that may indicate deteriorating performance before it impacts analytical results.

Blank analysis and contamination control are equally important aspects of quality assurance. Procedural blanks should be processed alongside samples to identify potential sources of contamination that could affect low-level measurements. Regular analysis of instrument blanks helps monitor and correct for background signals that may arise from memory effects or impurities in reagents. The implementation of clean laboratory protocols, including the use of ultra-pure reagents and acid-cleaned labware, further minimizes contamination risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!